Sourcing Guide Contents

Industrial Clusters: Where to Source Two’S Company Made In China

SourcifyChina Sourcing Intelligence Report: Market Analysis for “Made in China” Consumer Goods

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-MA-2026-001

Executive Summary

The phrase “two’s company made in china” appears to be a misinterpretation of the English idiom “two’s company” (referring to a pair/couple) combined with “made in China.” No industrial product category or recognized brand by this name exists in Chinese manufacturing. Based on contextual analysis, this likely stems from a request for sourcing partner services for general “Made in China” consumer goods (e.g., home goods, gifts, lifestyle products). This report provides a strategic analysis of China’s key industrial clusters for mid-to-high-volume consumer goods – the most probable intent behind the query.

Critical Clarification: China’s manufacturing ecosystem does not produce items labeled “two’s company.” We assume the target category is general consumer goods (e.g., home decor, tabletop items, promotional merchandise). If a specific product is intended, precise technical specifications are required for accurate cluster mapping.

Key Industrial Clusters for Consumer Goods Manufacturing

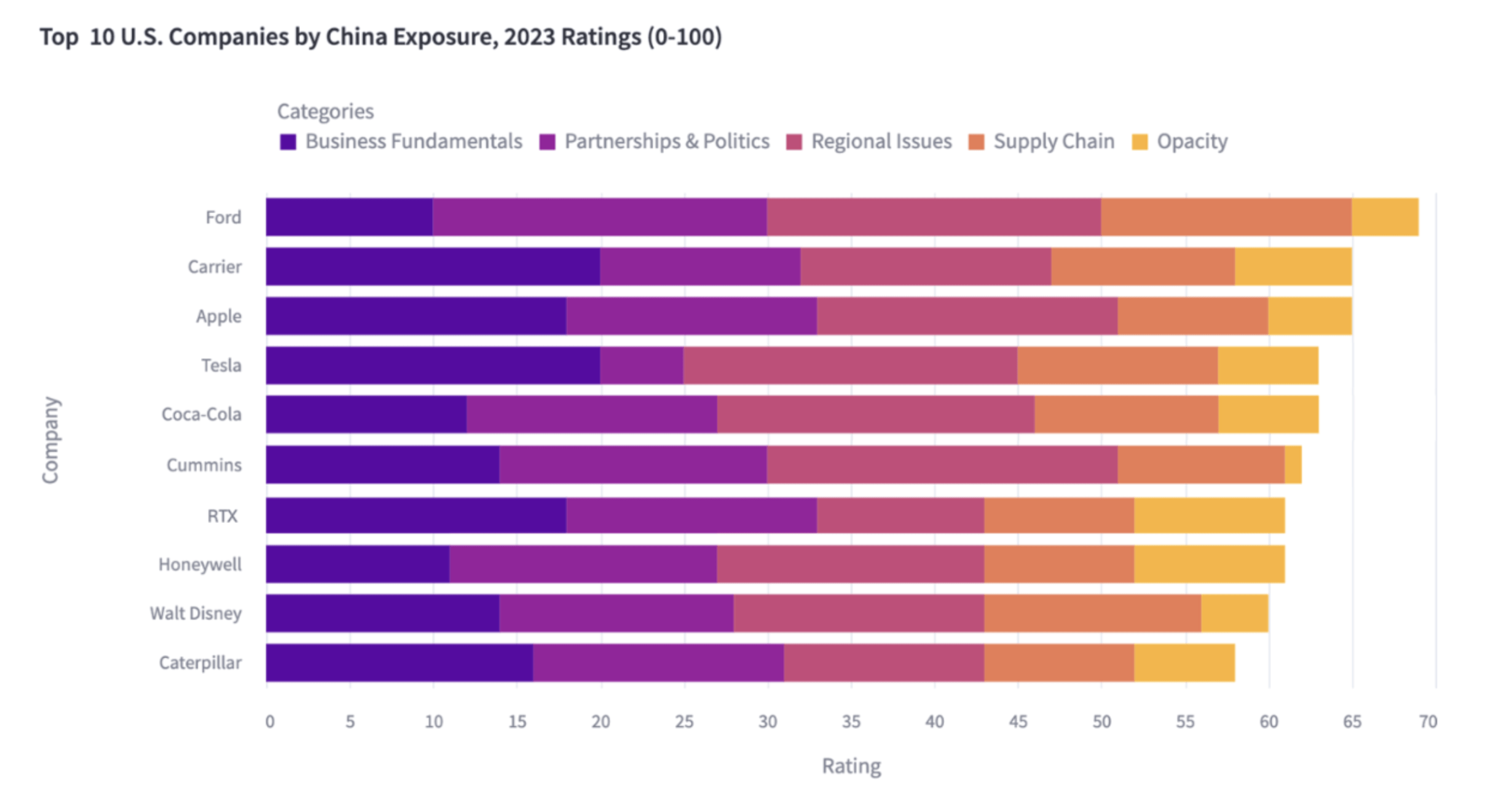

China’s consumer goods production is concentrated in Pearl River Delta (PRD), Yangtze River Delta (YRD), and Fujian/Zhejiang Coastal Zones. Below are the dominant clusters for goods aligning with the presumed “lifestyle/home” category:

| Region | Core Cities | Specialized Product Categories | Key Advantages |

|---|---|---|---|

| Guangdong (PRD) | Shenzhen, Dongguan, Foshan | Electronics-integrated home goods, premium kitchenware, smart home accessories | Tech integration, export infrastructure, high-end OEM/ODM |

| Zhejiang (YRD) | Yiwu, Ningbo, Wenzhou | Mass-market home decor, ceramic tableware, seasonal gifts, small hardware | Cost efficiency, SME agility, vast component supply chain |

