The global time delay fuse market is experiencing steady growth, driven by rising demand for circuit protection across industrial, automotive, and consumer electronics sectors. According to a report by Mordor Intelligence, the global fuse market is projected to grow at a CAGR of over 6.8% from 2023 to 2028, with time delay (or slow-blow) fuses capturing an increasing share due to their ability to withstand temporary current surges without tripping. This makes them ideal for applications involving motors, transformers, and power supplies. Additionally, Grand View Research highlights that advancing automation, coupled with stringent safety regulations in electrical systems, is further fueling adoption. As industries prioritize reliable overcurrent protection, manufacturers specializing in time delay fuses are scaling production and innovating to meet evolving technical standards. In this competitive landscape, seven key players have emerged as leaders, combining technological expertise, global reach, and robust product portfolios to dominate the market.

Top 7 Time Delay Fuses Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fuses and fuse holders

Domain Est. 1996

Website: eaton.com

Key Highlights: Bussmann series fuses play a major role in industrial or commercial facilities by providing reliable, maximum protection to power systems….

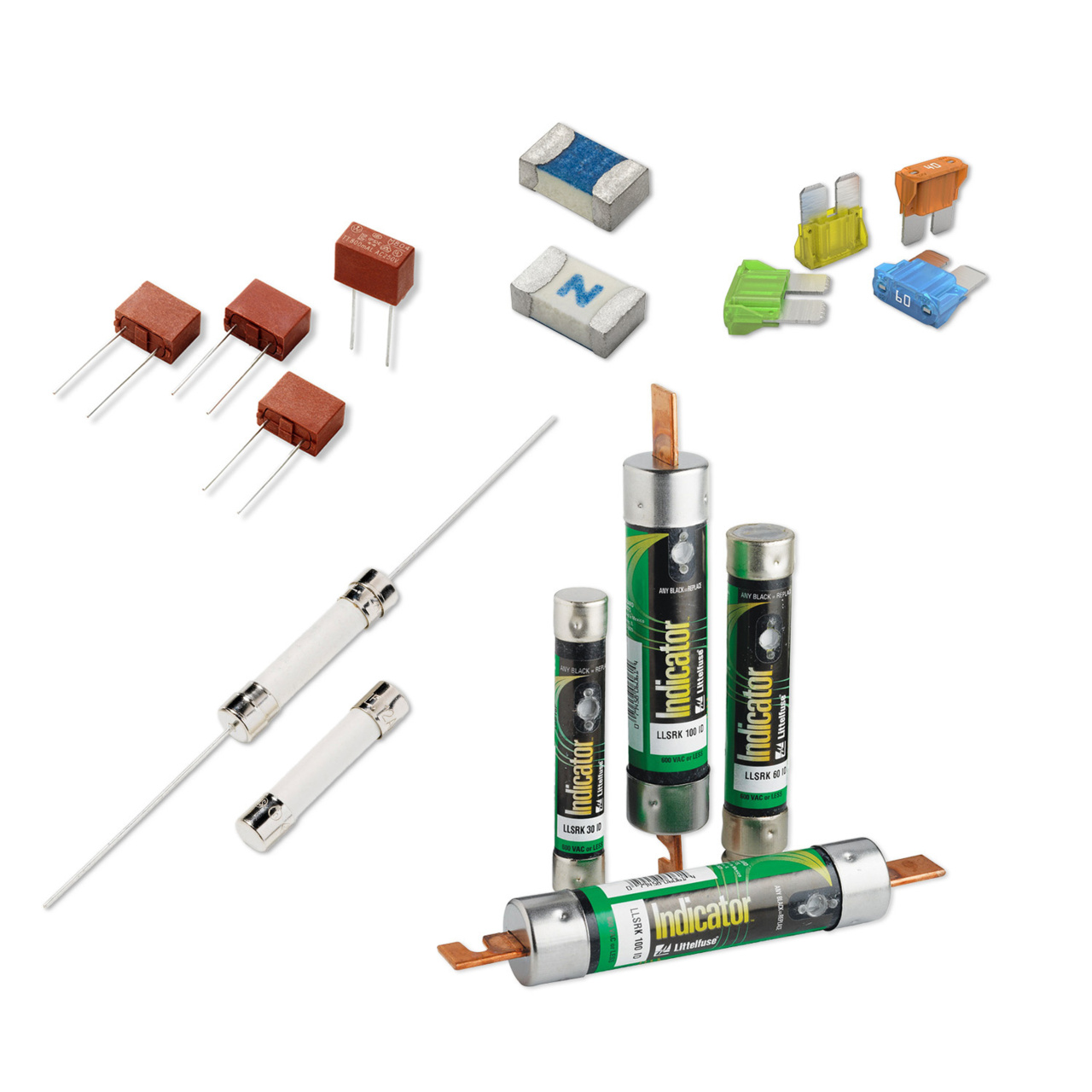

#2 Fuses: Types & Sizes

Domain Est. 1996

Website: littelfuse.com

Key Highlights: We offer a broad selection of fuse types, such as electrical and industrial fuses. Our industrial fuses are designed to deliver reliable overcurrent protection….

