The global electrical connectors market is experiencing robust growth, driven by increasing demand across industries such as automotive, consumer electronics, industrial automation, and telecommunications. According to Grand View Research, the market was valued at USD 75.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion is fueled by technological advancements, rising electrification trends, and the proliferation of smart devices. As manufacturers prioritize reliability, miniaturization, and high-speed data transmission, the selection of the right connector type has become critical in system design and performance. From board-to-board to RF connectors, each type serves a distinct function in ensuring efficient electrical connectivity. Below, we explore the top 9 types of connectors shaping innovation in electrical manufacturing today.

Top 9 Types Of Connectors In Electrical Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Connectors

Domain Est. 1996

Website: phoenixcontact.com

Key Highlights: Wide variety of connectors: from versatile circular connectors (M5 to M58), data, energy storage, and photovoltaic connectors to heavy-duty industrial ……

#2 Types of Electrical Connectors and Wire Connectors

Domain Est. 1992

Website: te.com

Key Highlights: Types of Electrical Connectors and Wire Connectors · AUDIO & VIDEO CONNECTORS · AUTOMOTIVE CONNECTORS · CIRCULAR CONNECTORS · CONNECTOR ACCESSORIES · CONTACTS · D- ……

#3 Connectors

Domain Est. 1994

Website: molex.com

Key Highlights: Molex offers a wide variety of Board-to-Board Connectors for microminiature, high-speed, high-density, and high-power applications….

#4 Connectors

Domain Est. 1996

Website: amphenol.com

Key Highlights: Our wide array of electrical and electronic connectors come in multiple form factors and are designed to meet the latest market needs….

#5 Electrical and Electronic Connectors

Domain Est. 1996

Website: hirose.com

Key Highlights: Connector Selector Categories, Applications, Customer Support, Partners, Locations, Contact Us, Privacy Policy | Terms of Use | Membership Agreement…

#6 Connectors

Domain Est. 1996

Website: jae.com

Key Highlights: For PCs and mobile devices, we have line up of interface connectors, board to board connectors, and card connectors. For automotive market, we have line up of ……

#7 WECO Electrical Connectors

Domain Est. 1999

Website: wecoconnectors.com

Key Highlights: Electrical Connectors and Accessories · PCB Connectors · SMarTconn. SMD/THR · Terminal Strips for Panel · Tab Connectors · Ceramic Terminal Blocks ……

#8 Wire Connectors

Domain Est. 2012

Website: idealind.com

Key Highlights: 30-day returnsOur complete line includes Twist-On Wire Connectors, Push-In Wire Connectors, Grounding Wire Connectors, DataCom Wire Connectors, among others….

#9 Winchester Interconnect

Domain Est. 2016

Website: winconn.com

Key Highlights: Winchester Interconnect is a global leader in connectors, RF & microwave, hermetic, fiber optic & cable assemblies. Trusted interconnect solutions for ……

Expert Sourcing Insights for Types Of Connectors In Electrical

2026 Market Trends for Types of Connectors in Electrical

The electrical connectors market is undergoing rapid transformation driven by technological advancements, increasing electrification, and the growing demand for reliable and efficient connectivity solutions across industries. As we approach 2026, several key trends are shaping the landscape for different types of electrical connectors. These trends reflect shifts in manufacturing, consumer electronics, automotive, renewable energy, and industrial automation sectors. Below is an analysis of the most significant market trends expected to influence major connector types in 2026.

Rising Demand for Miniaturized Connectors

One of the most prominent trends in 2026 is the surge in demand for miniaturized connectors, particularly in consumer electronics and medical devices. As devices become smaller and more portable—such as wearables, hearing aids, smartphones, and implantable medical equipment—there is a growing need for compact, high-density connectors that maintain performance integrity. Micro and nano connectors, including micro USB, USB-C, and FPC (Flexible Printed Circuit) connectors, are expected to dominate this segment. Manufacturers are investing heavily in ultra-miniaturized designs using advanced materials to ensure durability and signal integrity at reduced form factors.

Growth in High-Speed Data Connectors

With the global rollout of 5G, edge computing, and high-performance computing (HPC), the demand for high-speed data connectors is accelerating. In 2026, connectors such as HDMI, USB 3.2/4, Thunderbolt, and RF coaxial connectors will experience strong growth. These connectors enable faster data transmission, lower latency, and improved bandwidth, making them essential in data centers, telecommunications infrastructure, and advanced consumer electronics. The push towards AI-driven systems and real-time data processing further amplifies the need for reliable high-speed interconnects capable of handling multi-gigabit data rates.

