The global tire stud removal tool market is experiencing steady growth, driven by increasing automotive production, rising demand for vehicle maintenance solutions, and the expanding aftermarket sector. According to Grand View Research, the global automotive aftermarket tools market was valued at USD 48.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This upward trajectory reflects heightened consumer focus on vehicle upkeep and the growing need for specialized tools like tire stud removers in both professional repair shops and DIY environments. As demand for precision, durability, and efficiency rises, manufacturers are innovating to deliver high-performance solutions tailored to diverse vehicle types and user requirements. In this evolving landscape, nine key manufacturers have emerged as leaders, combining engineering excellence with data-backed product development to meet the needs of a global customer base.

Top 9 Tire Stud Removal Tool Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ken

Domain Est. 1998

Website: kentool.com

Key Highlights: Ken-Tool is the leading manufacturer of tire service tools in the world. Headquartered in Akron, Ohio, Ken-Tool has been providing the tire industry and ……

#2 ESCO

Domain Est. 1997

Website: esco.net

Key Highlights: ESCO is the world leader in manufacturing and supplying quality tire service equipment for the automotive, agricultural, commercial truck, off-the-road (OTR), ……

#3 Stud Removal

Domain Est. 1997

#4 71200 Stud Remover

Domain Est. 1998

Website: lislecorp.com

Key Highlights: Allows for easy removal of studs. Tool has two holes, 1/2″ (14mm) and 3/4″ (19mm) for optimum fit, minimizing damage to threads. Range ……

#5 8 Piece SAE/Metric Stud Removal Set

Domain Est. 1999

Website: gearwrench.com

Key Highlights: Count on GEARWRENCH to get the job done with our innovative tools. Check out the GEARWRENCH 41760D 8 Pc. SAE/Metric Stud Removal Set here….

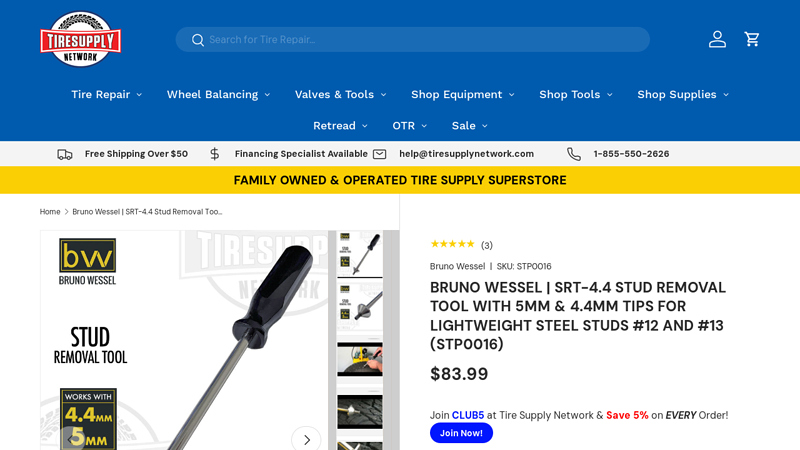

#6 Stud Removal Tool

Domain Est. 2000

Website: brunowessel.com

Key Highlights: For use on steel bodied passenger/light truck studs TSMI sizes 11 through 17; Works on both new and used studs; Replaceable tip 5MM (included); This tool is ……

#7 Stud Installation Tool

Domain Est. 2009

Website: gripstuds.com

Key Highlights: Grip Studs handy tools are designed to install and remove tire or footwear studs. The power tools chuck into variable speed drills for ease of installation….

#8 SRT

Domain Est. 2018

#9 MT

Domain Est. 2024

Website: garagesupplyguys.com

Key Highlights: In stock $25.57 deliveryMT-RSR 14-34R wheel stud remover tool for 3/4″ studs. A must-have for easy and efficient wheel stud removal in automotive repairs….

