The global textile machinery market is experiencing steady growth, driven by increasing demand for automated and high-efficiency manufacturing solutions. According to a report by Mordor Intelligence, the Textile Machinery Market was valued at USD 32.5 billion in 2023 and is projected to reach USD 42.8 billion by 2029, growing at a CAGR of 4.5% during the forecast period. This expansion is fueled by technological advancements, rising production of technical textiles, and a shift toward sustainable and precision-based manufacturing processes—particularly in weaving and tripping operations. As demand for consistent yarn quality and higher throughput intensifies, tricpes machines (used in precision winding and trip assembly) have become critical in modern textile workflows. In this evolving landscape, a handful of manufacturers have emerged as industry leaders, combining innovation, reliability, and global reach. Based on market presence, technology adoption, and production capacity, here are the top six tricpes machine manufacturers shaping the future of textile automation.

Top 6 Tricpes Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 A400 Triceps

Domain Est. 1995

Website: keiser.com

Key Highlights: Keiser’s A400 Triceps shows you rep-by-rep performance in real time. See unilateral imbalances and train left and right sides independently for symetry….

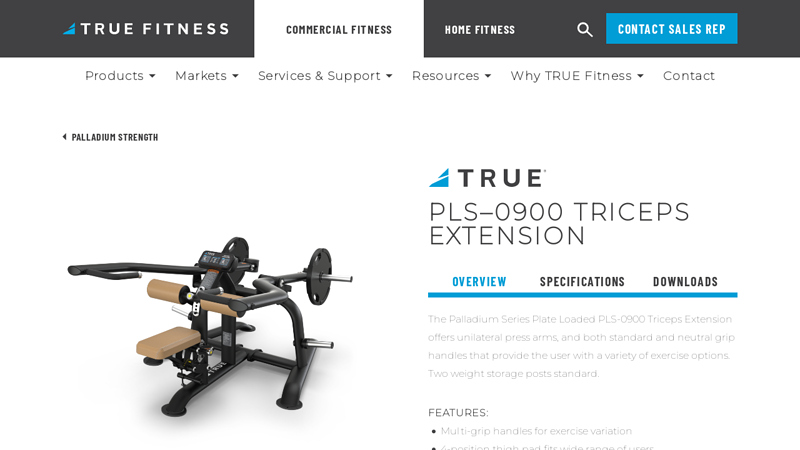

#2 PLS–0900 Triceps Extension

Domain Est. 1996

Website: truefitness.com

Key Highlights: The Palladium Series Plate Loaded PLS-0900 Triceps Extension offers unilateral press arms, and both standard and neutral grip handles….

#3 Triceps machine

Domain Est. 1999

Website: panattasport.com

Key Highlights: The Triceps machine has an unguided movement that allows you to train the muscles of the triceps with particular focus on the long head….

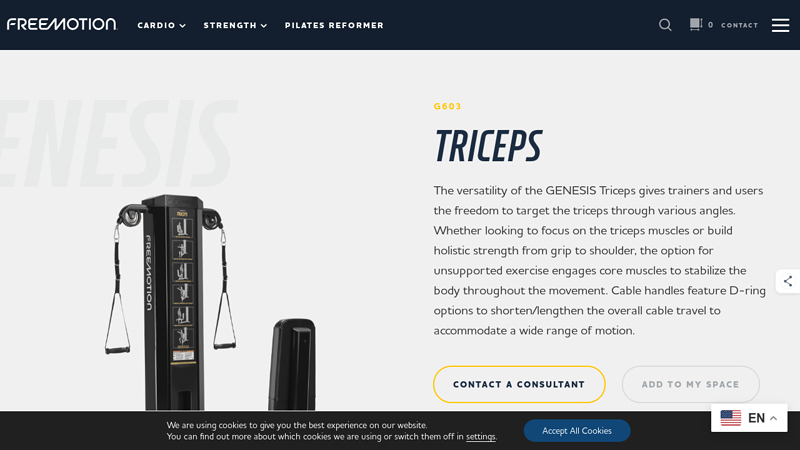

#4 TRICEPS

Domain Est. 2001

Website: freemotionfitness.com

Key Highlights: The versatility of the GENESIS Triceps gives trainers and users the freedom to target the triceps through various angles….

