The global trailer hitch hoist market is experiencing steady expansion, driven by rising demand across automotive, industrial, and recreational sectors. According to Grand View Research, the global automotive aftermarket tools and equipment market—of which trailer hitch hoists are a critical component—was valued at USD 54.3 billion in 2022 and is projected to grow at a CAGR of 5.2% through 2030. This growth is fueled by increasing vehicle ownership, the proliferation of trailers for both commercial and lifestyle use, and a growing emphasis on equipment that simplifies hitch installation and maintenance. Mordor Intelligence corroborates this trend, noting that rising adoption of utility trailers in agriculture, construction, and RV industries is accelerating demand for durable, user-friendly hoisting solutions. As the need for efficient, ergonomic tools intensifies, manufacturers of trailer hitch hoists are scaling innovation in load capacity, portability, and durability. In this competitive landscape, nine key players have emerged as leaders, combining engineering excellence with scalable production to meet evolving market demands.

Top 9 Trailer Hitch Hoist Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 National Association of Trailer Manufacturers

Domain Est. 1998

Website: natm.com

Key Highlights: NATM is the only association of its kind dedicated to and governed by light-and-medium-duty trailer manufacturers, suppliers, dealers, and tow vehicle OEMs ……

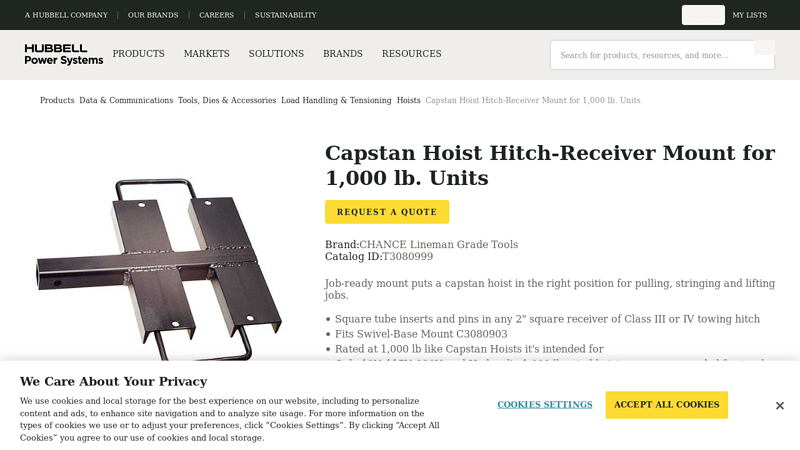

#2 Capstan Hoist Hitch-Receiver Mount for 1,000 lb. Units

Domain Est. 1995

Website: hubbell.com

Key Highlights: 30-day returnsJob-ready mount puts a capstan hoist in the right position for pulling, stringing and lifting jobs. Square tube inserts and pins in any 2″ square receiver of …Missi…

#3 Galbreath

Domain Est. 2013

Website: galbreathproducts.com

Key Highlights: We manufacture a variety of truck-mounted and trailer hoists in single-, tandem- and multi-axle configurations designed to accommodate most types of roll-off ……

#4 Blue Ox

Domain Est. 1994

Website: blueox.com

Key Highlights: Upgrade your towing experience with Blue Ox Towing Products – the industry leader in reliable, durable, and easy-to-use towing solutions….

#5 Winches and Hoists

Domain Est. 1996

Website: warn.com

Key Highlights: 2–6 day delivery 60-day returnsView WARN winches and hoists across all product lines. Purchase our most popular products like truck, powersports, and portable ……

