The global welding consumables market, driven by robust demand from construction, automotive, and manufacturing sectors, is projected to grow at a CAGR of 4.8% from 2023 to 2030, according to Grand View Research. With mild steel remaining the most widely welded material due to its versatility and cost-effectiveness, the demand for high-performance TIG filler rods continues to rise. In fact, the Asia Pacific region alone accounts for over 40% of global welding consumables consumption, fueled by rapid industrialization and infrastructure development. As manufacturers seek consistent weld quality, superior tensile strength, and optimal arc stability, the competition among TIG filler rod producers has intensified. Based on market presence, product performance, and technical specifications, the following nine manufacturers have emerged as leaders in supplying TIG filler rods for mild steel applications—delivering reliability in an increasingly data-driven industrial landscape.

Top 9 Tig Filler Rod For Mild Steel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 TIG Rod (GTAW)

Domain Est. 1995

Website: airgas.com

Key Highlights: Customers large and small, turn to Airgas to provide the best Welding TIG Rod products for industrial, commercial, laboratory and workplace environments….

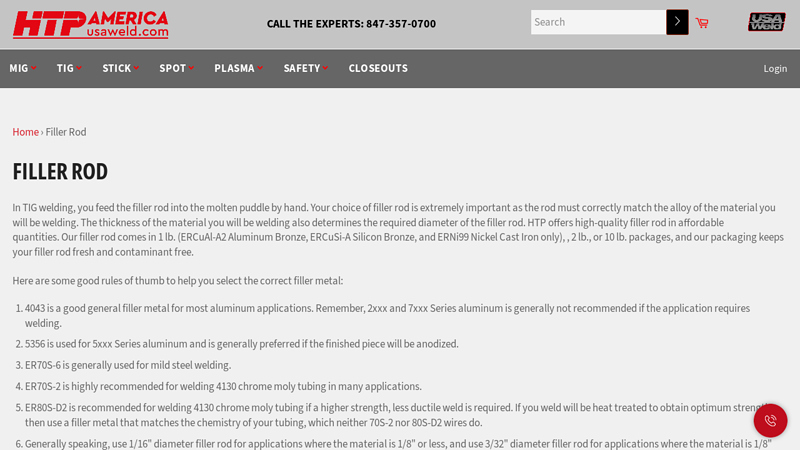

#2 Filler Rod

Domain Est. 1999

Website: usaweld.com

Key Highlights: Free delivery over $100 30-day returnsER70S-6 is generally used for mild steel welding. ER70S-2 is highly recommended for welding 4130 chrome moly tubing in many applications. ER80…

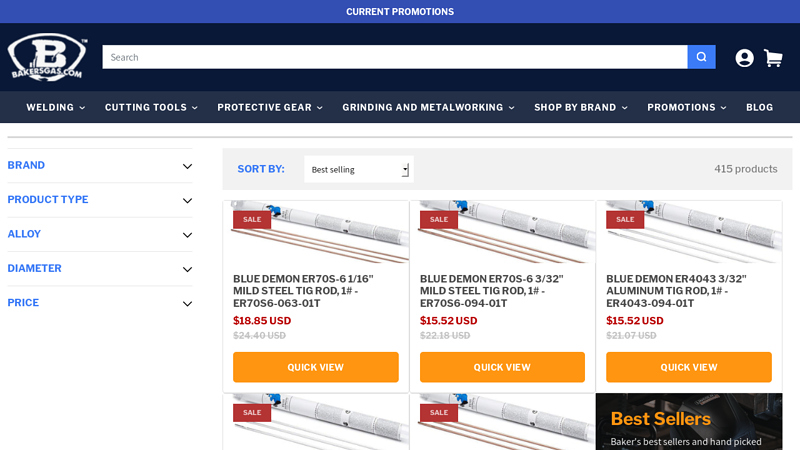

#3 TIG Rod

Domain Est. 1999

Website: bakersgas.com

Key Highlights: Free delivery over $150Baker’s Gas has a large offering of various different material types and sizes of TIG rod. Click here to shop the full collection….

