The global specialty coatings market, which includes tri-color paint products widely used in automotive detailing, industrial applications, and consumer goods, is experiencing steady growth driven by demand for high-performance, visually distinctive finishes. According to a report by Grand View Research, the global automotive coatings market—where tri-color and multi-tone finishes are increasingly popular—was valued at USD 38.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Additionally, Mordor Intelligence projects that the specialty paints and coatings market will expand significantly, fueled by innovations in pigment technology and rising consumer preference for customized, durable color solutions across industries. With this momentum, manufacturers specializing in tri-color formulations are at the forefront of product differentiation and technical advancement. Below are the top 9 tri-color paint manufacturers leading this transformative space through innovation, scalability, and quality.

Top 9 Tri Color Paint Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Dupli-Color has perfect color match for your vehicle

Domain Est. 1997

Website: duplicolor.com

Key Highlights: Dupli-Color is the only brand with colors tested and approved by vehicle manufacturers for a perfect match to your original factory finish. Vehicle; Color Code….

#2 Automotive Finishes

Domain Est. 1998

Website: industrial.sherwin-williams.com

Key Highlights: Sherwin-Williams Automotive Finishes is the leading manufacturer and distributer of high-quality paint and coating systems for automotive and fleet ……

#3 Colours, Inc.

Domain Est. 1999

Website: gocolours.com

Key Highlights: Commercial & Industrial. We are dedicate to delivering top-tier PPG paint products and tailored solutions for truck, fleet, and industrial manufacturing….

#4 Endura Paint

Domain Est. 2002

Website: endurapaint.com

Key Highlights: Endura is a manufacturer of high performance polyurethane and epoxy industrial coatings. Product lines include, industrial paint systems, ……

#5 Createx Colors™

Domain Est. 1997

Website: createxcolors.com

Key Highlights: Createx Colors is the number one, most widely used and trusted airbrush paint manufacturer in the world….

#6 HMG Paints Limited

Domain Est. 1998 | Founded: 1930

Website: hmgpaint.com

Key Highlights: Established in 1930 HMG has grown to become the UK’s Leading Independent Paint Manufacturer. Offering innovative and compliant paints and coatings to a variety ……

#7 PPG

Domain Est. 1990

Website: ppg.com

Key Highlights: Discover how PPG’s global team of innovators drives sustainable solutions, enhances productivity, and celebrates 140 years of color leadership. Join us!…

#8 Tri

Domain Est. 2002

Website: tri-art.ca

Key Highlights: Shop or find local dealers of Tri-Art products, including brands like Rheotech, Art Noise, Tri-Art High Viscosity, Tri-Art Liquids, Liquid Glass and more….

#9 Paint Solutions Specially Formulated for the Pro

Domain Est. 2004

Website: ppgpaints.com

Key Highlights: PPG provides high-quality paint products, color services, and support to professional painters, contractors, designers, architects, and specifiers….

