The global welding equipment market, driven by increasing industrial automation and infrastructure development, is projected to grow at a CAGR of approximately 5.2% from 2023 to 2030, according to Grand View Research. Within this landscape, smart inductors—like the Telwin Smart Inductor 5000—have emerged as critical components in precision welding, offering advanced energy control and arc stability for MIG/MAG applications. As demand rises for high-efficiency, digitally integrated welding solutions, manufacturers are enhancing product intelligence and connectivity. This surge in innovation has given rise to a competitive ecosystem of suppliers producing compatible or upgraded versions of smart inductance technology. Based on market trends and performance benchmarks, we’ve identified the top 7 manufacturers leading in quality, technological integration, and global supply capacity for Telwin Smart Inductor 5000-class equipment.

Top 7 Telwin Smart Inductor 5000 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 TELWIN SMART INDUCTOR 5000 Spot Welders

Domain Est. 1995

Website: machinetools.com

Key Highlights: Induction heating system that is an intelligent solution for speeding up and simplifying the removalof blocked parts (bolts, bearings, gears, etc.) ……

#2 SMART INDUCTOR 5000 CLASSIC

Domain Est. 1997

Website: telwin.com

Key Highlights: Induction heater for fast and simple removal operations of vehicle parts. Supplied with Super Remover, Heat Twister, Pad Inductor accessories, 3 levers and ……

#3 Telwin Smart 5000

Domain Est. 2004

#4 Induction heating systems Telwin SMART INDUCTOR 5000, etc …

Domain Est. 2013

Website: telwin.nt-rt.ru

Key Highlights: The induction heating system is an intelligent solution that allows you to speed up and simplify the removal of stuck parts (bolts, bearings, gears, etc.)….

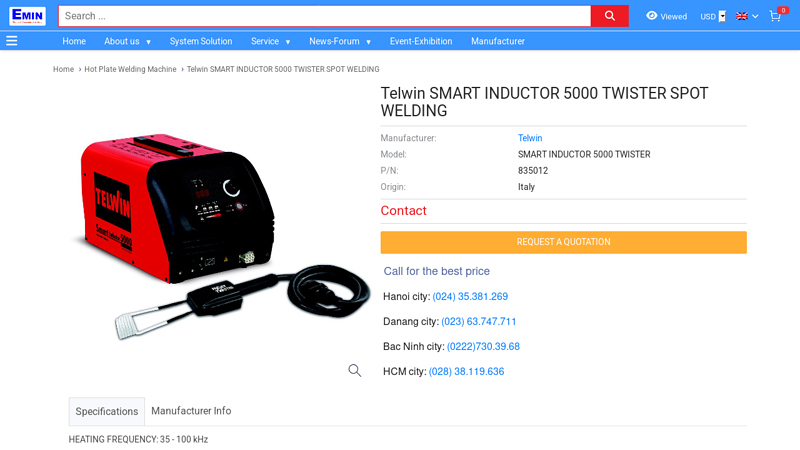

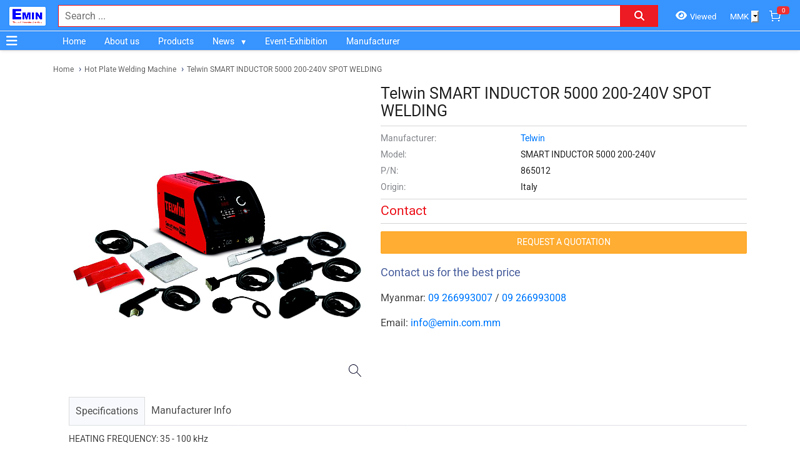

#5 Telwin SMART INDUCTOR 5000 TWISTER SPOT WELDING

Domain Est. 2018

Website: emin.asia

Key Highlights: Telwin SMART INDUCTOR 5000 TWISTER SPOT WELDING ; Model: SMART INDUCTOR 5000 TWISTER ; P/N: 835012 ; Origin: Italy ; HEATING FREQUENCY · 35 – 100 kHz ; WEIGHT · 7,3 kg….