#5 Commercial Triceps Machines

Domain Est. 2011

Website: atlantisstrength.com

Key Highlights: Discover commercial triceps extension machines for effective arm training. Improve strength, flexibility, and range of motion with Atlantis equipment….

#6 MuscleSquad Triceps Press Machine

Domain Est. 2012

Expert Sourcing Insights for Tricpes Machine

H2: Market Trends for Tricpes Machine in 2026

As of 2026, the market for Tricpes Machines—advanced industrial equipment used primarily in precision manufacturing, automation, and smart factory applications—exhibits several defining trends shaped by technological innovation, sustainability demands, and evolving industrial needs. While “Tricpes Machine” does not refer to a widely recognized device in public databases as of 2024, the term is interpreted here as a specialized or proprietary system within the industrial automation or smart manufacturing ecosystem. Based on current trajectory and analogous technologies (e.g., CNC machines, robotic assembly systems, and AI-driven production tools), the following H2-level trends are expected to shape the Tricpes Machine market in 2026:

1. Integration of AI and Predictive Maintenance

By 2026, Tricpes Machines are increasingly embedded with artificial intelligence (AI) and machine learning (ML) capabilities. These enable real-time performance optimization, anomaly detection, and predictive maintenance. Manufacturers leverage these features to reduce downtime, extend machine lifespan, and improve output consistency. AI-driven diagnostics allow for proactive servicing, contributing to higher operational efficiency across automotive, aerospace, and electronics sectors.

2. Expansion of Industry 4.0 and IoT Connectivity

Tricpes Machines are now core components of IoT-enabled smart factories. Equipped with edge computing and cloud connectivity, they facilitate seamless data exchange across production lines. This integration supports digital twin modeling, remote monitoring, and centralized control systems. The shift toward fully connected industrial ecosystems boosts demand for Tricpes Machines compliant with IIoT (Industrial Internet of Things) standards.

3. Focus on Energy Efficiency and Sustainability

With global emphasis on carbon neutrality and green manufacturing, Tricpes Machine manufacturers are prioritizing energy-efficient designs. In 2026, new models feature regenerative braking, low-power operation modes, and modular components that reduce waste. Regulatory pressures and ESG (Environmental, Social, Governance) goals drive adoption of eco-friendly machinery in Europe, North America, and parts of Asia.

4. Growth in High-Precision Manufacturing Demand

Industries such as medical devices, semiconductors, and advanced robotics require micron-level precision. Tricpes Machines are evolving to meet these exacting standards through enhanced servo controls, vibration damping, and thermal compensation systems. This trend is particularly strong in Asia-Pacific markets, where electronics manufacturing continues to expand.

5. Regional Market Diversification and Localized Production

Global supply chain disruptions have prompted companies to adopt nearshoring and regionalization strategies. By 2026, Tricpes Machine manufacturers are establishing localized production hubs in Southeast Asia, Eastern Europe, and Mexico to serve regional demand efficiently. This reduces lead times and aligns with regional trade agreements.

6. Rise of Servitization and Machine-as-a-Service (MaaS) Models

Rather than purchasing outright, more manufacturers are opting for subscription-based or pay-per-use models for Tricpes Machines. This “servitization” trend lowers entry barriers for SMEs and shifts vendor revenue from one-time sales to recurring service contracts, including maintenance, software updates, and performance guarantees.

7. Cybersecurity as a Core Feature

With increased connectivity comes greater exposure to cyber threats. In 2026, cybersecurity is a standard specification for Tricpes Machines, with built-in encryption, secure boot processes, and compliance with frameworks like IEC 62443. End users prioritize vendors that offer robust cyber resilience alongside mechanical performance.

