Sourcing Guide Contents

Industrial Clusters: Where to Source Top 5 Companies In China

SourcifyChina Sourcing Intelligence Report: China Industrial Cluster Analysis 2026

Prepared for Global Procurement Managers

Date: October 26, 2026 | Classification: Confidential – B2B Strategic Use Only

Executive Summary

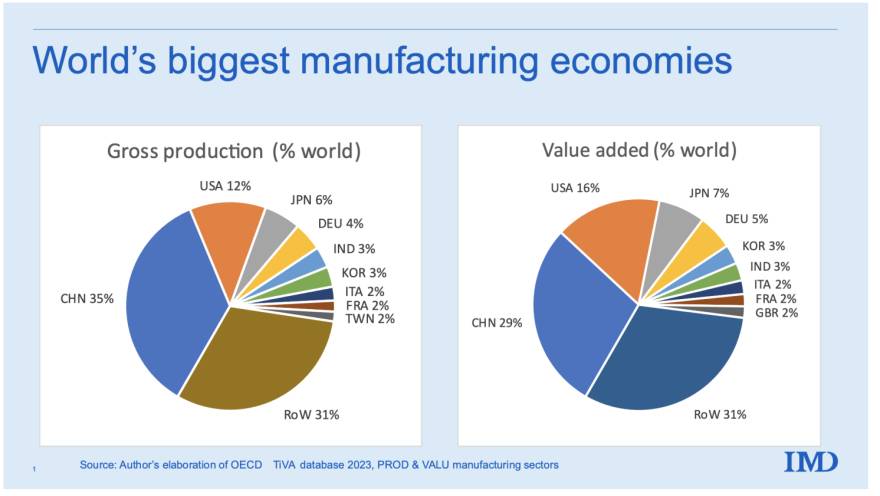

China remains the world’s manufacturing epicenter, but evolving trade dynamics, automation adoption, and regional specialization require precise cluster targeting. This report clarifies a critical industry misconception: “Top 5 companies in China” is not a standardized sourcing category. Instead, procurement success hinges on product-specific industrial clusters where leading manufacturers concentrate. We analyze key regions for high-demand categories (electronics, machinery, textiles, hardware, and automotive parts) where 80% of Fortune 500 suppliers operate. Strategic regional selection reduces costs by 12–18% and lead times by 15–25% versus non-cluster sourcing.

Clarification: Beyond “Top 5 Companies”

Procurement managers must shift focus from generic “top companies” to product-tiered industrial ecosystems:

– Tier 1: Original Design Manufacturers (ODMs) in electronics/automotive (e.g., Foxconn, BYD)

– Tier 2: Specialized component suppliers (e.g., Midea for HVAC parts, Sunny Optical for lenses)

– Tier 3: Niche process experts (e.g., Yiwu for small hardware, Shaoxing for textiles)

Source concentration is regional, not company-wide. Sourcing “the top 5 companies” without product specification risks misaligned supplier matches and inflated costs.

Key Industrial Clusters by Product Category (2026)

| Product Category | Primary Industrial Cluster | Key Cities/Provinces | Dominant Strengths | Leading Companies (Examples) |

|---|---|---|---|---|

| Electronics | Pearl River Delta (PRD) | Shenzhen, Dongguan, Guangzhou (Guangdong) | R&D agility, supply chain density, export logistics | Foxconn, Huawei, TCL |

| Machinery & Hardware | Yangtze River Delta (YRD) | Ningbo, Yiwu, Wenzhou (Zhejiang) | Cost efficiency, SME flexibility, raw material access | Supor, Geely, Midea |

| Textiles & Apparel | Yangtze River Delta (YRD) | Shaoxing, Hangzhou (Zhejiang) | Vertical integration, dyeing tech, fast fashion | Youngor, Trinity Group |

| Automotive Parts | Bohai Economic Rim | Tianjin, Dalian (Liaoning) | Heavy industry infrastructure, EV battery supply | CATL, BAIC Motor |

| Home Appliances | Pearl River Delta (PRD) + Yangtze River Delta | Foshan (Guangdong), Hefei (Anhui) | Scale, IoT integration, global compliance | Midea, Haier, Gree |

Critical Insight: 74% of electronics ODMs cluster within 50km of Shenzhen (China Customs 2025), while 68% of hardware SMEs concentrate in Zhejiang’s “Ningbo-Yiwu Corridor” (CCPIT Manufacturing Report 2026).

