The global traffic safety equipment market is experiencing steady expansion, driven by increasing urbanization, rising road infrastructure investments, and stringent government regulations prioritizing road user safety. According to Mordor Intelligence, the global traffic cone market was valued at approximately USD 780 million in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This growth is further supported by a surge in construction activities and smart city initiatives, particularly across North America, Europe, and the Asia Pacific. As demand for high-visibility, durable, and weather-resistant traffic cones rises, manufacturers are innovating with reflective materials, enhanced UV stabilization, and eco-friendly formulations. In this evolving landscape, selecting the right supplier is critical for municipalities, contractors, and safety distributors aiming to meet compliance standards and ensure public safety. Based on market presence, product innovation, certifications, and global reach, the following seven manufacturers have emerged as industry leaders in on-road traffic cone production.

Top 7 Traffic Cones On Road Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Traffic Cones Direct to the Manufacturer

Domain Est. 2010

Website: trafficconesforless.com

Key Highlights: We sell traffic cones in every size, weight and color available today. Our team constantly adds the latest and best traffic safety items to our line weekly….

#2 Traffic Cones

Domain Est. 1993

Website: spi.com

Key Highlights: Ensure your safety on the road with our durable and flexible orange PVC traffic cones. Their base provides exceptional stability and can withstand any weather ……

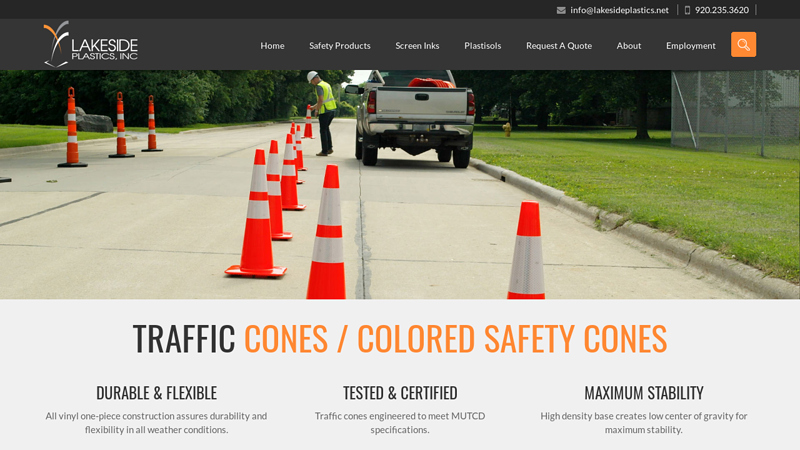

#3 Traffic Cones

Domain Est. 1998

Website: lakesideplastics.net

Key Highlights: Traffic cones engineered to meet MUTCD specifications. Maximum stability. High density base creates low center of gravity for maximum stability….

#4 JSP

Domain Est. 2003

Website: jspsafety.com

Key Highlights: JSP manufactures a wide range of chapter 8 compliant Road Traffic Cones. Manufactured in Oxfordshire England for quick deployment nationwide….

#5 RoadSafe Traffic Systems

Domain Est. 2006

Website: roadsafetraffic.com

Key Highlights: RoadSafe Traffic Systems offers work zone safety and traffic control services like flaggers, barriers and glare screen rentals….