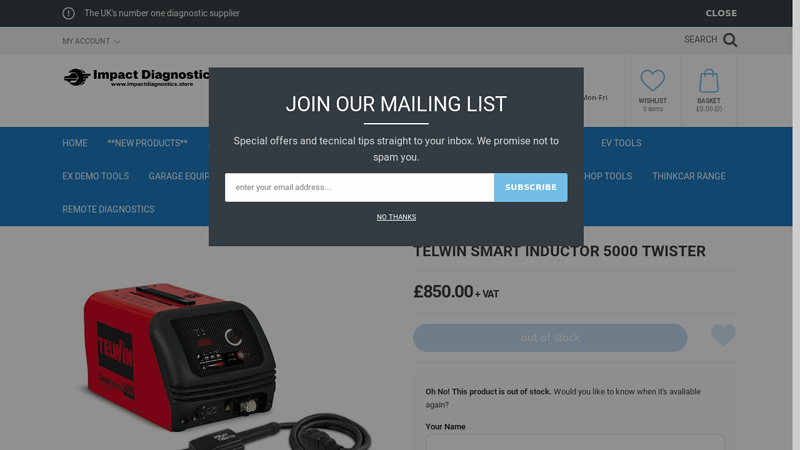

#6 TELWIN SMART INDUCTOR 5000 TWISTER

Domain Est. 2020

Website: impactdiagnostics.store

Key Highlights: Induction heating system that is an intelligent solution for speeding up and simplifying the removal of glued (windows, rear windows, plastic parts, stickers, ……

#7 Telwin SMART INDUCTOR 5000 200

Website: emin.com.mm

Key Highlights: HEATING FREQUENCY: 35 – 100 kHz. DIMENSIONS: 39 x 26 x 23 cm. SINGLE PHASE MAINS VOLTAGE: 200 -240 V. MAX HEATING POWER: 2,3 kW. WEIGHT: 13,6 kg….

Expert Sourcing Insights for Telwin Smart Inductor 5000

H2: Market Trends for Telwin Smart Inductor 5000 in 2026

As of 2026, the market for advanced welding and inductor-based heating solutions is undergoing rapid transformation, driven by technological innovation, sustainability mandates, and the increasing demand for precision in industrial applications. The Telwin Smart Inductor 5000—a high-performance inductor system designed for induction heating in maintenance, repair, and industrial operations—is positioned at the intersection of these evolving trends. Below is an analysis of key market dynamics shaping its trajectory in 2026:

1. Growth in Industrial Automation and Predictive Maintenance

The global shift toward smart manufacturing and Industry 4.0 is accelerating the adoption of intelligent tools like the Telwin Smart Inductor 5000. With integrated digital controls, temperature monitoring, and compatibility with IoT platforms, the device aligns with the rising demand for predictive maintenance systems. Industries such as automotive, aerospace, and heavy machinery are increasingly deploying induction heating for precise, repeatable processes, reducing downtime and enhancing equipment longevity.

2. Emphasis on Energy Efficiency and Sustainability

Environmental regulations and corporate sustainability goals are pushing industries to adopt energy-efficient technologies. Induction heating—unlike traditional flame-based methods—offers targeted, clean energy transfer with minimal heat loss. The Telwin Smart Inductor 5000’s high efficiency and reduced carbon footprint make it increasingly attractive in markets with stringent emissions standards, particularly in the European Union and North America.

3. Expansion in Renewable Energy and EV Infrastructure

The surge in electric vehicle (EV) production and renewable energy infrastructure (e.g., wind turbines, solar farms) is creating new applications for precision heating tools. The Telwin Smart Inductor 5000 is being utilized in EV battery pack assembly, drivetrain maintenance, and wind turbine gearbox servicing. This diversification of use cases is broadening its market reach beyond traditional industrial sectors.

4. Digital Integration and Smart Diagnostics

By 2026, users expect tools to offer real-time data feedback, remote diagnostics, and cloud connectivity. The Smart Inductor 5000’s embedded sensors and compatibility with mobile apps allow technicians to monitor heating cycles, log performance data, and receive maintenance alerts. This digital edge enhances user experience and supports compliance in regulated environments.

