The global plastic extrusion (PEX) manufacturing market is experiencing steady expansion, driven by rising demand in construction, plumbing, and HVAC applications. According to Grand View Research, the global plastic pipes and fittings market—closely tied to PEX production—was valued at USD 81.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth underscores the increasing need for efficiency, precision, and innovation in PEX manufacturing operations. As competition intensifies and production volumes rise, manufacturers are turning to advanced tools and technologies to optimize output, reduce waste, and ensure compliance with industry standards. From extrusion monitoring systems to predictive maintenance platforms, data-driven tooling solutions are becoming essential for maintaining a competitive edge. In this context, we’ve identified the top 10 tools reshaping PEX manufacturing—each selected based on performance metrics, adoption rates, and measurable impact on operational efficiency.

Top 10 Tools For Pex Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 PEX Tools & Accessories

Domain Est. 1996

Website: nibco.com

Key Highlights: To ensure watertight connections in PEX and PE-RT systems, use the right tools for the situation. Choose tools ranging from sleeve, crimp, cutters, clamps, and ……

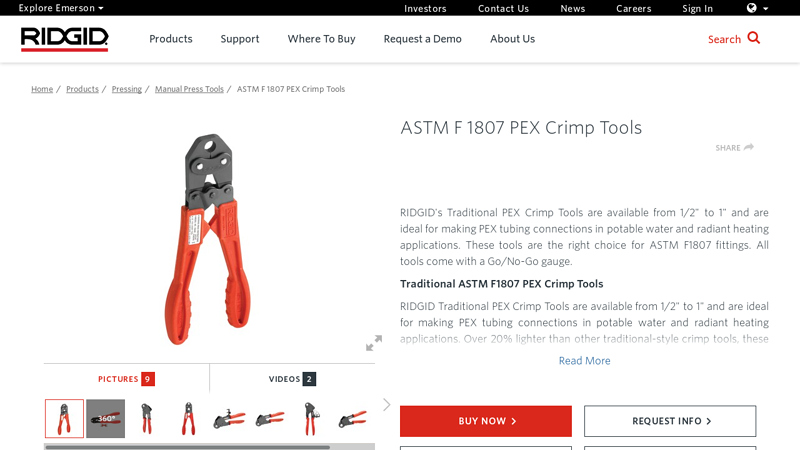

#2 ASTM F 1807 PEX Crimp Tools

Domain Est. 1995

Website: ridgid.com

Key Highlights: Rating 5.0 (2) RIDGID Traditional PEX Crimp Tools are available from 1/2″ to 1″ and are ideal for making PEX tubing connections in potable water and radiant heating ……

#3 Tools For PEX Plumbing & Radiant Heating Systems

Domain Est. 1995

Website: watts.com

Key Highlights: We offer a complete line of quality tools that ensure professional results for your PEX potable or heating project. Have a question or two?…

#4 Uponor

Domain Est. 1996

Website: uponor.com

Key Highlights: Discover Uponor PEX plumbing system tools and components, including pipe cutters, bend supports, multiport tees and the Milwaukee® ProPEX expansion tool….

#5 PEX Tools & Connections

Domain Est. 1998

Website: supplyhouse.com

Key Highlights: Free delivery over $99 · 90-day returnsResources for PEX projects, choosing what system to use, and buying materials. Find answers to all your questions, helpful compatability gui…

#6 Tools

Domain Est. 2000

Website: aymcdonald.com

Key Highlights: AY McDonald Mfg. Co.’s plumbing accessories make sure you are always prepared for the job at hand by providing high quality plumbing specialty and accessories….

#7 SharkBite Plumbing Products

Domain Est. 2003

Website: sharkbite.com

Key Highlights: Cut repair & install time in half with SharkBite Plumbing Products. Explore our complete line of plumbing fittings, PEX pipe, valves, adapters and more….

