The global rivet market, which includes threaded rivnuts, is experiencing steady growth driven by rising demand from key industries such as automotive, aerospace, and construction. According to Mordor Intelligence, the global rivet market was valued at USD 5.9 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2029. This expansion is fueled by increasing production of commercial aircraft, lightweight vehicle manufacturing, and infrastructure development, all of which require high-strength, reliable fastening solutions. Threaded rivnuts, in particular, are gaining traction due to their ability to create durable internal threads in thin or soft materials—making them essential in modern assembly processes. As demand escalates, a select group of manufacturers has emerged at the forefront of innovation, quality, and global reach. Below is a data-driven look at the top nine threaded rivnut manufacturers shaping this competitive landscape.

Top 9 Threaded Rivnuts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rivet Nut Fasteners & Installation Tooling

Domain Est. 1996

Website: sherex.com

Key Highlights: Sherex Fastening Solutions is a leading manufacturer of innovative engineered fastening solutions including rivet nut fasteners, tooling, and automation….

#2 Rivet Nuts

Domain Est. 2009

Website: rivetsonline.com

Key Highlights: With our huge, in-stock inventory, we’re sure to have rivet nuts your project requires. We offer standard threaded fasteners in steel, stainless steel, and ……

#3 Blind Rivet Nuts

Domain Est. 1996

Website: pemnet.com

Key Highlights: Learn about how rivet nuts can join panels or provide mounting threads with access to only one side of a hole….

#4 Rivet Nuts

Domain Est. 1996

Website: dbroberts.com

Key Highlights: Rivet nuts, also known as threaded inserts or blind rivet nuts, are cylindrical fasteners with an internally threaded hole, designed for secure attachment….

#5 Rivet Nuts

Domain Est. 1997

Website: lawsonproducts.com

Key Highlights: 90-day returnsDiscover Lawson rivet nuts designed for strength and long-lasting performance. Create strong threaded connections easily—order Lawson rivet nuts…

#6 R

Domain Est. 1999

Website: avkfasteners.com

Key Highlights: RN Series RivetNut Threaded Insert features a heavy duty head profile and increased wall thickness in the collapse area. This makes the RN RivetNut ideal for ……

#7 RIVNUT® blind rivet nuts and RIVSTUD® blind rivet studs

Domain Est. 2000

Website: boellhoff.com

Key Highlights: RIVNUT® blind rivet nuts and RIVSTUD® blind rivet studs are a versatile solution for attaching a resilient thread to thin-walled components….

#8 Rivet Nuts Small Head Threaded Inserts Low Profile Thin Wall Open …

Domain Est. 2012

#9 Blind Rivet Nuts

Domain Est. 2017

Website: profil-global.com

Key Highlights: Rivet nuts, also known as threaded inserts or nutserts, are versatile fasteners used to add strong, permanent threads to thin materials and hollow sections….

Expert Sourcing Insights for Threaded Rivnuts

H2: 2026 Market Trends for Threaded Rivnuts

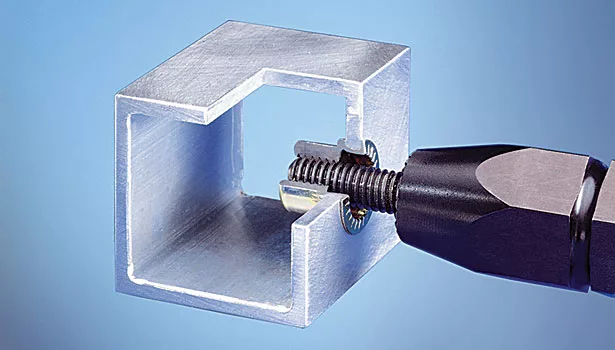

The global market for threaded rivnuts is poised for significant evolution by 2026, driven by advancements in manufacturing technology, increasing demand from key end-use industries, and a growing emphasis on lightweight and durable fastening solutions. As industries continue to prioritize efficiency, reliability, and sustainability, threaded rivnuts—known for their strength, ease of installation, and versatility in blind-hole applications—are expected to play a critical role in structural and assembly processes.

One of the primary drivers shaping the 2026 market landscape is the expansion of the automotive and aerospace sectors. In the automotive industry, the shift toward electric vehicles (EVs) is fueling demand for lightweight components that maintain structural integrity. Threaded rivnuts made from aluminum and high-strength steel alloys are increasingly used in EV chassis and battery enclosures, supporting weight reduction and improved energy efficiency. Similarly, in aerospace, the need for reliable fastening in composite materials is boosting adoption, particularly with corrosion-resistant rivnuts suitable for harsh environments.

Another emerging trend is the integration of smart manufacturing and automation. By 2026, manufacturers of threaded rivnuts are expected to adopt Industry 4.0 principles, including real-time monitoring, predictive maintenance, and automated rivet installation systems. This shift enhances production precision, reduces waste, and supports just-in-time delivery models—critical for large-scale industrial clients.