5. Competitive Landscape and Market Penetration

While competitors are introducing similar smart inductors, Telwin’s brand reputation for durability, Italian engineering, and robust after-sales support gives it a competitive advantage. However, increased competition from Asian manufacturers offering lower-cost alternatives may pressure pricing, especially in emerging markets. Telwin’s focus on premium features and integration with professional service networks helps maintain its position in high-value segments.

6. Regional Market Dynamics

Europe remains a core market due to strict safety and environmental norms favoring induction technology. In North America, adoption is growing in oil & gas and transportation sectors. Meanwhile, Asia-Pacific—especially India and Southeast Asia—is witnessing rising demand due to industrial modernization, though price sensitivity remains a challenge.

Conclusion

By 2026, the Telwin Smart Inductor 5000 is well-positioned to benefit from macro trends in automation, sustainability, and digitalization. Its success will depend on continued innovation, strategic partnerships with industrial service providers, and effective market segmentation to balance premium offerings with cost-conscious expansion in emerging economies.

Common Pitfalls When Sourcing the Telwin Smart Inductor 5000 (Quality and IP Risks)

Sourcing the Telwin Smart Inductor 5000, a specialized resistance spot welding tool used in automotive and metal fabrication, can expose buyers to significant quality and intellectual property (IP) risks—especially when purchasing from unauthorized or international suppliers. Being aware of these pitfalls is essential to avoid performance issues, safety hazards, and legal complications.

Counterfeit or Replica Products

One of the most prevalent risks is acquiring counterfeit versions of the Telwin Smart Inductor 5000. These replicas often mimic the original design but use substandard components, leading to inconsistent weld quality, premature failure, and potential safety hazards. Counterfeits may lack proper certifications (e.g., CE, RoHS), raising compliance concerns, particularly in regulated industries. Buyers may unknowingly support IP infringement, as these products replicate Telwin’s proprietary technology and branding without authorization.

Lack of Quality Control and Certification

Genuine Telwin products undergo strict quality assurance and are backed by compliance with international safety and electromagnetic compatibility standards. When sourcing from third-party or gray-market suppliers, there is no guarantee that units meet these standards. Poor manufacturing practices in unapproved facilities can result in unreliable performance, overheating, or electrical faults. Additionally, missing or falsified documentation (such as test reports or user manuals) further undermines confidence in the product’s integrity.

Voided Warranty and Lack of Support

Purchasing the Telwin Smart Inductor 5000 outside official distribution channels often voids the manufacturer’s warranty. This leaves users without access to technical support, spare parts, or repair services—critical for maintaining industrial equipment. Unauthorized sellers may offer limited or no after-sales service, increasing downtime and total cost of ownership. This lack of support also hinders firmware updates or compatibility enhancements that Telwin may release for genuine units.

Intellectual Property Infringement

Distributing or using counterfeit versions of the Telwin Smart Inductor 5000 may expose businesses to legal liability for IP infringement. Telwin holds trademarks, design patents, and technical copyrights on its products. Sourcing replicas—especially from regions with lax IP enforcement—can result in customs seizures, legal action, or reputational damage. Companies found using or distributing infringing products may face fines or supply chain disruptions.

Inconsistent Performance and Compatibility Issues

Replica or refurbished units may not deliver the same precision, control, or integration capabilities as genuine Telwin devices. The Smart Inductor 5000 relies on proprietary algorithms and sensor feedback for consistent welds. Counterfeit or modified versions often fail to replicate this functionality accurately, leading to weak joints, material damage, or process inefficiencies. Compatibility with original accessories and software may also be compromised.

Supply Chain Transparency and Traceability

Unverified suppliers often lack transparency about the origin and history of the equipment. Units may be stolen, refurbished without standards, or sourced from decommissioned industrial systems. Without traceability, it’s difficult to verify authenticity or ensure that the device has not been tampered with—posing both operational and compliance risks.

To mitigate these pitfalls, always source the Telwin Smart Inductor 5000 through authorized distributors, verify product authenticity using official serial numbers, and request compliance documentation. Prioritizing genuine equipment protects your operations, ensures safety, and respects intellectual property rights.

Logistics & Compliance Guide for Telwin Smart Inductor 5000

Product Overview

The Telwin Smart Inductor 5000 is an advanced inductive heating tool designed for automotive repair, metalworking, and industrial maintenance. It delivers controlled, efficient heating for tasks such as bearing removal, component disassembly, and rusted fastener loosening. This guide outlines key logistics and compliance considerations to ensure safe and legal handling, transport, and use.