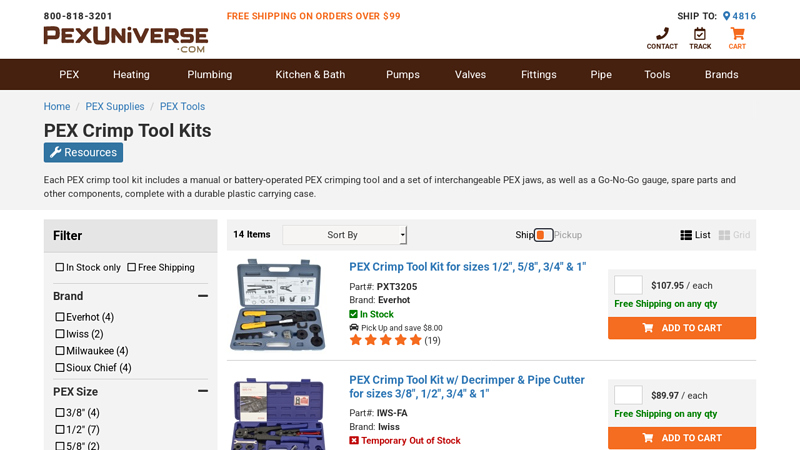

#8 PEX Crimp Tool Kits

Domain Est. 2009

Website: pexuniverse.com

Key Highlights: Free delivery over $99 · 30-day returnsComplete crimp tool kits with interchangeable jaws for installation of all PEX tubing types & sizes. Available in manual or battery-operated…

#9 PEX Crimp, Press, Expansion, Clamp and Cinch Tools

Domain Est. 2017

Website: icrimptools.com

Key Highlights: Free delivery over $100 30-day returnsiCrimp offers PEX tools including crimp, press, expansion, clamp and cinch tools known for their durability, corrosion resistance, and ease of…

#10 PEX Tools & Accessories

Domain Est. 1996

Expert Sourcing Insights for Tools For Pex

H2: 2026 Market Trends for Tools for PEX Plumbing Systems

The market for tools used in cross-linked polyethylene (PEX) plumbing systems is expected to experience significant evolution by 2026, driven by advancements in plumbing technology, increased adoption of PEX in residential and commercial construction, and a growing emphasis on efficiency and sustainability. Below is an analysis of key market trends shaping the Tools for PEX sector through 2026.

1. Rising Demand in Residential Construction

The continued expansion of single-family and multi-family housing, particularly in North America and Europe, is a primary driver for PEX tool demand. PEX tubing offers flexibility, freeze resistance, and ease of installation compared to traditional copper or PVC piping. As construction timelines shorten and labor costs rise, contractors increasingly favor PEX systems, boosting the need for reliable crimping, expansion, and insertion tools.

2. Growth in Retrofit and Renovation Projects

Home renovation and plumbing upgrade projects are on the rise, especially in aging housing stock. PEX’s adaptability makes it ideal for retrofits, where space and access are limited. This trend increases demand for compact, user-friendly PEX tools—especially handheld expansion and cinch clamp tools—that allow for minimal wall disruption and faster installation.

3. Technological Advancements in Tool Design

By 2026, PEX tools are expected to incorporate smart features such as wireless connectivity, torque calibration, and battery optimization. Leading manufacturers are integrating IoT capabilities into powered expansion tools, enabling real-time performance tracking and quality assurance. These innovations improve accuracy, reduce human error, and support compliance with building codes.

4. Shift Toward Battery-Powered and Cordless Tools

The trend toward cordless power tools across the construction industry is extending to PEX installation. Battery-powered PEX expansion and crimping tools offer greater mobility, especially in unfinished or remote job sites. Advancements in lithium-ion battery technology are enhancing tool runtime and durability, making cordless options increasingly preferred by professional plumbers.

5. Emphasis on Tool Standardization and Compatibility

As PEX tubing brands (e.g., Uponor, Rehau, Viega) expand their product lines, tool manufacturers are focusing on multi-system compatibility. By 2026, tools capable of working with various PEX connection methods (crimp, clamp, expansion) are expected to dominate the market. This reduces the need for plumbers to carry multiple tools, improving efficiency and reducing costs.