Sustainability is also gaining traction. With increasing regulatory pressure and corporate sustainability goals, suppliers are exploring recyclable materials and eco-friendly surface treatments (e.g., zinc-nickel coatings) to minimize environmental impact. Additionally, innovations in self-clinching and multi-grip rivnuts are broadening application scopes, especially in electronics and renewable energy sectors such as solar panel mounting systems.

Regionally, Asia-Pacific is anticipated to lead market growth due to rapid industrialization, expanding infrastructure projects, and a robust manufacturing base in countries like China, India, and South Korea. Meanwhile, North America and Europe will continue to see steady demand, driven by aerospace innovation and stringent safety standards.

In conclusion, the 2026 market for threaded rivnuts will be characterized by technological innovation, material advancements, and sector-specific customization. Companies that invest in R&D, sustainable practices, and automation are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Threaded Rivnuts: Quality and Intellectual Property (IP) Concerns

Sourcing threaded rivnuts—also known as blind rivet nuts or rivet nuts—can present several challenges, particularly in ensuring consistent quality and avoiding intellectual property (IP) infringement. Below are key pitfalls to watch for in both areas.

Quality-Related Pitfalls

Inconsistent Material Composition

One of the most common quality issues is inconsistent or misrepresented base materials. Rivnuts are often made from steel, stainless steel, or aluminum, each suited to different environmental and load requirements. Suppliers may use substandard alloys or fail to meet specified grades (e.g., using 304 stainless steel instead of 316), leading to premature corrosion or mechanical failure.

Poor Thread Integrity

Threaded rivnuts rely on precise internal threading to ensure proper bolt engagement. Poor manufacturing can result in stripped, misaligned, or galled threads. This is often due to inadequate tapping processes or improper heat treatment, reducing load capacity and reusability.

Inaccurate Dimensional Tolerances

Rivnuts must fit precisely into pre-drilled holes and expand correctly during installation. Suppliers from less-regulated markets may produce parts with out-of-spec diameters or lengths, leading to installation issues, weak joints, or failure to meet engineering requirements.

Insufficient Plating or Coating

Corrosion protection is critical in many applications. Inadequate plating (e.g., zinc coating too thin or uneven) or skipping passivation on stainless steel parts can result in rust and reduced service life, especially in outdoor or high-humidity environments.

Lack of Traceability and Certification

Reputable suppliers provide material certifications (e.g., mill test reports) and compliance documentation (e.g., RoHS, REACH). Sourcing from vendors without traceability makes it difficult to validate quality or address failures in the field.

Intellectual Property (IP) and Branding Pitfalls

Counterfeit or Knockoff Products

Many threaded rivnuts are protected by design or utility patents, particularly proprietary head styles, knurling patterns, or installation mechanisms. Sourcing from unauthorized manufacturers may result in counterfeit versions that mimic patented designs, exposing the buyer to legal risk.

Unauthorized Use of Brand Names and Logos

Some suppliers falsely label generic rivnuts with well-known brand names (e.g., “POP®” or “Avdel®”) to imply authenticity. This not only misleads buyers but also constitutes trademark infringement and can lead to supply chain liability.

Design Patent Infringement

Even if a rivnut performs the same function, copying patented features—such as specific grooves, undercuts, or mandrel designs—can violate IP rights. Buyers may unknowingly incorporate infringing parts into their products, potentially facing cease-and-desist letters or litigation.

Limited Legal Recourse in International Sourcing

When sourcing from regions with weak IP enforcement, it can be difficult to hold suppliers accountable for using patented designs. Contracts may offer little protection, and legal action can be costly and impractical across jurisdictions.

Best Practices to Avoid Pitfalls

- Verify Supplier Credentials: Work with authorized distributors or manufacturers known for quality and compliance.

- Request Certifications: Insist on material test reports, ISO certifications, and compliance documentation.

- Conduct Sample Testing: Perform dimensional checks, thread engagement tests, and salt spray testing for corrosion resistance.

- Audit IP Status: Consult legal or technical experts to confirm that the rivnut design does not infringe on active patents.

- Use Clear Specifications: Define material grades, finishes, dimensions, and acceptance criteria in procurement contracts.

By proactively addressing these quality and IP-related pitfalls, organizations can ensure reliable performance, reduce liability, and maintain the integrity of their supply chain when sourcing threaded rivnuts.