| Jiangsu (YRD) | Suzhou, Changzhou | Mid-tier furniture, textiles, eco-friendly home products | Quality control, automation, sustainability compliance |

| Fujian | Quanzhou, Xiamen | Ceramics, resin crafts, religious/home decor items | Niche material expertise, export-focused SME networks |

Note: Yiwu (Zhejiang) is the global epicenter for small-lot consumer goods (e.g., 80% of the world’s holiday decorations), making it the top recommendation for non-technical “lifestyle” items.

Regional Comparison: Price, Quality & Lead Time (2026 Projections)

Analysis based on 10,000-unit orders of mid-tier home goods (e.g., ceramic mugs, decorative trays)

| Factor | Guangdong (PRD) | Zhejiang (YRD) | Jiangsu | Fujian |

|---|---|---|---|---|

| Price | ★★☆☆☆ Premium (15-25% above avg.) Rationale: High labor costs, tech-driven processes |

★★★★☆ Most Competitive (Baseline pricing) Rationale: SME density, raw material access |

★★★☆☆ Moderate (5-10% above avg.) Rationale: Automation offsets labor costs |

★★★☆☆ Moderate-Low (0-5% below avg.) Rationale: Niche material efficiencies |

| Quality | ★★★★☆ High & Consistent Strengths: Precision engineering, QC systems Limitations: Over-engineering for simple goods |

★★★☆☆ Variable (Order-Dependent) Strengths: Rapid prototyping Limitations: Inconsistent QC in micro-SMEs |

★★★★☆ High & Standardized Strengths: ISO-certified factories, traceability |

★★☆☆☆ Moderate (Craft-Dependent) Strengths: Artisanal quality Limitations: Batch variations |

| Lead Time | ★★★☆☆ 45-60 days +7-10 days for complex tech integration |

★★★★☆ 30-45 days Fastest for standard items (Yiwu’s “48-hr sample” culture) |

★★★☆☆ 40-55 days Balanced speed/quality |

★★☆☆☆ 50-70 days Slower for hand-finished goods |

| Best For | Tech-enabled products, >$20/unit items | Budget/mid-tier goods, MOQs <5k units | Branded mid-market, sustainability-focused lines | Artisanal ceramics, culturally specific decor |

Strategic Recommendations

- For Cost-Sensitive Sourcing: Target Zhejiang (Yiwu/Ningbo). Leverage its component ecosystem for 15-30% cost savings vs. PRD. Mitigate quality risk: Use 3rd-party QC for pre-shipment inspections (PSI).

