The global three-phase portable generator market is experiencing robust expansion, driven by rising demand for reliable backup power across industrial, construction, and remote operational sites. According to Grand View Research, the global portable generator market was valued at USD 3.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Mordor Intelligence further highlights that increasing infrastructure development, coupled with frequent power outages in emerging economies, is accelerating the adoption of high-capacity three-phase models capable of powering heavy machinery and commercial systems. With technological advancements enhancing fuel efficiency, noise reduction, and digital integration, manufacturers are now competing on performance, durability, and smart features. In this evolving landscape, nine key players have emerged as leaders, setting industry benchmarks through innovation, global reach, and consistent product reliability.

Top 9 Three Phase Portable Generator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Gillette Generators

Domain Est. 2000

Website: gillettegenerators.com

Key Highlights: Gillette Generators. Generators · Standby · Commercial Gas · Industrial Diesel · Portable · Prime · Prime Gas · T4F-Stage 5 Prime Diesel. Manuals. Standby ……

#2 Three Phase Generators

Domain Est. 2005

Website: absolutegenerators.com

Key Highlights: Three-phase generators deliver the robust, high-density power required for commercial, agricultural, and industrial applications….

#3 Generators

Website: denyo.co.jp

Key Highlights: Generators · Single Phase · Three phase ( – 25kVA) · Three phase ( 26 – 100kVA) · Three phase ( 101 – 300kVA) · Three phase ( 301 – 1100kVA) · Three phase (1400kVA~)….

#4 Cummins Generator Sets

Domain Est. 1990

Website: cummins.com

Key Highlights: We design, manufacture, and test all major components of our generator sets – the engine, alternator, and control systems – so they work in harmony from the ……

#5 Standby Generators

Domain Est. 1995

Website: generac.com

Key Highlights: Free delivery4.8. (2373) · View Details. Product. Standby Generator, 20kW | 3-Phase | WiFi Enabled. Base Model/SKU: G007077_. Model Number: G0070770. Starting at: $6,239.00….

#6 Kubota Generator

Domain Est. 1997

Website: generator.kubota.com

Key Highlights: The heart of the Kubota generators are Kubota’s own diesel engines. Used widely in world-renowned machinery, these sturdily built, one-side-maintenance type ……

#7 Shop Three Phase Diesel Generators from General Power

Domain Est. 2001

Website: genpowerusa.com

Key Highlights: General Power offers a wide range of three phase generators for sale, designed to meet different applications and site requirements. From compact units for ……

#8 3 Phase Generators

Domain Est. 2002

Website: electricgeneratorsdirect.com

Key Highlights: Free delivery over $2003 Phase Generator superstore. Huge selection of Three Phase Generators. Buy Three Phase Commercial Generator Direct and save….

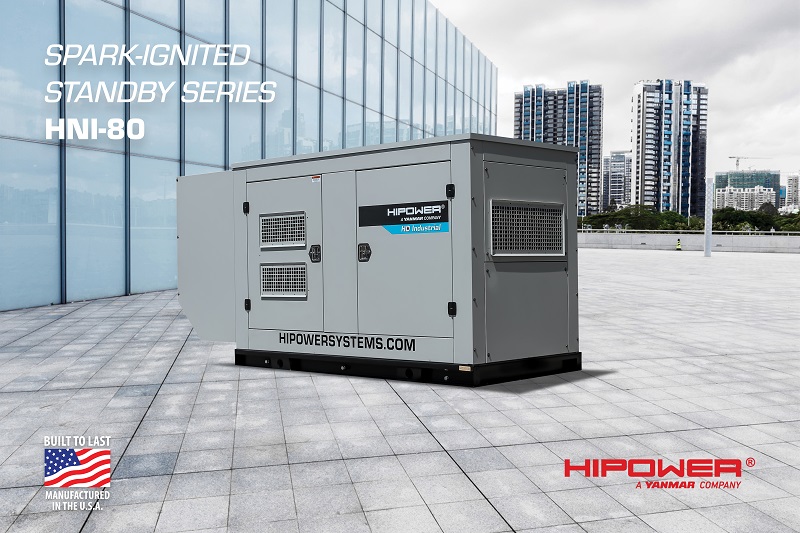

#9 HIPOWER SYSTEMS a Yanmar Company, Generator Sets

Domain Est. 2008

Website: hipowersystems.com

Key Highlights: Delivering prime power solutions in a wide range of power nodes, HIPOWER Mobile generators are engineered specifically for the needs of the North American ……

Expert Sourcing Insights for Three Phase Portable Generator

2026 Market Trends for Three-Phase Portable Generators

The global market for three-phase portable generators is poised for significant transformation by 2026, driven by technological innovation, rising energy demands, and evolving industrial and commercial needs. These robust power solutions, capable of delivering balanced electrical output across three alternating currents, are increasingly being adopted across construction, telecommunications, healthcare, and disaster relief sectors. This analysis explores key trends shaping the three-phase portable generator market in 2026 under major thematic drivers.

