The global market for self-drilling screws, commonly known as tornillo autoperforante in Spanish-speaking regions, has experienced steady growth driven by rising demand in construction, automotive, and electrical industries. According to Mordor Intelligence, the global self-tapping screws market was valued at USD 8.23 billion in 2023 and is projected to grow at a CAGR of over 5.4% from 2024 to 2029. This expansion is fueled by increased infrastructure development and the preference for fast, reliable metal-to-metal and metal-to-wood fastening solutions in both industrial and residential applications. With Asia-Pacific emerging as a key manufacturing and consumption hub, competition among producers has intensified, pushing innovation in coatings, thread design, and corrosion resistance. In this evolving landscape, a select group of manufacturers has risen to prominence through scale, quality, and technological expertise—shaping the top eight tornillo autoperforante manufacturers leading the market today.

Top 8 Tornillo Autoperforante Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wholesale Tornillo Autoperforante Hexagonal Manufacturer and …

Domain Est. 2022

Website: sinsunfastener.com

Key Highlights: Tornillo autoperforante hexagonal Manufacturers, Factory, Suppliers From China, If needed, welcome to make contact with us by our web page or phone consultation…

#2 Tornillo Autoperforante

Domain Est. 2010

Website: boltsstore.com

Key Highlights: Con una longitud total de 50 mm y un diámetro de 6 mm, este tornillo proporciona una sujeción sólida y duradera. Su diseño autoperforante elimina la necesidad ……

#3 Autoperforantes

Domain Est. 2013

Website: comercialcmp.com.ar

Key Highlights: Tornillo autoperforante Tipo 2 c/arandela punta mecha hexagonal 14 x 2 · $15.861,55. $13.482,32 transferencia ; Tornillo autoperforante Tel-Dry T2 punta aguja 6 x ……

#4 Tornillo autoperforante profesional de cabeza plana cuadrada

Domain Est. 2017

Website: precision-hardware-manufacturer.com

Key Highlights: Tornillo autoperforante de destornillador cuadrado de cabeza troncocónica Rofessional ; Material. Acero inoxidable ; Tamaño. ST3.5-ST6.4 ; Longitud. 3-100mm ; Tipo ……

#5 Tornillo autoperforante

Domain Est. 2020

Website: princefastener.com

Key Highlights: Los tornillos autoperforantes se utilizan principalmente para la conexión y fijación de algunas placas delgadas, como placas de acero de color y láminas de ……

#6 TORNILLO AUTOPERFORANTE HEXAGONAL 8 X 2″ (100PCS)

Domain Est. 2021

Website: ferrovoz.com

Key Highlights: Tornillo fabricado en fierro zincado para la unión de perfiles metálicos en construcciones sobre placas de yeso. Las fotografías y descripción del producto ……

#7 Tornillos autoperforantes Easydrive

Domain Est. 2022

Website: es.dbluefastener.com

Key Highlights: Nuestros tornillos autoperforantes Easydrive también vienen en varios tipos de cabeza, como cabeza plana, arandela hexagonal y brida, así como en varias ……

#8 Tornillo autoperforante

Domain Est. 2023

Website: delongfastener.com

Key Highlights: Tornillos autoperforantes y arandelas elásticas. Ofrecemos precios competitivos según sus necesidades. Entrega puntual. Contáctenos para obtener una oferta ……

Expert Sourcing Insights for Tornillo Autoperforante

H2: 2026 Market Trends for Tornillo Autoperforante (Self-Drilling Screw)

The global market for tornillos autoperforantes (self-drilling screws) is poised for continued growth and transformation by 2026, driven by evolving construction practices, material innovations, and regional economic dynamics. Key trends shaping the market in the H2 (second half) context of 2026 include:

-

Sustained Growth in Construction & Infrastructure: The primary driver remains robust global construction activity, particularly in non-residential (industrial, commercial) and infrastructure sectors. Demand for steel structures, roofing, cladding, and prefabricated buildings – where self-drilling screws are essential – is expected to remain strong, especially in developing economies and regions focused on infrastructure renewal (e.g., North America, Asia-Pacific). The push for faster construction timelines directly favors the speed and efficiency of self-drilling screws.

-

Heightened Focus on Corrosion Resistance & Durability: Building codes and sustainability demands are pushing for longer-lasting structures. This translates into significant growth for screws with advanced coatings:

- Triple-Layer Coatings (e.g., Zn-Al-Mg): Offer superior corrosion resistance compared to traditional galvanizing, crucial for harsh environments (coastal, industrial) and extended warranty requirements. Expect wider adoption, moving beyond niche applications.

- Improved Organic Coatings: Development of thicker, more durable polymer coatings (like epoxy-based) providing both corrosion protection and aesthetic finishes.

