The global construction equipment market is witnessing steady expansion, driven by increasing infrastructure development and urbanization, particularly across emerging economies. According to Mordor Intelligence, the construction equipment market is projected to grow at a CAGR of over 5.8% from 2023 to 2028, with laser-guided leveling systems playing a critical role in enhancing precision and efficiency on job sites. As demand for advanced grading and site preparation solutions rises, Topcon’s LN-150 laser receiver has become a benchmark for reliability and accuracy. This surge in demand has spurred a competitive manufacturing ecosystem focused on compatible accessories, support systems, and value-added innovations around the LN-150 platform. Based on market presence, product quality, and distribution reach, the following analysis identifies the top four manufacturers supporting or building upon Topcon LN-150 technology.

Top 4 Topcon Ln 150 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 LN-150

Domain Est. 2000

Website: mytopcon.topconpositioning.com

Key Highlights: LN-150 · Single-operator solution for precise 3D layout · Easy one-button self-leveling setup · WIFI and long-range Bluetooth® instrument communication options ……

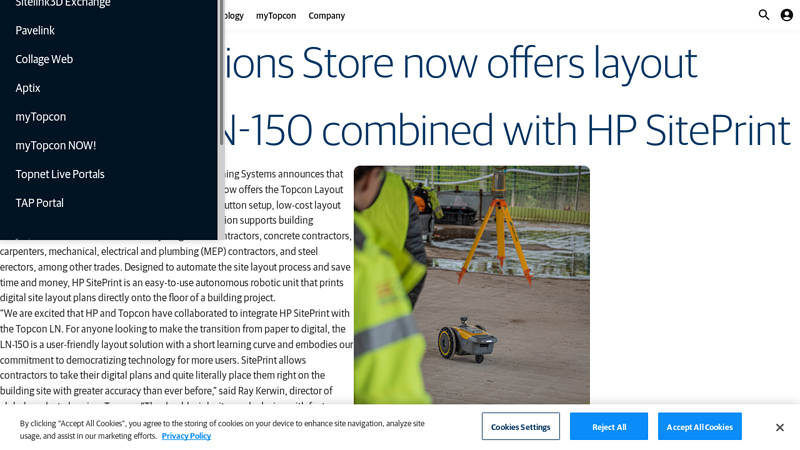

#2 Topcon Solutions Store now offers layout solution of LN

Domain Est. 2000

Website: topconpositioning.com

Key Highlights: Topcon Solutions Store now offers layout solution of LN-150 combined with HP SitePrint….

#3 Lay out sites faster and control machines with robotic total stations

Domain Est. 2007

Website: topconsolutions.com

Key Highlights: Which robotic total station is right for your job? Topcon’s GT-Series, LN-Series, GTL-Series and MS-Series total stations feature powerful electronic distance ……

#4 LN-150/Homeworld Construction Corporation/Aug.2024

Domain Est. 2022

Website: topconpositioning.asia

Key Highlights: LN-150 can be used at both kind of projects that are open sky and/or inside the building, while GNSS can be only used in open sky environment….

Expert Sourcing Insights for Topcon Ln 150

H2: 2026 Market Trends Analysis for Topcon LN 150

As we approach 2026, the market landscape for high-precision surveying and construction equipment is evolving rapidly, driven by technological advancements, increased demand for automation, and growing infrastructure investments globally. The Topcon LN-150, a compact and versatile 3D machine control receiver designed for construction and grading applications, is expected to experience several key market trends during this period.

-

Increased Adoption in Mid-Sized Construction Projects

The Topcon LN-150 is poised to gain broader acceptance in mid-sized construction firms due to its cost-effectiveness and ease of integration with existing machinery. As more contractors seek affordable entry points into automated machine control, the LN-150’s plug-and-play design and compatibility with Topcon’s Sitelink3D platform will make it an attractive option. Market analysis suggests a rise in demand from residential developers, utility contractors, and road maintenance crews who prioritize accuracy without the complexity of full 3D systems. -

Integration with Cloud-Based Fleet Management

By 2026, digital construction ecosystems will increasingly rely on real-time data sharing and remote monitoring. The LN-150 is expected to benefit from enhanced connectivity features, allowing seamless integration with cloud platforms such as Topcon’s MAGNET software suite. This trend will enable contractors to monitor machine performance, track project progress, and conduct remote diagnostics—improving efficiency and reducing downtime. -

Expansion in Emerging Markets

Infrastructure development in regions such as Southeast Asia, Africa, and Latin America is accelerating, creating new opportunities for affordable, reliable machine control solutions. The Topcon LN-150’s rugged design and support for multiple GNSS constellations (GPS, GLONASS, Galileo, BeiDou) position it well for deployment in diverse geographies with varying satellite coverage. Distributor networks and localized support services are expected to expand, further driving adoption. -