Expansion of Automotive and EV-Specific Connectors

The automotive sector, particularly electric vehicles (EVs), is a key driver of connector innovation. By 2026, high-voltage connectors designed for EV powertrains, battery management systems (BMS), and charging infrastructure will see significant market expansion. Automotive-grade connectors such as HVIL (High-Voltage Interlock Loop), J1939, and CCS (Combined Charging System) connectors are becoming standard in EV manufacturing. These connectors must meet stringent safety, thermal, and durability requirements. Additionally, the rise of autonomous and connected vehicles is increasing the demand for high-reliability signal connectors for sensors, cameras, and in-vehicle networks (e.g., Ethernet connectors).

Increased Adoption of Circular and Harsh Environment Connectors

Industries such as industrial automation, aerospace, defense, and renewable energy are driving demand for circular connectors that offer robust performance in harsh environments. In 2026, ruggedized connectors with IP67/IP68 ratings, resistance to vibration, moisture, and extreme temperatures will be in high demand. M12, M8, and MIL-DTL-38999 connectors are widely used in factory automation, robotics, and outdoor power systems. The shift toward Industry 4.0 and smart manufacturing is accelerating the deployment of such connectors in sensor networks, control systems, and automated machinery.

Sustainability and Material Innovation

Environmental regulations and sustainability goals are influencing connector design and manufacturing processes. By 2026, there will be a stronger emphasis on recyclable materials, lead-free soldering, and energy-efficient production. Connector manufacturers are exploring bio-based plastics, halogen-free insulation, and reduced material usage without compromising performance. This trend is particularly evident in the European and North American markets, where RoHS and REACH compliance are strictly enforced.

Expansion of Renewable Energy Applications

The global push for clean energy is boosting demand for specialized connectors in solar and wind power systems. In 2026, MC4 connectors will remain dominant in photovoltaic (PV) installations due to their reliability and ease of use. Meanwhile, wind turbines require high-power, durable connectors capable of withstanding continuous mechanical stress and harsh weather. Hybrid connectors that combine power, signal, and data transmission are gaining traction in renewable energy systems to simplify installation and improve monitoring capabilities.

Smart and Intelligent Connectors

Emerging trends in IoT and smart infrastructure are paving the way for intelligent connectors equipped with sensing and diagnostic capabilities. By 2026, smart connectors featuring built-in monitoring for temperature, current, and connection status will gain adoption in critical applications such as data centers, healthcare devices, and industrial systems. These connectors enhance predictive maintenance, reduce downtime, and improve overall system reliability.

Conclusion

The electrical connectors market in 2026 will be defined by innovation, specialization, and responsiveness to evolving industry needs. Key trends—including miniaturization, high-speed data transmission, EV adoption, ruggedization, sustainability, and smart functionality—are reshaping the demand for different connector types. Companies that invest in advanced materials, automation-compatible designs, and application-specific solutions will be best positioned to capture growth in this dynamic market. As electrification and digitalization continue to accelerate across sectors, the role of reliable, high-performance connectors will become more critical than ever.

Common Pitfalls Sourcing Types of Connectors in Electrical (Quality, IP)

Sourcing the right electrical connectors requires careful attention to both quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to performance issues, safety hazards, and costly failures. Here are some common pitfalls to avoid:

Overlooking IP Rating Requirements for the Environment

One of the most frequent mistakes is selecting connectors without verifying that their IP rating matches the operating environment. Using an IP65-rated connector in a submersion application requiring IP68 can result in water ingress, short circuits, or equipment damage. Conversely, over-specifying (e.g., using IP69K in a dry indoor setting) unnecessarily increases costs. Always assess environmental conditions—dust, moisture, washdowns, or outdoor exposure—and match the connector’s IP rating accordingly.

Prioritizing Cost Over Long-Term Quality

Opting for cheaper connectors from unreliable suppliers often leads to compromised materials, inconsistent tolerances, and poor contact resistance. Low-quality connectors may fail prematurely due to overheating, arcing, or mechanical wear. This short-term savings can result in higher lifecycle costs due to maintenance, downtime, or safety incidents. Always balance cost with proven quality indicators such as certifications (UL, CE, RoHS), manufacturer reputation, and material specifications (e.g., brass contacts, UV-resistant housings).