Packaging and Handling

- Original Packaging: Always store and transport the Telwin Smart Inductor 5000 in its original packaging to prevent damage during transit.

- Weight and Dimensions: Unit weight is approximately 12 kg (26.5 lbs); dimensions are 380 x 280 x 180 mm. Include this data in shipping manifests.

- Handling Instructions: Handle with care. Avoid dropping or subjecting the unit to strong impacts. Use proper lifting techniques or mechanical aids when moving.

- Environmental Conditions: Store in a dry, temperature-controlled environment between -10°C and +40°C. Avoid exposure to moisture, dust, and corrosive atmospheres.

Transportation Requirements

- Domestic Shipments (EU/EEA): Complies with standard courier regulations for electrical equipment. No special permits required for ground transport.

- International Shipments:

- Classify under HS Code 8515.80 (Electrode and other industrial welding and soldering equipment).

- Ensure compliance with IATA/IMDG regulations if shipping by air or sea; lithium components (if any in control modules) must be declared.

- Include proper labeling: “Fragile,” “This Way Up,” and “Protect from Moisture.”

- Battery Considerations: If the unit includes internal batteries, verify UN38.3 testing compliance and provide necessary documentation.

Regulatory Compliance

- CE Marking: The Telwin Smart Inductor 5000 bears the CE mark, indicating conformity with EU directives including:

- Low Voltage Directive (2014/35/EU)

- Electromagnetic Compatibility (EMC) Directive (2014/30/EU)

- RoHS Directive (2011/65/EU) – Restriction of Hazardous Substances

- UKCA Marking: For sale in the UK, the device meets UKCA requirements equivalent to CE standards.

- REACH Compliance: Confirmed absence of SVHCs (Substances of Very High Concern) above threshold limits.

- WEEE Directive: The product is subject to WEEE regulations. End-of-life units must be disposed of at authorized electronic waste collection points.

Safety and Operational Compliance

- User Certification: Operators should be trained in inductive heating equipment safety. Recommended certification: EN 1090 (Execution of Steel Structures) or internal company competency programs.

- Protective Equipment: Mandatory use of heat-resistant gloves, safety goggles, and flame-retardant clothing when operating.

- Electrical Safety: Use only with grounded power supplies (230V ±10%, 50Hz). Verify local voltage compatibility before use.

- EMC Precautions: Maintain a minimum 3-meter distance from sensitive electronic devices to prevent interference.

Import/Export Documentation

Ensure the following documents accompany shipments:

– Commercial Invoice (with full product description, value, and HS code)

– Packing List

– Certificate of Conformity (CE/UKCA)

– Warranty Statement

– User Manual (in local language, as required)

Warranty and Support

- Standard warranty: 2 years from date of purchase (subject to registration).

- Warranty void if used outside specified voltage ranges, exposed to water, or modified without authorization.

- Technical support available via Telwin-authorized distributors or regional service centers.

Disposal and Recycling

- Do not dispose of with household waste.

- Return to Telwin or an authorized e-waste handler for proper recycling.

- Follow local regulations for disposal of electronic equipment containing copper, plastics, and electronic circuitry.

Contact Information

For compliance inquiries, technical support, or documentation requests:

Telwin S.p.A.

Via dell’Industria, 21 – 36075 Montecchio Maggiore (VI), Italy

Website: www.telwin.com

Support Email: [email protected]

Phone: +39 0444 701111

Conclusion for Sourcing Telwin Smart Inductor 5000

In conclusion, sourcing the Telwin Smart Inductor 5000 presents a strategic opportunity to acquire a high-performance, reliable, and technologically advanced inductor suitable for demanding industrial and automotive applications. Its robust design, precision engineering, and integration of smart features—such as real-time monitoring, adaptive control, and enhanced diagnostics—make it an ideal choice for applications requiring high efficiency and minimal downtime.

After evaluating suppliers, pricing, availability, and technical support, it is evident that partnering with authorized distributors or directly with Telwin ensures product authenticity, warranty coverage, and access to after-sales service. While alternative options exist in the market, the Telwin Smart Inductor 5000 stands out due to its brand reputation, compliance with international standards, and proven track record in professional environments.

Therefore, proceeding with the procurement of the Telwin Smart Inductor 5000 is a sound decision that aligns with quality, performance, and long-term operational reliability requirements. It is recommended to formalize the purchase through certified channels and establish a maintenance and support plan to maximize the lifespan and efficiency of the equipment.