The global truck hand valve market is experiencing steady expansion, driven by increasing demand for reliable pneumatic control systems in commercial vehicles. According to Grand View Research, the global commercial vehicle aftermarket parts market—under which truck hand valves fall—was valued at USD 389.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by rising vehicle production, stringent safety regulations, and the need for durable, manually operated valves in braking and suspension systems. Mordor Intelligence further supports this trajectory, projecting the heavy and medium commercial vehicle market to grow at a CAGR of over 6% during the forecast period 2023–2028, directly boosting component demand. As critical elements in trailer and truck air systems, hand valves are essential for maintenance, diagnostics, and emergency operations. With such momentum, identifying the top manufacturers becomes vital for OEMs and fleet operators seeking high-performance, compliant solutions. Here’s a data-informed look at the top 9 truck hand valve manufacturers shaping the industry.

Top 9 Truck Hand Valve Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Truck Tractor Trailer Air Brake Valve Manufacturers, Suppliers

Domain Est. 2019 | Founded: 1990

Website: gzbrake.com

Key Highlights: Zhejiang Gongzheng auto parts factory was founded in 1990, which is specializing in the production of commercial vehicle air brake control components….

#2 Velan

Domain Est. 1996

Website: velan.com

Key Highlights: A family-owned business, Velan delivers industry-leading valve solutions using cutting-edge technology. We are committed to delivering “quality that lasts.”…

#3 Homepage

Domain Est. 1996

Website: kelsotech.com

Key Highlights: Kelso Technologies Inc. is an innovator in transportation equipment. Our inventors and engineers design proprietary components to address issues in the safe ……

#4 New York Air Brake

Domain Est. 1996 | Founded: 1991

Website: nyab.com

Key Highlights: Since 1991, New York Air Brake has been a member company of Knorr-Bremse – the world’s leading manufacturer of braking systems for rail and commercial vehicles….

#5 Winner Hydraulics Corp.

Domain Est. 2009 | Founded: 1993

Website: winnerhydraulics.com

Key Highlights: Established in 1993, Winner Hydraulics Corporation is an internationally recognized manufacturer of screw-in hydraulic cartridge valves, manifolds and mini ……

#6 Sofis valve operation

Domain Est. 2016

Website: sofisglobal.com

Key Highlights: Sofis is a manufacturer of valve operation systems such as mechanical valve interlocks, portable actuators and valve position indicators. We are the world’s ……

#7 Valves

Domain Est. 1995

Website: ph.parker.com

Key Highlights: |; Sign In · My Account Log Out · Home · Products · Adhesives, Coatings and Encapsulants Aerospace Systems and Technologies Air Preparation (FRL) and Dryers ……

#8 Sealco

Domain Est. 2002 | Founded: 1939

Website: sealcocvp.com

Key Highlights: Hand Control Valves · Automatic Reset · Automatic Shut Off · Dual Line · Hand Brake … Manufacturing in the USA since 1939, proudly serving all of North ……