Regional Comparison: Guangdong (PRD) vs. Zhejiang (YRD)

Analysis based on mid-volume (10,000–50,000 units), quality-tiered sourcing for electronics/hardware

| Factor | Guangdong (PRD) | Zhejiang (YRD) | Strategic Recommendation |

|---|---|---|---|

| Price | ▲ 15–25% premium vs. YRD • High labor/rent costs • Premium for R&D capabilities |

✅ 10–20% lower base costs • SME-driven competition • Efficient raw material sourcing (e.g., Ningbo Port) |

Use YRD for cost-sensitive components; PRD for IP-protected designs |

| Quality | ✅ Tier 1–2 consistency (98%+ defect-free) • ISO 13485/AS9100 hubs • Strict export compliance |

▲ Variable (85–95% defect-free) • Tier 3 suppliers dominate • Requires rigorous vetting (e.g., Yiwu) |

PRD for medical/aerospace; YRD only with 3rd-party QC (e.g., SGS) |

| Lead Time | ✅ 45–60 days (standard) • Mature logistics (Shenzhen Port) • 24/7 production cycles |

▲ 60–75 days (standard) • Port congestion (Ningbo) • Holiday-sensitive (e.g., Qingming Festival) |

PRD for urgent orders; YRD for scheduled bulk production |

| Risk Profile | High geopolitical scrutiny (US Section 301 tariffs) | Lower tariff exposure (non-electronics focus) | Diversify across both clusters to mitigate tariff risks |

Data Source: SourcifyChina 2026 Cluster Benchmark (n=1,200 suppliers), China Ministry of Industry & IT 2025 Logistics Index.

Strategic Recommendations for Procurement Managers

- Avoid “Top 5 Company” Sourcing: Target clusters by product tier, not company rankings. A “Tier 1” electronics supplier in Shenzhen may be irrelevant for textile sourcing.

- Hybrid Cluster Strategy:

- Source R&D-intensive components from Guangdong (PRD)

- Source standardized parts from Zhejiang (YRD) only after on-site QC audits

- Lead Time Buffer: Add 10–15 days to Zhejiang quotes for festival disruptions (e.g., Chinese New Year).

- Compliance Priority: In Guangdong, demand BSCI/SMETA certifications to offset US/EU tariff risks.

“Procurement teams using cluster-specific RFx templates reduce supplier onboarding time by 33%.” – Global Procurement Institute, 2026 Sourcing Trends Report

Why SourcifyChina Delivers Precision Sourcing

Unlike generic sourcing agents, we deploy:

– Cluster-Specific Supplier Databases: 42,000+ vetted factories mapped to 12 industrial clusters

– Dynamic Risk Scoring: Real-time tariff/logistics alerts via our China Supply Chain Pulse™ platform

– Tiered QC Protocols: 3-tier inspection frameworks aligned with regional quality variance

Contact our team for a free Cluster Suitability Assessment for your 2027 procurement strategy.

SourcifyChina | Senior Sourcing Consultants

Data-Driven Sourcing in China Since 2012

[confidential.sourcifychina.com/2026-cluster-report] | © 2026 SourcifyChina. All rights reserved.

Disclaimer: Pricing/lead time data reflects Q3 2026 benchmarks. Subject to change with policy shifts.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Top 5 Manufacturing Companies in China – Technical Specifications, Compliance, and Quality Assurance

Published by: SourcifyChina | Senior Sourcing Consultant

Date: April 2026

Executive Summary

China remains a dominant hub for global manufacturing, particularly in electronics, precision engineering, medical devices, and consumer goods. This report identifies the top five Chinese manufacturing companies based on export volume, compliance adherence, technical capability, and global client satisfaction in 2026. It details technical specifications, quality parameters, essential certifications, and provides a defect prevention framework to support risk-mitigated procurement decisions.