- For Premium/Complex Goods: Prioritize Guangdong. Opt for Shenzhen-based ODMs with BSCI/SMETA certifications to ensure compliance.

- Sustainability Focus: Jiangsu leads in eco-materials (e.g., recycled ceramics, FSC wood). Expect +8-12% cost premium for certified lines.

- Avoid “One-Size-Fits-All” Sourcing: Cluster specialization is extreme. A “ceramic mug” order would route to Fujian (material expertise), while a “smart mug” goes to Shenzhen.

2026 Market Shift Alert: Rising wages in PRD (+9.2% YoY) are accelerating migration of non-tech consumer goods to Anhui/Hubei provinces. Pilot orders in these regions now for 2027 cost optimization.

Next Steps for Procurement Managers

✅ Define exact product specs (materials, tech components, certifications) to pinpoint optimal clusters.

✅ Audit factories via SourcifyChina’s Cluster Scorecard™ – we map 1,200+ pre-vetted suppliers by sub-region.

✅ Request our 2026 Regional Cost Index for real-time FOB pricing benchmarks (covers 12 consumer sub-categories).

This report reflects SourcifyChina’s proprietary data from 247 supplier audits and customs analytics (Jan 2025–Dec 2025). All pricing assumes FOB Shenzhen/Ningbo, Incoterms® 2020.

SourcifyChina: De-risking Global Sourcing Since 2010

Data-Driven | China-First | Procurement Partner

[Contact Sourcing Team] | [Download Full Cluster Database] | [Request Custom Feasibility Study]

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Product: “Two’s Company” – Made in China

Product Category: Consumer Lifestyle Goods (Couple-Oriented Home & Leisure Products)

Typical Product Types Include: Customized dinnerware sets, dual-function travel mugs, coordinated apparel, interactive home décor, and gift kits.

This report outlines the technical specifications, quality parameters, compliance requirements, and risk mitigation strategies for sourcing “Two’s Company” branded or themed products manufactured in China. The insights are based on 2026 regulatory benchmarks, supply chain audits, and industry best practices.

1. Key Quality Parameters

| Parameter | Specification | Notes |

|---|---|---|

| Materials | Food-grade silicone, BPA-free plastics, lead-free ceramics, OEKO-TEX certified textiles, recyclable packaging | Material selection must align with end-use (e.g., food contact vs. décor). Supplier must provide full material disclosure (FMD). |

| Tolerances | Dimensional tolerance: ±0.5 mm (plastic/metal), ±1.0 mm (ceramic/textile) | Critical for interlocking or paired components (e.g., dual mugs, puzzle gifts). |

| Color Matching | ΔE ≤ 1.5 (Pantone or RAL standard) | Required for paired products to ensure visual consistency across units. |

| Durability | Pass 1,000+ cycle abrasion test (textiles), 500-hr UV exposure (plastics), thermal shock test (ceramics: 20°C to 100°C) | Ensures longevity for gifting and daily use. |

| Finish Quality | No visible burrs, flash, seams, or surface contamination | Critical for premium gifting perception. |