#4 MIG Wires and TIG Rods

Domain Est. 1996

Website: lincolnelectric.com

Key Highlights: MIG Wires and TIG Rods. Filler metals made from the highest quality steel to maximize consistency, feedability and arc performance….

#5 TIG Rods

Domain Est. 1997

Website: voestalpine.com

Key Highlights: We offer a comprehensive range of premium quality rods for TIG welding, covering all major grades. Premium quality wires for demanding applications….

#6 TIG Welding Filler Rod

Domain Est. 1998

#7 TIG Welding Rods

Domain Est. 2000

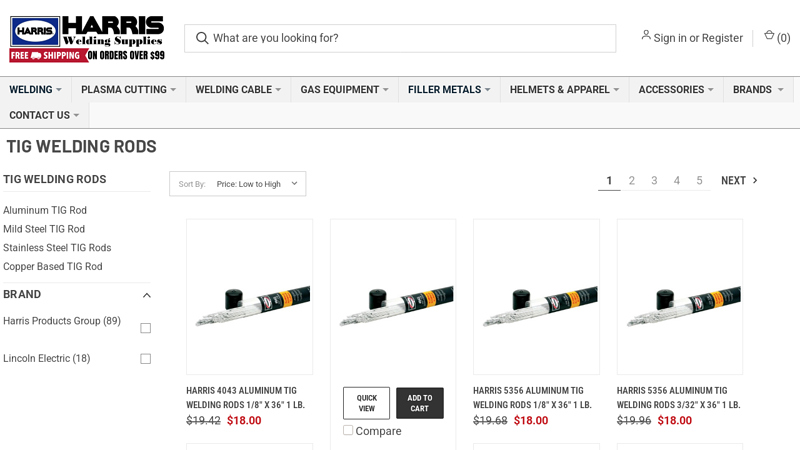

#8 Mild Steel MIG/TIG/Stick Alloys

Domain Est. 2006

Website: harrisproductsgroup.com

Key Highlights: Harris mild steel alloys are perfect for welding cold rolled steel in thicknesses from thin sheet metal to thick plate steel….

#9 Get the Best TIG Filler Rods for Mild Steel Online

Domain Est. 2021

Expert Sourcing Insights for Tig Filler Rod For Mild Steel

2026 Market Trends for TIG Filler Rod for Mild Steel

The global market for TIG (Tungsten Inert Gas) filler rods for mild steel is poised for steady growth through 2026, driven by advancements in welding technologies, increasing industrial automation, and rising demand from key end-use sectors such as automotive, construction, and manufacturing. This analysis explores the primary market trends shaping the TIG filler rod industry for mild steel in 2026.

Rising Demand from Manufacturing and Automotive Sectors

The automotive and general manufacturing industries continue to be major consumers of TIG welding processes, particularly for precision applications involving mild steel. As automakers transition toward lightweight, fuel-efficient vehicle designs, high-integrity welds are increasingly required—especially in chassis, exhaust systems, and structural components. TIG filler rods offer superior control and clean welds, making them ideal for these applications. The ongoing expansion of electric vehicle (EV) production is also expected to boost demand, as EV battery enclosures and motor housings often require the clean, spatter-free welds that TIG welding provides.

Growth in Industrial Automation and Skilled Labor Shortages

Automation in welding processes is on the rise, with robotic TIG welding systems gaining traction in high-volume production environments. While traditionally slower than MIG welding, advances in automated TIG systems are improving throughput and consistency. This trend is increasing the demand for high-quality, consistent TIG filler rods designed for automated feeding. Additionally, a persistent shortage of skilled manual welders in developed markets is driving industries to adopt semi-automated and automated welding solutions, further boosting the need for reliable filler materials compatible with these systems.