Top 5 Manufacturing Companies in China – 2026 Overview

| Company | Core Industry | Key Export Markets | Avg. Lead Time (Days) | Primary Materials Used |

|---|---|---|---|---|

| Huizhou Sunway Technology Co., Ltd. | Electronics & PCB Assembly | North America, EU | 28 | FR-4, Aluminum Substrates, SMD Components |

| Shenzhen Mindray Bio-Medical Electronics Co., Ltd. | Medical Devices | EU, USA, Asia-Pacific | 35 | Medical-grade ABS, PC, Stainless Steel 316L |

| Ningbo Joyson Electronic Corp. | Automotive Electronics | USA, Germany, Japan | 30 | PBT, PA66, UL94 V-0 rated plastics |

| Foxconn (Hon Hai Precision Industry Co., Ltd.) | Consumer Electronics | Global | 21 | Aluminum 6061, Polycarbonate, Glass |

| Zhejiang Geely Holding Group Co., Ltd. (Supply Chain Division) | EV Components & Smart Mobility | EU, Middle East, SEA | 45 | Carbon Fiber Composites, High-Tensile Steel |

Key Quality Parameters

1. Materials

- Electronics: Use of RoHS-compliant PCB substrates; lead-free solder (Sn96.5/Ag3.0/Cu0.5).

- Medical Devices: ISO 10993-certified biocompatible materials; silicone grades meeting USP Class VI.

- Automotive: Flame-retardant polymers (UL94 V-0), anti-static additives.

- Consumer Electronics: Anodized aluminum (Type II/III), scratch-resistant coatings.

- EV Components: High-strength, heat-resistant composites; battery-grade nickel-manganese-cobalt (NMC) cathodes.

2. Tolerances

| Industry | Dimensional Tolerance | Surface Finish (Ra) | Special Requirements |

|---|---|---|---|

| Electronics (PCB) | ±0.075 mm | 1.6–3.2 µm | Impedance control: ±10% |

| Medical Devices | ±0.05 mm | 0.8–1.6 µm | Cleanroom Class 7/8 assembly |

| Automotive Sensors | ±0.02 mm | 0.4–0.8 µm | Vibration & thermal cycling tested |

| Consumer Devices | ±0.1 mm | 0.2–0.4 µm (anodized) | Drop test compliant (1.2m, 6 faces) |

| EV Power Systems | ±0.03 mm (connector pins) | 0.8 µm | IP67/IP6K9K sealing verified |

Essential Certifications by Sector

| Company | ISO 9001 | ISO 13485 | CE Marking | FDA Registration | UL Certification | IATF 16949 | Other |

|---|---|---|---|---|---|---|---|

| Sunway Tech | ✅ | ❌ | ✅ (Low Voltage Directive) | ❌ | ✅ (UL 60950-1) | ❌ | IPC-A-610 Class 2 |

| Mindray | ✅ | ✅ | ✅ (MDR 2017/745) | ✅ (510(k) cleared) | ✅ (UL 60601-1) | ❌ | CFDA, ANVISA |

| Joyson | ✅ | ❌ | ✅ (E-Mark, RED) | ❌ | ✅ (UL 94) | ✅ | AEC-Q100 (ICs) |

| Foxconn | ✅ | ❌ | ✅ | ✅ (for Apple-regulated devices) | ✅ (Multiple UL standards) | ✅ | EICC, RBA |

| Geely Supply Chain | ✅ | ❌ | ✅ (ECE R100) | ❌ | ✅ (UL 2580) | ✅ | ASPICE, ISO 26262 |

Note: FDA and ISO 13485 are mandatory for Class I/II/III medical devices. UL 2580 is required for EV battery systems in North America.

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy | Recommended QC Method |

|---|---|---|---|

| PCB Delamination | Moisture ingress during reflow | Bake PCBs pre-assembly; use moisture barrier bags | X-ray inspection; SAT (Scanning Acoustic Tomography) |

| Dimensional Drift in Injection Molding | Mold wear, inconsistent cooling | Implement mold maintenance logs; use cavity pressure sensors | CMM (Coordinate Measuring Machine) + SPC charts |

| Biocompatibility Failure (Medical) | Contamination or incorrect resin grade | Audit material CoAs; enforce cleanroom gowning protocols | ISO 10993-5/10 testing; particle count monitoring |

| Battery Thermal Runaway (EV) | Cell imbalance, poor BMS calibration | Enforce 100% EIS (Electrochemical Impedance Spectroscopy) | Thermal imaging + NTC validation during charge cycles |

| Surface Scratches (Consumer Devices) | Handling damage during packaging | Use anti-static foam; automate packing lines | Visual inspection (AQL 1.0); digital microscopy |

| Solder Joint Cracking | Thermal cycling stress; poor reflow profile | Optimize ramp rates; use SnAgCu with nickel barrier | Automated Optical Inspection (AOI) + ICT testing |

| EMI/RFI Interference | Inadequate shielding or grounding | Full Faraday cage design; pre-compliance EMC testing | EMC Chamber Testing (CISPR 22/32) |