#3 GDG

Domain Est. 2006

Website: us.mersen.com

Key Highlights: Mersen is a global expert in electrical power and advanced materials for high-tech industries. With more than 50 industrial sites and 21 R&D centers in 33 ……

#4 Time Delay Automotive Fuses

Domain Est. 1994

Website: newark.com

Key Highlights: Free delivery over $150 · 60-day returnsFind a huge range of Time Delay Automotive Fuses at Newark Electronics. We stock a wide range of Automotive Fuses, such as Fast Acting, ……

#5 Time Delay Fuse

Domain Est. 1997

#6 Time Delay Fuses

Domain Est. 1999

Website: baypower.com

Key Highlights: Bay Power offers an extensive selection of time delay fuses. Get 15 Amp to 30 Amp time delay fuses, and more, with lightning-fast shipping and expert ……

#7 Buss Fuses

Domain Est. 2009

Website: bussfuses.net

Key Highlights: The following Bussmann Fuses fall under general or special purpose fuses class: ; Plug Fuse, Dual Element, Time Delay Fuse, S ; Rejection Base Fuse Adapter, SA….

Expert Sourcing Insights for Time Delay Fuses

H2: Projected Market Trends for Time Delay Fuses in 2026

The global market for time delay fuses is anticipated to experience steady growth by 2026, driven by increasing demand for reliable circuit protection in industrial automation, renewable energy systems, and consumer electronics. A key trend shaping the market is the rising integration of time delay fuses in electric vehicle (EV) charging infrastructure, where their ability to withstand temporary current surges without nuisance tripping enhances system reliability. Additionally, growing investments in smart grid technologies across North America, Europe, and parts of Asia-Pacific are expected to boost demand for protective components like time delay fuses.

Another significant trend is the shift toward compact and high-performance fuse designs that support miniaturization in modern electronic devices. Manufacturers are focusing on developing advanced materials and hybrid fuse technologies that offer improved thermal stability and longer operational life. This innovation is particularly evident in the telecommunications and data center sectors, where uninterrupted power supply and surge protection are critical.

Regulatory standards and safety certifications are also influencing market dynamics. Stricter electrical safety regulations in emerging economies are prompting industries to adopt compliant protection solutions, further expanding the addressable market for time delay fuses. Moreover, the ongoing industrial modernization in regions such as India, Southeast Asia, and Latin America is creating new opportunities for market players.

In terms of competitive landscape, key manufacturers are investing in R&D and strategic partnerships to enhance product portfolios and expand regional distribution networks. The market is expected to remain moderately consolidated, with leading companies emphasizing sustainability and digital manufacturing to gain a competitive edge.

Overall, by 2026, the time delay fuse market is projected to grow at a CAGR of approximately 4.5–5.5%, reaching an estimated market value of USD 1.8–2.1 billion, depending on regional adoption rates and technological advancements.

Common Pitfalls When Sourcing Time Delay Fuses (Quality, IP)

Sourcing time delay fuses may seem straightforward, but overlooking critical quality and intellectual property (IP) aspects can lead to system failures, safety hazards, and legal risks. Being aware of these common pitfalls helps ensure reliable and compliant procurement.

1. Prioritizing Cost Over Quality and Certification

One of the most frequent mistakes is selecting fuses based solely on the lowest price. Low-cost fuses often use substandard materials (e.g., inferior fuse elements, poor housing plastics) and lack proper quality control, leading to:

- Inconsistent time-delay characteristics

- Premature failure or nuisance blowing

- Risk of fire or equipment damage during overloads

- Non-compliance with safety standards (e.g., UL, IEC, CCC)

Always verify that fuses are certified by recognized bodies and meet the required industry standards for your application.

2. Ignoring Manufacturer Authenticity and Gray Market Risks

Counterfeit or gray market fuses are a serious concern. These products may bear legitimate brand names but are either fake, reconditioned, or sourced through unauthorized channels. Risks include:

- Lack of traceability and quality assurance

- Inaccurate performance under stress

- Potential IP infringement

- Voided warranties and liability in case of failure

Ensure you source from authorized distributors or directly from the manufacturer to avoid counterfeit components.

