The global agricultural machinery market is experiencing robust growth, driven by increasing demand for mechanized farming solutions to enhance productivity and reduce labor dependency. According to a 2023 report by Mordor Intelligence, the global agricultural tractors market was valued at USD 50.8 billion and is projected to grow at a CAGR of 5.4% from 2023 to 2028. As part of this expansion, specialized attachments such as tractor power rakes are gaining prominence among farmers and land management professionals for efficient soil preparation, thatch removal, and debris clearing. With rising adoption of compact and utility tractors—especially in small and medium-sized farms—the demand for compatible, high-performance power rakes is on a steady upward trajectory. This growth is further supported by advancements in attachment technology and a shift toward multifunctional implements that maximize equipment utilization. In this evolving landscape, a select group of manufacturers have emerged as leaders in innovation, reliability, and market reach. Below are the top 8 tractor power rake manufacturers shaping the industry today.

Top 8 Tractor Power Rake Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

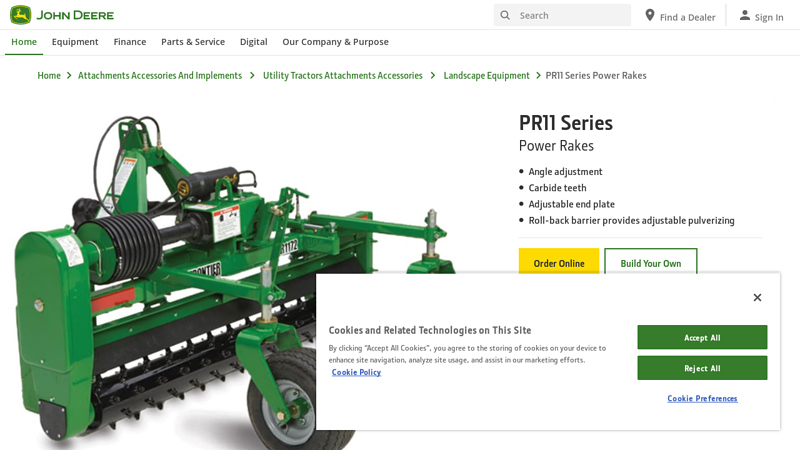

#1 Frontier PR11 Power Rakes

Domain Est. 1990

#2 Power Rake

Domain Est. 2000

Website: turfteq.com

Key Highlights: The TURF TEQ Power Rake is a valuable time-saving tool for all types of seedbed preparation, lawn renovation and raking jobs….

#3 Power Rake Attachments

Domain Est. 2000

Website: koenigequipment.com

Key Highlights: John Deere power rakes are perfect for landscape tasks such as seedbed preparation, rock raking, site development, and more…

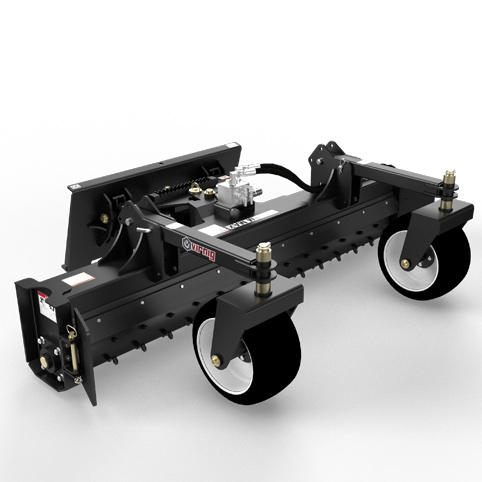

#4 All About the virnig Power Rake

Domain Est. 2002

Website: virnigmfg.com

Key Highlights: The Virnig Power Rake is designed and built with quality and performance as top priorities. Unlike other skid steer power rakes, it stands up to daily use and ……

#5 KP540 Power Rake

Domain Est. 2002

Website: ventrac.com

Key Highlights: The Power Rake is designed for leveling rough ground, new yard installations, gravel driveways, as well as removing surface rocks and debris….

#6 Power Rakes & Soil Conditioners

Domain Est. 2010

#7 Power Rake

Domain Est. 2012

Website: paladinattachments.com

Key Highlights: The Paladin® Rake features a 6-inch polypropylene barrier that can be adjusted to choose the desired size of material to be left on the seedbed….

#8 X-treme Power Rake

Domain Est. 2022

Website: ironcraftusa.com

Key Highlights: The IronCraft X-treme Power Rake provides a versatile tool for your skid steer attachments, in a manual or hydraulic version….