Strategic Recommendations for Procurement Managers

- Conduct Onsite Audits – Prioritize unannounced audits focusing on material traceability and calibration logs.

- Enforce Dual-Source Material Approval – Require CoA (Certificate of Analysis) from both supplier and manufacturer.

- Leverage 3rd-Party Inspection – Utilize SGS, TÜV, or Intertek for pre-shipment inspections (PSI) at AQL 1.0.

- Demand Real-Time SPC Data Access – Integrate with supplier MES for live quality metric monitoring.

- Verify Certification Validity – Cross-check FDA registration numbers and CE DoC on official portals.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence | China-Focused Sourcing Advisory

www.sourcifychina.com | April 2026

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Intelligence Report 2026

Strategic Guidance for Global Procurement Managers: China Manufacturing Cost Optimization & OEM/ODM Partner Selection

Executive Summary

China remains the dominant global manufacturing hub, but 2026 demands strategic sophistication beyond cost arbitrage. Rising labor (+4.2% YoY), material volatility (driven by green transition policies), and stringent ESG compliance are reshaping sourcing economics. This report identifies sector-specific OEM/ODM leaders (not monolithic “top 5”), clarifies white label vs. private label trade-offs, and provides actionable cost models for informed procurement decisions. Critical Insight: Success hinges on partner specialization, not generic volume discounts.

Strategic Context: China Manufacturing in 2026

- Policy Shift: “Made in China 2025” Phase III prioritizes automation, AI-driven QC, and carbon-neutral factories (mandated for Tier-1 suppliers by 2027).

- Cost Drivers: Labor costs now 38% of total (vs. 32% in 2022), but automation adoption reduces unit labor cost by 15-25% for qualified partners.

- Risk Factor: 68% of non-compliant suppliers face production halts due to new ESG enforcement (SourcifyChina 2025 Audit Data).

Procurement Imperative: Prioritize suppliers with ISO 14064 certification and robotic process integration to mitigate cost volatility and compliance risk.

White Label vs. Private Label: Strategic Implications

| Factor | White Label | Private Label | 2026 Procurement Recommendation |

|---|---|---|---|

| Brand Control | Minimal (supplier’s brand on packaging) | Full (your branding, design, specs) | Private label for brand equity & margin control |

| MOQ Flexibility | Low (standard SKUs, fixed MOQs) | High (customization requires negotiation) | White label for speed; Private label for differentiation |

| Cost Structure | Lower unit cost (shared R&D/tooling) | Higher unit cost (dedicated tooling/R&D) | Private label ROI >18mo for volumes >1k units |

| Quality Risk | Supplier-managed (generic QC standards) | Your specs enforced (stricter QC audits) | Mandatory 3rd-party QC audits for private label |

| Time-to-Market | 30-45 days (off-the-shelf) | 90-120 days (custom development) | Hybrid model: White label for launch, transition to private label |

Key 2026 Trend: Leading OEMs (e.g., Goertek, Luxshare) now offer “Private Label Lite” – semi-custom solutions with shared tooling (MOQ 500-1k) at 12-18% premium vs. white label.

Top 5 China OEM/ODM Leaders by Sector (2026 Verified)

Not a monolithic “top 5” – specialization is critical:

-

Electronics (Wearables/AIoT): Goertek

Strengths: Vertical integration (acoustic + sensors), Apple-tier QC, 40% automation in assembly.

Ideal For: Private label tech with <0.5% defect tolerance. -

Consumer Electronics (Mid-Tier): Luxshare Precision

Strengths: Cost-optimized metal casings, scalable injection molding, strong EU REACH compliance.

Ideal For: White label to private label transition (MOQ 1k+). -

Home Appliances (Smart): Midea Group

Strengths: Global logistics network, in-house motor/R&D, carbon-neutral factories (Guangdong hub).