Expert Sourcing Insights for Tri Color Paint

H2: 2026 Market Trends for Tri-Color Paint

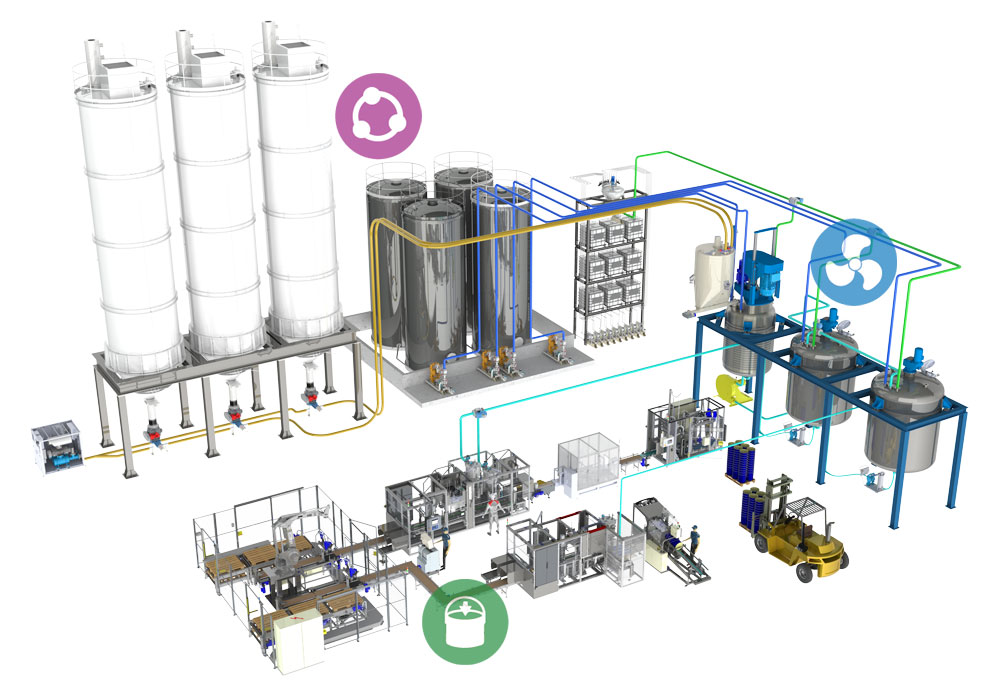

Looking ahead to 2026, the market for tri-color paint systems (typically referring to multi-layer or multi-tone paint finishes, often involving base, mid, and clear or effect coats, popular in automotive, industrial, and premium architectural applications) is poised for significant evolution driven by technological innovation, sustainability demands, and shifting consumer preferences. Here’s a breakdown of key trends:

1. Sustainability & Regulatory Compliance as Core Drivers

- Low-VOC & Zero-VOC Dominance: Stricter global environmental regulations (e.g., EU Green Deal, US EPA rules) will push tri-color systems towards water-based, high-solids, and 100% solids formulations. Solvent-based systems will face increasing restrictions, accelerating R&D in eco-friendly alternatives without sacrificing performance.

- Bio-Based & Renewable Raw Materials: Expect increased incorporation of bio-derived resins, solvents, and additives (e.g., from castor oil, lignin, plant oils) to reduce carbon footprint and enhance brand sustainability profiles.

- Circular Economy Focus: Development of paints designed for easier coating removal during recycling (e.g., for end-of-life vehicles or appliances) and increased use of recycled content in packaging and potentially pigments will gain traction.

- Transparency & Ecolabels: Demand for full ingredient disclosure (e.g., Health Product Declarations – HPDs) and certifications (e.g., Cradle to Cradle, Greenguard) will intensify, becoming key differentiators.

2. Advanced Technologies & Performance Enhancement

- Smart & Functional Coatings Integration: Tri-color systems will increasingly incorporate functional layers: self-healing polymers (repairing micro-scratches), thermochromic materials (color-changing with temperature), photochromic effects (light-responsive), or antimicrobial properties, especially in healthcare and high-touch architectural surfaces.

- Nanotechnology Advancements: Wider use of nanoparticles (e.g., silica, titania) for enhanced durability (scratch, UV, chemical resistance), improved flow/leveling, and unique optical effects (deeper color, enhanced metallic/flake orientation) within the multi-layer structure.

- AI & Digital Color Matching: AI-driven software will dominate color formulation and matching, enabling faster, more accurate creation of complex tri-color effects and virtual sampling, reducing waste and lead times.