Competitive Pressure from Rival Technologies

While the LN-150 offers strong value, it will face intensified competition from similar receivers by Trimble, Leica Geosystems, and emerging Chinese manufacturers offering lower-priced alternatives. To maintain market share, Topcon may emphasize software integration, customer support, and bundled service packages. Firmware updates enhancing accuracy and multi-machine compatibility could also be introduced ahead of 2026. -

Sustainability and Equipment Longevity

Environmental regulations and sustainability initiatives are influencing equipment purchasing decisions. The LN-150’s modular design supports repairability and upgrades, aligning with circular economy principles. Contractors seeking to extend the lifecycle of their machinery may prefer Topcon’s ecosystem, reinforcing the LN-150’s role in retrofitting older bulldozers and excavators with modern control systems.

Conclusion

By H2 2026, the Topcon LN-150 is anticipated to remain a relevant and competitive solution in the machine control segment, particularly for cost-conscious and mid-tier operations. Its success will depend on Topcon’s ability to innovate within its software ecosystem, expand global support infrastructure, and respond to evolving customer demands for connectivity, precision, and sustainability.

Common Pitfalls When Sourcing Topcon LN-150: Quality and Intellectual Property Risks

Sourcing a precision instrument like the Topcon LN-150 (a high-end laser receiver used in surveying and construction) carries significant risks, especially concerning quality and intellectual property (IP). Being aware of these pitfalls is crucial to avoid financial loss, project delays, and potential legal issues.

Quality-Related Pitfalls

1. Counterfeit or Refurbished Units Misrepresented as New

One of the most prevalent risks is receiving counterfeit or improperly refurbished Topcon LN-150 units sold as genuine new products. Counterfeit devices often use substandard components, leading to poor accuracy, calibration drift, and shortened lifespan. They may also fail to meet environmental durability standards (e.g., water or dust resistance).

2. Inadequate Calibration and Testing

Even if a unit is genuine, it may not have been properly calibrated or tested before sale. The LN-150 requires precise factory calibration for accurate laser signal detection. Units sourced from unauthorized distributors or gray market channels may lack valid calibration certificates or have been reset improperly, compromising measurement reliability.

3. Use of Non-OEM or Low-Grade Replacement Parts

In refurbished or repaired units, sellers might use non-Topcon replacement parts (e.g., sensors, circuit boards, or housings). These parts can degrade performance and are not covered under Topcon’s warranty. Over time, this leads to increased maintenance costs and system failures.

4. Lack of Warranty and Technical Support

Purchasing from unauthorized vendors often means forgoing legitimate manufacturer warranties and technical support. If the device malfunctions, users may face difficulties obtaining service, spare parts, or software updates—critical for maintaining performance and compatibility with other Topcon systems.

Intellectual Property (IP)-Related Pitfalls

1. Unauthorized Distribution and Grey Market Goods

Sourcing from unauthorized dealers may involve grey market products—genuine Topcon devices imported without the manufacturer’s consent. While the hardware may be authentic, such purchases violate Topcon’s distribution agreements and may breach regional IP protections, exposing buyers to potential legal or compliance risks, especially in regulated industries.

2. Software Licensing and Firmware Tampering

The LN-150 relies on proprietary firmware and software for full functionality. Illegitimate units may come with pirated, cracked, or modified firmware. This not only violates Topcon’s software IP but can also introduce security vulnerabilities and prevent access to future updates, rendering the device obsolete over time.

3. Risk of Trademark and Brand Infringement

Counterfeit sellers often misuse Topcon’s trademarks and branding to deceive buyers. Purchasing such products—knowingly or unknowingly—can indirectly support IP infringement. In some jurisdictions, companies may face reputational or legal consequences for using counterfeit equipment in professional projects.

4. Lack of Access to Proprietary Ecosystem

Topcon’s equipment often integrates into a broader ecosystem (e.g., MAGNET software, data transfer protocols). Unauthorized or tampered LN-150 units may not fully support these integrations due to IP-protected communication protocols, limiting functionality and interoperability.

Best Practices to Mitigate Risks

- Purchase only from authorized Topcon distributors or directly from Topcon.

- Verify the product’s serial number with Topcon’s customer service.

- Request proof of authenticity, warranty documentation, and calibration certificates.

- Avoid deals that seem too good to be true—deep discounts often indicate counterfeit or grey market goods.

- Ensure software and firmware are originally licensed and up-to-date.

By recognizing these quality and IP pitfalls, buyers can make informed decisions and ensure they receive reliable, legally compliant equipment that meets professional standards.