- Demand for Higher Grade Materials: Increased use of stainless steel (A2/A4) and higher strength carbon steel grades for demanding applications.

-

Innovation in Design & Performance: Competition is driving technical advancements:

- Optimized Drill Points: Designs improving drilling efficiency through thicker gauge steel, different alloys, and geometries that reduce heat and wear, enabling faster installation and longer tool life.

- Enhanced Thread Design: Threads optimized for better pull-out resistance, vibration resistance, and sealing (e.g., for roofing applications requiring watertight joints).

- Specialized Screws: Growth in screws designed for specific applications like structural connections (requiring certified performance), composite materials, or insulation fastening, often featuring unique head styles, threads, or underhead seals.

-

Consolidation & Supply Chain Optimization: The market may see continued consolidation among manufacturers and distributors seeking economies of scale, broader geographic reach, and enhanced R&D capabilities. Supply chains will focus on resilience, potentially involving regionalization/nearshoring to mitigate geopolitical and logistical risks, impacting sourcing strategies for raw materials and finished goods.

-

Sustainability & Circular Economy Pressures: Environmental regulations and corporate sustainability goals will gain prominence:

- Material Efficiency: Design for reduced material use without compromising strength.

- Recyclability: Emphasis on fully recyclable materials (steel, coatings).

- Lower Embodied Carbon: Development of manufacturing processes with reduced energy consumption and carbon footprint. Transparency in Environmental Product Declarations (EPDs) may become more important for specification.

-

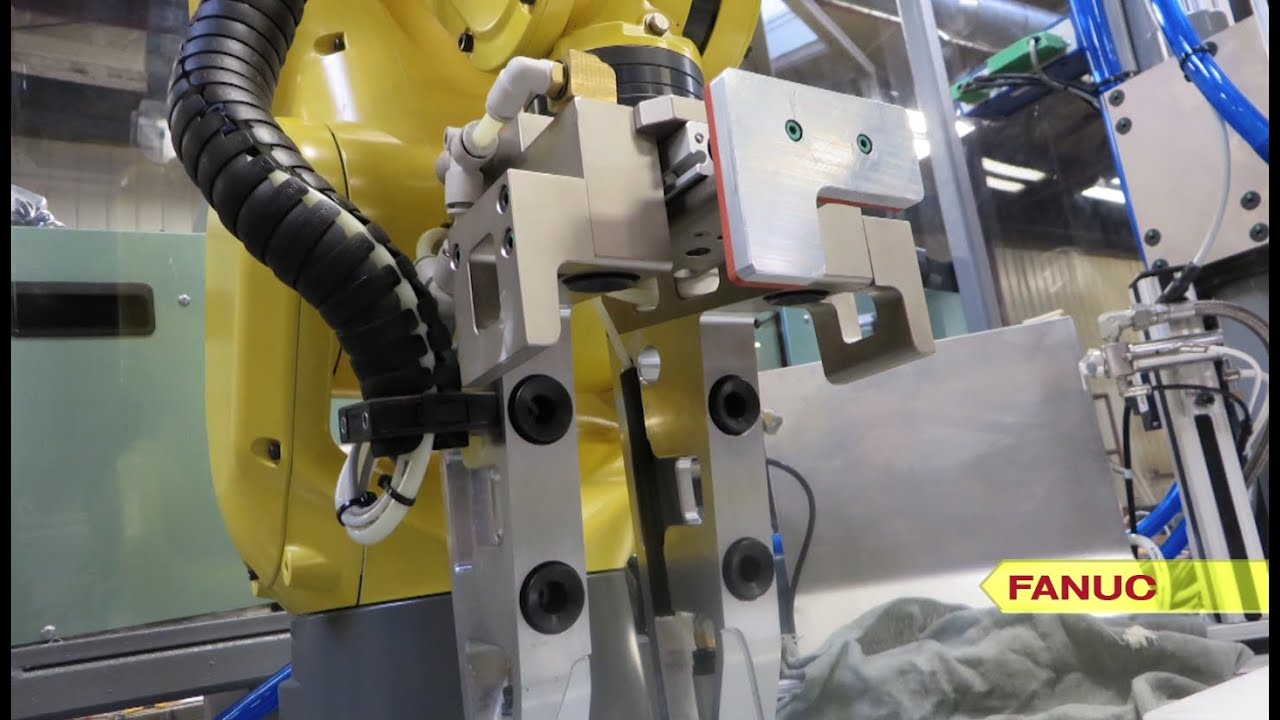

Digitalization & Smart Fastening: While still emerging, integration with digital tools is a growing trend:

- QR Codes/RFID: Screws or packaging with traceability for quality control and warranty verification.

- Compatibility with Automated Installation: Design features supporting robotic or automated screwdriving systems in prefabrication plants.