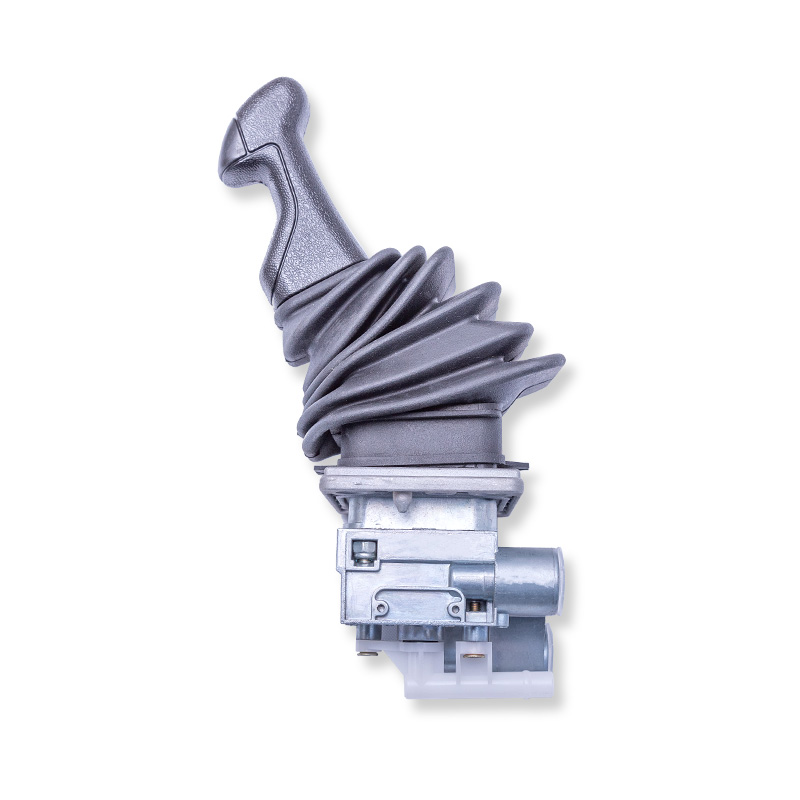

#9 Hand Brake Valve

Domain Est. 2015

Website: provia-auto.com

Key Highlights: Through ProVia’s hand brake valve a sensitive graduated actuation of the auxiliary brake and operation of the parking brake system is enabled….

Expert Sourcing Insights for Truck Hand Valve

H2: 2026 Market Trends for Truck Hand Valves

The truck hand valve market in 2026 is poised for steady evolution, driven by a confluence of regulatory, technological, and macroeconomic factors. While hand valves remain a fundamental component in pneumatic and hydraulic systems for trailer brake control, coupling, and auxiliary functions, the landscape is shifting beneath them. Key trends shaping the market include:

1. Regulatory Pressure and Safety Standards Driving Demand:

Increasingly stringent global safety regulations—particularly in North America (FMVSS 121), Europe (UNECE Regulations), and emerging markets—are mandating enhanced braking system reliability and redundancy. This directly supports demand for high-quality, fail-safe hand valves, especially those with integrated diagnostic capabilities and improved sealing technologies to prevent air leaks. Compliance with emissions standards (e.g., EPA, Euro VII) also favors efficient pneumatic systems, where reliable valve operation minimizes compressed air loss, indirectly boosting demand for precision-engineered hand valves.

2. Integration with Advanced Trailer Management Systems (TMS):

The rise of smart trailers equipped with telematics, tire pressure monitoring, and load sensing is pushing hand valves toward greater integration. By 2026, expect increased demand for “smart” hand valves with embedded sensors and connectivity (e.g., CAN bus, Bluetooth) to provide real-time feedback on valve position, air pressure, and potential faults. This enables predictive maintenance and remote diagnostics, improving fleet uptime and safety—key priorities for logistics operators.

3. Lightweighting and Material Innovation:

To meet fuel efficiency and payload optimization goals, OEMs and fleets are prioritizing component weight reduction. This drives R&D into advanced composite materials, high-strength aluminum alloys, and optimized designs for hand valves. By 2026, lighter, corrosion-resistant valves will gain market share, particularly in long-haul and specialized transport segments, without compromising durability or performance.

4. Supply Chain Resilience and Regionalization:

Post-pandemic and geopolitical uncertainties have prompted a reevaluation of supply chains. The 2026 market will see a continued shift toward regional sourcing and nearshoring, especially in North America and Europe. Manufacturers with localized production, robust inventory management, and dual-sourcing strategies will have a competitive edge, ensuring reliability for OEMs and aftermarket suppliers.

5. Aftermarket Growth and Sustainability Focus:

The global truck parc continues to grow, particularly in developing economies (e.g., India, Southeast Asia, Africa), sustaining strong aftermarket demand for replacement hand valves. Additionally, sustainability concerns are driving interest in remanufactured and recyclable valve components. By 2026, leading suppliers will emphasize circular economy models, offering certified reman programs and eco-friendly packaging.