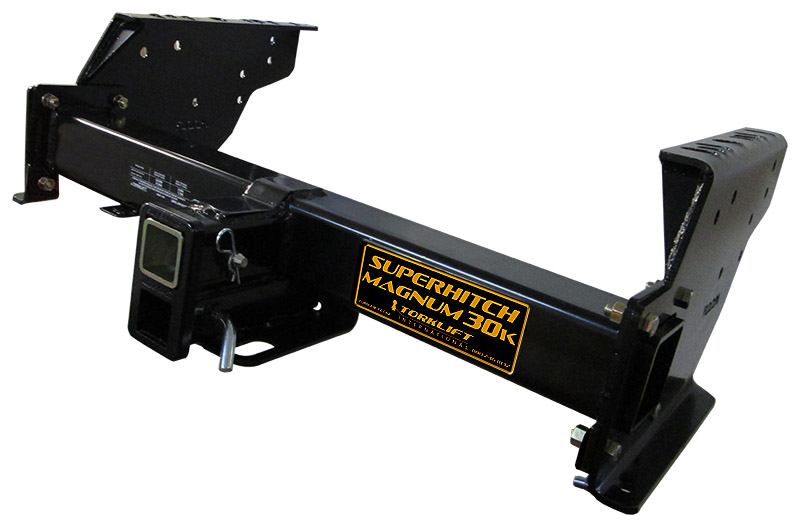

#6 Torklift International

Domain Est. 1997

Website: torklift.com

Key Highlights: Torklift International manufactures towing hitches, camper tiedowns and stabilizers, for all types of camper and towing requirements….

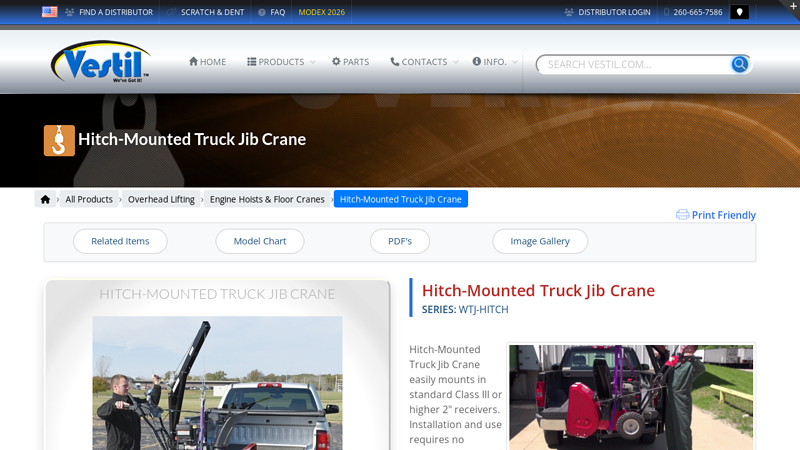

#7 Hitch

Domain Est. 1998

Website: vestil.com

Key Highlights: Hitch-Mounted Truck Jib Crane easily mounts in standard Class III or higher 2″ receivers. Installation and use requires no modifications to receiver or truck. ……

#8 Spitzlift Receiver Hitch Mounted Crane for Trucks and Vans

Domain Est. 2001

Website: spitzlift.com

Key Highlights: Product Description: The SpitzLift Truck Receiver Hitch Kit fits any 2″ receiver hitch and does not require any modifications or installation to the vehicle….

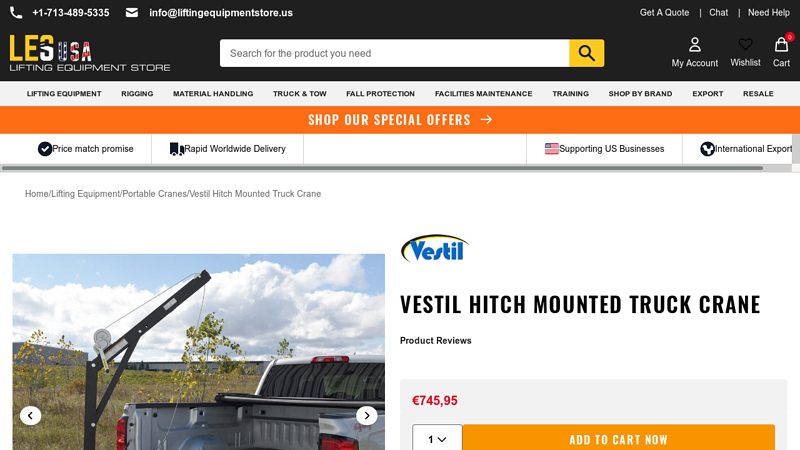

#9 Vestil Hitch Mounted Truck Crane

Domain Est. 2018

Website: liftingequipmentstore.us

Key Highlights: In stock $26.50 deliveryCoupling easily to the hitch mount, this crane boasts a lifting capacity of 600lbs with a reach of 47-1/2″. Mounts to Class III or Higher 2″ Receiver….