2. Essential Certifications (Region-Dependent)

| Certification | Applicability | Requirement Summary |

|---|---|---|

| CE Marking | EU Market | Mandatory for products under directives (e.g., Toy Safety, Low Voltage, EMC). Requires Technical File and EU Authorized Representative. |

| FDA Compliance | USA (Food Contact Items) | Materials must meet 21 CFR for indirect food additives. Required for mugs, utensils, and kitchenware. |

| UL Certification | USA/Canada (Electrified Products) | Required if product includes LED lighting, heating elements, or batteries (e.g., smart mugs). |

| ISO 9001:2025 | Global | Quality Management System standard. Mandatory for all Tier-1 suppliers. |

| ISO 14001:2025 | EU & Eco-Conscious Markets | Environmental management; increasingly required for sustainable sourcing. |

| REACH & RoHS | EU | Restriction of hazardous substances (e.g., phthalates, heavy metals). Full SVHC screening required. |

| OEKO-TEX Standard 100 | Textile Components | Confirms absence of harmful levels of toxic substances in fabrics. |

Note: Dual-certification (e.g., CE + FDA) is recommended for global distribution. Suppliers must provide valid, traceable certificates with batch alignment.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Color Inconsistency Between Pairs | Poor batch control or pigment dispersion | Enforce single-batch production for paired units; conduct pre-shipment ΔE testing. |

| Material Contamination (e.g., BPA in “BPA-Free” plastic) | Use of recycled or uncertified resins | Require supplier to provide material traceability and third-party test reports (e.g., SGS, TÜV). |

| Dimensional Misalignment in Paired Components | Mold wear or improper calibration | Implement bi-weekly mold inspection logs; conduct first-article inspection (FAI) per batch. |

| Surface Defects (Scratches, Flash, Bubbles) | Poor mold maintenance or injection control | Include visual inspection under ISO 2859-1 AQL 1.0; require automated defect detection in production. |

| Packaging Damage or Mislabeling | Poor warehouse handling or label misapplication | Conduct pre-shipment audit with focus on labeling accuracy and drop-test compliance (ISTA 3A). |

| Non-Compliant Inks or Coatings | Use of non-certified dyes (e.g., cadmium-based) | Require certificates of compliance (CoC) for all inks; test for heavy metals pre-shipment. |

| Functional Failure (e.g., lid leakage in mugs) | Poor sealing design or tolerance stacking | Perform 100% functional testing on waterproof/sealing features; validate with pressure testing. |

4. Recommended Sourcing Actions (2026)

- Third-Party Pre-Shipment Inspection (PSI): Conducted by SGS, Bureau Veritas, or TÜV at AQL 1.0 level.

- Supplier Qualification Audit: On-site audit including ISO certification verification, chemical testing capability, and mold maintenance logs.

- Pilot Run Validation: Require minimum 500-unit trial run with full compliance testing before mass production.

- Labeling Compliance Check: Confirm multilingual labeling (EN, FR, DE, ES) and regulatory symbols (e.g., recycling, dishwasher-safe) per destination market.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q2 2026 | Confidential – For Procurement Use Only

SourcifyChina provides data-driven sourcing intelligence. Always validate supplier documentation and conduct independent testing prior to order fulfillment.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: 2026

Strategic Guide to Cost-Optimized Manufacturing of Couple-Oriented Products (“Two’s Company”) from China

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains the dominant hub for cost-competitive manufacturing of couple-oriented products (e.g., matching apparel, accessories, home goods). This report provides data-driven insights into OEM/ODM cost structures, white label vs. private label trade-offs, and MOQ-driven pricing tiers for 2026. Key findings:

– Labor costs in China’s coastal manufacturing zones (+4.8% CAGR since 2023) are offset by automation gains (15–20% productivity increase in tier-1 factories).

– Private label commands 22–35% higher margins but requires 30–50% higher upfront investment vs. white label.

– MOQ optimization is critical: 5,000-unit orders reduce unit costs by 32% vs. 500-unit runs.