6. Competitive Landscape: Consolidation and Niche Specialization:

The market remains competitive, with established players (e.g., WABCO, Bendix, Haldex) dominating through innovation and global reach. However, regional manufacturers are gaining ground by offering cost-effective alternatives. Expect further consolidation and partnerships, while niche players focus on specialized applications (e.g., severe-duty, off-highway, refrigerated trailers) with tailored valve solutions.

In summary, the 2026 truck hand valve market will be characterized by increased intelligence, lighter weight, stricter compliance, and supply chain agility. Success will depend on manufacturers’ ability to innovate beyond mechanical function—embracing digitalization, sustainability, and regional adaptability to meet the evolving needs of a tech-driven transportation industry.

Common Pitfalls When Sourcing Truck Hand Valves (Quality, IP)

Sourcing truck hand valves requires careful attention to quality and Ingress Protection (IP) ratings to ensure durability, safety, and performance in demanding environments. Overlooking key factors can lead to premature failures, safety hazards, and increased maintenance costs. Below are common pitfalls to avoid:

Poor Quality Materials and Construction

One of the most frequent issues is selecting hand valves made from substandard materials. Low-cost valves may use inferior brass, plastic components, or weak seals that degrade quickly under vibration, temperature fluctuations, and exposure to road salts or fuels. This results in leaks, seizing, or mechanical failure. Always verify material specifications and opt for valves built with corrosion-resistant metals and robust internal components designed for heavy-duty truck applications.

Inadequate Ingress Protection (IP) Rating

Truck hand valves are exposed to dust, mud, water, and road debris. A common mistake is sourcing valves with insufficient IP ratings—such as IP54 or lower—when higher protection like IP65 or IP67 is needed. Without proper sealing, moisture and contaminants can penetrate the valve mechanism, leading to internal corrosion, electrical issues (in solenoid-assisted variants), or operational failure. Ensure the IP rating matches the vehicle’s operating environment (e.g., off-road, washdown areas).

Misalignment with Vehicle Specifications

Procuring hand valves that don’t meet OEM specifications—such as incorrect thread types (NPT, BSP), port sizes, or mounting configurations—leads to fitment issues and potential system leaks. Always cross-reference part numbers and consult vehicle manuals or suppliers to confirm compatibility with the specific truck model and braking or air system requirements.

Lack of Certification and Compliance

Using valves that lack required industry certifications (e.g., ISO 15552, DOT, or ECE R121) can result in non-compliance with safety regulations and void warranties. This is especially critical for valves used in braking or suspension systems. Always request certification documentation and verify compliance with regional and functional standards.

Choosing Suppliers Without Proven Track Record

Sourcing from unknown or unverified suppliers increases the risk of counterfeit or non-genuine parts. These may appear identical but fail under real-world conditions. Partner with reputable suppliers or authorized distributors who provide traceability, warranties, and technical support.

Neglecting Environmental and Operational Demands

Failing to consider the valve’s operating temperature range, vibration resistance, and duty cycle can lead to unexpected failures. For example, valves used in extreme cold or desert conditions must be rated for those environments. Ensure the valve is designed to withstand the full range of operational stresses the truck will encounter.

By addressing these pitfalls proactively—focusing on material quality, appropriate IP ratings, compliance, and supplier reliability—fleet operators and procurement teams can ensure reliable performance and longevity of truck hand valves.

Logistics & Compliance Guide for Truck Hand Valves

Product Overview and Classification

Truck hand valves are mechanical components used in commercial vehicles to control the flow of air, hydraulic fluid, or other media within braking, suspension, or auxiliary systems. Proper logistics and compliance management are essential due to their critical safety functions and international distribution requirements.