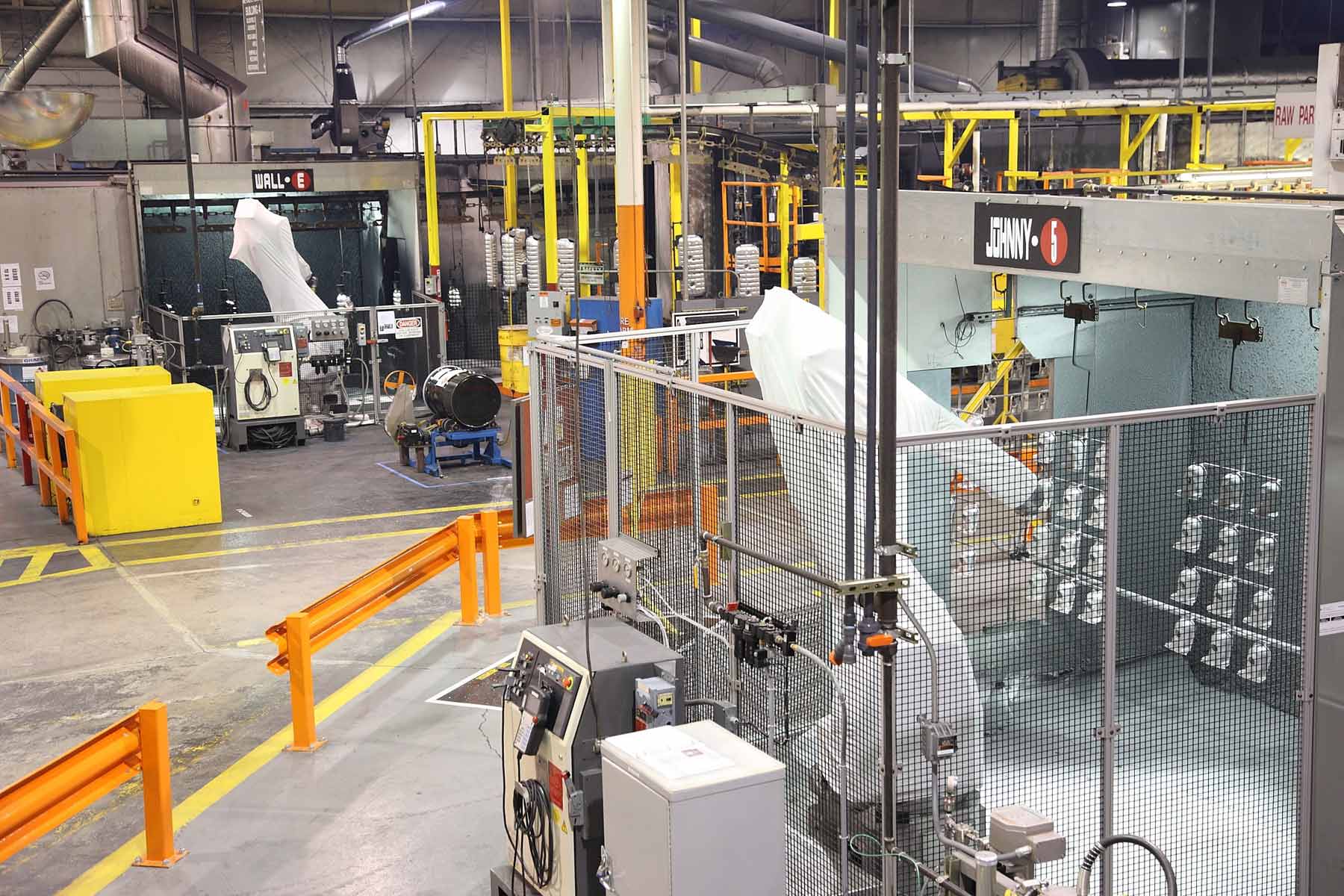

- Robotics & Automation: Increased adoption of robotic application (especially in automotive and industrial settings) will drive demand for tri-color systems optimized for precise, consistent application (e.g., specific viscosity, drying profiles).

3. Consumer & Aesthetic Trends

- Demand for Personalization & Unique Effects: Consumers (auto, luxury goods, architecture) will crave distinctive finishes. Tri-color systems offer complexity: deep, multi-dimensional metallics, chameleonic color-shift pigments (e.g., tri-color flip effects), textured layers (e.g., matte over gloss), and bespoke combinations.

- “Quiet Luxury” & Sophisticated Neutrals: While bold colors exist, the high-end market will favor sophisticated, multi-tonal neutrals (e.g., layered greys, taupes, deep blues) with subtle depth and luster achieved through tri-color layering, conveying understated quality.

- Experience-Driven Finishes: Focus on tactile and visual experiences – coatings with unique feel (soft-touch, leather-like) combined with complex visual depth from the tri-color build.

4. Supply Chain & Manufacturing Resilience

- Localization & Regionalization: Geopolitical tensions and pandemic lessons will push manufacturers to diversify supply chains and establish regional production hubs for key raw materials and finished coatings to mitigate disruption risks.

- Digital Supply Chain Integration: Greater use of digital platforms for real-time inventory management, predictive logistics, and supplier collaboration will be essential for efficiency.