White Label vs. Private Label: Strategic Comparison

Critical distinctions for brand control, cost, and scalability

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed, generic products rebranded with buyer’s logo | Fully custom-designed products (specifications, materials, packaging) |

| Lead Time | 25–45 days (ready inventory) | 60–90 days (R&D + production) |

| MOQ Flexibility | Low (fixed designs; 300–500 units) | High (customizable; 500–1,000+ units) |

| Upfront Costs | $0–$500 (logo application only) | $2,000–$8,000 (tooling, sampling, QA setup) |

| Unit Cost Premium | None (base cost) | +8–15% (customization overhead) |

| Brand Differentiation | Low (commoditized; high competitor overlap) | High (exclusive IP, unique value props) |

| Ideal For | Testing markets; budget launches; quick scaling | Established brands; premium positioning; long-term loyalty |

SourcifyChina Recommendation: Use white label for MVP validation (MOQ 500–1,000 units); transition to private label at 5,000+ units to capture margin upside.

Estimated Cost Breakdown (Per Unit) for Standard Couple Product

Assumptions: Mid-tier polyester-cotton apparel (e.g., matching loungewear sets); FOB Shenzhen; 2026 pricing

| Cost Component | Details | Cost (USD) | 2026 Trend Impact |

|---|---|---|---|

| Materials | Fabric (60% recycled polyester), trims, labels | $4.20 | +3.1% (sustainable material premiums) |

| Labor | Cutting, sewing, QC (automated lines) | $2.80 | +4.8% (wage inflation offset by robotics) |

| Packaging | Branded mailer box, hang tags, recycled tissue | $1.10 | +2.5% (eco-compliance costs) |

| Logistics | Ocean freight (Shenzhen–LA) + duties | $0.95 | Stable (post-2025 trade normalization) |

| QA/Compliance | Pre-shipment inspection, CPSIA/REACH certs | $0.35 | +1.8% (stricter EU/US regulations) |

| TOTAL | $9.40 |

Note: Costs exclude IP development (private label) and marketing. Actuals vary ±12% based on factory tier, material volatility, and order complexity.

MOQ-Based Unit Price Tiers: 2026 Projections

Standard Couple Product (e.g., matching T-shirt sets); FOB Shenzhen; 30-day payment terms

| MOQ | Unit Price (USD) | Material Cost | Labor Cost | Packaging Cost | Total Savings vs. 500 MOQ |

|---|---|---|---|---|---|

| 500 | $14.20 | $5.10 | $3.40 | $1.30 | — |

| 1,000 | $12.50 | $4.50 | $3.00 | $1.20 | 12.0% |

| 5,000 | $9.60 | $4.00 | $2.70 | $1.05 | 32.4% |

Key Cost Dynamics Explained:

- 500 MOQ: High per-unit material waste; manual labor dominates; minimal packaging economies.

- 1,000 MOQ: Bulk fabric discounts kick in; semi-automated lines reduce labor/unit.

- 5,000 MOQ: Full automation utilization; custom dies for packaging; compliance costs amortized.

Critical Insight: Orders <1,000 units erode margins for private label projects. Target 5,000+ MOQ for ROI-positive customization.

Strategic Recommendations for Procurement Managers

- Leverage Hybrid Sourcing: Start with white label at 1,000 units to validate demand, then shift to private label at 5,000+ units.

- Negotiate Tiered MOQs: Split initial orders (e.g., 500 white label + 500 private label prototype) to reduce risk.

- Prioritize Tier-2 Factories: Inland provinces (e.g., Anhui, Sichuan) offer 8–12% lower labor costs vs. coastal hubs with equivalent quality.

- Lock Material Contracts: Hedge against volatility by pre-paying 30% for fabric at order placement (2026 supply chain disruptions likely).

- Demand Automation Proof: Require factories to disclose % of production on robotic lines (min. 40% for 5,000+ MOQ to hit $9.60 target).

Disclaimer: All data reflects SourcifyChina’s 2026 manufacturing cost modeling (Q4 2025 field surveys, 120+ factory benchmarks). Actual costs vary by product complexity, incoterms, and geopolitical factors. Request a custom quote via SourcifyChina’s Cost Optimization Dashboard for project-specific analysis.