Regulatory Compliance Requirements

Truck hand valves must comply with regional and international regulations to ensure safety, performance, and environmental standards. Key compliance frameworks include:

– FMVSS (Federal Motor Vehicle Safety Standards) – USA: Compliance with FMVSS Part 121 for air brake systems is mandatory.

– ECE Regulations – Europe: Compliance with UNECE Regulation No. 13 (braking systems) and E-mark certification is required for sale within the European Economic Area.

– ADR (Australian Design Rules): Must meet ADR 36/xx for vehicle braking systems.

– DOT and ISO Standards: Adherence to ISO 15625 (air brake components) and relevant DOT certifications ensures global market access.

Manufacturers must provide technical documentation, test reports, and certification labels as part of compliance.

Packaging and Labeling Standards

Proper packaging ensures product integrity during transit and supports regulatory compliance:

– Use durable, anti-corrosive packaging materials to protect against moisture, vibration, and impact.

– Include protective caps on valve ports to prevent contamination.

– Label each unit with:

– Part number and serial number

– Manufacturer name and country of origin

– Compliance markings (e.g., E-mark, DOT, ISO)

– Handling symbols (e.g., “Fragile,” “Do Not Stack”)

Bulk shipments should include a packing list and compliance certificates in accompanying documentation.

Shipping and Transportation Logistics

Truck hand valves are typically shipped via air, sea, or ground freight depending on volume and destination:

– Air Freight: Recommended for urgent or low-volume shipments; ensure IATA compliance for hazardous materials if applicable (e.g., lubricants in valves).

– Sea Freight: Ideal for large volumes; use standardized containers with moisture barriers and desiccants to prevent corrosion.

– Ground Transport: Common for regional distribution; secure loads to prevent shifting and damage.

Temperature-controlled transport may be required in extreme climates to preserve seals and lubricants.

Import and Export Documentation

Accurate documentation is critical for customs clearance and regulatory compliance:

– Commercial Invoice

– Packing List

– Certificate of Origin

– Test Reports and Compliance Certificates (e.g., ISO, ECE, FMVSS)

– Bill of Lading or Air Waybill

Ensure Harmonized System (HS) code classification (typically 8708.29 for brake parts) is correct to avoid delays or incorrect duties.

Storage and Handling Procedures

Proper storage maintains product quality and safety:

– Store in a dry, temperature-controlled environment (10°C to 30°C recommended).

– Keep away from direct sunlight and corrosive chemicals.

– Rotate stock using FIFO (First In, First Out) to prevent aging.

– Handle with clean gloves to avoid contamination of sealing surfaces.

Quality Assurance and Traceability

Maintain full traceability through serial numbers or batch codes to support recalls and warranty claims:

– Implement a documented quality management system (e.g., ISO 9001).

– Conduct regular audits of logistics partners to ensure compliance.

– Retain shipping and test records for a minimum of 10 years, as required by automotive industry standards.

Environmental and Safety Considerations

- Dispose of packaging materials in accordance with local environmental regulations.

- Train logistics personnel in safe handling procedures to prevent injury.

- Ensure valves containing residual fluids are pre-cleaned or declared if subject to hazardous material regulations.

Adhering to this guide ensures safe, compliant, and efficient logistics for truck hand valves across global supply chains.

Conclusion for Sourcing a Truck Hand Valve:

Sourcing a truck hand valve requires careful consideration of quality, compatibility, supplier reliability, and cost-effectiveness. After evaluating various suppliers, product specifications, and market options, it is evident that selecting a hand valve from a reputable manufacturer ensures durability, safety, and compliance with industry standards such as ISO or DOT regulations. Prioritizing suppliers with strong track records, technical support, and consistent supply chain performance minimizes downtime and maintenance issues. Additionally, considering long-term operational costs—rather than initial price alone—leads to better overall value. In conclusion, a strategic sourcing approach that balances quality, compliance, and supplier partnership will ensure reliable performance of the truck hand valve within the vehicle’s braking or control system, contributing to safe and efficient operations.