6. Expansion in Emerging Markets

While North America remains the largest market for PEX tools, regions such as Latin America, Southeast Asia, and parts of Eastern Europe are witnessing growing adoption of PEX plumbing due to urbanization and infrastructure development. This creates new opportunities for tool manufacturers to expand distribution and offer cost-effective, durable solutions tailored to local conditions.

7. Sustainability and Regulatory Influence

Green building standards and water conservation regulations are encouraging the use of PEX systems, which reduce leaks and water waste. Tools that support precise, leak-free installations will be in higher demand. Additionally, regulations requiring certified installation practices may increase the use of calibrated, professional-grade tools over manual alternatives.

8. Increased Competition and Market Consolidation

The PEX tool market is seeing heightened competition among key players such as Milwaukee, Ridgid, Paladin, and SharkBite. By 2026, expect further consolidation through acquisitions and partnerships, as companies aim to broaden their product portfolios and enhance R&D capabilities. This could lead to more integrated tool ecosystems (e.g., tool-battery-accessory compatibility across product lines).

Conclusion

By 2026, the Tools for PEX market will be characterized by innovation, increased automation, and broader global adoption. Plumbers and contractors will increasingly rely on smart, efficient, and versatile tools to meet the demands of modern construction. Manufacturers that prioritize ergonomics, compatibility, and sustainability are likely to lead the market, positioning PEX tools as essential components in the future of plumbing infrastructure.

Common Pitfalls Sourcing Tools For PEX (Quality, IP)

Sourcing tools for cross-linked polyethylene (PEX) plumbing and radiant heating systems—such as crimpers, expansion tools, cutters, and fittings—can be fraught with challenges, particularly concerning quality and intellectual property (IP). Avoiding these pitfalls is essential to ensure system reliability, long-term performance, and legal compliance.

Poor Tool Quality Leading to System Failures

One of the most significant risks when sourcing PEX tools is selecting low-quality or counterfeit equipment. Inferior tools often fail to meet precise specifications required for reliable PEX connections. For example, poorly calibrated crimpers or expanders may result in inconsistent ring compression or over-expansion of tubing, leading to leaks, joint failures, and costly repairs. Cheap tools may also wear out quickly, increasing maintenance costs and downtime. Always verify that tools comply with industry standards such as ASTM F1807 or ASTM F2159 and opt for reputable manufacturers with proven track records.

Use of Non-Branded or Generic Tools with Compatibility Issues

Many generic or off-brand tools are marketed as compatible with leading PEX systems (e.g., Uponor, Viega, or Rehau), but they may not meet the exact tolerances required by these proprietary systems. Using non-approved tools can void warranties on PEX components and may not ensure a proper seal. Contractors risk liability if system failures occur due to incompatible tools. Always consult manufacturer guidelines and use tools specifically approved or recommended for the PEX brand being installed.

Intellectual Property (IP) Infringement Risks

Sourcing tools that replicate patented designs—such as proprietary expansion heads, calibration mechanisms, or ratcheting systems—can expose buyers and distributors to legal risks. Many PEX tool designs are protected by utility or design patents. Using or distributing counterfeit or clone tools infringes on these IP rights, potentially resulting in lawsuits, fines, or seizure of goods. Sourcing from authorized distributors or directly from IP holders ensures compliance and supports innovation within the industry.

Lack of Certification and Traceability

Tools lacking proper certification (e.g., ISO standards, UL listing, or manufacturer validation) present a hidden risk. Without traceability or documentation, it becomes difficult to verify tool performance or defend against liability claims after a failure. Certified tools undergo rigorous testing and are more likely to deliver consistent results. Always request documentation and verify tool traceability through batch numbers or serial tracking when available.

Inadequate Training and Support

Low-cost tools often come without adequate training materials, technical support, or service networks. This lack of support can lead to improper use, reducing tool lifespan and increasing the chance of installation errors. Reputable suppliers typically offer training resources, warranties, and customer service—key components in ensuring proper tool use and long-term reliability.