Emphasis on Weld Quality and Sustainability

Environmental regulations and quality standards are becoming stricter across industries, leading to a preference for cleaner welding methods. TIG welding produces minimal fumes and spatter compared to other processes, aligning with sustainability goals. As a result, manufacturers are increasingly specifying TIG filler rods for mild steel in projects requiring high weld integrity and minimal post-weld cleanup. This trend is particularly evident in infrastructure and architectural metalwork, where aesthetics and durability are paramount.

Regional Market Dynamics

Asia-Pacific remains the largest and fastest-growing market for TIG filler rods, led by China, India, and Southeast Asian countries. Rapid industrialization, infrastructure development, and a growing automotive sector are key drivers. North America and Europe are witnessing steady demand, supported by investments in advanced manufacturing and defense industries. However, price sensitivity in emerging markets may favor more cost-effective alternatives like MIG welding, limiting TIG filler rod growth in certain segments.

Technological Advancements and Product Innovation

Filler rod manufacturers are investing in improved alloy formulations and surface treatments to enhance arc stability, deposition rates, and mechanical properties. In 2026, expect to see more standardized, high-purity mild steel filler rods with consistent chemical compositions to meet stringent industry certifications (e.g., AWS A5.18). Additionally, pre-polished and anti-corrosion coated rods are gaining popularity for applications requiring minimal contamination and longer shelf life.

Price Volatility and Supply Chain Considerations

Fluctuations in raw material prices—particularly iron, manganese, and alloying elements—can impact the cost of TIG filler rods. Supply chain resilience has become a key concern post-pandemic, pushing manufacturers toward regional sourcing and inventory diversification. In 2026, companies that offer stable supply chains and transparent sourcing will gain a competitive edge.

Conclusion

The 2026 outlook for TIG filler rods for mild steel is positive, supported by technological progress, automation, and demand for high-quality welds. While competition from alternative welding methods persists, the unique advantages of TIG welding ensure continued relevance in precision applications. Manufacturers who innovate in product quality, sustainability, and supply chain efficiency will be best positioned to capitalize on emerging opportunities in this evolving market.

Common Pitfalls When Sourcing Tig Filler Rod For Mild Steel (Quality, IP)

When sourcing TIG filler rods for mild steel, especially with quality and intellectual property (IP) considerations in mind, several common pitfalls can compromise weld integrity, project timelines, and compliance. Being aware of these risks helps ensure you source reliable, legally compliant materials.

1. Substandard Material Quality and Impurities

One of the most frequent issues is receiving filler rods that do not meet required chemical or mechanical specifications. Low-quality rods may contain excessive impurities such as sulfur, phosphorus, or moisture, leading to weld defects like porosity, cracking, or poor fusion. These rods may also fail to meet AWS A5.18 or ER70S-6 standards, resulting in inconsistent arc performance and weak welds.

Tip: Always request mill test certificates (MTCs) and verify compliance with recognized standards before purchase.

2. Counterfeit or Misbranded Products

Counterfeit filler rods are a growing concern, especially when sourcing from unfamiliar or low-cost international suppliers. These rods may be mislabeled as high-quality brands (e.g., Lincoln Electric, ESAB) but are actually produced by unlicensed manufacturers. This not only affects weld performance but also raises intellectual property (IP) infringement issues.

Tip: Source from authorized distributors and verify brand authenticity through batch tracking and supplier audits.

3. Inconsistent Diameter and Surface Finish

Poor manufacturing control can result in inconsistent rod diameters or rough, oxidized surfaces. This affects feeding stability in automated systems and makes manual TIG welding more difficult, increasing the risk of contamination and arc instability.

Tip: Inspect sample batches for dimensional accuracy and surface smoothness before placing large orders.

4. Lack of Traceability and Documentation

Reputable suppliers provide full traceability, including heat numbers and compliance documentation. Failing to obtain this information can create problems during quality audits, certifications (e.g., ASME, API), or failure investigations. It also increases exposure to IP risks if undocumented materials are later found to infringe on patented compositions or processes.