- Digital Catalogs & BIM Integration: Enhanced digital tools for specification, selection, and integration into Building Information Modeling workflows.

H2 2026 Outlook Summary: The tornillo autoperforante market in 2026 is expected to be characterized by steady volume growth underpinned by construction demand, but with a significant shift towards higher-value, performance-driven products. Success will depend on manufacturers’ ability to innovate in corrosion protection and design, ensure supply chain stability, meet rising sustainability standards, and potentially embrace digitalization. Competition will likely intensify, favoring players with strong technical expertise, broad portfolios, and efficient operations.

Common Pitfalls Sourcing Tornillo Autoperforante (Quality, IP)

Sourcing tornillo autoperforante (self-drilling screws) can be deceptively complex, especially when balancing cost, quality, and intellectual property (IP) concerns. Below are common pitfalls to watch for in both quality assurance and IP compliance.

Quality-Related Pitfalls

Inconsistent Material Composition

Many low-cost suppliers use substandard steel alloys or incorrect grades (e.g., substituting 4.8 grade for 8.8 or 10.9), leading to reduced tensile strength and premature failure. Always request material test reports (MTRs) and verify compliance with international standards (e.g., ISO 3506, ASTM A510).

Poor Heat Treatment

Improper heat treatment compromises hardness and durability. Screws may appear strong but fail under stress or during installation. Ensure suppliers provide hardness test certifications and follow controlled quenching and tempering processes.

Inadequate Coating and Corrosion Resistance

Zinc plating thickness and uniformity are often inconsistent across cheaper imports. Thin or patchy coatings lead to rust, especially in humid or coastal environments. Specify minimum coating thickness (e.g., 5-8 µm for standard zinc, 8-12 µm for enhanced protection) and consider alternatives like mechanical galvanizing or Dacromet coating for harsh conditions.

Dimensional Inaccuracy

Off-spec thread pitch, head size, or drill point geometry can compromise installation and performance. Use first article inspection (FAI) and regular incoming quality control (IQC) checks with calibrated gauges.

Lack of Certification and Traceability

Reputable suppliers provide certifications like ISO 9001, CE marking, or ICC-ES reports for construction applications. Without traceability (batch/lot numbers), recalling defective screws becomes impossible.

Intellectual Property (IP) Risks

Counterfeit or Copycat Designs

Some suppliers replicate patented screw designs (e.g., specific drill point geometries or thread profiles) without licensing. This exposes buyers to legal liability, especially in regulated markets like the EU or North America.

Unauthorized Use of Brand Names or Logos

Suppliers may falsely advertise compliance with brands like TEK® (a registered trademark of ITW Buildex) or use misleading packaging. Always verify trademarks and avoid suppliers offering “TEK-style” or “equivalent to” products without proper licensing.

Patent Infringement in Design and Function

Innovative self-drilling screw designs (e.g., multi-cut drill points, high-speed threading) are often protected by utility patents. Sourcing generic versions that mimic these features can lead to infringement lawsuits, customs seizures, or import bans.

No IP Warranty or Indemnification

Many suppliers, especially from low-cost regions, do not offer IP warranties. If legal action arises, the buyer may be left liable. Insist on contractual indemnification clauses covering IP infringement.

Best Practices to Avoid Pitfalls

- Audit suppliers on-site or via third-party inspectors.

- Require full technical documentation, including MTRs, test reports, and compliance certificates.

- Register purchases with IP databases where applicable (e.g., EU IPRED).

- Work with legally vetted suppliers who respect IP rights and offer traceable, certified products.

By addressing these quality and IP pitfalls early, businesses can ensure reliable performance, regulatory compliance, and legal protection when sourcing tornillo autoperforante.

Logistics & Compliance Guide for Tornillo Autoperforante (Self-Drilling Screw)

This guide outlines the key logistics and compliance considerations for the international transportation, storage, and regulatory adherence of Tornillo Autoperforante (self-drilling screws), commonly used in construction and metal fabrication.

Product Classification and HS Code

Accurate classification is essential for customs clearance and tariff determination. Tornillo Autoperforante typically falls under the following Harmonized System (HS) code:

- HS Code Example: 7318.15 (Screws and bolts, whether or not with their nuts or washers, of iron or steel, threaded, self-tapping).

Note: Exact classification may vary by country and specific product characteristics (material, coating, dimensions). Always verify with local customs authorities.

Packaging and Labeling Requirements

Proper packaging ensures product integrity during transit and compliance with international shipping standards.

- Packaging: Use moisture-resistant, durable materials such as polyethylene-lined cartons or sealed plastic bags inside corrugated boxes. Bulk quantities may require steel or plastic pallets secured with stretch wrap.