In summary, prioritizing quality, compatibility, and IP compliance when sourcing PEX tools protects both the integrity of plumbing systems and the legal standing of contractors and distributors. Investing in certified, brand-approved tools from trusted suppliers mitigates risk and ensures optimal performance.

Logistics & Compliance Guide for Tools For Pex

This guide outlines the essential logistics and compliance procedures for handling Tools For Pex products. Adhering to these guidelines ensures efficient operations, regulatory compliance, and customer satisfaction.

Product Handling and Storage

Store Tools For Pex in a dry, temperature-controlled environment to prevent damage to tools and packaging. Keep items off the floor on pallets or shelves to avoid moisture exposure and contamination. Ensure proper ventilation and protect from direct sunlight to maintain tool integrity.

Inventory Management

Maintain accurate real-time inventory tracking using barcode scanning or RFID systems. Conduct regular cycle counts to reconcile physical stock with digital records. Implement a first-in, first-out (FIFO) rotation system to minimize obsolescence and ensure freshness of product batches.

Shipping and Distribution

Package Tools For Pex securely using manufacturer-approved materials to prevent transit damage. Label all shipments with clear SKU identifiers, barcodes, and handling instructions. Use certified carriers with tracking capabilities and comply with shipping regulations for both domestic and international deliveries.

Regulatory Compliance

Ensure all Tools For Pex products meet relevant safety and quality standards (e.g., OSHA, CE, RoHS). Maintain documentation including certificates of compliance, material safety data sheets (MSDS), and import/export licenses where applicable. Regularly audit compliance processes to align with evolving regulations.

Import and Export Requirements

For cross-border shipments, verify customs documentation including commercial invoices, packing lists, and Harmonized System (HS) codes specific to plumbing and installation tools. Confirm adherence to trade sanctions and restricted party screening protocols. Partner with licensed customs brokers to facilitate smooth clearance.

Environmental and Safety Standards

Dispose of packaging waste in accordance with local environmental regulations. Train staff on proper handling of tools, especially those with electrical or mechanical components. Report and document any incidents involving tool malfunction or safety concerns per internal and regulatory requirements.

Recordkeeping and Audits

Retain all logistics and compliance records for a minimum of seven years. This includes shipping logs, compliance certifications, inspection reports, and training records. Prepare for internal and third-party audits by maintaining organized, accessible documentation.

Training and Accountability

Provide regular training to logistics and warehouse personnel on compliance policies, handling procedures, and safety protocols. Assign compliance officers to oversee adherence and serve as points of contact for audits or regulatory inquiries.

Conclusion on Sourcing Tools for PEX (Cross-Linked Polyethylene) Installation

Selecting the appropriate sourcing tools for PEX (cross-linked polyethylene) installation is crucial to ensuring a reliable, efficient, and durable plumbing system. The variety of PEX types—PEX-A, PEX-B, and PEX-C—each require compatible tools and connection methods, such as crimp, clamp (cinch), or expansion systems. When sourcing tools, it’s essential to consider compatibility with the specific PEX type and fittings being used.

Crimping tools are cost-effective and widely used but require precise application to ensure secure, leak-free joints. Clamp tools offer easier visual inspection of connections and are particularly suitable for tight spaces. Expansion tools, while more expensive, provide the most secure connections and are ideal for professional installations, especially with PEX-A tubing.

Investing in high-quality, brand-specific or universally compatible tools from reputable manufacturers ensures long-term performance and minimizes the risk of failures. Additionally, including essential accessories—such as tubing cutters, deburring tools, and calibration gauges—into the sourcing plan enhances productivity and connection integrity.

Ultimately, the right sourcing strategy balances cost, compatibility, ease of use, and long-term reliability. Proper training and adherence to manufacturer guidelines further ensure optimal results. By carefully evaluating project needs and tool specifications, contractors and plumbing professionals can source the most effective tools for successful PEX system installations.