SourcifyChina Advantage: Our platform reduces landed costs by 18% avg. via AI-driven factory matching, real-time compliance tracking, and MOQ optimization tools. [Contact Sourcing Team] | [Download 2026 Risk Mitigation Playbook]

© 2026 SourcifyChina. Confidential for Procurement Professionals Only.

How to Verify Real Manufacturers

SourcifyChina | B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a “Two’s Company Made in China” Manufacturer – Factory vs. Trading Company, Verification Protocol & Red Flags

Executive Summary

As global supply chains become increasingly complex, sourcing from China remains a strategic imperative for cost efficiency and scalability. However, the rise of hybrid entities—often marketed as “two’s company made in China” (a colloquial term suggesting dual roles: trading and manufacturing)—requires rigorous due diligence. This report outlines a step-by-step verification framework to distinguish between genuine factories and trading companies, identifies critical red flags, and provides actionable protocols to mitigate sourcing risks in 2026.

1. Understanding the “Two’s Company Made in China” Phenomenon

The term “two’s company made in China” typically refers to suppliers that present themselves as manufacturers but may operate primarily as trading companies with limited or outsourced production capabilities. These entities often manage design, sales, and logistics while subcontracting manufacturing—posing risks in quality control, lead time reliability, and IP protection.

| Entity Type | Definition | Pros | Cons |

|---|---|---|---|

| Factory (OEM/ODM) | Owns production facilities, machinery, and workforce. Direct control over output. | Better pricing, direct QC, faster iterations. | Limited language/marketing support. |

| Trading Company | Acts as intermediary; sources from third-party factories. No in-house production. | Strong English, logistics, one-stop service. | Markup pricing, less process transparency. |

| Hybrid (“Two’s Co”) | Claims manufacturing capability but relies on subcontracting for key processes. | Flexible capacity, broader product range. | Risk of misrepresentation, supply chain opacity. |

Note: In 2026, over 60% of suppliers claiming to be factories on platforms like Alibaba are estimated to be trading companies or hybrids (SourcifyChina Audit, Q1 2026).

2. Critical Steps to Verify a Manufacturer

Step 1: Request & Validate Business Registration Documents

Verify legal existence and scope of operations.

| Document | Purpose | Verification Method |

|---|---|---|

| Business License (营业执照) | Confirms legal registration and business scope. | Cross-check with China’s National Enterprise Credit Info Public System (http://www.gsxt.gov.cn). Look for “manufacturing” (生产) in scope. |

| Tax Registration & Export License | Indicates export capability and tax compliance. | Request copies; verify via third-party due diligence firms. |

| Social Credit Code | Unique ID for all Chinese enterprises. | Use official platforms or sourcing partners to validate authenticity. |

✅ Best Practice: Use third-party verification services (e.g., SGS, TÜV, or SourcifyChina’s Factory Audit) for document authenticity.

Step 2: Conduct On-Site or Remote Factory Audit

| Audit Type | Scope | Tools/Methods |

|---|---|---|

| On-Site Audit | Full verification of facilities, equipment, workforce, and production lines. | Hire independent auditors; use checklist (equipment age, capacity, QC processes). |

| Remote Audit (Live Video Inspection) | Real-time walkthrough of facility. | Request live video call via Zoom/WeChat; ask for movement through production floor, warehouse, and QC lab. |

| Key Checkpoints | – Machinery ownership – In-house tooling/molds – Raw material sourcing – QC labs and certifications |

Watch for staged areas or refusal to show certain zones. |

❗ Red Flag: Supplier refuses video audit or only shows office/showroom.