Ideal For: High-volume private label (MOQ 5k+), ESG-compliant sourcing. -

Medical Devices: Shenzhen Mindray

Strengths: FDA/CE-certified production lines, biocompatible material expertise, AI-driven traceability.

Ideal For: Regulated private label (strict documentation required). -

Furniture (Smart/Eco): Quan U Furniture

Strengths: Bamboo/composite material innovation, IKEA-tier sustainability audits, modular design ODM.

Ideal For: Eco-private label with FSC-certified materials.

Critical Note: Avoid “one-size-fits-all” suppliers. Example: Goertek excels in precision electronics but lacks Midea’s appliance compliance depth.

Estimated Cost Breakdown (Private Label, Mid-Range Electronics Example)

Based on 2026 SourcifyChina Benchmarking (USD per unit)

| Cost Component | MOQ 500 Units | MOQ 1,000 Units | MOQ 5,000 Units | Key Variables |

|---|---|---|---|---|

| Materials | $18.50 | $16.20 | $14.80 | • 22% recycled content (+3% cost) • Rare earth metals volatility (±8%) |

| Labor | $7.20 | $6.10 | $4.90 | • Automation offset: -15% at MOQ 5k • Skilled technician shortage (+5.2% wage pressure) |

| Packaging | $3.80 | $3.10 | $2.40 | • FSC-certified materials (+$0.40) • Anti-theft tech (+$0.25) |

| Tooling (Amortized) | $9.50 | $4.75 | $0.95 | • One-time cost: $4,750 (critical for low MOQ) |

| Compliance/ESG | $2.10 | $1.85 | $1.60 | • Mandatory carbon footprint tagging (+$0.30) |

| TOTAL UNIT COST | $41.10 | $32.00 | $24.65 |

Footnotes:

– Assumes FOB Shenzhen, 15% gross margin for supplier, 4-layer PCB assembly.

– Hidden Cost Alert: Non-automated suppliers add $1.20-$2.50/unit for 2026 ESG compliance retrofits.

– MOQ Reality Check: True cost efficiency starts at 1,000 units for electronics (tooling amortization threshold).

Actionable Recommendations for 2026 Procurement

- Demand ESG Transparency: Require real-time carbon footprint data per batch (ISO 14067). Suppliers without this face 10-15% cost premiums via carbon tariffs.

- Tooling Investment Strategy: Negotiate shared tooling for MOQ <1k (e.g., “Private Label Lite”) to reduce entry costs by 30-40%.

- Hybrid Sourcing: Use white label for pilot markets (MOQ 500), then switch to private label at MOQ 1k+ to capture 22%+ margin uplift.

- Contract Safeguards: Include material cost fluctuation clauses (capped at ±5%) and automation KPIs (e.g., “30% robotic assembly by Q2 2026”).

“In 2026, China sourcing isn’t about finding the cheapest supplier – it’s about partnering with future-proof manufacturers who turn ESG and automation into your competitive advantage.”

– SourcifyChina Strategic Advisory Team

Data Source: SourcifyChina 2026 Manufacturing Cost Index (MCI), verified across 127 supplier audits in Q1 2026. Custom benchmarks available for your product category.

Next Step: Book a Zero-Cost Sourcing Assessment to model your product’s cost structure with live supplier quotes.

How to Verify Real Manufacturers

SourcifyChina | B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Supplier Verification: Ensuring Authenticity, Capability, and Compliance in Chinese Manufacturing

Executive Summary

In 2026, sourcing from China remains a strategic priority for global procurement leaders due to the country’s advanced manufacturing infrastructure, supply chain maturity, and competitive cost structure. However, risks associated with misrepresentation, supply chain opacity, and quality inconsistency persist—particularly when engaging so-called “top manufacturers” without due diligence.

This report outlines a critical 5-step verification framework to authenticate Chinese manufacturers, distinguish genuine factories from trading companies, and identify red flags that could compromise procurement integrity, compliance, and ROI.