Assuming All Connectors With the Same IP Rating Perform Equally

IP ratings indicate protection levels but do not reflect performance under mechanical stress, vibration, or repeated mating cycles. Two connectors with IP67 ratings may differ significantly in sealing durability, contact plating, or housing strength. Some may lose their seal after a few insertions, especially if the gasket design or locking mechanism is subpar. Always review test reports, real-world performance data, and manufacturer specifications beyond just the IP code.

Neglecting Quality Documentation and Traceability

Failing to request or verify quality documentation—such as test reports, material certifications, or production batch traceability—can expose projects to counterfeit or non-compliant components. This is especially critical in regulated industries (medical, automotive, rail). Ensure suppliers provide full documentation and adhere to recognized quality standards like ISO 9001.

Misunderstanding Connector Compatibility and Interchangeability

Assuming connectors with similar appearances or IP ratings are interchangeable can lead to improper mating, poor electrical contact, or compromised seals. Variations in pin configuration, keying, thread type, or gasket design can prevent a true IP seal or damage mating components. Always confirm compatibility with existing systems and avoid mixing brands unless explicitly certified as interoperable.

Ignoring Installation and Maintenance Factors

Even high-quality, correctly rated connectors can fail if improperly installed. Common issues include under- or over-tightening threaded connectors, damaging seals during assembly, or using incorrect tools. Lack of training or inadequate installation procedures can void IP protection. Factor in ease of installation and provide proper training or torque specifications to maintain connector integrity.

By recognizing and addressing these pitfalls, sourcing professionals can ensure reliable, safe, and cost-effective electrical connector selection tailored to application demands.

Types of Connectors in Electrical: Logistics & Compliance Guide

When managing the logistics and ensuring compliance for electrical connectors, understanding the various types is crucial. Each connector type has unique specifications, handling requirements, and regulatory considerations that impact sourcing, shipping, storage, and installation. This guide outlines key connector types and their associated logistics and compliance implications.

Power Connectors

Power connectors are designed to transmit electrical power between devices, circuits, or systems. Common types include IEC connectors (e.g., C13/C14), NEMA plugs, and industrial power connectors (e.g., IEC 60309).

Logistics Considerations:

– Require robust packaging to prevent pin deformation or insulation damage.

– High-current variants may be heavier, affecting shipping costs and handling.

– Should be stored in dry, temperature-controlled environments to prevent corrosion.

Compliance Requirements:

– Must meet international safety standards such as IEC 60320, UL 498, or CSA C22.2.

– Certification marks (e.g., UL, CE, TÜV) must be visibly present.

– Import/export may require conformity with local electrical codes (e.g., NEC in the U.S., BS 1363 in the UK).

Signal Connectors

Signal connectors transmit data or control signals and include types such as D-Sub, USB, HDMI, and RJ45.

Logistics Considerations:

– Sensitive to electrostatic discharge (ESD); must be shipped in anti-static packaging.

– Often small and numerous—require secure, organized packaging to prevent loss or damage.

– Temperature and humidity control is essential for maintaining signal integrity.

Compliance Requirements:

– Must comply with EMI/RFI shielding standards (e.g., FCC Part 15 in the U.S.).

– RoHS and REACH compliance is mandatory in the EU for hazardous substance restrictions.

– High-speed data connectors may require compliance with signal integrity standards (e.g., USB-IF certification).

Coaxial Connectors

Used in RF and high-frequency applications, common types include BNC, SMA, F-type, and N-type connectors.

Logistics Considerations:

– Threads and center pins are delicate—require protective caps during transit.

– Shielding integrity must be maintained; avoid kinking or compression of cables.

– Often used in telecom and broadcast industries—subject to tight delivery timelines.

Compliance Requirements:

– Must meet RF performance standards (e.g., IEC 60169, MIL-STD-348).

– Environmental sealing may require IP ratings (e.g., IP67) for outdoor use.

– 5G and telecom deployments may require compliance with carrier-specific certifications.

Terminal Blocks

These connectors provide secure wire joining points and are used in control panels and industrial equipment. Types include screw, spring-clamp, and PCB terminal blocks.

Logistics Considerations:

– Bulk packaging is common; inventory management should avoid mix-ups between voltage/current ratings.

– Metal components may be susceptible to rust—store in low-humidity areas.

– Often used in industrial environments—may require ruggedized packaging.

Compliance Requirements:

– Must comply with IEC 60947 (low-voltage switchgear) or UL 1059 (terminal blocks).

