The global fasteners market, driven by robust demand from automotive, aerospace, construction, and industrial machinery sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2030, according to Grand View Research. Within this expanding landscape, clevis pins—critical components in hinge and pivot assemblies—have seen rising production specialization. As industries prioritize precision, durability, and compliance with international standards like ISO and ASME, the manufacturing ecosystem for clevis pins has diversified significantly. From high-volume OEM suppliers to niche custom fabricators, manufacturers are leveraging advanced materials and lean production techniques to meet evolving application requirements. Based on market segmentation and production capabilities identified in industry analyses by Mordor Intelligence, seven distinct types of clevis pin manufacturers have emerged as key players shaping supply chains worldwide.

Top 7 Types Of Clevis Pins Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fastening Pins: Cotter, Clevis, Dowel, Spring & More

Domain Est. 1996

Website: wmberg.com

Key Highlights: WM Berg manufactures a wide range of industrial fastening pins including cotter pins, clevis pins, dowel pins, spring pins (roll pins), taper pins, grooved ……

#2 Clevis Pins

Domain Est. 1997

Website: shakeproof.com

Key Highlights: Clevis pins are fasteners with a pin shape that are used with a clevis, a type of U-shaped fastener. They are not threaded, but rather smooth and cylindrical. A ……

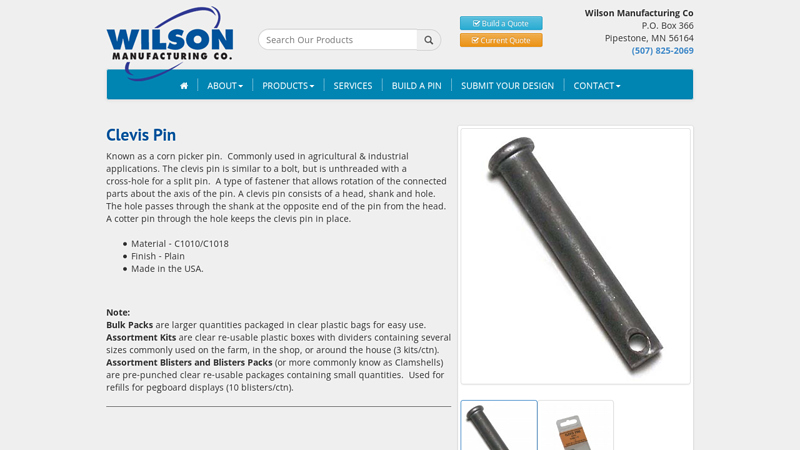

#3 Clevis Pin

Domain Est. 1999

Website: wilsonmfgco.com

Key Highlights: Clevis Pin. Known as a corn picker pin. Commonly used in agricultural & industrial applications. The clevis pin is similar to a bolt, but is unthreaded with ……

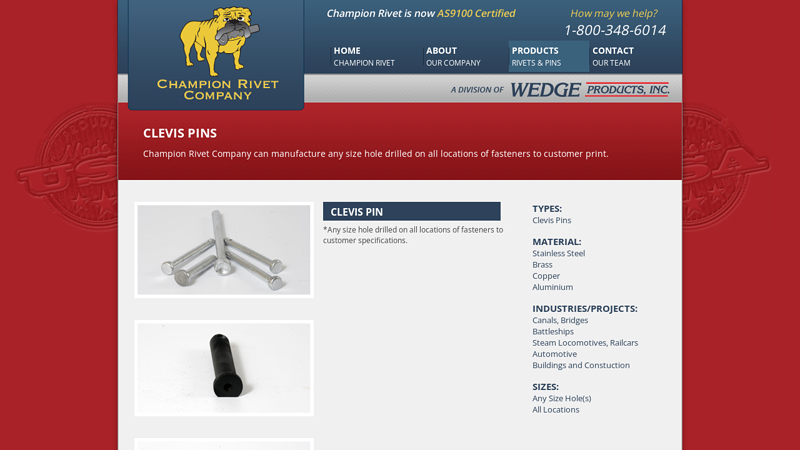

#4 Clevis Pins Company, Leading Manufacturer of Clevis Fasteners

Domain Est. 2013

Website: championrivets.com

Key Highlights: Our clevis pins and fasteners supply the automotive and construction industries. We are the leading manufacturer of fasteners and clevis pins….