Logistics & Compliance Guide for Threaded Rivnuts

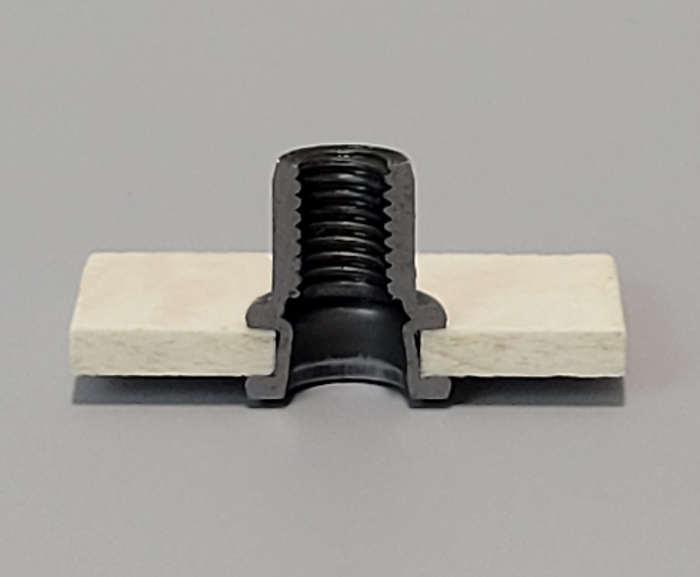

Overview of Threaded Rivnuts

Threaded Rivnuts, also known as blind rivet nuts or rivet studs, are threaded inserts used to create strong, durable internal threads in thin or sheet materials where access is limited to one side. They are commonly used in automotive, aerospace, electronics, and industrial manufacturing. Proper logistics handling and compliance with regulatory standards are essential to ensure product quality, safety, and performance.

Material and Packaging Specifications

Threaded Rivnuts are typically manufactured from materials such as aluminum, steel, or stainless steel, each with specific grade and finish requirements. Packaging must prevent damage, corrosion, and contamination during transit and storage. Use moisture-resistant packaging (e.g., sealed polybags with desiccants) for corrosion-prone materials. Bulk packaging should be clearly labeled with part number, material type, finish, quantity, and lot traceability information.

Storage and Handling Requirements

Store Rivnuts in a dry, temperature-controlled environment to prevent oxidation and moisture damage. Keep containers sealed until ready for use. Handle with clean tools or gloves to avoid contamination, especially for aerospace or medical-grade applications. Segregate different materials, finishes, and sizes to prevent mix-ups and ensure correct inventory rotation (FIFO – First In, First Out).

Transportation and Shipping Guidelines

Ship Rivnuts in secure, stackable containers to prevent movement and damage during transit. Use cushioning materials where necessary to avoid deformation. Label all shipments with handling instructions such as “Fragile,” “Keep Dry,” and “Do Not Stack Excessively.” For international shipments, ensure compliance with IATA, IMDG, or other applicable transport regulations if hazardous coatings or materials are involved.

Regulatory and Industry Compliance

Ensure all Rivnuts meet relevant industry standards such as:

– ASME B1.1 – Unified Inch Screw Threads

– NASM13925 – Aerospace Rivet Nuts

– ISO 15977 – Blind Rivet Nuts – General Specifications

– RoHS and REACH – For restriction of hazardous substances (applicable to plating and coatings)

– Conflict Minerals Compliance (Dodd-Frank Act Section 1502) – If sourcing tantalum, tin, tungsten, or gold

Certifications (e.g., ISO 9001, AS9100) from suppliers should be verified and maintained in documentation.

Traceability and Documentation

Maintain full traceability from raw material to finished product. Documentation must include:

– Material Certifications (e.g., Mill Test Reports)

– Certificates of Conformance (CoC)

– Lot and batch numbers

– Test reports for mechanical properties (e.g., torque-out, push-out strength)

– Packaging and labeling data

Digital tracking systems are recommended for audit readiness and quality control.

Import/Export and Customs Compliance

For cross-border shipments, ensure proper HS (Harmonized System) code classification—typically under heading 7318 (Screws, bolts, nuts, etc.). Provide accurate commercial invoices, packing lists, and origin declarations. Verify export control classifications (e.g., EAR99 under U.S. Export Administration Regulations) and comply with sanctions lists (e.g., OFAC, BIS). Special licenses may be required for military or aerospace-grade fasteners.

Environmental and Safety Considerations

Dispose of packaging and non-conforming Rivnuts according to local environmental regulations. Metal waste should be recycled where feasible. Ensure worker safety during handling by providing appropriate PPE (e.g., gloves, eye protection) and proper ventilation if dealing with chemically treated components.

Quality Assurance and Audits

Conduct regular supplier audits and in-house inspections to verify compliance with specifications. Implement a non-conformance reporting (NCR) system for defective products. Perform periodic testing (e.g., thread engagement, pull-out strength) to validate performance and regulatory adherence.

Summary

Effective logistics and compliance management for Threaded Rivnuts ensures product reliability, regulatory adherence, and operational efficiency. From proper storage and packaging to documentation and export controls, every stage must align with industry standards and legal requirements to support high-quality manufacturing and global supply chain integrity.

Conclusion for Sourcing Threaded Rivnuts:

Sourcing threaded rivnuts requires a strategic approach that balances quality, cost, availability, and technical specifications. After evaluating suppliers, materials, plating options, and compliance standards, it is clear that partnering with reputable manufacturers and distributors is essential to ensure consistent product performance and reliability. Factors such as application requirements (e.g., material thickness, load capacity, environmental exposure), lead times, and minimum order quantities must be carefully considered to support production efficiency and project timelines.

Additionally, investing in samples and conducting rigorous testing prior to large-scale procurement can mitigate risks related to fit, function, and durability. Ultimately, establishing long-term relationships with flexible, responsive suppliers who offer technical support and adhere to industry standards will enhance supply chain resilience and support the overall success of manufacturing and assembly operations. Effective sourcing of threaded rivnuts is not just about cost savings—but about securing a reliable, high-performance component that contributes to the integrity of the final product.