Rising Demand from Industrial and Commercial Sectors

By 2026, industrialization in emerging economies and infrastructure development projects are expected to fuel demand for reliable off-grid power. Three-phase portable generators are preferred in industrial applications due to their ability to power heavy-duty machinery, HVAC systems, and production lines efficiently. As governments in regions such as Southeast Asia, Africa, and Latin America invest in smart cities and industrial parks, the need for mobile, high-capacity power sources will grow. Additionally, commercial events, data centers, and temporary facilities are increasingly relying on three-phase generators for uninterrupted operations, further expanding market reach.

Advancements in Hybrid and Inverter Technologies

A major trend shaping the 2026 landscape is the integration of hybrid and inverter technologies into three-phase portable generators. Manufacturers are focusing on systems that combine diesel or gasoline engines with battery storage and smart inverters to improve fuel efficiency, reduce emissions, and provide cleaner power output. These hybrid models are particularly appealing for sensitive electronics and medical equipment that require stable voltage and frequency. The adoption of digital controls and IoT-enabled monitoring systems allows for remote diagnostics and predictive maintenance, enhancing operational reliability and user convenience.

Shift Toward Sustainable and Low-Emission Solutions

Environmental regulations and corporate sustainability goals are pushing the market toward cleaner alternatives. By 2026, we expect increased deployment of three-phase portable generators powered by alternative fuels such as biodiesel, liquefied petroleum gas (LPG), and hydrogen. Additionally, the development of dual-fuel and fully electric portable systems — though still limited by battery energy density — will gain traction, especially in urban and noise-sensitive areas. Regulatory frameworks like the U.S. EPA Tier 4 and EU Stage V emissions standards will continue to influence product design, favoring low-emission models.

Growth in Rental and Shared-Economy Models

The high initial cost of three-phase portable generators is prompting a rise in rental and subscription-based business models. By 2026, equipment rental companies are expected to play a pivotal role in market expansion, particularly for short-term infrastructure projects, film productions, and emergency response operations. Digital platforms enabling on-demand generator leasing, with integrated logistics and maintenance support, will improve accessibility and utilization rates. This trend is especially prominent in developed markets where flexibility and cost-efficiency are prioritized.

Regional Market Dynamics and Supply Chain Evolution

Asia-Pacific is projected to dominate the three-phase portable generator market by 2026, led by China, India, and Indonesia, where rapid urbanization and frequent power outages drive demand. North America and Europe will see steady growth, primarily fueled by grid resilience initiatives and climate-related power disruptions. However, supply chain challenges — including semiconductor shortages and raw material volatility — will continue to impact production timelines and pricing. As a result, manufacturers are diversifying sourcing strategies and investing in localized production to mitigate risks.

Conclusion

By 2026, the three-phase portable generator market will be characterized by technological sophistication, environmental consciousness, and flexible deployment models. While traditional diesel-powered units will remain prevalent, the shift toward hybrid, low-emission, and digitally integrated systems will define the future of the industry. Stakeholders must adapt to regulatory pressures, regional demand variations, and evolving customer expectations to remain competitive in this dynamic market landscape.

Common Pitfalls When Sourcing a Three-Phase Portable Generator (Quality & IP)

Sourcing a three-phase portable generator involves more than just matching power output to your needs. Overlooking key quality and ingress protection (IP) factors can lead to performance issues, safety hazards, and costly downtime. Here are the most common pitfalls to avoid:

Underestimating Build Quality and Component Standards

Many buyers focus solely on kilowatt ratings and overlook the importance of construction quality. Low-cost generators often use inferior materials—such as thin steel casings, substandard alternators, or undersized wiring—that degrade quickly under load or in harsh environments. Poorly engineered cooling systems and insufficient vibration damping can lead to overheating and mechanical failure. Always verify the manufacturer’s reputation, inspect component specifications (e.g., AVR type, frame material), and request third-party certifications (like ISO or CE) to ensure durability.

Ignoring Ingress Protection (IP) Ratings for Real-World Conditions

The IP rating indicates protection against dust and moisture, which is critical for a portable generator used in diverse environments. A common mistake is selecting a unit with insufficient IP protection—such as IP23 (basic splash resistance)—for outdoor or construction sites where rain, dust, or debris are present. For reliable operation in adverse conditions, aim for at least IP54 (dust-protected and resistant to water splashes from any direction). Units with higher ratings (e.g., IP55 or IP65) offer better longevity and safety, especially in coastal, muddy, or high-humidity areas.

Overlooking Certification and Compliance with Regional Standards

Purchasing a generator without verifying compliance with local electrical and emissions standards (e.g., UL, CSA, CE, or EPA Tier 4) is a significant risk. Non-compliant units may fail inspections, void insurance, or be illegal to operate. Additionally, counterfeit products often mimic legitimate branding but lack genuine safety certifications. Always request documentation and verify certification marks directly with the issuing body.

Relying on Nominal Power Without Considering Continuous Load

Suppliers may advertise peak or surge power, leading buyers to assume the generator can sustain that output. However, three-phase applications often require continuous operation near rated capacity. A generator that overloads under sustained use will overheat, reduce efficiency, and shorten lifespan. Always confirm the continuous (prime or standby) power rating under three-phase load and ensure a 10–20% safety margin for your total connected load.