Tip: Ensure every shipment includes traceable documentation and aligns with your quality management system (e.g., ISO 9001).

5. Ignoring Intellectual Property (IP) Compliance

Using filler rods that replicate patented alloy formulations or branded products without authorization exposes your company to legal liability. Some suppliers may offer “compatible” or “equivalent” rods that skirt IP protections, but this can still lead to infringement claims.

Tip: Work with legal and procurement teams to vet suppliers for IP compliance, especially when sourcing generics or offshore alternatives.

6. Inadequate Packaging and Moisture Exposure

TIG filler rods are sensitive to moisture and contamination. Poor packaging—such as non-sealed containers or lack of desiccants—can lead to rust or hydrogen pickup, increasing the risk of hydrogen-induced cracking in the weld.

Tip: Require vacuum-sealed or hermetically packaged rods, particularly for critical applications.

By avoiding these common pitfalls, you ensure not only high-quality welds but also regulatory and IP compliance, protecting both your operations and your organization’s reputation.

Logistics & Compliance Guide for TIG Filler Rod for Mild Steel (H2)

Version: H2 – Hydrogen-Controlled Classification Reference

1. Product Overview

Product Name: TIG Filler Rod for Mild Steel

Common Designations:

– AWS A5.18 ER70S-6

– EN ISO 14341-A G 42 3 C/M

– Typical Alloy: Low-carbon steel with deoxidizers (Si, Mn)

Key Characteristics:

– Used for Gas Tungsten Arc Welding (GTAW/TIG) of mild and low-alloy steels

– Contains controlled levels of deoxidizers for stable arc and good bead profile

– May be copper-coated for improved feed and shelf life

– H2 Designation: Indicates diffusible hydrogen content ≤ 2 mL/100g of deposited weld metal (critical for hydrogen-induced cracking resistance)

2. Classification & Compliance Standards

| Standard | Requirement | Compliance Status |

|——–|————|——————|

| AWS A5.18/A5.18M | Filler metal for carbon steel arc welding | Meets ER70S-6 |

| ISO 14341 | G 42 3 C/M (420 MPa tensile, 3% impact at -20°C) | Compliant |

| ASME Section II, Part C | SFA 5.18 | Certified |

| EN 1090-1 | Execution of steel structures | Applicable for structural use |

| H2 (Hydrogen Level) | Diffusible H₂ ≤ 2 mL/100g | Verified via test certificate |

✅ Note: The “H2” classification is critical for applications involving high-strength steels, thick sections, or environments prone to hydrogen-induced cracking (HIC) or cold cracking.

3. Packaging & Labeling Requirements

Packaging:

– Supplied in sealed plastic-coated cardboard spools or vacuum-sealed bags

– 1 lb (0.45 kg), 5 lb (2.27 kg), or 10 lb (4.54 kg) options

– Desiccant included if vacuum-packed to prevent moisture absorption

– Rods stored straight to avoid bending; typically 36″ (914 mm) cut lengths or coiled

Labeling (Per AWS & ISO):

– Product name: “TIG Filler Rod ER70S-6”

– AWS/ISO classification

– Lot number and heat number

– Manufacturer name and country of origin

– H2 designation clearly marked (e.g., “H₂ ≤ 2 mL/100g”)

– Net weight, diameter (e.g., 1/16″, 3/32″, 1/8″)

– Expiry date (if applicable)

– Storage instructions: “Keep Dry. Store Indoors.”

4. Storage & Handling Guidelines

Storage Conditions:

– Temperature: 10–30°C (50–86°F)

– Humidity: <50% RH

– Store in original packaging until use

– Elevate off floor; avoid concrete surfaces (moisture absorption)

– Keep away from rain, condensation, and chemical vapors

Handling:

– Use clean, dry gloves to prevent oil/moisture transfer

– Avoid prolonged exposure to ambient air after opening

– Re-seal partially used packs with desiccant if possible

– Do not store near welding fluxes or cleaning solvents

⚠️ Warning: Moisture absorption increases diffusible hydrogen → risk of cracking in susceptible joints.