Expert Sourcing Insights for Tire Stud Removal Tool

2026 Market Trends for Tire Stud Removal Tool

The tire stud removal tool market is poised for notable evolution by 2026, shaped by changing vehicle technologies, shifting consumer behaviors, and advancements in tool design. While remaining a niche sector within the broader automotive tool industry, several key trends are expected to influence demand, innovation, and competition.

Growing DIY Automotive Maintenance Culture

A significant driver for the tire stud removal tool market is the continued rise of do-it-yourself (DIY) automotive maintenance. Increasing vehicle complexity and higher labor costs at repair shops are pushing more vehicle owners—especially among younger demographics and budget-conscious consumers—to perform basic repairs themselves. Tire stud replacement, often necessary after wheel damage or seasonal tire changes in snowy regions, is a common DIY task. By 2026, online tutorials, accessible toolkits, and e-commerce platforms will further empower this trend, boosting demand for reliable, user-friendly stud removal tools.

Expansion in Electric Vehicle (EV) Adoption

The rapid growth of the electric vehicle market will indirectly impact tire tool demand. EVs often feature heavier curb weights and different torque specifications, which can place additional stress on wheel studs. Moreover, many EV owners tend to be tech-savvy and inclined toward DIY maintenance and modifications. As EV ownership increases globally, particularly in North America and Europe, the need for durable, precision-engineered tools—including stud removers capable of handling unique EV wheel setups—will grow. Manufacturers may begin tailoring tools to meet the specific requirements of EV wheel assemblies.

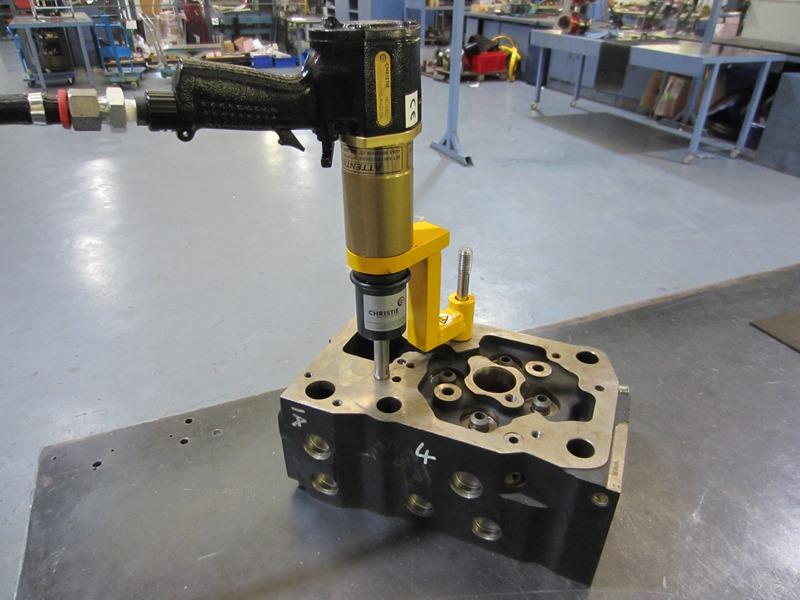

Technological Advancements in Tool Design

By 2026, expect to see innovation in material science and ergonomics within the tire stud removal tool segment. High-strength, lightweight materials such as heat-treated chromoly steel or advanced composites will enhance durability and reduce user fatigue. Features like anti-slip grips, integrated extraction sleeves, and compatibility with impact wrenches will become standard in premium models. Additionally, smart tools equipped with torque sensors or connected via mobile apps for usage analytics could emerge, particularly targeting professional mechanics and fleet service centers.

Regional Market Dynamics and Seasonality

Demand for tire stud removal tools remains highly seasonal and region-dependent, peaking in colder climates during fall and winter tire changeovers. North America, Northern Europe, and parts of Asia (e.g., Japan, mountainous regions of China) will continue to be key markets. By 2026, climate change may slightly shift these seasonal patterns, but the fundamental need for stud maintenance in snow-prone areas will persist. E-commerce platforms will play a crucial role in meeting regional spikes in demand through just-in-time inventory and targeted marketing.