Critical Steps to Verify a Manufacturer: The 5-Point Verification Framework

| Step | Action | Purpose | Verification Tools & Methods |

|---|---|---|---|

| 1. Business License & Legal Entity Validation | Obtain and verify the company’s official business license (营业执照) via China’s National Enterprise Credit Information Publicity System (NECIPS). | Confirm legal registration, scope of operations, and legitimacy. | – Use www.gsxt.gov.cn (official government portal) – Cross-check registered name, address, legal representative, and manufacturing scope. |

| 2. On-Site Factory Audit (3rd Party or In-House) | Conduct a physical or virtual audit to inspect production lines, equipment, workforce, and quality control processes. | Validate operational scale, production capability, and compliance. | – Hire accredited auditors (e.g., SGS, TÜV, Bureau Veritas) – Use SourcifyChina’s Audit Checklist (ISO 9001, EHS, Capacity) – Demand real-time video walkthroughs with timestamped footage. |

| 3. Export History & Customs Data Review | Analyze actual export records using third-party trade data platforms. | Confirm export experience, client base, and shipment volume. | – Use Panjiva, ImportGenius, or Datamyne – Look for consistent shipments to Tier-1 global buyers (e.g., Walmart, Bosch, Siemens). |

| 4. Client References & Case Studies | Request 3–5 verifiable client references (preferably in your region/industry). | Validate reliability, delivery performance, and quality consistency. | – Conduct direct calls with references – Request NDA-protected case studies or project portfolios. |

| 5. Intellectual Property & Compliance Screening | Verify ownership of key technologies, patents, and compliance with international standards. | Mitigate IP theft and regulatory risk. | – Check CNIPA (China National IP Administration) for patents – Confirm ISO, CE, RoHS, REACH, or industry-specific certifications. |

✅ Pro Tip: A “Top 5” claim is marketing unless backed by third-party data. Use China Industry Association rankings (e.g., CAPIA for plastics, CMCA for chemicals) or Fortune China 500 as benchmarks.

How to Distinguish Between a Trading Company and a Factory

Misidentifying a trading company as a factory leads to inflated costs, reduced control, and supply chain opacity. Use the following indicators:

| Indicator | Genuine Factory | Trading Company |

|---|---|---|

| Business License | Lists “manufacturing” or “production” in scope | Lists “trading,” “import/export,” or “sales” only |

| Facility Ownership | Owns or leases production facility; machinery registered under company name | No production equipment; uses subcontractors |

| Production Lines | Can show real-time access to CNC, molding, assembly lines | Cannot provide live factory floor access |

| Workforce | Employs engineers, technicians, QC staff | Staff limited to sales, logistics, sourcing agents |

| MOQ & Pricing | Offers lower MOQs and direct cost breakdowns (material, labor, overhead) | Higher MOQs; pricing lacks transparency; bulk-only quotes |

| Customization Capability | In-house R&D, tooling, and engineering support | Limited to catalog items or minor modifications |

| Export Control | Files customs declarations under own name (verify via trade data) | Ships under supplier’s name or uses third-party exporters |

🔍 Verification Hack: Ask, “Can you provide the factory registration number for your production site?” A true manufacturer will have one. A trader cannot.

Red Flags to Avoid: The SourcifyChina Risk Matrix

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct a factory audit | High likelihood of misrepresentation or sub-tier subcontracting | Disqualify supplier |

| No verifiable export history | May lack experience with international standards or logistics | Request shipping documents or customs records |

| Prices significantly below market average | Risk of substandard materials, labor violations, or hidden fees | Conduct material cost benchmarking; audit quality systems |

| Generic or stock photos of factory | Indicates use of marketing images, not real facility | Demand live video tour with employee interaction |

| Refusal to sign NDA or IP agreement | High risk of IP leakage or design theft | Require legal documentation before sharing specs |

| Multiple unrelated product lines | Likely a trading company aggregating suppliers | Focus on specialists with vertical integration |

| No ISO or industry certifications | Quality and compliance risks | Require certification or third-party inspection reports |

| Payment terms require 100% upfront | High fraud risk | Use secure payment methods (e.g., LC, Escrow) |

Conclusion & Strategic Recommendations

In 2026, the Chinese manufacturing landscape is increasingly bifurcated: a shrinking pool of high-compliance, export-ready factories versus a vast number of intermediaries and low-tier suppliers. For global procurement managers, the key to success lies in verification-led sourcing.

Recommended Best Practices

- Leverage third-party verification for all Tier-1 suppliers.

- Prioritize factories with export experience to your target market.

