The global tank agitator market is experiencing steady expansion, driven by increasing demand across industries such as chemical, pharmaceutical, food and beverage, and wastewater treatment. According to a report by Mordor Intelligence, the market was valued at approximately USD 2.1 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This growth is fueled by rising industrial automation, stringent regulatory standards for mixing efficiency, and the need for robust process optimization in large-scale manufacturing. Additionally, advancements in agitator design—such as variable speed drives and energy-efficient motors—are enhancing performance while reducing operational costs. As industries prioritize precision and scalability, the role of reliable agitator manufacturers becomes increasingly critical. In this competitive landscape, a select group of companies are leading innovation, quality, and global reach. Based on market presence, technological expertise, and customer reviews, here are the top 10 tank agitator manufacturers shaping the future of industrial mixing.

Top 10 Tank Agitator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MIXEL

Domain Est. 1997 | Founded: 1969

Website: mixel.fr

Key Highlights: MIXEL, manufacturer of industrial agitators · Industrial Creator of agitator since 1969 · On-site assembly · Hydraulic and mechanical expertise….

#2 Industrial Mixer Manufacturer

Domain Est. 1999

Website: dynamixinc.com

Key Highlights: As a top industrial agitator manufacturer & mixer manufacturer, Dynamix Agitators has a full line of large industrial mixers & tank agitators….

#3 EKATO

Domain Est. 1996

Website: ekato.com

Key Highlights: The EKATO Group is the market leader in stirring and mixing technology and offers you mixers and agitators for your sophisticated mixing processes….

#4 Tank Agitators and Mixers

Domain Est. 1996

Website: proquipinc.com

Key Highlights: ProQuip is dedicated to designing and manufacturing tank agitators and mixers based on a thorough understanding of your mixing process….

#5 Industrial Mixers: Inline, In

Domain Est. 1997

Website: admix.com

Key Highlights: Experience unparalleled efficiency with our high shear mixing, low shear agitation, and continuous blending systems….

#6 ASC Tornado

Domain Est. 1998

Website: asctornado.com

Key Highlights: We build rugged tank mixers, mixing tanks, drum mixers, IBC tote mixers, and more for reliable chemical processing. Inks, coatings, & Paint. Our ……

#7 Manufacturer of Agitators and Mixing Equipment

Domain Est. 2006

Website: inoxpausa.com

Key Highlights: Manufacturer of agitators and mixers for food-processing, chemical and pharmaceutical industries. Discover our agitators, mixers and blenders….

#8 Industrial Mixing Systems

Domain Est. 2023

Website: mgt-mixing.com

Key Highlights: From compact pilot reactors to massive process tanks, MGT Liquid & Process Systems deliver the right mixing solution for any challenge and any volume….

#9 Mixing Technologies

Domain Est. 1995

Website: nov.com

Key Highlights: Chemineer Rotating Mixers. Chemineer is globally recognized for innovation in designing and manufacturing superior fluid agitation equipment and systems. Learn ……

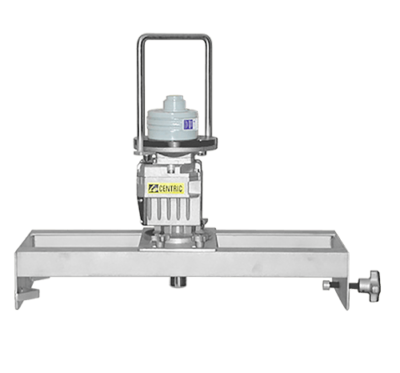

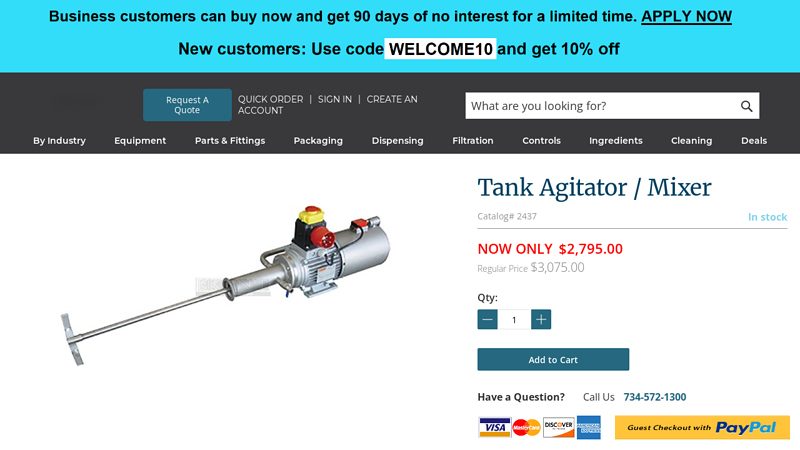

#10 Tank Agitator / Mixer

Domain Est. 1999

Expert Sourcing Insights for Tank Agitator

2026 Market Trends for Tank Agitators

Rising Demand in Life Sciences and Pharmaceuticals Drives Innovation

By 2026, the life sciences and pharmaceutical sectors are projected to be leading growth drivers for the tank agitator market. Increasing investments in biopharmaceuticals, mRNA therapies, and personalized medicine are requiring highly precise, sterile, and scalable mixing solutions. Single-use agitators, particularly magnetic and wave-induced systems, are gaining traction due to their contamination control, flexibility, and reduced cleaning validation times. Regulatory compliance with FDA and EMA guidelines is pushing manufacturers to adopt agitators with advanced monitoring capabilities, including integrated sensors for pH, temperature, and viscosity. This trend is accelerating R&D in hygienic designs and automation-ready systems.