5. Transportation & Logistics

Mode of Transport:

– Road, rail, sea, or air (non-hazardous under IATA/IMDG)

– Not classified as dangerous goods (UN3089, environmentally hazardous, does not apply)

Packaging for Shipment:

– Packed in strong corrugated cartons with internal dividers

– Palletized with stretch wrap; corner boards recommended

– Waterproof cover if shipped outdoors

Documentation Required:

– Commercial Invoice

– Packing List

– Certificate of Conformity (C of C)

– Mill Test Certificate (EN 10204 3.1 or 3.2) showing:

– Chemical composition

– Mechanical properties (tensile, yield, elongation)

– H2 hydrogen test results

– Traceability (heat/lot number)

🌍 Export Compliance:

– No ITAR/EAR restrictions

– Complies with REACH and RoHS (if copper-coated, confirm Pb/Ni limits)

– Verify local welding standards in destination country (e.g., JIS Z 3312 in Japan)

6. Quality Assurance & Traceability

- Full heat traceability from raw material to finished rod

- Third-party certification available upon request (e.g., DNV, Lloyds Register)

- Retain test certificates for minimum 5 years

- Batch sampling for hydrogen testing (gas chromatography or glycerol method per AWS A4.2)

7. Application & Safety Considerations

Recommended Use:

– Mild steel fabrication, pressure vessels, structural steel, automotive

– Ideal for critical joints requiring low hydrogen (H2) filler

Pre-Weld Checks:

– Confirm base metal cleanliness (oil, rust, moisture)

– Preheat if required by WPS (especially for thick sections)

– Use dry shielding gas (Argon or Ar/CO₂ mix)

PPE & Ventilation:

– Wear welding helmet, gloves, and flame-resistant clothing

– Ensure adequate ventilation to avoid fume buildup (Mn, Fe oxides)

– Complies with OSHA 29 CFR 1910.252 and ANSI Z49.1

8. Disposal & Environmental Compliance

- Non-hazardous waste when unused

- Recyclable as ferrous scrap

- Follow local regulations for metal waste disposal

- Empty packaging: recyclable cardboard/plastic

9. Supplier & Support Information

Typical Suppliers:

– Lincoln Electric

– ESAB

– Hobart Brothers

– Miller Electric

– Bernard / Tregaskiss

Support Documentation:

– Product Datasheet

– Safety Data Sheet (SDS) – Section 14: Transport Information

– Welding Procedure Specifications (WPS) templates

– H2 test validation reports

10. Summary – Key Compliance Points for H2 Filler Rod

| Requirement | Status |

|———–|——–|

| H₂ ≤ 2 mL/100g | ✅ Required and tested |

| AWS A5.18 ER70S-6 | ✅ Standard classification |

| Proper labeling (incl. H2) | ✅ Mandatory |

| Dry storage | ✅ Prevents moisture uptake |

| Mill Test Certificate | ✅ Required for traceability |

| Non-hazardous transport | ✅ IATA/IMDG compliant |

Revision H2 – Last Updated: April 2024

For technical support, contact your filler metal supplier or welding engineer. Always refer to the latest edition of AWS/ISO standards.