- Labeling:

- Product name: “Tornillo Autoperforante” or “Self-Drilling Screw”

- Specifications: Diameter, length, thread type, head style (e.g., hex washer head), material (e.g., carbon steel), coating (e.g., zinc-plated, galvanized)

- Quantity per package

- Batch/lot number and manufacturing date

- Manufacturer/importer name and address

- Country of origin (mandatory for customs)

- Handling symbols (e.g., “Fragile,” “This Way Up”)

Shipping and Transportation

Ensure safe and efficient transportation across different modes (air, sea, land).

- Mode Selection:

- Sea Freight: Most cost-effective for bulk shipments; use ISPM 15-compliant wooden pallets if applicable.

- Air Freight: Faster but more expensive; ideal for urgent or high-value orders.

- Land Transport: Suitable for regional distribution; ensure vehicles are covered and secure.

- Documentation:

- Commercial Invoice

- Packing List

- Bill of Lading (B/L) or Air Waybill (AWB)

- Certificate of Origin (if required for preferential tariffs)

- Material Safety Data Sheet (MSDS) – generally not hazardous, but recommended

Import/Export Compliance

Adhere to national and international trade regulations.

- Export Controls: Most self-drilling screws are not subject to export restrictions, but verify if dual-use regulations apply (e.g., for aerospace-grade materials).

- Import Regulations: Check destination country requirements, including:

- Customs duties and VAT

- Product conformity assessments

- Labeling in local language (e.g., Spanish in Latin America, English in the U.S.)

- Trade Agreements: Leverage FTAs (e.g., USMCA, EU-Mexico Global Agreement) to reduce tariffs where applicable.

Quality and Safety Standards

Compliance with recognized standards ensures product reliability and market access.

- Common Standards:

- ISO 10666: Self-drilling screws for steel cladding and sheeting

- ASTM F1941: Standard specification for mechanical properties of steel bolts, screws, and studs

- DIN 7504: German standard for self-drilling screws

- EN 14592: European standard for timber structures – connection devices

- Certifications: Provide test reports or certification (e.g., CE marking for EU, INMETRO for Brazil) when required.

Environmental and Regulatory Compliance

Address environmental and hazardous substance regulations.

- RoHS (EU): Ensure screws are free from restricted substances (Pb, Cd, Hg, etc.), especially if coated or plated.

- REACH (EU): Declare Substances of Very High Concern (SVHC) if present above threshold.

- WEEE: Not typically applicable to screws, but consider end-of-life implications in product lifecycle assessments.

- Packaging Waste Directives: Comply with local packaging recycling laws (e.g., in Germany, France).

Storage and Handling

Maintain product quality during warehousing and distribution.

- Storage Conditions: Store in a dry, temperature-controlled environment to prevent corrosion, especially for zinc-coated or carbon steel screws.

- Handling: Avoid exposure to moisture, chemicals, or salt air. Rotate stock using FIFO (First In, First Out) to prevent aging.

Returns and Recalls

Establish procedures for defective or non-compliant shipments.

- Return Policy: Define conditions for returns (e.g., wrong specification, damaged packaging).

- Recall Plan: In case of non-conformance (e.g., failed tensile strength), have a traceability system (via batch numbers) and communication protocol with distributors.

Conclusion

Proper logistics planning and compliance adherence are critical for the successful international trade of Tornillo Autoperforante. By following this guide, suppliers and importers can minimize delays, ensure regulatory compliance, and deliver high-quality products to market efficiently. Always consult local legal and customs experts to confirm requirements for specific destinations.

Conclusión sobre el sourcing de tornillos autoperforantes:

El proceso de sourcing de tornillos autoperforantes requiere una evaluación estratégica que combine calidad, costo, capacidad de suministro y cumplimiento de especificaciones técnicas. Tras analizar distintos proveedores, tanto locales como internacionales, se concluye que es fundamental establecer alianzas con fabricantes certificados que garanticen materiales resistentes (como acero al carbono endurecido o acero inoxidable) y tratamientos superficiales adecuados (como galvanizado o zincado) para asegurar un desempeño óptimo en diversas aplicaciones, especialmente en sectores como la construcción metálica, carpintería metálica o montaje industrial.

Además, factores como la reducción de tiempos de entrega, estabilidad en precios, y capacidad de personalización del producto juegan un papel clave en la toma de decisiones. Optar por proveedores con sistemas de control de calidad robustos (como ISO 9001) y con experiencia comprobada en el mercado, minimiza riesgos operativos y garantiza la continuidad del suministro.

En resumen, un sourcing efectivo de tornillos autoperforantes no solo se basa en el costo unitario más bajo, sino en una evaluación integral del valor total de la adquisición, donde se prioriza la confiabilidad, el desempeño del producto y la relación a largo plazo con los proveedores.