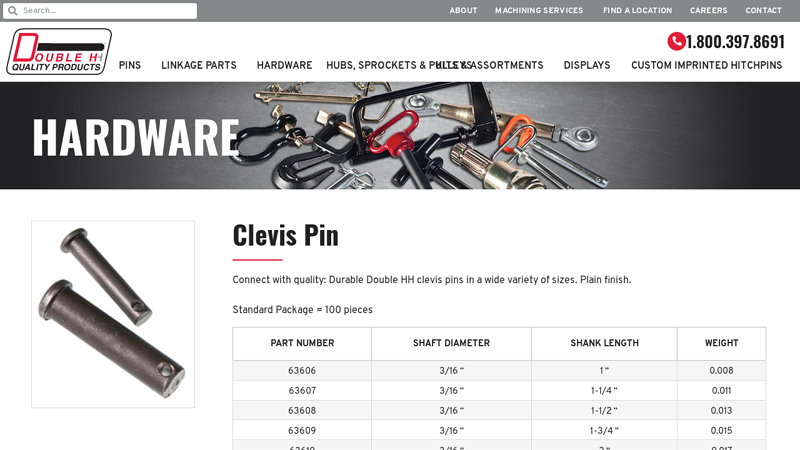

#5 Clevis Pin

Domain Est. 1998

Website: doublehh.com

Key Highlights: Connect with quality: Durable Double HH clevis pins in a wide variety of sizes. Plain finish. Standard Package = 100 pieces. PART NUMBER, SHAFT DIAMETER, SHANK ……

#6 Clevis Pins

Domain Est. 2003

Website: americanboltcorp.com

Key Highlights: These pins are ideal for use in clevis fastener assemblies, hitch pins, and pivot points. Choose from zinc-plated, stainless steel, and ……

#7 The Different Types of Clevis Pins

Domain Est. 2004

Website: reidsupply.com

Key Highlights: Clevis pins come in many different shapes and sizes. View our new blog to learn about some of the main types….

Expert Sourcing Insights for Types Of Clevis Pins

2026 Market Trends for Types Of Clevis Pins

As the global industrial and manufacturing sectors evolve, the demand for reliable, cost-effective fastening solutions continues to grow. Clevis pins—essential components in machinery, automotive, aerospace, construction, and agricultural equipment—are experiencing shifts in design, material use, and application preferences. The following analysis explores key market trends expected to shape the various types of clevis pins by 2026.

Rising Demand for High-Strength and Corrosion-Resistant Clevis Pins

A significant trend driving the clevis pin market is the increasing demand for high-strength and corrosion-resistant materials. By 2026, manufacturers are expected to favor stainless steel, alloy steel, and nickel-based clevis pins, especially in harsh environments such as marine, chemical processing, and offshore applications. These materials offer improved durability and longevity, reducing maintenance costs and downtime. The aerospace and defense sectors are particularly investing in high-performance clevis pins that meet stringent safety and reliability standards.

Growth in Self-Locking and Safety-Critical Clevis Pin Designs

Safety and ease of maintenance are becoming top priorities across industries. As a result, self-locking clevis pins—such as those with spring-loaded mechanisms or integrated cotter holes—are gaining traction. These designs reduce the risk of pin dislodgement under vibration or dynamic loads. By 2026, the market is expected to see increased adoption of safety-clevis pins in heavy machinery, transportation, and robotics, where accidental detachment could lead to catastrophic failures.

Expansion of Lightweight Clevis Pins in Automotive and Aerospace

With the push toward fuel efficiency and reduced emissions, the automotive and aerospace industries are shifting toward lightweight materials. Aluminum and titanium clevis pins are seeing growing interest due to their strength-to-weight ratios. Though traditionally less common than steel variants, these lightweight alternatives are projected to capture a larger market share by 2026, particularly in electric vehicles (EVs) and unmanned aerial vehicles (UAVs), where weight reduction directly impacts performance and energy consumption.

Advancements in Precision Manufacturing and Customization

The trend toward modular and customized industrial systems is encouraging the development of precision-engineered clevis pins. Advances in CNC machining, 3D printing, and automated quality control are enabling faster production of custom-sized and shaped clevis pins to meet specific OEM requirements. By 2026, suppliers offering tailored clevis pin solutions—complete with specific tolerances, coatings, or head designs—are expected to gain a competitive edge, particularly in niche markets such as medical devices and automation equipment.