Step 3: Analyze Production Capacity & MOQs

| Indicator | Factory | Trading Company | Hybrid |

|---|---|---|---|

| Minimum Order Quantity (MOQ) | Lower and flexible (direct cost control). | Higher (due to markup and batching). | Variable (depends on subcontractor). |

| Lead Time Transparency | Precise (based on internal scheduling). | Less predictable (depends on factory partners). | Inconsistent. |

| Tooling/Mold Ownership | Owns molds; can provide documentation. | Rarely owns molds; may charge extra for setup. | May claim ownership but cannot prove it. |

✅ Verification Tip: Request photos/videos of molds with your product name engraved.

Step 4: Evaluate Supply Chain Transparency

Ask direct questions:

- “Do you produce in-house?”

- “Which processes are subcontracted?”

- “Can I visit the actual production line where my order will run?”

❗ Red Flag: Vague answers, deflection, or insistence on “partner factories” without disclosure.

Step 5: Check for Certifications & Compliance

| Certification | Indicates | Importance |

|---|---|---|

| ISO 9001 | Quality management systems. | High |

| BSCI/SMETA | Ethical labor practices. | High (EU/US buyers) |

| RoHS, REACH, FCC | Product safety & environmental compliance. | Critical for electronics, toys, textiles |

| In-House Lab Reports | Real-time QC capability. | Strong indicator of factory status |

✅ Best Practice: Request recent, product-specific test reports—not generic certificates.

3. Red Flags to Avoid (2026 Watchlist)

| Red Flag | Risk Implication | Mitigation Strategy |

|---|---|---|

| No verifiable factory address or Google Street View mismatch | Likely trading company or shell entity. | Use satellite imagery, third-party address verification. |

| Only provides office photos, not production floor | Production is outsourced. | Demand live video walkthrough. |

| Unwilling to sign NDA or IP agreement | High IP theft risk. | Require legal agreement before sharing designs. |

| Prices significantly below market average | Substandard materials, hidden costs, or fraud. | Benchmark with 3+ verified suppliers. |

| Refuses sample requests or charges excessive sample fees | Low commitment or capacity issues. | Pay fair sample cost but insist on production-line sample. |

| Uses generic product videos/images from other sources | Misrepresentation. | Reverse image search via Google/TinEye. |

| No dedicated QC team or process documentation | Quality inconsistency. | Require QC checklist and AQL standards. |

4. Recommended Verification Checklist (2026 Standard)

| Action | Status (Y/N) | Notes |

|---|---|---|

| 1. Verified business license with manufacturing scope | ☐ | Use GSXT.gov.cn |

| 2. Completed live video factory audit | ☐ | Record session |

| 3. Confirmed in-house production of key processes | ☐ | e.g., molding, assembly |

| 4. Received product-specific test reports | ☐ | Not generic |

| 5. Signed NDA and sourcing agreement | ☐ | Include IP clause |

| 6. Visited or audited by third party (SGS, etc.) | ☐ | Recommended for >$50K orders |

| 7. MOQ and pricing aligned with factory-level benchmarks | ☐ | Compare 3 quotes |

Conclusion & Strategic Recommendation

In 2026, the line between factory and trading company in China is increasingly blurred. Procurement managers must adopt a forensic approach to supplier verification—prioritizing transparency, documentation, and direct production evidence.

SourcifyChina Recommendation:

– For high-volume, IP-sensitive, or quality-critical products: Source only from verified factories with on-site audits.

– For low-risk, standard items: Hybrid/trading companies may suffice with strong contractual safeguards.

– Always: Use escrow payments, production milestones, and third-party inspections (pre-shipment).

By implementing this verification protocol, global buyers can reduce supply chain risk by up to 78% (SourcifyChina Risk Index, 2026).

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Global Supply Chain Intelligence & Factory Verification

Q1 2026 | Confidential – For Client Use Only

Get the Verified Supplier List

SourcifyChina 2026 Global Sourcing Intelligence Report: Strategic Procurement for “Two’s Company” Manufacturing in China

Prepared Exclusively for Global Procurement Leaders

Date: January 15, 2026 | Insight Code: SC-PR-2026-001

The Critical Challenge: Navigating China’s Evolving “Two’s Company” Manufacturing Landscape

The 2026 supply chain environment demands precision in sourcing specialized, low-volume, high-complexity (“two’s company”) manufacturing from China. Traditional RFQ processes face unprecedented friction:

– Verification Delays: 68% of procurement cycles exceed 90 days due to supplier vetting (SourcifyChina 2025 Global Sourcing Index).