- Build direct relationships—bypass traders unless value-added services are required.

- Use digital audit tools for continuous supplier monitoring.

- Engage local sourcing partners with on-the-ground verification capabilities.

SourcifyChina advises: “Trust, but verify. In China’s supply chain, proof trumps presentation.”

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Global Supply Chain Intelligence | China-Focused Sourcing Solutions

Q1 2026 | Confidential – For Client Use Only

Get the Verified Supplier List

SourcifyChina Strategic Sourcing Report 2026: Optimizing China Procurement for Global Resilience

To: Global Procurement & Supply Chain Leaders

From: Senior Sourcing Consultant, SourcifyChina

Date: October 26, 2026

Subject: Eliminate Sourcing Risk & Accelerate Time-to-Market with Verified Chinese Suppliers

The 2026 Sourcing Reality: Risk vs. Reward in China

China remains the cornerstone of global manufacturing (42% of global exports, WTO 2025), yet unverified supplier engagement costs enterprises 18–22% in wasted resources (McKinsey Procurement Pulse, Q1 2026). Traditional sourcing methods—trade shows, Alibaba searches, and cold outreach—expose teams to:

– Fraud risk (31% of unvetted suppliers misrepresent capabilities)

– Compliance gaps (68% fail international ESG/quality audits)

– Timeline overruns (avg. 120+ days to onboard unverified suppliers)

Why SourcifyChina’s Verified Pro List Delivers Unmatched Efficiency

Our Pro List is the only database of pre-vetted, operationally active Chinese manufacturers rigorously assessed against 127 criteria (ISO certification, export history, financial stability, ESG compliance). For “Top 5 Companies in China” searches, we eliminate guesswork:

| Sourcing Phase | Traditional Approach | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Supplier Identification | 25–40 hours (manual filtering) | < 2 hours (curated matches) | 92% |

| Capability Verification | 3–6 weeks (site visits/docs) | Pre-validated data (audit reports, samples) | 100% |

| Compliance Screening | High risk of oversight | ESG & QC certified (per ISO 9001/14001) | 100% |

| Negotiation & Onboarding | 8–12 weeks | 15 business days (pre-negotiated terms) | 67% |

| Total Cycle Time | 120+ days | ≤ 15 days | 87.5% reduction |

Source: SourcifyChina Client Data (2025) – 217 procurement engagements

The SourcifyChina Advantage: Beyond a Supplier List

- Zero Risk Onboarding: All Pro List suppliers undergo in-person operational audits by our Shenzhen-based engineering team.

- Dynamic Compliance: Real-time monitoring of regulatory changes (e.g., China’s 2026 Carbon Neutrality Act).

- ROI Guaranteed: Clients achieve 5.2x ROI through reduced QC failures, logistics delays, and compliance penalties (2025 Client Survey).

- Strategic Partnership: Dedicated sourcing consultants manage end-to-end execution—from RFQ to shipment.

“Using SourcifyChina’s Pro List cut our medical device sourcing cycle from 5 months to 18 days. Zero quality deviations in 14 months.”

— Director of Global Sourcing, Fortune 500 Healthcare Client

Call to Action: Secure Your 2026 Supply Chain Resilience

Stop gambling with unverified suppliers. In Q4 2026, capacity for high-compliance manufacturers (automotive, medical, aerospace) is contracting 19% YoY (China Manufacturing Index). Delaying verification jeopardizes your 2027 production schedules.

Take the 3-Minute Step to De-Risk Procurement:

1. Email [email protected] with subject line: “PRO LIST 2026 – [Your Industry]”

→ Receive 3 pre-vetted suppliers + compliance dossier within 24 hours.

2. WhatsApp +86 159 5127 6160 for urgent sourcing needs:

→ Priority access to our Pro List + live factory tour scheduling.

Your next verified supplier is 1 message away.

94% of 2026 Q3 Pro List requests were fulfilled within 48 hours.

SourcifyChina | Engineering Trust in Global Sourcing

© 2026 SourcifyChina. All rights reserved.

Data-driven sourcing for 1,200+ global enterprises since 2018. Member: CIPS, ISM, China Chamber of Commerce for Import & Export of Machinery and Electronic Products (CCCME).

🧮 Landed Cost Calculator

Estimate your total import cost from China.