The global market for plumbing fixtures and components, including essential parts like toilet tank washers, continues to expand steadily, driven by rising residential and commercial construction, urbanization, and increased focus on water efficiency. According to a report by Grand View Research, the global plumbing fixtures market size was valued at USD 95.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth trajectory underscores the increasing demand for durable, leak-proof components such as toilet tank washers, which play a critical role in ensuring the efficient operation of flush systems. As reliance on low-maintenance and water-saving plumbing solutions intensifies, manufacturers specializing in precision washers are gaining prominence. Based on market presence, product quality, innovation, and distribution reach, here are the top 9 toilet tank washers manufacturers shaping the industry.

Top 9 Toilet Tank Washers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

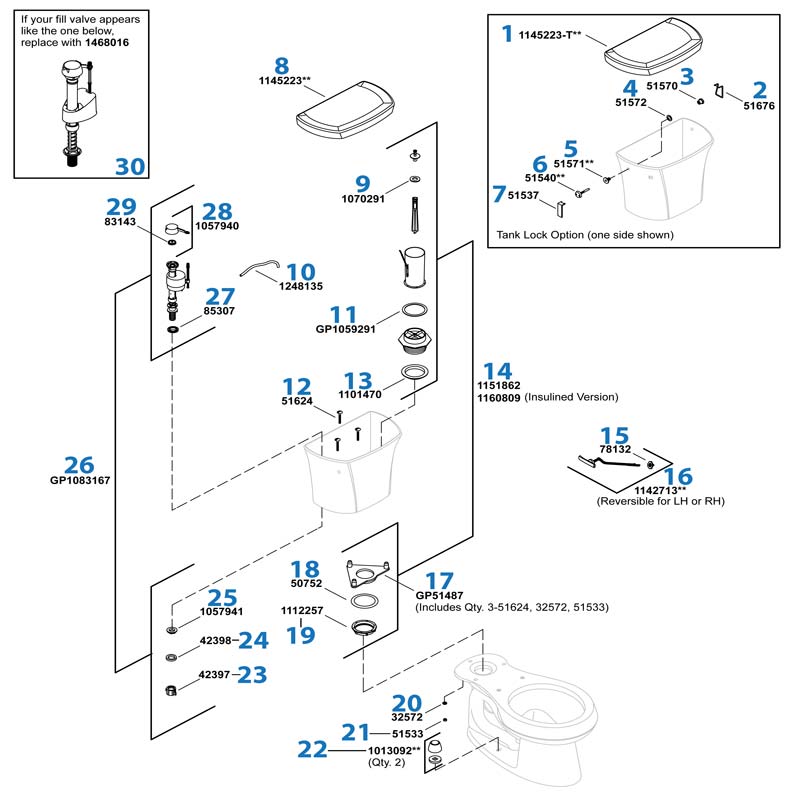

#1 KOHLER Service & Replacement Parts

Domain Est. 1994

Website: kohler.com

Key Highlights: Find you part in the KOHLER Toilets and KOHLER Faucets Service Parts Books. Product Support. Information on product installation, troubleshooting, ……

#2 Korky® Toilet Repair

Domain Est. 1995

Website: korky.com

Key Highlights: We are continuously committed to designing repair parts that are universal to fit the majority of toilets. Korky manufactures in the United States to provide ……

#3 Plumbing & Toilet Trim

Domain Est. 1995

Website: lavelle.com

Key Highlights: Plumbing & Toilet Trim. We manufacture a complete line of standard and custom plumbing products. When you choose a rubber part for a plumbing application ……

#4 Toilet Tank

Domain Est. 1995

Website: plumbingsupply.com

Key Highlights: Free delivery over $98.99Find replacement tank-to-bowl gaskets, toilet bolt kits, and everything you’ll need to fix a leak or get your toilet tank in tip-top shape again….

#5 Harvey® Tank

Domain Est. 1996

Website: oatey.com

Key Highlights: Each kit includes a double thick rubber sponge gasket, brass tank bolts, cloth reinforced rubber washers, heavy round washers and brass hex nuts….

#6 Toilet Parts

Domain Est. 2001

Website: portland-michigan.org

Key Highlights: View a list of various toilet parts and their functions….