- Energy Efficiency Focus: Pressure to reduce manufacturing energy consumption will drive innovation in low-bake and ambient-cure tri-color systems, reducing reliance on high-temperature ovens.

5. Market-Specific Dynamics

- Automotive: Remains the largest driver. Trends include complex “digital” colors (achieved via multi-layer effects), enhanced durability for EVs (battery protection, scratch resistance), and sustainable options for premium EVs. Tri-coat systems will be crucial for brand differentiation.

- Architectural: Growth in premium residential and commercial projects using tri-color effects for feature walls, furniture, and facade elements, driven by demand for unique, high-quality finishes. Focus on durability and ease of application.

- Industrial/General Manufacturing: Increased use on appliances, electronics, and consumer goods for branding, durability, and aesthetic appeal. Need for efficient, fast-curing systems compatible with high-speed lines.

Conclusion for 2026:

The tri-color paint market in 2026 will be characterized by a convergence of sustainability, advanced functionality, and hyper-personalization. Success will depend on manufacturers’ ability to innovate with eco-friendly formulations (H2 focus: low-VOC, bio-based), leverage digital tools (AI, automation), and deliver complex, durable, and unique aesthetic effects that meet evolving regulatory standards and consumer desires. Companies failing to adapt to these H2-driven sustainability and technological shifts will face significant competitive disadvantages. The “triple threat” of environmental compliance, performance enhancement, and aesthetic innovation will define market leaders.

Common Pitfalls When Sourcing Tri-Color Paint: Quality and Intellectual Property Issues

Sourcing tri-color paint—often used in automotive, industrial, or artistic applications—can present several challenges, particularly concerning quality consistency and intellectual property (IP) rights. Being aware of these pitfalls helps ensure reliable supply, legal compliance, and brand integrity.

Quality-Related Pitfalls

Inconsistent Color Matching

One of the most frequent issues when sourcing tri-color paint is inconsistent color formulation. Variations in pigment concentration, batch production methods, or raw material sources can result in noticeable differences between batches. This is especially problematic when the paint is used across multiple components or over extended production timelines.

Poor Adhesion and Durability

Low-quality tri-color paints may exhibit poor adhesion to substrates or degrade quickly under environmental stress (UV exposure, moisture, temperature fluctuations). This compromises both appearance and protective function, leading to customer dissatisfaction and increased warranty claims.

Lack of Standardized Testing

Suppliers may not adhere to industry standards (e.g., ASTM, ISO) for performance testing. Without proper documentation on gloss retention, chemical resistance, or weatherability, buyers risk procuring subpar products that fail in real-world applications.

Inadequate Technical Support

Some suppliers lack the technical expertise to support formulation adjustments, application troubleshooting, or compliance documentation. This can delay production and increase costs, especially in regulated industries.

Intellectual Property-Related Pitfalls

Unauthorized Use of Proprietary Formulations

Sourcing tri-color paint from unverified suppliers increases the risk of inadvertently using counterfeit or reverse-engineered formulations protected by patents or trade secrets. This exposes the buyer to legal liability, including infringement lawsuits.

Misrepresentation of Brand-Originated Colors

Using tri-color paint that mimics branded or licensed colors (e.g., automotive OEM finishes) without proper authorization can lead to trademark or design rights violations. Even if the paint is technically accurate, unauthorized reproduction may constitute IP infringement.

Lack of IP Documentation and Warranties

Many suppliers fail to provide clear IP indemnification or documentation confirming that their products do not infringe on third-party rights. Without contractual protection, the buyer assumes full legal risk in case of disputes.

Gray Market and Diversion Risks

Purchasing through unauthorized distribution channels may result in diverted or counterfeit products. These paints may not only be off-spec but could also violate the manufacturer’s IP-protected supply agreements.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Vet suppliers through audits and sample testing.

– Require compliance with quality standards and batch traceability.

– Obtain written warranties on both performance and IP clearance.

– Work with legally authorized distributors or licensed formulators.

– Consult legal counsel when sourcing paints for regulated or branded applications.

Proactive due diligence minimizes risks and ensures that tri-color paint meets both performance expectations and legal requirements.

Logistics & Compliance Guide for Tri Color Paint

Overview

This guide outlines the key logistics and compliance considerations for the storage, handling, transportation, and regulatory adherence related to Tri Color Paint products. Ensuring compliance with safety, environmental, and transportation regulations is essential to maintain operational efficiency and legal responsibility.