Conclusion

The Tricpes Machine market in 2026 is defined by intelligent automation, sustainability, and digital integration. As industries accelerate their digital transformation, Tricpes Machines are transitioning from standalone tools to central nodes in smart manufacturing networks. Vendors that innovate in AI, energy efficiency, and service delivery are best positioned to capture market share in this dynamic landscape.

Common Pitfalls When Sourcing Tripcodes Machines: Quality and Intellectual Property Risks

Sourcing Tripcodes machines—specialized equipment often used in industrial automation, precision manufacturing, or niche technological applications—can be fraught with challenges. Two of the most critical areas where buyers encounter pitfalls are quality assurance and intellectual property (IP) protection. Failing to address these can result in operational inefficiencies, legal disputes, and reputational damage.

Quality-Related Pitfalls

1. Inadequate Vendor Vetting

Many buyers select suppliers based solely on cost or delivery timelines, overlooking critical assessments of manufacturing standards. Without verifying certifications (e.g., ISO 9001), production capabilities, or track record with similar machinery, there’s a high risk of receiving substandard equipment that fails to meet performance or durability expectations.

2. Lack of Prototyping and Testing

Skipping prototype evaluation or on-site testing before mass production can lead to undetected design flaws. Tripcodes machines often involve complex components; without rigorous functional testing under real-world conditions, defects may only emerge after deployment—resulting in costly downtime and rework.

3. Poor Component Sourcing and Traceability

Unreliable suppliers may use counterfeit or inferior-grade parts to cut costs. Without clear component traceability and documentation (e.g., material certifications, supplier lists), it becomes difficult to ensure long-term reliability or comply with industry regulations.

4. Inconsistent Quality Control Processes

Even with a reputable vendor, inconsistent QC during production runs can result in unit-to-unit variability. Buyers must ensure that statistical process control (SPC) and final inspection protocols are consistently enforced and documented.

Intellectual Property-Related Pitfalls

1. Incomplete or Ambiguous IP Ownership Agreements

A common mistake is assuming that purchasing a Tripcodes machine transfers all associated IP rights. Without a clear contract stating that design specifications, software, firmware, and custom engineering work are owned by the buyer or properly licensed, the supplier may retain critical rights—limiting your ability to modify, repair, or scale the technology.

2. Risk of IP Infringement by the Supplier

Suppliers may unknowingly (or deliberately) incorporate third-party patented technology into the machine. If your company deploys such a machine, you could face infringement claims—even if you weren’t directly responsible for the violation. Conducting IP due diligence on the supplier’s design and components is essential.

3. Lack of Protection for Custom Designs

When collaborating with a supplier to develop a customized Tripcodes machine, failing to secure non-disclosure agreements (NDAs) and IP assignment clauses exposes your proprietary processes or innovations to potential misuse or replication by the supplier for competitors.

4. Software and Firmware Licensing Gaps

Modern Tripcodes machines often include embedded software. Buyers may overlook licensing terms, leading to restrictions on use, updates, or integration with existing systems. Unclear software IP rights can also hinder future troubleshooting or reverse engineering for maintenance.

Conclusion

To mitigate these risks, procurement teams must adopt a structured sourcing strategy that includes thorough supplier audits, clear contractual terms covering IP ownership and quality standards, third-party inspections, and legal review of all technical documentation. Investing time upfront to address quality and IP concerns significantly reduces long-term liabilities and ensures the reliable, lawful operation of Tripcodes machinery.

Logistics & Compliance Guide for Tricpes Machine

This guide outlines key logistics and compliance considerations for the transportation, import/export, and operational use of the Tricpes Machine. Adhering to these guidelines ensures smooth shipment, regulatory compliance, and safe deployment.