Logistics & Compliance Guide for Topcon LN-150

Product Overview

The Topcon LN-150 is a high-precision laser receiver designed for construction and grading applications. It is compatible with rotating laser systems and provides accurate grade control for equipment such as dozers, graders, and excavators. This guide outlines key logistics and compliance considerations for importing, distributing, and using the LN-150 globally.

Regulatory Compliance

The Topcon LN-150 must comply with regional and international regulatory standards to ensure legal distribution and safe operation. Key compliance areas include:

Electromagnetic Compatibility (EMC)

The device meets EMC directives such as:

– EU: EN 61326-1 (Industrial environment) per the EMC Directive 2014/30/EU

– USA: FCC Part 15, Class A – suitable for industrial environments

– Canada: ICES-003, Class A

Users must ensure installation and usage follow these standards to avoid interference with other electronic equipment.

Laser Safety Standards

Although the LN-150 is a laser receiver (not an emitter), it is designed to work with Class 3R or Class 2 rotating lasers. Compliance includes:

– Adherence to IEC 60825-1 for associated laser systems

– Proper labeling and user awareness of laser safety protocols

RoHS and REACH Compliance

The LN-150 complies with:

– RoHS (EU Directive 2011/65/EU): Restricts hazardous substances such as lead, cadmium, and mercury

– REACH (EC 1907/2006): Requires disclosure of Substances of Very High Concern (SVHC)

Topcon provides material compliance documentation upon request.

Import and Export Requirements

Shipping the LN-150 across borders requires adherence to international trade regulations.

Harmonized System (HS) Code

Recommended HS Code: 8543.70.90 – Other electronic signaling or safety control apparatus.

Note: Confirm with local customs authorities, as classification may vary by country.

Export Controls

The LN-150 is generally not subject to strict export controls (e.g., ITAR or EAR), but distributors must:

– Verify end-use and end-user through screening processes

– Comply with sanctions lists (OFAC, EU, UN)

– Maintain records per local export regulations

Packaging and Handling

To ensure safe transit and storage:

- Original Packaging: Use Topcon-provided packaging with shock-absorbing materials

- Environmental Conditions:

- Storage: -20°C to +60°C, up to 95% non-condensing humidity

- Operating: -20°C to +50°C

- Labeling: Include UN38.3 certification if shipped with lithium batteries (e.g., LR-5 remote control)

Battery Compliance (LR-5 Remote Control)

The LN-150 is often used with the LR-5 remote, which may contain a lithium battery.

- UN38.3 Certification: Required for air transport of lithium batteries

- IATA Dangerous Goods Regulations: Classify under Section II, UN 3481 (lithium-ion batteries contained in equipment)

- Ensure proper packaging and documentation when shipping internationally

Documentation Requirements

For logistics and customs clearance, maintain the following:

- Commercial Invoice

- Packing List

- Certificate of Conformity (CE, FCC)

- RoHS and REACH Declarations

- Bill of Lading / Air Waybill

- Export Declaration (if applicable)

Topcon provides standard compliance documentation through their distribution portal.

Warranty and Registration

- The LN-150 comes with a standard 2-year manufacturer’s warranty

- Register the product on Topcon’s official support portal to activate warranty and receive compliance updates

- Distributors must report any compliance-related field issues to Topcon Product Support

End-of-Life and Recycling

Comply with WEEE (EU Directive 2012/19/EU) and local e-waste regulations:

– Do not dispose of in household waste

– Use certified e-waste recycling channels

– Topcon participates in take-back programs in select regions – contact local support for details

Contact and Support

For compliance documentation or logistics support:

– Topcon Positioning Group: https://positioning.topcon.com

– Global Support: +1-800-648-0833 (Americas), +31-2-524-2200 (EMEA)

– Email: [email protected]

Note: Regulations vary by country. Always consult local authorities and Topcon representatives for region-specific compliance requirements.

Conclusion for Sourcing Topcon LN-150:

After a thorough evaluation of the Topcon LN-150 laser receiver, it is evident that sourcing this model presents a reliable and efficient solution for construction and civil engineering applications requiring high-accuracy laser detection. The LN-150 offers excellent sensitivity, intuitive operation, durable build quality, and strong compatibility with Topcon’s range of laser systems, making it well-suited for grading, excavation, and leveling tasks.

When sourcing the Topcon LN-150, it is recommended to procure through authorized distributors or certified suppliers to ensure product authenticity, access to warranty support, and availability of technical assistance. Additionally, evaluating total cost of ownership—including accessories, battery options, and potential calibration services—will support long-term operational efficiency.

In conclusion, sourcing the Topcon LN-150 is a sound investment for contractors and surveying professionals seeking dependable performance, precision, and integration within a trusted ecosystem of laser-guided equipment.