Product Classification & Hazard Identification

Tri Color Paint products may include solvent-based, water-based, or specialty coatings, each with distinct hazard profiles. Determine the specific classification of each paint formulation according to:

– Globally Harmonized System (GHS) for classification and labeling

– OSHA Hazard Communication Standard (HCS) 2012

– Safety Data Sheets (SDS) for each product, which must be up-to-date and readily accessible

Common hazards may include flammability, skin/eye irritation, and environmental toxicity.

Storage Requirements

Store Tri Color Paint products in compliance with local, state, and federal regulations:

– Use a well-ventilated, dry, and temperature-controlled area (typically 50°F–80°F / 10°C–27°C)

– Keep away from ignition sources, direct sunlight, and incompatible materials (e.g., oxidizers, strong acids/bases)

– Ensure containers are tightly sealed and stored upright

– Implement secondary containment (e.g., spill trays or berms) for bulk storage to prevent environmental contamination

– Label all containers clearly with product name, hazard warnings, and date of receipt

Handling Procedures

Safe handling practices must be followed to protect personnel and maintain product integrity:

– Require appropriate personal protective equipment (PPE), including gloves, goggles, and respirators when necessary

– Prohibit eating, drinking, or smoking in handling areas

– Train employees on proper dispensing techniques to minimize spills and exposure

– Conduct routine inspections of storage and handling areas for leaks, damage, or deterioration

Transportation & Shipping Compliance

When transporting Tri Color Paint, adhere to the following regulations:

– Department of Transportation (DOT) 49 CFR: Classify paints as hazardous materials if they meet criteria for flammability (e.g., flash point ≤ 140°F / 60°C)

– Use UN-standard packaging with proper closures and cushioning

– Display required hazard labels (e.g., Flammable Liquid, Health Hazard) on outer packaging

– Complete shipping papers, including proper shipping name, UN number, hazard class, and packing group

– Ensure drivers and carriers are trained in hazardous materials transportation (DOT HAZMAT training)

Environmental & Disposal Compliance

Manage waste and environmental impact responsibly:

– Follow EPA Resource Conservation and Recovery Act (RCRA) regulations for hazardous waste determination

– Store waste paint and contaminated materials in labeled, compatible containers

– Dispose of waste through licensed hazardous waste handlers with proper manifests

– Prevent spills using spill kits and immediate cleanup procedures; report significant spills to appropriate authorities per CERCLA and SPCC rules if applicable

Regulatory Documentation & Recordkeeping

Maintain accurate records to demonstrate compliance:

– Safety Data Sheets (SDS) for all products (updated every 3–5 years or when formulations change)

– Employee training records for HAZCOM, HAZMAT, and emergency response

– Inventory logs of hazardous materials stored on-site

– Spill response reports and waste disposal manifests

– Permits required by local environmental agencies (e.g., air quality permits for spray operations)

Emergency Preparedness

Prepare for incidents involving Tri Color Paint:

– Maintain spill response kits with absorbents, neutralizers, and PPE

– Post emergency contact numbers and evacuation routes

– Train personnel in fire response, first aid, and spill containment

– Conduct regular drills and review emergency procedures annually

Conclusion

Adhering to this logistics and compliance guide ensures the safe and lawful handling of Tri Color Paint products. Regular audits, employee training, and staying current with regulatory updates are critical to maintaining compliance and protecting people, property, and the environment.

Conclusion for Sourcing Tri-Color Paint:

After a thorough evaluation of potential suppliers, quality requirements, cost considerations, and application needs, sourcing tri-color paint has been determined to be both feasible and beneficial for our production and branding objectives. The selected supplier offers high-quality, durable, and consistently pigmented paint that meets all technical and environmental standards. Their reliability in delivery, competitive pricing, and ability to customize color formulations provide a strong strategic advantage.

In conclusion, establishing a partnership with the chosen vendor ensures supply chain efficiency, product consistency, and long-term cost savings. Moving forward, it is recommended to formalize the agreement, implement ongoing quality checks, and maintain open communication to support continuous improvement and scalability in our tri-color paint sourcing strategy.