#7 Recommended way to bolt toilet tank

Domain Est. 2009

Website: diy.stackexchange.com

Key Highlights: All rubber washers are always used closest to where water could possibly leak out. Metal washers back them up for strength in sealing….

#8 Toilets Page

Domain Est. 2020

Website: gerber-us.com

Key Highlights: The construction coupled with the tank components make for a great working toilet at an even better value….

#9 Toilet Nuts, Bolts & Washers

Domain Est. 1996

Expert Sourcing Insights for Toilet Tank Washers

H2: 2026 Market Trends for Toilet Tank Washers

The global market for toilet tank washers is anticipated to undergo significant transformation by 2026, driven by advancements in plumbing technology, growing emphasis on water conservation, and rising demand for hygienic bathroom solutions. As a critical yet often overlooked component in flush mechanisms, toilet tank washers are evolving to meet higher durability, efficiency, and sustainability standards.

One major trend shaping the 2026 market is the integration of eco-friendly materials. Manufacturers are increasingly replacing traditional rubber washers with synthetic elastomers and food-grade silicone compounds that offer longer lifespans and resistance to mineral buildup, thereby reducing maintenance frequency and water waste from leaks. This shift aligns with global water-saving regulations, especially in regions like Europe and North America, where water efficiency standards (e.g., EPA’s WaterSense) are pushing for low-leakage components.

Another key trend is the rise of smart toilet systems. While primarily focused on bidets and self-cleaning features, smart toilets require reliable and high-performance internal components, including advanced tank washers designed for consistent sealing under fluctuating water pressures. As smart toilet adoption grows—particularly in Asia-Pacific markets like Japan and South Korea—demand for precision-engineered washers compatible with automated flushing systems is expected to rise.

Additionally, the aftermarket and DIY plumbing sector continues to expand, fueled by homeowners seeking cost-effective repairs. This has led to increased availability of universal-fit and heavy-duty toilet tank washers in retail and e-commerce channels. By 2026, product lines emphasizing ease of installation, compatibility with multiple valve types (e.g., ballcock, flapperless), and clear labeling are expected to dominate consumer preferences.

Regionally, emerging markets in Latin America, Africa, and Southeast Asia will contribute to market growth due to urbanization and infrastructure development. However, these regions also present challenges related to inconsistent water quality, prompting demand for corrosion-resistant and scale-resistant washer materials.

In summary, the 2026 toilet tank washer market will be shaped by sustainability mandates, smart plumbing integration, material innovation, and expanding access to maintenance solutions. Companies that prioritize longevity, compatibility, and environmental compliance are likely to lead in this niche but essential segment of the bathroom fixtures industry.

Common Pitfalls When Sourcing Toilet Tank Washers (Quality, IP)

Sourcing toilet tank washers—especially when considering quality and intellectual property (IP) protection—can present several hidden challenges. Being aware of these pitfalls helps ensure reliable performance, legal compliance, and long-term cost savings.

Poor Material Quality Leading to Premature Failure

One of the most frequent issues is sourcing washers made from substandard materials. Low-quality rubber or silicone compounds degrade quickly when exposed to water, chlorine, and common tank additives. This leads to cracking, hardening, or swelling, resulting in leaks and frequent replacements. Always verify material specifications (e.g., EPDM rubber) and request durability test reports.

Inconsistent Dimensional Tolerances

Inferior washers often suffer from inconsistent sizing and poor manufacturing tolerances. Even slight deviations can prevent a proper seal between the tank and flush valve or fill valve, causing water seepage and inefficient operation. Ensure suppliers adhere to ISO or industry-standard dimensional controls and provide sample testing.

Lack of IP Due Diligence and Risk of Infringement

Sourcing from manufacturers that replicate patented washer designs without authorization exposes buyers to intellectual property risks. Using counterfeit or infringing components can result in legal action, shipment seizures, or reputational damage. Conduct thorough IP audits and require suppliers to provide proof of design rights or licensing agreements.

Misrepresentation of Certification and Compliance

Some suppliers falsely claim compliance with water efficiency standards (e.g., NSF/ANSI 61, WRAS, or ASSE). Using non-compliant washers may violate plumbing codes and affect product certifications. Request valid, up-to-date certification documents and consider third-party verification.