– Clearance and creepage distances must adhere to insulation standards.

– Suitable for use in hazardous locations only if rated (e.g., ATEX, IECEx).

Circular Connectors

Rugged, multi-pin connectors used in harsh environments (e.g., aerospace, military, industrial). Examples include M12, MIL-DTL-5015, and circular DIN connectors.

Logistics Considerations:

– Often used in mission-critical applications—traceability and batch tracking are essential.

– Require protective caps and shock-resistant packaging.

– May have long lead times due to specialized manufacturing.

Compliance Requirements:

– Must meet MIL-spec, IP, or UL 486A-B standards depending on use.

– Defense and aerospace applications may require ITAR or DFARS compliance.

– Environmental ratings (e.g., IP68, temperature range) must be documented and verified.

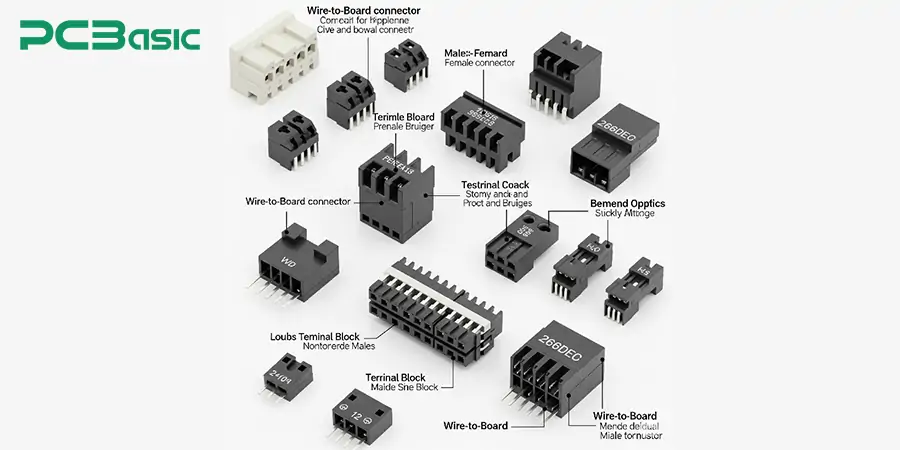

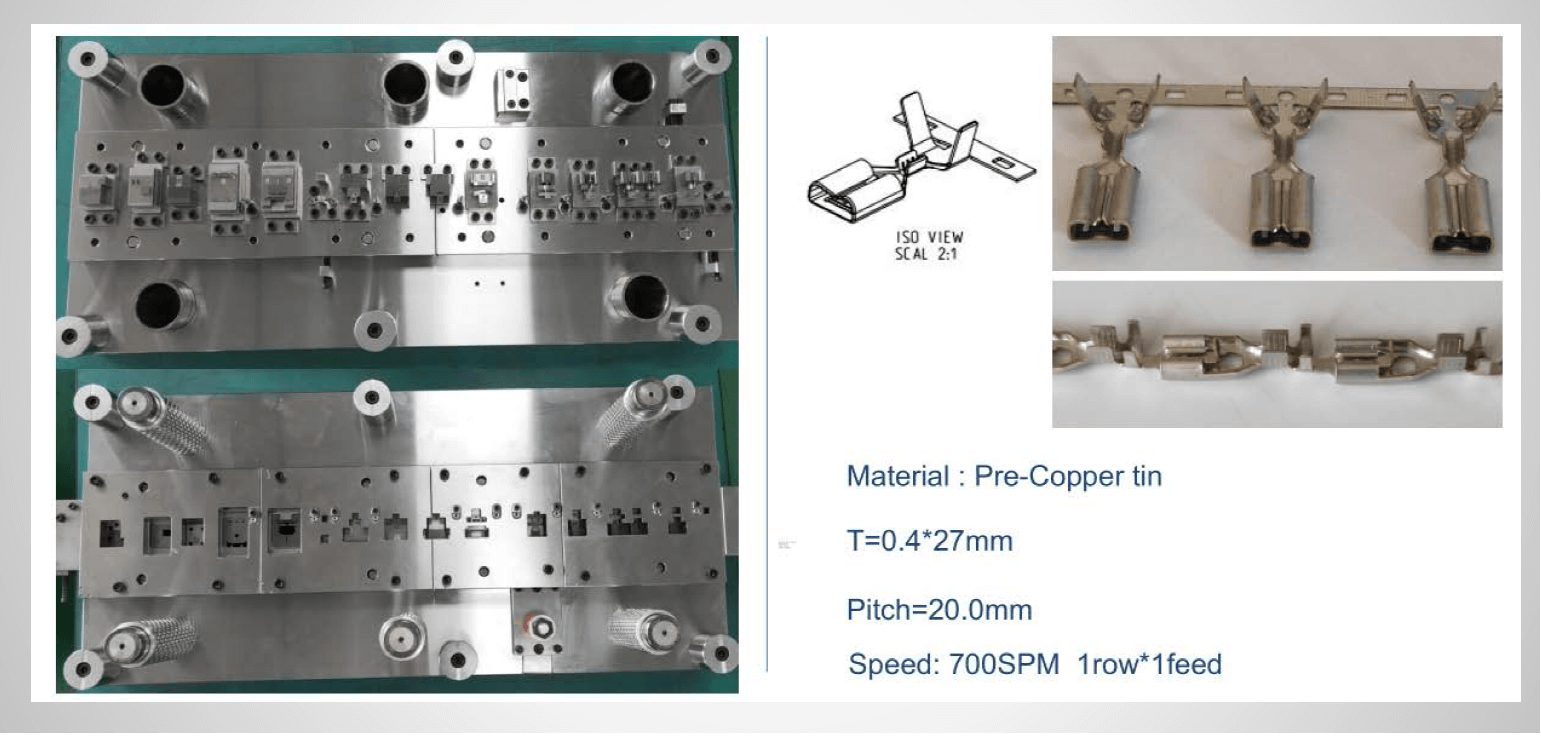

PCB Connectors

Designed for direct mounting on printed circuit boards, including board-to-board, wire-to-board, and FPC/FFC connectors.

Logistics Considerations:

– Highly sensitive to ESD and mechanical stress—must be handled with ESD-safe tools.

– Small size increases risk of contamination; cleanroom handling may be required.

– Reel or tray packaging must be sealed and labeled correctly for automated assembly.

Compliance Requirements:

– Must comply with IPC standards (e.g., IPC-6012 for PCBs).

– RoHS, REACH, and conflict minerals reporting (e.g., Dodd-Frank Act) are typically required.

– Surface mount types must meet reflow soldering profile standards.

Fiber Optic Connectors

Used for high-speed data transmission, including LC, SC, ST, and MTP types.

Logistics Considerations:

– Extremely sensitive to dust and scratches—end-faces must be capped and protected.

– Require clean, dry storage; avoid exposure to contaminants.

– Often shipped in individual sealed packages with handling instructions.

Compliance Requirements:

– Must meet IEC 61753 (performance) and IEC 61300 (test methods).

– Data center and telecom installations follow TIA/EIA-568 standards.

– Compliance with low-smoke zero-halogen (LSZH) cable requirements in confined spaces.