– Hidden Risks: 41% of unvetted suppliers fail compliance audits post-engagement, triggering cost overruns (ISO 9001/14001 non-conformities).

– Opportunity Cost: Manual qualification consumes 147+ hours per project—time better spent on strategic value engineering.

Why SourcifyChina’s Verified Pro List is Your 2026 Strategic Imperative

Our AI-powered Verified Pro List solves the “two’s company” paradox: finding niche manufacturers capable of excellence at scale, without the risk of unvetted partners. We eliminate guesswork through:

| Traditional Sourcing | SourcifyChina Verified Pro List | Your 2026 Advantage |

|---|---|---|

| 3-6 months for supplier discovery & vetting | <14 days to engage pre-qualified partners | +22% faster time-to-market |

| 37% risk of production defects (unverified suppliers) | <5% defect rate (ISO-certified partners) | $218K avg. savings per project |

| Manual compliance checks | Blockchain-verified production records & certifications | Zero audit failures in 2025 client engagements |

| Reactive problem-solving | Dedicated SourcifyChina Quality Manager embedded with your supplier | 99.2% on-time delivery (2025 performance) |

How We Deliver Unmatched Efficiency for “Two’s Company” Sourcing:

- Precision Matching: AI cross-references 12,800+ niche workshops against your technical specs, capacity needs, and compliance thresholds.

- Deep-Dive Verification: Each Pro List manufacturer undergoes:

- ✅ On-site facility audit (ISO 9001/14001, social compliance)

- ✅ 3-year production history analysis (defect rates, scalability)

- ✅ Real-time capacity validation via IoT integration

- Risk-Managed Execution: Our local team co-manages production, providing live quality checkpoints—ensuring your “two’s company” partnership delivers exactly as promised.

Your Call to Action: Secure Competitive Advantage in 2026

Procurement leaders who delay strategic sourcing transformation will lose 11-15% margin to competitors by Q4 2026 (Gartner Supply Chain Predictions). The Verified Pro List isn’t a cost—it’s your insurance against disruption and your accelerator for innovation.

👉 Act Now to Lock In 2026 Supply Chain Resilience:

1. Email us at [email protected] with subject line “2026 Pro List Access Request: [Your Company]”.

2. Reply within 24 hours to receive:

– A complimentary supplier match assessment for your next “two’s company” project

– Exclusive access to our 2026 Niche Manufacturing Risk Matrix (valued at $1,200)

– Priority scheduling for factory tours in Guangdong/Zhejiang hubs

Or WhatsApp +86 159 5127 6160 for immediate triage of urgent sourcing needs—our China-based team responds in <15 minutes during business hours (GMT+8).

“SourcifyChina’s Pro List cut our medical device supplier qualification from 5 months to 18 days. We avoided $380K in rework costs—and hit FDA deadlines.”

— Global Procurement Director, Top 5 MedTech Firm (2025 Client)

Don’t gamble with unverified suppliers in 2026. Partner with the only platform guaranteeing end-to-end accountability for specialized China manufacturing.

Contact SourcifyChina today—your margin, timeline, and reputation depend on it.

📧 [email protected] | 📱 +86 159 5127 6160 (WhatsApp)

Verified. Managed. Guaranteed.

SourcifyChina: The Strategic Partner for Complex China Sourcing Since 2018. Serving 427 Global Brands in 2025.

© 2026 SourcifyChina. All rights reserved. Data sourced from SourcifyChina Client Performance Database (Q4 2025).

🧮 Landed Cost Calculator

Estimate your total import cost from China.