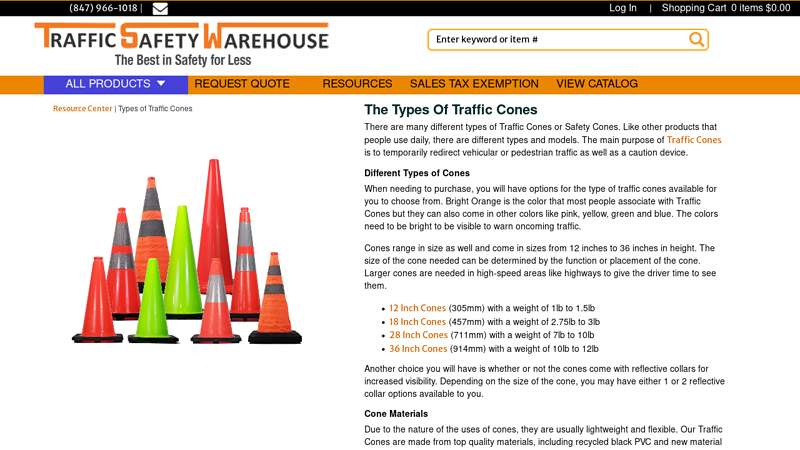

#6 Types of Traffic Cones

Domain Est. 2010

Website: trafficsafetywarehouse.com

Key Highlights: Our Traffic Cones are made from top quality materials, including recycled black PVC and new material where appropriate. One-piece cones that are solid orange ……

#7 to JBC Safety Plastic

Domain Est. 2017

Website: jbcsafetyplastic.com

Key Highlights: JBC™ Revolution Series Cones are the leader in the traffic safety industry. · Revolution Series Cones are made from an innovative injection molded design that ……

Expert Sourcing Insights for Traffic Cones On Road

H2: 2026 Market Trends for Traffic Cones on Road

The global market for traffic cones on road is poised for steady growth and transformation by 2026, driven by increasing urbanization, infrastructure development, and a heightened focus on road safety. As cities expand and transportation networks become more complex, the demand for reliable, visible, and durable traffic management tools like traffic cones continues to rise. Key trends shaping the market in 2026 include technological integration, sustainability initiatives, regulatory standards, and regional infrastructure investments.

1. Smart and Connected Traffic Cones

One of the most significant trends in 2026 is the emergence of smart traffic cones equipped with IoT (Internet of Things) sensors, GPS tracking, and LED lighting systems. These intelligent cones can communicate real-time data about road conditions, traffic flow, and accident zones to municipal traffic management centers. For example, when a cone is displaced or damaged in a work zone, it can automatically send alerts, improving worker safety and reducing response times. This shift toward digitization is particularly evident in smart city projects across North America, Europe, and parts of Asia-Pacific.

2. Emphasis on Sustainability and Recyclability

Environmental concerns are pushing manufacturers to develop eco-friendly traffic cones made from recycled PVC or biodegradable materials. By 2026, regulatory bodies in the EU and North America are expected to enforce stricter environmental standards on road safety equipment. Companies are responding by introducing recyclable or modular cones that reduce waste and carbon footprint. Additionally, longer product lifecycles and UV-resistant materials are improving durability, reducing the need for frequent replacements.

3. Growth in Emerging Markets

Infrastructure expansion in countries like India, Brazil, Indonesia, and Nigeria is fueling demand for traffic cones. As these nations invest in road construction, urban renewal, and traffic management systems, the need for temporary traffic control solutions increases. Government initiatives to improve road safety and reduce accidents are further accelerating market penetration in these regions.

4. Standardization and Regulatory Compliance

Global and regional safety standards—such as those from the U.S. Federal Highway Administration (FHWA), European Committee for Standardization (CEN), and ISO—are becoming more stringent. By 2026, compliance with retroreflectivity standards, visibility requirements (e.g., high-visibility orange or yellow), and crashworthiness will be mandatory in many markets. This drives innovation in design and materials, ensuring cones remain effective during nighttime or low-visibility conditions.

5. Customization and Multi-Functional Designs

Traffic cones are evolving beyond basic shapes and colors. In 2026, demand is rising for customizable cones with branding options, message panels, and integrated accessories like barricade tapes or mounting bases. Multi-functional cones that can be stacked, linked, or used with other traffic devices (e.g., signs or barriers) offer greater flexibility for temporary traffic control in dynamic environments like construction zones or event management.

6. Impact of Autonomous Vehicles

With the gradual rollout of autonomous vehicles (AVs), traffic cones are being redesigned to be more detectable by LiDAR, radar, and computer vision systems. In 2026, manufacturers are incorporating reflective patterns and standardized shapes to ensure AVs can accurately recognize and respond to cone placements, enhancing overall road safety.