Neglecting After-Sales Support and Spare Parts Availability

Even high-quality generators require maintenance and occasional repairs. Sourcing from obscure brands or distant suppliers can result in long lead times for spare parts and limited technical support. This is especially problematic for portable units used in remote or mission-critical applications. Prioritize suppliers with local service networks, available technical documentation, and a proven track record of customer support.

By addressing these pitfalls early in the sourcing process, you can ensure a reliable, safe, and durable three-phase portable generator that meets both performance and environmental demands.

Logistics & Compliance Guide for Three Phase Portable Generator

This guide outlines the key logistical considerations and compliance requirements for safely transporting, operating, and maintaining a three phase portable generator. Adherence to these guidelines ensures operational efficiency, regulatory compliance, and personnel safety.

Transportation and Handling

Proper handling during transportation is critical to prevent damage and ensure safety. Always secure the generator on a flat, stable surface using rated tie-down points. Use appropriate equipment such as forklifts with wide forks or cranes with lifting slings rated for the generator’s weight. Never lift by control panels, fuel tanks, or cooling fins. Ensure the unit is turned off, cooled down, and fuel valves are closed before moving. Transport with the engine oil level below the fill line to prevent leaks. Follow all local and international transport regulations, including those for hazardous materials if fueling is required.

Site Preparation and Placement

Select a level, well-ventilated outdoor location away from buildings, windows, and air intakes to prevent carbon monoxide accumulation. Maintain minimum clearance (typically 3–5 feet) around the unit for cooling and maintenance access. Use vibration-dampening pads to reduce noise and wear. Ensure the site is protected from water ingress and standing water. Confirm ground fault protection and proper grounding per local electrical codes (e.g., NEC Article 250 in the U.S.). Position the generator to allow exhaust discharge away from personnel and equipment.

Electrical Connection and Load Management

Connect only through a properly rated transfer switch or distribution panel to avoid backfeeding the grid. Ensure the generator’s voltage, frequency (50/60 Hz), and phase configuration (e.g., 400V 3-phase, 120/208V) match the load requirements. Use industrial-grade cables with adequate gauge and insulation for the load distance and environment. Balance the three-phase load as evenly as possible across all phases to prevent overheating and inefficiency. Never exceed the generator’s continuous kW/kVA rating. Use a load bank for testing if necessary.

Regulatory Compliance

Ensure the generator complies with emissions standards such as EPA Tier 4 (U.S.), EU Stage V (Europe), or equivalent local regulations. Verify noise levels meet site-specific requirements (e.g., OSHA or local ordinances). Maintain documentation including the generator’s EPA or EU certification label, operator manual, and maintenance records. In workplaces, comply with OSHA 29 CFR 1910.146 (confined spaces), 1910.303 (electrical safety), and 1910.1000 (air contaminants). For international use, confirm adherence to IEC 60034 and ISO 8528 standards.

Safety and Operational Procedures

Conduct pre-operational checks including oil, coolant, fuel, and battery levels. Inspect air filters and exhaust systems for blockage. Never refuel while the generator is running or hot—allow cooling for at least 15 minutes. Use approved fuel containers and grounding procedures to prevent static discharge. Train operators on emergency shutdown, fire response, and lockout/tagout (LOTO) procedures. Install CO detectors in nearby occupied areas. Keep fire extinguishers (Class B/C) accessible.

Maintenance and Recordkeeping

Perform regular maintenance per the manufacturer’s schedule: oil and filter changes, coolant checks, air filter cleaning, and battery testing. Store maintenance logs and inspection reports for audit purposes. For rental or shared equipment, conduct inspections before each use. Replace worn hoses, belts, and electrical components promptly. Conduct annual load bank testing to verify performance and prevent wet stacking in diesel units.

Environmental and Disposal Considerations

Manage fuel and oil responsibly—store in approved containers and dispose of waste fluids through licensed recyclers. Prevent fuel spills using secondary containment where possible. For decommissioned units, follow WEEE (Waste Electrical and Electronic Equipment) directives or local e-waste regulations. Recycle batteries, oil, and coolant properly to minimize environmental impact.

Documentation and Training

Maintain an up-to-date operations manual, compliance certificates, and site-specific risk assessments. Provide certified training for all operators covering startup, shutdown, emergency response, and regulatory requirements. Keep training records on file and conduct refresher courses annually or after incidents.

In conclusion, sourcing a three-phase portable generator requires careful consideration of power requirements, portability, fuel efficiency, brand reliability, and compliance with safety standards. A three-phase generator is ideal for powering heavy-duty industrial equipment, construction tools, and commercial applications that demand balanced and efficient power distribution. When selecting the right model, it is essential to evaluate factors such as wattage output, voltage stability, runtime, noise levels, and ease of maintenance. Additionally, choosing a generator from a reputable supplier with solid after-sales support ensures long-term performance and reliability. By aligning technical specifications with operational needs and budget constraints, businesses and contractors can make a well-informed decision that ensures uninterrupted power supply, enhanced productivity, and cost-effective operation in diverse field conditions.