Expert Sourcing Insights for Tractor Power Rake

H2: 2026 Market Trends for Tractor Power Rakes

The global tractor power rake market is poised for steady growth through 2026, driven by increasing mechanization in agriculture and landscaping, rising demand for efficient land preparation tools, and advancements in tractor attachment technology. Key trends shaping the market include:

-

Growing Demand in Agriculture and Landscaping

With the expansion of small to mid-sized farms and a surge in residential and commercial landscaping, tractor power rakes are becoming essential for soil leveling, debris removal, and seedbed preparation. Urbanization and the development of green spaces in emerging economies are expected to amplify demand. -

Adoption of Compact and Versatile Equipment

There is a noticeable shift toward compact tractors and multi-functional attachments, especially among homeowners, municipalities, and landscaping contractors. Power rakes compatible with sub-compact and utility tractors are seeing increased adoption due to their ease of use and adaptability across different terrains. -

Technological Integration and Durability Enhancements

Manufacturers are incorporating high-tensile steel tines, improved frame designs, and adjustable depth controls to boost performance and longevity. Some models are now featuring quick-hitch compatibility and modular designs, allowing seamless integration with a variety of tractor brands and models. -

Expansion in Emerging Markets

Regions such as Asia-Pacific, Latin America, and Africa are witnessing rising investments in agricultural mechanization. Government initiatives promoting farm productivity and infrastructure development are expected to drive tractor and implement sales, including power rakes, in these regions. -

Sustainability and Eco-Friendly Practices

As environmental concerns grow, there is an increasing preference for equipment that supports sustainable land management. Tractor power rakes that minimize soil disruption and support conservation tillage are gaining favor among eco-conscious farmers and landscapers. -

E-Commerce and Direct-to-Consumer Sales Growth

Online retail platforms are becoming critical distribution channels, enabling easier access to tractor attachments for end-users in rural and remote areas. Enhanced digital marketing and online product configurators are improving customer engagement and purchase decisions.

In summary, the 2026 tractor power rake market will be shaped by technological innovation, expanding application areas, and geographic diversification. Stakeholders who focus on versatility, durability, and accessibility are likely to capture significant market share in this evolving landscape.

Common Pitfalls When Sourcing a Tractor Power Rake (Quality and Intellectual Property)

Sourcing a tractor power rake—whether for agricultural, landscaping, or construction purposes—requires careful consideration of both product quality and intellectual property (IP) concerns. Falling into common pitfalls can lead to poor performance, safety hazards, legal issues, and financial losses. Below are key challenges to watch for:

Poor Build Quality and Material Selection

One of the most frequent issues when sourcing tractor power rakes is receiving units made from substandard materials or with poor workmanship. Low-cost manufacturers may use thin steel, inferior bearings, or weak welds to cut production costs. This results in reduced durability, frequent breakdowns, and shorter equipment lifespan—especially under heavy-duty use.

Key Red Flags:

– Lack of detailed specifications (e.g., steel gauge, heat treatment of tines)

– No third-party certifications (e.g., ISO, CE)

– Minimal product testing data or customer reviews

Inadequate Design for Intended Application

Not all power rakes are created equal. Some models are designed for light-duty yard work, while others are built for commercial or agricultural use. Sourcing a model that doesn’t match your operational needs can lead to inefficiency or equipment damage.

Common Issues Include:

– Incorrect tine spacing or depth adjustment range

– Incompatible PTO (Power Take-Off) shaft sizing

– Mismatched tractor horsepower requirements

Lack of Compliance with Safety and Industry Standards

Many imported or generic power rakes do not meet regional safety standards (e.g., OSHA in the U.S., CE in Europe). Using non-compliant equipment exposes operators to safety risks and may result in liability or regulatory fines.

Watch For:

– Missing safety shields or guarding

– Absence of required warning labels

– Non-standardized safety interlocks

Intellectual Property Infringement Risks

When sourcing from third-party or overseas suppliers, there’s a risk of inadvertently purchasing counterfeit or knock-off equipment that infringes on patented designs or trademarks. Major manufacturers (e.g., Land Pride, Bush Hog) often hold patents on specific tine configurations, frame designs, or mounting systems.