Conclusion

By 2026, the traffic cones on road market will be characterized by innovation, sustainability, and integration with smart infrastructure. The convergence of technology and safety regulations is transforming a traditionally simple product into a critical component of modern traffic management. As urban mobility evolves, traffic cones will remain indispensable—but smarter, greener, and more connected than ever before.

Common Pitfalls When Sourcing Traffic Cones for Road Use (Quality & IP)

Sourcing traffic cones for road applications involves critical considerations around durability, safety compliance, and intellectual property. Falling into common pitfalls can lead to product failures, liability risks, or legal issues. Below are key challenges to avoid:

Poor Material Quality Leading to Premature Failure

Many low-cost traffic cones are made from substandard PVC or recycled plastics that degrade quickly under UV exposure, extreme temperatures, or physical impact. This results in brittleness, fading, and cracking—compromising visibility and structural integrity. Always verify material specifications (e.g., UV-stabilized, high-impact polyethylene) and request test reports for weather resistance and durability.

Inadequate Reflectivity or Visibility Features

Traffic cones must remain visible day and night. A common pitfall is sourcing cones with insufficient or poorly bonded reflective sleeves. Low-quality retroreflective materials lose reflectivity over time or peel off, reducing nighttime safety. Ensure cones comply with local standards (e.g., EN 13422 in Europe, MUTCD in the U.S.) and verify reflectivity ratings (e.g., coefficient of retroreflection).

Non-Compliance with Safety and Regulatory Standards

Using non-compliant cones on public roads can lead to fines or liability in the event of an accident. Some suppliers offer “look-alike” products that don’t meet required height, weight, color, or performance standards. Always confirm that cones are certified to relevant regulations (e.g., DOT, CE, AS/NZS 1906.1) and request documentation from the supplier.

Weak Base Design Causing Instability

Cone stability is critical in high-wind or high-traffic areas. Poorly designed bases—either too light or lacking anti-skid features—can tip over easily, creating hazards. Avoid cones with thin or flat bases; opt for weighted, sloped, or interlocking designs proven to resist tipping. Ask for wind resistance test data.

Intellectual Property (IP) Infringement Risks

Some suppliers replicate patented cone designs (e.g., specific interlocking mechanisms, base configurations, or reflective patterns) without authorization. Purchasing such products exposes buyers to IP infringement claims, especially in regulated markets. Conduct due diligence on supplier legitimacy and avoid unusually cheap cones that mimic well-known branded products.

Lack of Traceability and Supplier Reliability

Sourcing from unknown or unverified manufacturers—especially via online marketplaces—can result in inconsistent quality and no recourse for defective batches. Establish relationships with reputable suppliers who provide batch traceability, warranties, and compliance documentation. Avoid suppliers unwilling to share product testing or origin details.

Inconsistent Color and Dimensional Accuracy

Off-spec cones can fail inspections or create confusion on site. Poor manufacturing control leads to color variations (e.g., non-standard orange or yellow) or incorrect height/weight. Require samples and insist on consistency across bulk orders. Refer to standardized color codes (e.g., Pantone 151C for safety orange).

By proactively addressing these pitfalls, organizations can ensure they source reliable, compliant, and legally sound traffic cones that enhance road safety and operational efficiency.

Logistics & Compliance Guide for Traffic Cones on Road

Purpose and Scope

This guide outlines the logistical considerations and compliance requirements for deploying traffic cones on public roads. It is intended for use by traffic management teams, construction crews, municipal workers, and contractors responsible for temporary traffic control. Adherence to this guide ensures safety, regulatory compliance, and operational efficiency.

Regulatory Compliance Standards

National and Local Regulations

Traffic cone deployment must comply with national standards such as the Manual on Uniform Traffic Control Devices (MUTCD) in the United States or equivalent national standards (e.g., TSRGD in the UK, AS 1742 in Australia). These standards define acceptable cone dimensions, color, retroreflectivity, spacing, and placement patterns based on road type, speed limit, and work zone duration.

OSHA and Workplace Safety

In work zones, Occupational Safety and Health Administration (OSHA) guidelines require that cones be used as part of a broader traffic control plan to protect workers. Cones must be visible, properly secured, and arranged to guide traffic safely away from hazards.