Expert Sourcing Insights for Trailer Hitch Hoist

H2: 2026 Market Trends for Trailer Hitch Hoist

The trailer hitch hoist market is poised for notable transformation by 2026, driven by advancements in automotive technology, increased demand for recreational and utility towing, and a growing emphasis on convenience and safety. As consumer lifestyles continue to evolve, especially with the rise in outdoor recreation and DIY home projects, trailer hitch hoists—devices designed to lift, store, and secure cargo using a vehicle’s trailer hitch—are gaining traction across both consumer and commercial sectors.

One of the primary drivers shaping the 2026 market is the surge in sales of pickup trucks, SUVs, and RVs. With these vehicle segments maintaining strong growth, particularly in North America and parts of Europe, the installed base of potential users continues to expand. This creates a natural downstream demand for compatible accessories such as hitch-mounted hoists used for carrying bicycles, cargo carriers, generators, and even small ATVs.

Technological innovation is also playing a pivotal role. By 2026, we anticipate wider adoption of electric-powered and smart-enabled hitch hoist systems. These next-generation hoists integrate wireless controls, load sensors, and app-based monitoring to enhance user experience, improve safety, and reduce physical effort. The integration with vehicle diagnostics via Bluetooth or CAN bus systems is expected to become a differentiating feature among premium product lines.

Sustainability and material efficiency are emerging as key considerations. Manufacturers are increasingly using lightweight, corrosion-resistant materials—such as aluminum alloys and reinforced composites—to improve durability and fuel efficiency. These eco-conscious designs align with broader automotive industry trends toward reducing vehicle weight and emissions.

Moreover, e-commerce growth is reshaping distribution channels. By 2026, direct-to-consumer sales through online platforms are expected to dominate, supported by detailed product videos, customer reviews, and virtual installation guides. This shift empowers informed purchasing decisions and enables smaller niche brands to compete with established players.

Finally, regulatory standards and safety certifications will likely tighten, especially in response to concerns about improper load distribution and hitch compatibility. Industry stakeholders are expected to collaborate on standardization efforts, which could lead to better labeling, universal fit guides, and improved compatibility databases.

In summary, the 2026 trailer hitch hoist market will be characterized by innovation, digital integration, and consumer-centric design, positioning it for steady growth in an increasingly mobile and outdoor-oriented world.

Common Pitfalls When Sourcing a Trailer Hitch Hoist (Quality, IP)

Sourcing a trailer hitch hoist involves more than just finding the lowest price—overlooking key quality and intellectual property (IP) considerations can lead to safety hazards, legal issues, and long-term costs. Below are common pitfalls to avoid:

Poor Build Quality and Material Selection

Many low-cost trailer hitch hoists use substandard steel, inadequate welding, or inferior finishes that compromise structural integrity. This increases the risk of failure under load, especially in corrosive environments. Always verify material specifications (e.g., grade of steel, powder coating or galvanization) and inspect for consistent weld quality.

Lack of Load Capacity Certification

Some suppliers exaggerate or fail to provide verifiable load ratings. Ensure the hoist is independently tested and certified to meet recognized standards (e.g., ASME, CE) and that the rated capacity is clearly documented and appropriate for your intended use.

Inadequate Weather and Corrosion Resistance

Trailer hitch hoists are often exposed to outdoor conditions. Sourcing units without proper corrosion protection—such as non-IP-rated electrical components or missing rust-resistant coatings—leads to premature failure. Confirm the ingress protection (IP) rating (e.g., IP65 or higher) for any electrical or hydraulic components.

Misrepresentation of IP (Ingress Protection) Ratings

Suppliers may falsely claim high IP ratings without third-party validation. A genuine IP rating ensures protection against dust and moisture. Always request test reports or certification from accredited labs to verify the claimed IP rating.

Intellectual Property Infringement Risks

Sourcing from manufacturers that copy patented designs or use counterfeit branding exposes your company to legal liability. Conduct due diligence to ensure the product does not infringe on existing patents or trademarks, especially when dealing with OEMs in regions with lax IP enforcement.

Absence of Compliance Documentation

Reputable suppliers provide technical documentation, including test reports, compliance certificates (e.g., RoHS, REACH), and user manuals. Avoid vendors who cannot supply these, as it may indicate non-compliance with regional safety and environmental regulations.

Inconsistent Quality Control Processes

Without robust quality management systems (e.g., ISO 9001), manufacturers may deliver inconsistent products. Audit potential suppliers’ quality processes and request samples or factory inspection reports before large-scale orders.

Overlooking After-Sales Support and Warranty

Low-cost hoists often come with limited or no warranty and poor technical support. This can result in downtime and higher total cost of ownership. Ensure the supplier offers clear warranty terms and accessible customer service.