3. Overlooking Intellectual Property and Brand Licensing

Some time delay fuses incorporate patented technologies or designs. Sourcing generic alternatives without verifying IP rights can lead to:

- Infringement lawsuits, especially in regulated or export-sensitive markets

- Use of inferior knock-offs that don’t replicate the genuine product’s time-delay performance

- Damage to brand reputation if discovered in end products

Always confirm whether the fuse design is protected and whether the supplier has proper licensing agreements.

4. Inadequate Verification of Time-Delay Performance Specifications

Not all “time delay” fuses perform the same. Misunderstanding or assuming performance parameters (e.g., I²t values, withstand current, melting time) can result in:

- Incompatibility with inrush currents (e.g., in motors or power supplies)

- Failure to protect downstream components

- Unnecessary downtime due to tripping

Request detailed datasheets, test reports, and, if possible, conduct sample validation under real-world conditions.

5. Neglecting Environmental and Ingress Protection (IP) Ratings

For industrial or outdoor applications, the fuse’s housing must provide adequate protection against dust, moisture, and contaminants. Overlooking IP ratings can lead to:

- Corrosion or short circuits

- Reduced lifespan

- Safety hazards in harsh environments

Ensure the fuse’s IP rating (e.g., IP67) matches the intended operating environment. Sealed, ruggedized fuses are essential in demanding conditions.

6. Failing to Evaluate Supply Chain Reliability

Even high-quality fuses are useless if they’re unavailable when needed. Relying on suppliers with poor logistics or limited production capacity can disrupt manufacturing. Always assess:

- Supplier stability and reputation

- Lead times and minimum order quantities

- Long-term availability and lifecycle status

Choose partners who offer consistent supply and proactive obsolescence management.

By addressing these pitfalls proactively, you can ensure that the time delay fuses you source deliver the required performance, safety, and legal compliance.

Logistics & Compliance Guide for Time Delay Fuses

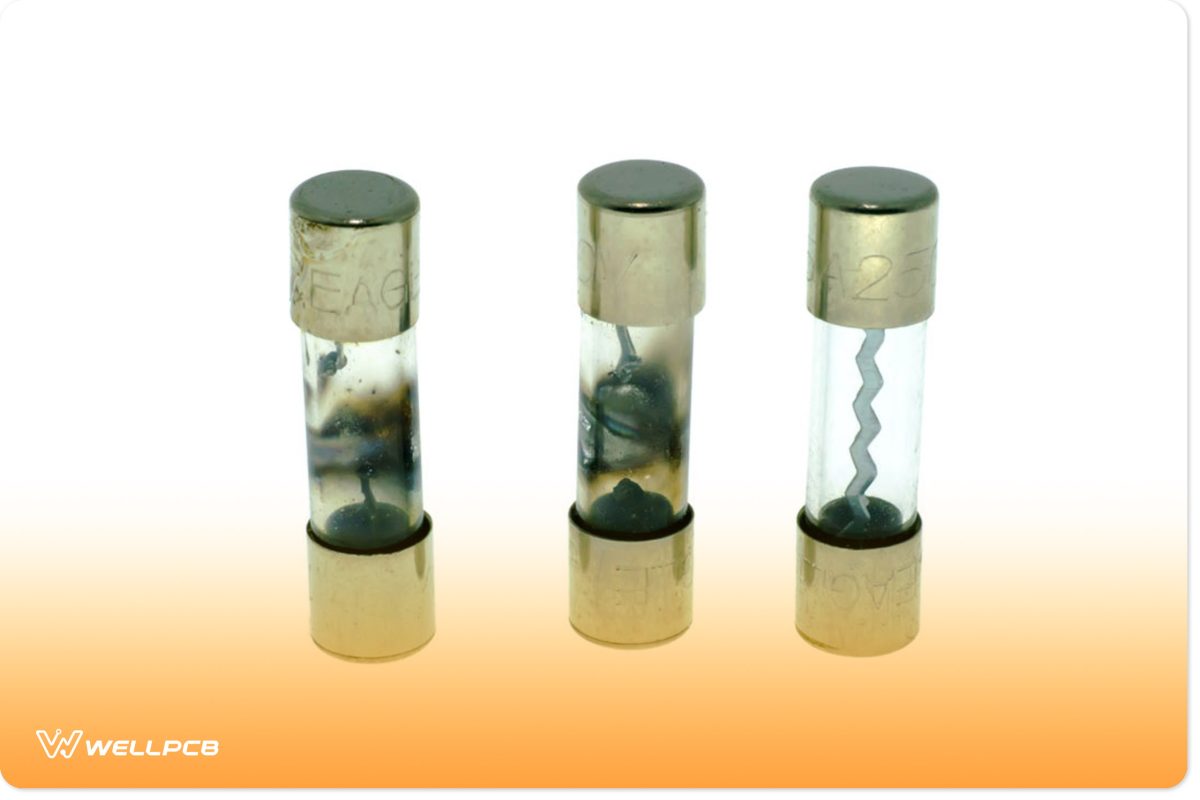

Overview of Time Delay Fuses

Time delay fuses, also known as slow-blow fuses, are designed to tolerate temporary current surges during equipment startup without blowing, while still providing protection against sustained overcurrents. Their unique characteristics necessitate specific handling, storage, transportation, and compliance protocols to ensure safety, reliability, and regulatory adherence.