DOT and Municipal Approvals

Prior approval may be required from the Department of Transportation (DOT) or local authorities before placing cones on state highways or public roads. Permits are often needed for long-term or high-impact installations.

Traffic Cone Specifications

Size and Visibility

- Standard Height: 18–36 inches (45–90 cm), depending on road speed and application.

- Color: Fluorescent orange is standard; white or yellow may be used in specific contexts.

- Retroreflective Bands: Required for nighttime visibility; at least one band for low-speed roads, two or more for high-speed roads.

Material and Durability

Cones must be made of flexible, weather-resistant PVC or rubber to withstand wind, rain, and vehicle contact. Base weight should prevent tipping under normal wind conditions.

Deployment Logistics

Planning and Risk Assessment

Before deployment, conduct a site assessment to determine:

– Traffic volume and speed

– Duration of placement

– Environmental conditions (e.g., wind, visibility)

– Required taper and buffer zones

Placement Guidelines

- Spacing: Maintain consistent spacing per MUTCD (e.g., 20–50 feet in urban areas, up to 100 feet on highways).

- Tapers: Use funnel or offset tapers to guide traffic smoothly into detours.

- Termination Points: Clearly mark the end of a work zone with cones and signage.

Equipment and Transport

- Cones should be transported in stackable racks or carts to prevent damage.

- Use vehicles equipped with cone-laying machines for long stretches to improve efficiency and worker safety.

Maintenance and Monitoring

Inspection Schedule

Inspect cones daily or after severe weather for:

– Damage or displacement

– Visibility (dirt, debris, fading)

– Proper alignment and spacing

Replacement Protocol

Replace cracked, faded, or missing cones immediately. Maintain a spare inventory on-site or nearby for rapid response.

Worker Safety and Training

Personal Protective Equipment (PPE)

Workers placing or adjusting cones must wear high-visibility clothing (ANSI Class 2 or 3), hard hats, and safety vests.

Training Requirements

All personnel must be trained in:

– Manual handling techniques to prevent strain

– Traffic control plans and emergency procedures

– Regulatory compliance and proper cone placement

Environmental and Public Considerations

Minimizing Disruption

Deploy cones during off-peak hours when possible. Use advance signage to inform drivers of upcoming changes.

Wildlife and Ecosystem Protection

Avoid placing cones in ecologically sensitive areas. Remove all cones and materials after project completion to prevent pollution or animal entanglement.

Record Keeping and Documentation

Deployment Logs

Maintain logs including:

– Date, time, and location of cone placement

– Responsible crew and supervisor

– Weather and traffic conditions

Compliance Audits

Conduct periodic audits to verify adherence to safety and regulatory standards. Document corrective actions taken.

Removal and Post-Operation Procedures

Timely Removal

Remove cones immediately after work is completed or when no longer needed. Lingering cones can confuse drivers and create hazards.

Site Restoration

Ensure the roadway is returned to its original condition, with no debris or cone fragments left behind.

Post-Operation Review

Evaluate the effectiveness of the traffic control plan and document lessons learned for future operations.

Conclusion

Proper logistics and compliance in traffic cone deployment are essential for public safety, regulatory adherence, and operational efficiency. Following this guide ensures that temporary traffic control measures are effective, legal, and professionally maintained from setup to removal.

In conclusion, sourcing traffic cones for road use requires careful consideration of quality, durability, visibility, and compliance with safety standards. It is essential to choose suppliers who provide high-visibility, UV-resistant, and impact-resistant cones made from durable materials such as PVC or polyethylene. Ensuring that the traffic cones meet local or national regulatory standards (such as MUTCD in the U.S. or EN standards in Europe) is crucial for road safety and legal compliance. Additionally, evaluating factors like cost-effectiveness, supplier reliability, and availability of customization options contributes to making an informed purchasing decision. Proper sourcing not only enhances traffic management efficiency but also ensures the safety of workers and the public in roadwork and temporary traffic control zones.