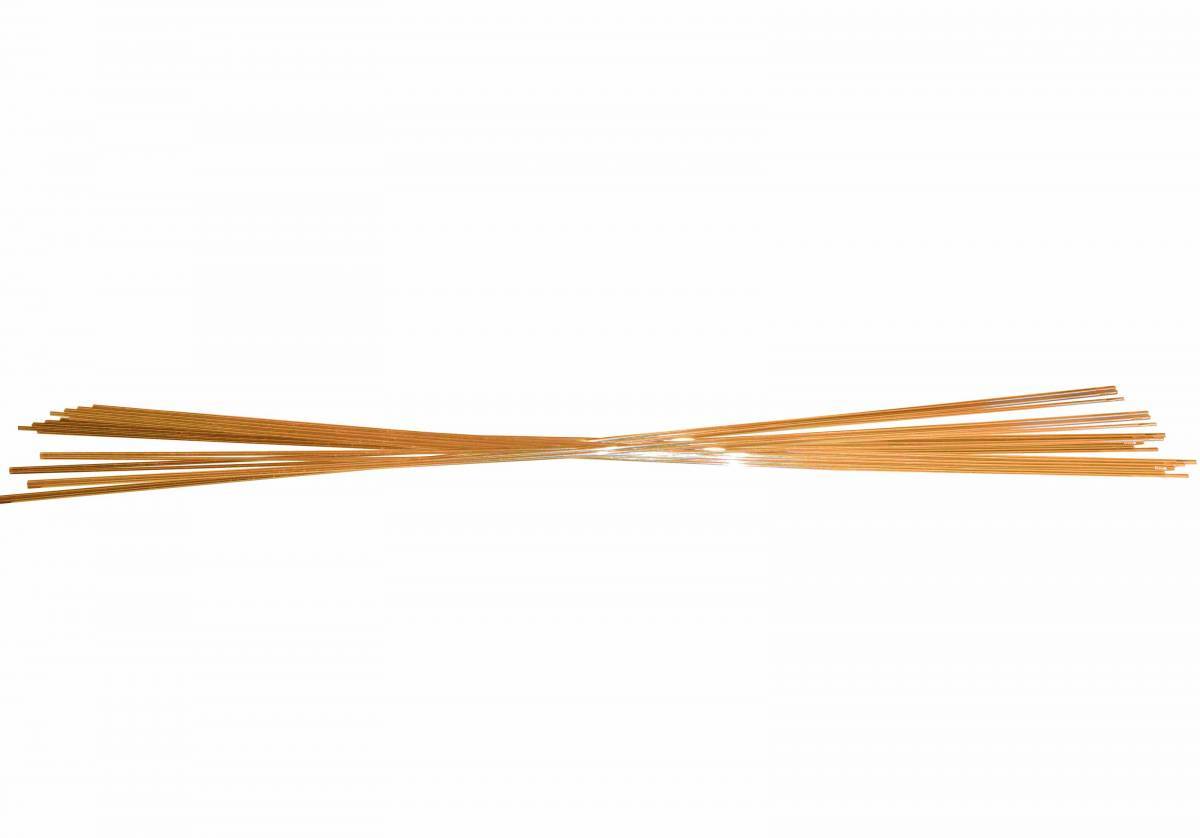

Conclusion: Sourcing TIG Filler Rods for Mild Steel

Sourcing the appropriate TIG filler rod for mild steel is essential to achieving strong, clean, and high-quality welds. The most commonly used and recommended filler rod for mild steel in TIG welding is ER70S-2, due to its excellent arc stability, consistent bead appearance, and superior mechanical properties. When sourcing this filler rod, it is important to consider factors such as material purity, diameter compatibility with the application and welding equipment, and adherence to AWS (American Welding Society) standards to ensure weld integrity.

Procurement should prioritize reputable suppliers or manufacturers with a proven track record of quality control and consistency. Whether sourcing locally or internationally, verifying product certifications and conducting periodic quality checks can help mitigate the risk of defects such as porosity or inclusions. Additionally, proper storage of filler rods in a clean, dry environment is crucial to prevent contamination from moisture, oil, or debris, which can compromise weld quality.

In summary, a strategic sourcing approach—balancing quality, cost, and reliability—will ensure that the selected TIG filler rod meets the performance requirements for mild steel welding applications, supporting both structural integrity and long-term durability in the final product.