Regulatory Compliance Requirements

Time delay fuses must comply with various international and national standards depending on the region and application. Key standards include:

– UL 248 (U.S.): Governed by Underwriters Laboratories; covers fuse types used in North America.

– IEC 60269 (International): Specifies requirements for low-voltage fuses used globally.

– CSA C22.2 No. 30 (Canada): Canadian standards for fuse safety and performance.

– RoHS & REACH (EU): Restrict hazardous substances in electrical components; ensure material declarations are provided.

– ATEX/IECEx (Hazardous Areas): Required if fuses are used in explosive atmospheres.

Ensure all fuses are certified with appropriate markings (e.g., UL, CSA, CE) and that technical documentation (e.g., test reports, DoC) is maintained.

Packaging and Labeling Standards

Proper packaging and labeling ensure product integrity and regulatory compliance:

– Use anti-static and moisture-resistant packaging for electronic-grade fuses.

– Label each package with:

– Fuse type, rating (voltage, current, breaking capacity)

– Time-delay characteristic (e.g., “T”, “D”)

– Manufacturer name and part number

– Compliance marks (UL, CE, etc.)

– Lot or batch number for traceability

– Handling symbols (e.g., “Fragile”, “Keep Dry”)

– Include multilingual labels if shipping internationally.

Storage Conditions

To maintain fuse performance and safety:

– Store in a clean, dry, temperature-controlled environment (15°C to 30°C recommended).

– Avoid exposure to extreme temperatures, humidity, dust, or corrosive atmospheres.

– Keep fuses in original sealed packaging until ready for use.

– Implement FIFO (First In, First Out) inventory management to prevent aging.

– Avoid stacking heavy items on fuse packaging to prevent physical damage.

Transportation and Handling

During logistics operations:

– Use shock-absorbent packaging and secure loads to prevent movement in transit.

– Avoid dropping or subjecting packages to mechanical stress.

– For air freight, ensure compliance with IATA regulations—fuses are generally non-hazardous but verify with carrier.

– Use temperature-controlled transport if stored in climate-sensitive environments.

– Maintain chain of custody documentation for high-reliability or safety-critical applications.

Import and Export Documentation

When shipping across borders:

– Prepare accurate commercial invoices, packing lists, and certificates of origin.

– Include product specifications and compliance certificates (e.g., UL, CE, RoHS).

– Classify fuses under the correct HS Code (e.g., 8536.10 for electrical fuses).

– Comply with destination country’s electrical safety and conformity assessment requirements.

– For shipments to the EU, ensure a responsible EU importer is designated under the CE marking framework.

Quality Assurance and Traceability

Maintain full product traceability throughout the supply chain:

– Record batch/lot numbers for every shipment received and distributed.

– Conduct periodic audits of storage conditions and inventory.

– Retain compliance documentation for a minimum of 10 years, per industry best practices.

– Partner only with certified manufacturers and authorized distributors.

Disposal and End-of-Life Management

Dispose of expired or damaged fuses responsibly:

– Follow WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions.

– Recycle metal components (e.g., copper, silver) through certified e-waste handlers.

– Avoid landfill disposal due to potential environmental impact of materials.

Conclusion

Adhering to proper logistics and compliance protocols for time delay fuses ensures operational safety, regulatory conformity, and product reliability. By following these guidelines—from certification and packaging to storage and disposal—supply chain stakeholders can mitigate risks and support consistent performance in critical electrical systems.

In conclusion, sourcing time delay fuses requires careful consideration of electrical specifications, application requirements, environmental conditions, and compliance standards. Time delay fuses are essential for protecting circuits that experience temporary inrush currents, such as those found in motors, transformers, and power supplies, without causing nuisance blowing. When sourcing these components, it is critical to match the fuse’s current and voltage ratings, time-delay characteristics, physical size, and breaking capacity to the specific needs of the system.

Working with reputable suppliers, ensuring product certifications (such as UL, CSA, or IEC), and verifying availability and lead times contribute to reliable and efficient sourcing. Additionally, maintaining a balance between cost, performance, and supply chain resilience helps ensure long-term operational reliability. By following best practices in selection and procurement, engineers and procurement teams can effectively integrate time delay fuses into their designs, enhancing system safety and longevity.