Sustainability and Circular Economy Considerations

As environmental concerns grow, the automotive aftermarket sector—including tool manufacturers—is under increasing pressure to adopt sustainable practices. By 2026, consumers may favor brands that use recycled materials in tool production, offer repair or recycling programs, and minimize packaging waste. Tools designed for longevity and modular upgrades (e.g., replaceable tips) will appeal to eco-conscious buyers and professional workshops aiming to reduce tool replacement costs.

Increased Competition and Market Consolidation

The tire stud removal tool market will likely experience intensified competition by 2026, with both established tool brands and new entrants vying for market share. Online marketplaces like Amazon and specialized auto parts retailers will amplify visibility and price transparency, pushing manufacturers toward differentiation through quality, warranties, and customer support. Smaller brands may focus on niche applications (e.g., off-road, heavy-duty trucks), while larger players could consolidate through acquisitions or expand product lines to include full wheel service kits.

In conclusion, the 2026 tire stud removal tool market will be shaped by the convergence of DIY culture, EV growth, technological innovation, and sustainability. Success will depend on a manufacturer’s ability to anticipate user needs, leverage digital sales channels, and adapt to the evolving automotive landscape.

Common Pitfalls When Sourcing a Tire Stud Removal Tool (Quality and Intellectual Property)

Sourcing a tire stud removal tool may seem straightforward, but overlooking key quality and intellectual property (IP) factors can lead to costly setbacks, including product failure, legal disputes, and reputational damage. Below are common pitfalls to avoid:

Poor Material Quality and Durability

Many low-cost suppliers use substandard steel or alloys that lack the hardness and tensile strength required for repeated use. This results in tools that deform, break, or strip lug studs, increasing downtime and customer dissatisfaction.

Inadequate Heat Treatment

Even with decent raw materials, improper heat treatment compromises performance. Tools that aren’t correctly hardened or tempered may wear quickly or fail under torque, especially when removing rusted or over-tightened studs.

Inconsistent Manufacturing Tolerances

Lack of precision in machining leads to misaligned sockets or uneven force distribution. This can damage wheel hubs, studs, or the tool itself—particularly problematic in high-torque applications.

Lack of Functional Testing

Suppliers may not conduct real-world testing under load conditions. Without verification, tools may perform acceptably in theory but fail in actual automotive environments, leading to warranty claims and returns.

Copying Branded Designs Without Licensing

A significant IP risk arises when sourcing tools that closely mimic patented designs from major brands (e.g., OEM or well-known aftermarket tools). Replicating unique geometries, ratcheting mechanisms, or socket configurations without proper licensing exposes buyers to infringement lawsuits.

Use of Counterfeit or Gray Market Goods

Some suppliers offer “compatible” tools that are outright counterfeits. These not only violate IP rights but also lack traceability and quality control, increasing liability risks for distributors and end users.

Incomplete or Missing Documentation

Reputable tools should come with documentation proving compliance with industry standards (e.g., ISO, DIN) and material certifications. Omitting these makes it difficult to verify quality or defend against product liability claims.

Overlooking Design Patents and Utility Models

Even if a tool appears generic, specific mechanisms—such as quick-release features or ergonomic handles—may be protected by utility patents or design rights. Failing to conduct an IP clearance search before mass production can result in costly redesigns or legal action.

Ignoring Trademark Infringement

Using logos, branding elements, or packaging that resembles established brands—even unintentionally—can lead to trademark disputes. This includes labeling tools with misleading brand names or model numbers.

Supply Chain Transparency Issues

Without vetting sub-suppliers or conducting factory audits, buyers may unknowingly source tools produced in facilities that violate IP rights or use unauthorized tooling, further exposing them to legal and reputational risk.