General Compliance & Logistics Best Practices

- Documentation: Maintain certificates of compliance (CoC), test reports, and material declarations.

- Labeling: Ensure proper labeling with part numbers, ratings, and compliance marks.

- Traceability: Implement serial or batch tracking for recalls and quality control.

- Training: Logistics staff should be trained in ESD safety, hazardous material handling (if applicable), and import regulations.

- Supplier Audits: Regularly audit suppliers for quality management (ISO 9001) and environmental compliance (ISO 14001).

Understanding the specific needs of each connector type ensures efficient logistics operations and full compliance with global regulations, minimizing delays and avoiding costly non-conformance issues.

Conclusion on Sourcing Types of Connectors in Electrical Applications

In conclusion, sourcing the appropriate types of electrical connectors is a critical aspect of ensuring the safety, reliability, and efficiency of electrical systems. With a wide variety of connectors available—including terminal blocks, plug-and-socket connectors, PCB connectors, spade and ring terminals, and industrial connectors—selecting the right type depends on factors such as current and voltage ratings, environmental conditions, ease of installation, and application-specific requirements.

Effective sourcing involves identifying reputable suppliers, considering standards compliance (such as UL, CE, or IEC), evaluating material quality, and balancing cost with performance. Additionally, advancements in technology have led to the development of more compact, durable, and high-performance connectors, especially for industries like automotive, aerospace, and renewable energy.

Ultimately, a well-informed sourcing strategy ensures compatibility, enhances system longevity, reduces maintenance costs, and supports the overall integrity of electrical designs. As electrical systems continue to evolve, staying updated on connector innovations and best sourcing practices will remain essential for engineers, procurement specialists, and project managers alike.