Sustainability and Recyclability Driving Material Innovation

Environmental regulations and corporate sustainability goals are influencing material choices in fastener manufacturing. The clevis pin market is witnessing a gradual shift toward recyclable materials and eco-friendly surface treatments (e.g., zinc-nickel coatings instead of cadmium plating). By 2026, manufacturers that adopt green production practices and offer sustainable clevis pin solutions are likely to appeal to environmentally conscious customers, especially in Europe and North America.

Regional Market Dynamics and Supply Chain Resilience

Asia-Pacific, led by China and India, is expected to remain the largest producer and consumer of clevis pins by 2026 due to rapid industrialization and infrastructure development. However, geopolitical factors and supply chain disruptions are prompting companies to diversify sourcing and invest in local manufacturing. Nearshoring and onshoring trends in North America and Europe may lead to increased domestic production of high-specification clevis pins, reducing dependency on imports.

Digital Integration and Smart Fastening Systems

While still in early stages, digitalization is beginning to influence fastener technology. By 2026, smart clevis pins embedded with sensors to monitor stress, temperature, or wear could emerge in critical applications. Though not yet mainstream, these innovations are being explored in sectors like predictive maintenance and Industry 4.0, where real-time data from components enhances system reliability and operational efficiency.

Conclusion

The clevis pin market in 2026 will be shaped by technological advancements, material innovation, and evolving industry needs. High-strength, lightweight, and safety-focused designs will dominate demand, while sustainability and customization will differentiate leading suppliers. As global industries continue to modernize, clevis pins will remain indispensable—but increasingly sophisticated—components of mechanical systems.

Common Pitfalls When Sourcing Types of Clevis Pins (Quality, IP)

Sourcing the right clevis pins is critical for the safety and reliability of mechanical and structural assemblies. However, buyers often encounter several pitfalls related to quality and IP (Ingress Protection) ratings. Being aware of these issues can prevent costly failures and ensure long-term performance.

Overlooking Material Quality and Certification

One of the most frequent mistakes is failing to verify the material specifications and certifications of clevis pins. Not all pins are created equal—low-grade steel or improperly heat-treated alloys may fail under stress. Buyers should insist on material test reports (MTRs) and ensure compliance with standards like ASTM, ISO, or SAE. Substandard materials can lead to premature wear, corrosion, or catastrophic failure.

Ignoring Environmental and IP Ratings

Many clevis pins are used in outdoor or harsh environments where exposure to moisture, dust, or chemicals is common. A common oversight is neglecting the Ingress Protection (IP) rating, especially when sourcing pins with retaining features like cotter pins or split pins. While clevis pins themselves aren’t typically assigned IP ratings, the assembly they’re part of may require environmental protection. Using non-stainless or unsealed components in wet or corrosive conditions can lead to rust and joint failure.

Assuming All Clevis Pins Are Interchangeable

There are various types of clevis pins—fixed head, loose pin, lynch pin style, and those with holes for cotter pins—each suited for specific applications. A frequent pitfall is assuming interchangeability without considering load direction, shear strength, or ease of removal. Using the wrong type can compromise safety and reduce service life.

Skipping Dimensional and Tolerance Verification

Even minor deviations in diameter, length, or hole placement can prevent proper fit or reduce load-bearing capacity. Sourcing from suppliers without strict quality control can result in inconsistent tolerances. Always request dimensional drawings and perform incoming inspections to avoid assembly issues or field failures.

Failing to Assess Supplier Reliability and Traceability

Choosing suppliers based solely on price often leads to quality issues. Unreliable vendors may lack traceability, proper testing procedures, or consistent manufacturing processes. This increases the risk of counterfeit or subpar components. Prioritize suppliers with certifications (e.g., ISO 9001) and clear supply chain traceability.

Neglecting Corrosion Resistance Needs

In applications exposed to weather or chemicals, using standard carbon steel pins without protective coatings (e.g., zinc plating, hot-dip galvanizing, or stainless steel construction) leads to rapid degradation. Buyers must match the pin’s corrosion resistance to the operating environment to maintain structural integrity.

Overlooking Retaining Mechanism Compatibility

Clevis pins often require secondary retention (cotter pins, R-clips, etc.). A common sourcing error is selecting a pin without ensuring compatibility with appropriate retainers. Mismatched components can loosen over time, leading to disassembly under load and safety hazards.

By carefully evaluating material quality, environmental demands, dimensional accuracy, and supplier credibility, buyers can avoid these common pitfalls and ensure they source the right type of clevis pin for their application.

Logistics & Compliance Guide for Types of Clevis Pins

Understanding the logistics and compliance requirements for clevis pins is essential for safe handling, transportation, storage, and regulatory adherence. This guide outlines key considerations for different types of clevis pins commonly used in industrial, construction, and mechanical applications.