Potential IP Pitfalls:

– Replica products that mimic branded designs without licensing

– Suppliers unable to provide proof of IP clearance or original design rights

– Risk of seizure by customs or legal action from IP holders

Insufficient After-Sales Support and Spare Parts Availability

Low-cost suppliers may offer attractive upfront pricing but lack reliable customer service, technical documentation, or access to replacement parts. This leads to extended downtime and higher long-term costs.

Indicators of Poor Support:

– No warranty or vague warranty terms

– Unresponsive customer service

– No local dealers or service centers

Conclusion

To avoid these pitfalls, conduct thorough due diligence when sourcing a tractor power rake. Verify material quality, ensure compatibility with your tractor and workload, confirm compliance with safety standards, and assess IP legitimacy. Whenever possible, purchase from reputable suppliers or authorized distributors to protect both performance and legal interests.

Logistics & Compliance Guide for Tractor Power Rake

This guide outlines the essential logistics and compliance considerations for the transportation, handling, and use of a Tractor Power Rake, ensuring safety, regulatory adherence, and operational efficiency.

Product Classification and Specifications

Identify the tractor power rake according to industry standards and specifications. This includes model number, weight, dimensions (length, width, height), and compatibility with specific tractor horsepower ranges. Accurate specifications are critical for proper shipping, storage, and regulatory documentation.

Transportation and Shipping Requirements

Ensure the power rake is securely fastened during transport using appropriate tie-down straps or chains. Use flatbed trailers or equipment haulers that comply with Department of Transportation (DOT) weight and load securement regulations (49 CFR Part 393). Over-the-road shipments must include proper labeling, including center of gravity indicators if applicable, and meet carrier insurance and permitting requirements for oversized loads if necessary.

Import/Export Compliance (if applicable)

For international movement, verify compliance with relevant customs regulations. Classify the power rake under the appropriate Harmonized System (HS) code—typically under 8433.52 or similar for agricultural machinery parts. Ensure all necessary documentation is prepared, including commercial invoices, packing lists, and certificates of origin. Comply with import/export controls such as those from the U.S. Census Automated Export System (AES) or equivalent in other countries.

Safety and Operational Compliance

The power rake must meet safety standards such as those set by the Occupational Safety and Health Administration (OSHA) and the American Society of Agricultural and Biological Engineers (ASABE). Ensure all safety shields, warning labels, and operator manuals are present and legible. Operators must be trained in accordance with OSHA 29 CFR 1910.178 for powered industrial trucks if used in conjunction with such equipment.

Environmental and Emissions Regulations

If the power rake is attached to a tractor with an internal combustion engine, ensure the tractor complies with Environmental Protection Agency (EPA) Tier regulations for off-road engines. The power rake itself, as an attachment, does not emit pollutants but must not interfere with the tractor’s emissions control systems.

Storage and Handling Guidelines

Store the power rake in a dry, covered area to prevent rust and degradation. Position on level ground with the tines supported to avoid stress on the frame. Follow manufacturer-recommended maintenance procedures such as greasing pivot points and inspecting for wear before and after use.

Documentation and Recordkeeping

Maintain up-to-date records including proof of compliance, maintenance logs, shipping manifests, and operator training certifications. These documents support audits, warranty claims, and regulatory inspections.

Warranty and Manufacturer Compliance

Adhere to the manufacturer’s assembly, operation, and maintenance instructions to preserve warranty coverage. Unauthorized modifications may void warranties and create compliance risks.

By following this logistics and compliance guide, businesses and operators can ensure the safe, legal, and efficient use of tractor power rakes across various operational environments.

Conclusion for Sourcing a Tractor Power Rake:

Sourcing a tractor power rake is a strategic decision that enhances land management efficiency, particularly for tasks such as thatch removal, soil preparation, and debris cleanup. After evaluating various options—whether purchasing new, buying used, or renting—the best choice depends on your specific needs, frequency of use, budget, and available equipment.

For frequent or commercial use, investing in a high-quality power rake compatible with your existing tractor ensures long-term reliability and productivity. For occasional use, renting or purchasing a used model may offer better cost-efficiency. Key considerations include compatibility with your tractor’s horsepower and attachment system (e.g., 3-point hitch), build quality, ease of maintenance, and available customer support.

By carefully assessing suppliers, comparing features, and considering total cost of ownership, you can source a tractor power rake that maximizes performance, durability, and return on investment. Ultimately, the right power rake will improve operational effectiveness and contribute to better land maintenance outcomes.