Avoiding these pitfalls requires thorough vetting of suppliers, independent verification of claims, and a focus on long-term reliability and legal compliance—not just upfront cost.

Logistics & Compliance Guide for Trailer Hitch Hoist

Product Classification and Harmonized System (HS) Code

Identify the correct HS Code for the trailer hitch hoist to ensure accurate customs classification. Typically, hoists fall under HS Code 8425–8428 (lifting, handling machinery). Confirm exact subcategory based on design (e.g., 8425.49 for other hoists). This affects tariffs, import duties, and regulatory compliance in target markets.

Import/Export Regulations

Comply with import/export laws in both origin and destination countries. Obtain necessary export licenses if required. Ensure adherence to International Trade Compliance standards, including EAR (Export Administration Regulations) or ITAR (International Traffic in Arms Regulations) if applicable. Verify that the product does not contain restricted materials or components.

Packaging and Labeling Requirements

Package the trailer hitch hoist securely to prevent damage during transit. Use durable materials and include protective padding. Label each unit with:

– Product name and model number

– Weight and dimensions

– Manufacturer information

– Compliance markings (e.g., CE, FCC, RoHS)

– Handling instructions (e.g., “Fragile,” “Do Not Invert”)

Transportation and Handling

Use standard freight methods such as LTL (Less Than Truckload) or FTL (Full Truckload) for domestic shipments. For international transport, coordinate sea or air freight based on urgency and cost. Ensure proper securing of units in containers or trailers to prevent shifting. Confirm carrier liability coverage and consider additional cargo insurance.

Weight and Load Capacity Documentation

Provide clear documentation of the hoist’s maximum load capacity (e.g., 350 lbs, 500 lbs) in user manuals and packaging. This is critical for compliance with safety standards and liability prevention. Include warnings about misuse or overloading.

Safety and Regulatory Certifications

Ensure the trailer hitch hoist meets relevant safety standards:

– United States: Comply with DOT (Department of Transportation) and FMVSS (Federal Motor Vehicle Safety Standards) for hitch compatibility.

– European Union: CE marking per Machinery Directive 2006/42/EC and EN ISO 12100.

– Canada: Confirm compliance with CSA standards.

Maintain certification documentation for audits and customs inspections.

User Instructions and Multilingual Support

Include comprehensive user manuals with installation, operation, and maintenance instructions. For international markets, provide translated manuals in local languages (e.g., Spanish, French, German). Clearly state compliance with regional regulations and safety warnings.

Warranty and Returns Logistics

Define warranty terms (e.g., 1-year limited warranty) and establish a returns process. Designate authorized service centers or return locations. Track warranty claims to monitor product performance and compliance with consumer protection laws.

Environmental and Disposal Compliance

Adhere to environmental regulations such as WEEE (Waste Electrical and Electronic Equipment) in the EU and EPA guidelines in the US. Provide end-of-life disposal instructions and ensure packaging is recyclable. Avoid use of hazardous substances per RoHS (Restriction of Hazardous Substances) directives.

Recordkeeping and Audit Preparedness

Maintain detailed records of compliance documentation, test reports, shipping manifests, and certification renewals. Prepare for customs audits or regulatory inspections by keeping an organized compliance file accessible to authorized personnel.

Conclusion for Sourcing a Trailer Hitch Hoist:

After evaluating various options and considerations, sourcing a trailer hitch hoist proves to be a practical and cost-effective solution for lifting and transporting heavy loads, such as motorcycle trailers, small engines, or outdoor equipment. Its compatibility with standard trailer hitch receivers (typically Class II, III, or IV) ensures easy installation and removal, offering versatility across different vehicles. Factors such as weight capacity, build quality, ease of use, and safety features should guide the selection process to ensure reliability and user safety.

Sourcing from reputable suppliers or manufacturers—whether through OEM channels, specialized outdoor equipment retailers, or trusted online marketplaces—helps guarantee product durability and compliance with safety standards. Additionally, comparing prices, warranties, and customer reviews enables informed decision-making and long-term value.

In summary, a trailer hitch hoist is a convenient, portable, and efficient lifting solution for both recreational and light-duty applications. By carefully sourcing the right model based on specific load requirements and vehicle compatibility, users can enhance their hauling capabilities while maintaining safety and convenience.