Types of Clevis Pins and Their Handling Requirements

Clevis pins come in various designs, each with unique logistical and compliance needs based on material, size, and application. Common types include:

- Standard Clevis Pins – Smooth, cylindrical pins with a cross-hole for a cotter pin. Typically used in low-vibration environments.

- Shouldered Clevis Pins – Feature a shoulder to provide precise alignment and reduce wear. Ideal for high-load or high-vibration applications.

- Slotted Clevis Pins – Have a slot at one end for use with a split pin or retaining ring. Used where quick disassembly is needed.

- Tapered Clevis Pins – Designed for tight fits and alignment in precision assemblies.

Material Considerations and Regulatory Compliance

The material of clevis pins affects both logistics and compliance:

- Carbon Steel: Most common; often zinc-plated or galvanized for corrosion resistance. Complies with ASTM A307 or SAE J429 standards.

- Stainless Steel (e.g., 304, 316): Used in corrosive or outdoor environments. Meets ASTM A276 or ISO 3506 standards; suitable for food-grade or marine applications.

- Alloy Steel: Used for high-strength applications. Must comply with ISO 898-1 or equivalent mechanical property standards.

Ensure all pins are marked with grade identification and manufacturer information to meet traceability requirements under ISO 9001 and AS9100 (if applicable).

Packaging and Storage Guidelines

Proper packaging and storage prevent damage and maintain compliance:

- Packaging: Use moisture-resistant, anti-corrosion packaging (e.g., VCI paper) for metal pins. Bulk packaging should prevent tangling and surface abrasion.

- Labeling: Include product type, material grade, size, batch number, and compliance markings (e.g., CE, RoHS if applicable).

- Storage: Store in a dry, temperature-controlled environment. Avoid direct contact with concrete floors; use pallets or shelving to prevent corrosion.

Transportation and Shipping Compliance

Transport clevis pins in accordance with international and regional regulations:

- Hazard Classification: Metallic clevis pins are generally non-hazardous. However, packaged materials may be subject to general freight regulations.

- Documentation: Include packing lists, certificates of compliance (CoC), and material test reports (MTRs) when required.

- Import/Export: For cross-border shipments, ensure compliance with customs regulations (e.g., HTS codes), and verify any restrictions on steel products under trade agreements.

Industry-Specific Compliance Standards

Different industries impose additional compliance obligations:

- Construction & Heavy Equipment: Must meet ASME B18.8.2 or DIN 1444 standards for mechanical fasteners.

- Aerospace: Requires NASM or MS specifications and full traceability under AS9100.

- Marine & Offshore: Pins must comply with DNV-GL, ABS, or ISO 18278 standards, with appropriate corrosion resistance.

- Food & Pharmaceutical: Stainless steel pins must meet FDA 21 CFR or EHEDG standards for hygienic design.

Quality Assurance and Inspection

Implement quality controls throughout the logistics chain:

- Incoming Inspection: Verify dimensions, material grade, surface finish, and certification documentation.

- In-Transit Monitoring: Use shock and humidity sensors for high-value or sensitive shipments.

- Traceability: Maintain lot tracking from manufacturer to end-user to support recalls or audits.

Environmental and Safety Compliance

Address environmental and workplace safety concerns:

- RoHS & REACH: Confirm that plating materials (e.g., cadmium, lead) comply with EU directives.

- OSHA & WHMIS: Provide safety data sheets (SDS) if coatings or treatments involve hazardous substances.

- Waste Disposal: Follow local regulations for disposal of damaged or excess metal fasteners.

By adhering to these logistics and compliance guidelines, organizations can ensure the safe, efficient, and lawful handling of all types of clevis pins across their supply chain.

In conclusion, when sourcing clevis pins, it is essential to consider the various types available—such as lynch pin style, cotter pin style, threaded, slotted, or solid clevis pins—based on the specific application requirements. Factors including load capacity, environmental conditions, material composition (e.g., stainless steel, alloy steel, or nylon), corrosion resistance, and ease of installation and removal play a critical role in determining the most suitable type. Additionally, ensuring compliance with industry standards (such as ASME, DIN, or ISO) and verifying compatibility with associated hardware like clevis fasteners and shackles will enhance safety and performance. By carefully evaluating these factors, buyers and engineers can select the optimal clevis pin type that ensures reliability, durability, and cost-effectiveness in their intended applications.