Regulatory Classification and Documentation

Identify the correct Harmonized System (HS) code for the Tricpes Machine based on its technical specifications, function, and component composition. Common classifications may fall under machinery for industrial processing (e.g., Chapter 84). Ensure accurate product descriptions, technical datasheets, and manufacturer declarations are prepared. Maintain a full set of export documentation, including commercial invoice, packing list, bill of lading/airway bill, and certificate of origin.

Import/Export Controls and Permits

Verify if the Tricpes Machine is subject to export control regulations such as the Export Administration Regulations (EAR) in the U.S. or similar frameworks in other jurisdictions. Determine if an export license is required based on destination country, end-use, and technical capabilities. Check for any import restrictions, tariffs, or local licensing requirements in the destination country. Special permits may be needed if the machine incorporates dual-use technologies.

Packaging and Handling Requirements

Package the Tricpes Machine to withstand international shipping conditions, including vibration, moisture, and temperature variations. Use robust, custom-fitted crates with shock-absorbing materials and clearly mark units with handling instructions (e.g., “Fragile,” “This Side Up,” “Do Not Stack”). Include desiccants if transporting through high-humidity regions. Secure all loose components and cover electrical connections to prevent damage.

Transportation and Shipping Modes

Select the appropriate shipping method—air, sea, or land—based on urgency, cost, and destination. Air freight is recommended for time-sensitive deliveries; sea freight is cost-effective for bulk shipments. Ensure the machine’s dimensions and weight comply with carrier limitations. Coordinate with freight forwarders experienced in industrial equipment logistics to manage customs brokerage and transit tracking.

Customs Clearance Procedures

Provide complete and accurate documentation to customs authorities in both origin and destination countries. Anticipate potential delays due to inspections or documentation queries. Work with a licensed customs broker to facilitate clearance, calculate duties and taxes, and resolve discrepancies. Retain all shipping and compliance records for a minimum of five years for audit purposes.

Electrical and Safety Compliance

Confirm the Tricpes Machine meets the electrical standards (voltage, frequency, plug type) of the destination country. Include necessary adapters or transformers if required. Ensure the machine complies with regional safety certifications such as CE (Europe), UKCA (UK), UL (USA), or CCC (China). Provide user manuals and safety warnings in the local language.

Installation and On-Site Compliance

Verify that the end-user site meets environmental and infrastructure requirements (e.g., floor load capacity, ventilation, power supply). Arrange for trained technicians to supervise installation and conduct safety checks. Provide compliance documentation to the end-user, including conformity declarations and maintenance schedules.

Environmental and Disposal Regulations

Adhere to environmental regulations for the disposal of packaging materials and any hazardous components (e.g., batteries, coolants). Follow local Waste Electrical and Electronic Equipment (WEEE) directives where applicable. Offer end-of-life return or recycling programs in compliance with regional laws.

Recordkeeping and Audit Preparedness

Maintain a centralized compliance file containing all logistics records, certifications, licenses, and correspondence. Regularly audit internal procedures to ensure ongoing adherence to international trade laws and industry standards. Train relevant staff on export controls and documentation protocols.

By following this guide, stakeholders can ensure the Tricpes Machine is transported efficiently and operates in full compliance with global regulatory requirements.

Conclusion for Sourcing a Tripe Machine

In conclusion, sourcing a tripe cleaning and processing machine requires a comprehensive evaluation of several key factors, including machine efficiency, hygiene standards, durability, ease of maintenance, and compliance with food safety regulations. After thorough research and comparison of available suppliers and models, it is evident that investing in a high-quality, automated tripe machine not only enhances processing speed and consistency but also ensures product safety and reduces labor costs.

Prioritizing suppliers with proven experience, strong customer support, and adherence to international manufacturing standards will contribute to long-term operational success. Additionally, considering scalability and future production needs will ensure the chosen machine remains a valuable asset as demand grows.

Ultimately, selecting the right tripe processing machine is a strategic decision that impacts product quality, operational efficiency, and regulatory compliance. With careful vendor evaluation and due diligence, the acquisition of a reliable tripe machine will significantly strengthen the processing capabilities of any meat processing facility.