Supplier Reliability and Hidden Costs

Choosing suppliers solely on low price can backfire. Unreliable manufacturing partners may deliver inconsistent batches, delay shipments, or vanish altogether. Hidden costs from returns, warranty claims, or downtime often outweigh initial savings. Perform supplier audits and establish long-term quality agreements.

Inadequate Packaging and Storage Conditions

Even high-quality washers can degrade if stored or shipped improperly. Exposure to UV light, extreme temperatures, or humidity during transit can compromise material integrity. Confirm that suppliers use protective packaging and follow proper storage protocols to maintain product integrity.

Logistics & Compliance Guide for Toilet Tank Washers

Product Classification and Regulatory Overview

Toilet tank washers are mechanical components used in flush toilets to regulate water flow and ensure proper tank sealing. These parts are typically classified under plumbing or bathroom fixtures. Depending on the material composition (e.g., rubber, silicone, brass, or plastic), regional regulations may apply, including environmental standards, material safety, and import/export compliance.

International Shipping and Customs Requirements

When shipping toilet tank washers internationally, ensure compliance with destination country customs regulations. Key steps include:

– Assigning the correct Harmonized System (HS) code—commonly 8481.80 (parts for taps, valves, and similar appliances) or 9023.00 (parts for sanitary appliances), depending on design.

– Preparing accurate commercial invoices, packing lists, and certificates of origin.

– Verifying if the shipment requires special labeling or documentation (e.g., bilingual labeling in Canada or CE marking in the EU).

Material Safety and Environmental Compliance

Toilet tank washers must meet material safety standards, especially if they come into contact with potable water. Key compliance areas include:

– NSF/ANSI 61: Required in the U.S. for components that contact drinking water, ensuring no harmful leaching of substances.

– RoHS (EU): Restricts hazardous substances in electrical and electronic components; applicable if washers contain metal alloys or conductive materials.

– REACH (EU): Requires disclosure of Substances of Very High Concern (SVHC) in products exceeding threshold limits.

– California Proposition 65: Mandates warning labels if components contain listed carcinogens or reproductive toxins.

Packaging and Storage Guidelines

Proper packaging ensures product integrity and regulatory compliance during transit:

– Use moisture-resistant and crush-proof packaging to prevent deformation, especially for rubber or silicone washers.

– Include desiccants if shipping to high-humidity regions.

– Label packages with handling instructions (e.g., “Do Not Stack,” “Keep Dry”) and include batch/lot numbers for traceability.

– Store in a cool, dry environment away from direct sunlight and ozone sources to prevent material degradation.

Import and Distribution Compliance by Region

- United States: Comply with EPA WaterSense guidelines if marketed as water-efficient; ensure adherence to state plumbing codes (e.g., UPC or IPC).

- European Union: CE marking may be required under Construction Products Regulation (CPR) or Pressure Equipment Directive (PED), depending on application.

- Canada: Meet requirements under the Canadian Standards Association (CSA B125 series) for plumbing fittings.

- Australia/New Zealand: Comply with AS/NZS 3500 plumbing code and obtain WaterMark certification for plumbing products.

Documentation and Recordkeeping

Maintain comprehensive records for compliance audits and traceability:

– Material declarations (e.g., RoHS, REACH, Proposition 65).

– Test reports for NSF/ANSI 61 or equivalent certifications.

– Batch production records and supplier certifications.

– Customs documentation and import licenses where applicable.

Conclusion

Effective logistics and compliance for toilet tank washers require attention to material regulations, accurate classification, proper packaging, and adherence to regional standards. Proactive documentation and certification management minimize delays, ensure market access, and support product safety and performance.

Conclusion for Sourcing Toilet Tank Washers:

In conclusion, sourcing toilet tank washers requires a balanced approach that considers quality, compatibility, cost-efficiency, and supplier reliability. It is essential to identify washers made from durable, water-resistant materials such as rubber or silicone that ensure leak-free performance and long service life. Standardization of sizes and adherence to plumbing specifications help in maintaining compatibility across various toilet models. Evaluating suppliers based on reputation, lead times, and ability to provide consistent quality in bulk is crucial for minimizing downtime and maintenance issues. Additionally, exploring local and global sourcing options can provide cost advantages without compromising on reliability. Ultimately, a well-structured sourcing strategy for toilet tank washers supports operational efficiency, reduces maintenance costs, and contributes to the overall reliability of plumbing systems in residential, commercial, or industrial settings.