To mitigate these pitfalls, conduct thorough due diligence: request material certifications, perform third-party testing, consult IP counsel for design clearance, and ensure supplier agreements include IP indemnification clauses.

Logistics & Compliance Guide for Tire Stud Removal Tool

Product Classification & Tariff Codes

Ensure accurate classification of the Tire Stud Removal Tool under the appropriate Harmonized System (HS) code for international shipping. Common classifications may fall under hand tools (e.g., HS 8205.40 for other hand tools made of base metal). Confirm the correct code with your customs broker or national tariff database to avoid delays and ensure accurate duty assessment.

Import/Export Regulations

Verify compliance with import and export regulations in both origin and destination countries. Some jurisdictions may impose restrictions on metal tools or require specific labeling. For export from the U.S., check if the item is subject to EAR (Export Administration Regulations). Most hand tools are designated as EAR99 and do not require a license for most destinations, but a final determination should be made based on end-use and destination.

Packaging & Labeling Requirements

Package the Tire Stud Removal Tool securely to prevent damage during transit. Include product identification, part number, country of origin, and any required safety warnings. Labeling must comply with destination country requirements, such as CE marking for the EU or ANSI standards if applicable. Use multilingual labels where necessary.

Safety & Environmental Compliance

Ensure the product meets mechanical safety standards for hand tools in target markets. While the Tire Stud Removal Tool is typically a simple mechanical device, verify compliance with regulations such as the EU’s Machinery Directive or OSHA guidelines in the U.S. Confirm that manufacturing materials comply with RoHS (Restriction of Hazardous Substances) if applicable.

Transportation & Shipping

Ship via ground or air freight depending on urgency and volume. Classify the tool correctly under IATA or IMDG regulations if shipped by air or sea—typically, non-hazardous. Use durable, stackable packaging to optimize space and reduce freight costs. Include proper shipping documentation, including commercial invoice, packing list, and bill of lading.

Customs Documentation

Prepare accurate customs documentation including:

– Commercial Invoice (with value, quantity, and HS code)

– Packing List

– Certificate of Origin (if claiming preferential tariffs under trade agreements)

Ensure all documents are complete and truthful to prevent customs delays or penalties.

Regulatory Certifications

Obtain necessary certifications based on target markets:

– CE Marking (for sale in the European Economic Area)

– UKCA Marking (for the United Kingdom)

– No specific certification is typically required in the U.S., but general consumer product safety standards apply.

Maintain records of compliance testing or manufacturer declarations.

Warranty & Product Liability

Clearly define warranty terms and include safety instructions with each unit. Include disclaimers regarding proper use to mitigate liability risks. Ensure the product liability insurance covers international sales, especially in regions with strict consumer protection laws.

End-of-Life & Recycling Considerations

Inform customers of proper disposal methods. As a metal tool, it is typically recyclable. Comply with WEEE (Waste Electrical and Electronic Equipment) directives if applicable, though most mechanical tools are exempt. Provide guidance on responsible end-of-life handling where required.

Recordkeeping & Audit Trail

Maintain comprehensive records of compliance documentation, shipping logs, certifications, and customs filings for a minimum of five years. This supports audits and ensures traceability in case of recalls or regulatory inquiries.

In conclusion, sourcing a reliable tire stud removal tool is essential for efficient and safe wheel maintenance, particularly in automotive repair shops, fleet operations, or for serious DIY enthusiasts. The ideal tool should combine durability, ease of use, and compatibility with various stud sizes and vehicle types. When sourcing, it is important to consider factors such as build quality, customer reviews, brand reputation, and value for money. Exploring reputable suppliers, comparing options from both online and local vendors, and verifying warranty or return policies can ensure a wise investment. Ultimately, selecting the right tire stud removal tool enhances productivity, reduces the risk of damage to wheel components, and supports long-term reliability in vehicle maintenance tasks.