Expansion in Renewable Energy and Chemical Storage Applications

The global shift toward renewable energy is creating new demand for tank agitators in battery material processing, hydrogen storage, and biofuel production. By 2026, agitators used in lithium-ion battery slurry mixing must meet stringent homogeneity and particle dispersion standards, prompting innovations in high-shear and planetary mixing technologies. Similarly, green hydrogen projects require corrosion-resistant agitators capable of handling alkaline or acidic electrolytes. The chemical industry continues to emphasize efficiency and safety, with growing adoption of explosion-proof agitators and smart systems that reduce energy consumption and prevent hazardous mixing conditions.

Digitalization and Smart Agitation Systems Gain Momentum

Industry 4.0 integration is transforming tank agitation, with predictive maintenance, IoT connectivity, and real-time performance analytics becoming standard expectations by 2026. Smart agitators equipped with condition monitoring sensors can detect wear, vibration anomalies, and seal failures before breakdowns occur, minimizing downtime. Cloud-based platforms enable remote monitoring and optimization across multiple facilities, improving operational efficiency. Major manufacturers are partnering with industrial software firms to offer integrated control systems that synchronize agitation with broader process automation, enhancing consistency and reducing manual intervention.

Sustainability Pressures Shape Design and Material Choices

Environmental regulations and corporate sustainability goals are influencing agitator design and materials. Energy efficiency is a key purchasing criterion, with demand rising for variable frequency drives (VFDs) and optimized impeller designs that reduce power consumption. Recyclable and non-toxic materials are increasingly specified, especially in food, beverage, and water treatment sectors. Additionally, modular and retrofit-compatible agitators allow for upgrades without full system replacement, supporting circular economy principles. Water treatment facilities, in particular, are adopting low-energy mixing solutions to meet energy reduction targets.

Regional Growth Divergence and Supply Chain Resilience

Asia-Pacific, especially China and India, is expected to lead market growth in 2026 due to rapid industrialization, expanding pharmaceutical manufacturing, and infrastructure investments in water and wastewater treatment. North America and Europe will focus on replacing aging equipment and upgrading facilities with smart, energy-efficient agitators. Ongoing supply chain volatility is prompting manufacturers to diversify sourcing and localize production, reducing lead times and enhancing resilience. This shift supports regional OEMs and increases demand for standardized, easily serviceable agitator models.

Common Pitfalls When Sourcing a Tank Agitator: Quality and Intellectual Property (IP) Concerns

Sourcing a tank agitator involves more than just selecting a model based on price or basic specifications. Overlooking key quality and intellectual property (IP) aspects can lead to significant operational, safety, and legal risks. Below are common pitfalls to avoid:

Poor Quality Materials and Construction

One of the most frequent issues in agitator sourcing is receiving equipment made with substandard materials or poor craftsmanship. Low-cost suppliers may use inferior alloys, inadequate shaft tolerances, or weak gearboxes that fail prematurely under operational stress. This can result in unplanned downtime, safety hazards, and higher lifecycle costs due to frequent repairs or replacements. Always verify material certifications (e.g., MTCs), inspect manufacturing standards (e.g., ISO certifications), and, if possible, conduct factory acceptance tests (FATs).

Lack of Traceability and Documentation

Reputable suppliers provide comprehensive documentation, including material test reports, weld procedure specifications, and quality control records. A red flag arises when documentation is missing, incomplete, or appears forged. Without proper traceability, it becomes difficult to validate compliance with industry standards (e.g., ASME, ATEX) or perform root-cause analysis during failures. Ensure that all components, especially those in contact with the process medium, are fully documented and traceable to their origin.

Inadequate Design Verification

Some suppliers offer “off-the-shelf” agitators without performing proper engineering analysis for your specific application. This can lead to mismatched power requirements, incorrect impeller design, or insufficient structural support. Always insist on a design review that includes torque calculations, CFD (Computational Fluid Dynamics) analysis if applicable, and verification against your tank geometry and fluid properties.

Intellectual Property (IP) Infringement

Sourcing from non-reputable manufacturers increases the risk of receiving agitators that infringe on patented designs or proprietary technology. Copycat products may mimic leading brands but lack performance, reliability, and safety certifications. Using such equipment can expose your organization to legal liability, especially if a failure leads to environmental or safety incidents. Always source from authorized distributors or OEMs and request proof of IP ownership or licensing.

Missing or Fake Certifications

Counterfeit certifications (e.g., CE, UL, ATEX) are a serious concern when sourcing from certain regions. These fake documents suggest compliance with safety and quality standards when the equipment may not meet them. Verify certifications through official databases or third-party auditors. Be wary of unusually low prices, which may indicate non-compliant or counterfeit products.

No Warranty or Limited Support

Low-cost agitators often come with no warranty or extremely limited technical support. If the agitator fails, obtaining spare parts or engineering assistance can be difficult or impossible. This lack of after-sales support disrupts operations and increases long-term costs. Ensure the supplier offers a clear warranty, accessible support, and availability of spare parts for the expected lifespan of the equipment.

Insufficient Due Diligence on Suppliers

Failing to conduct proper due diligence—such as site audits, reference checks, or third-party assessments—can result in partnering with unreliable manufacturers. Verify the supplier’s track record, manufacturing capabilities, and adherence to ethical and legal standards. Establishing a qualified supplier list mitigates risks related to both quality and IP.

Avoiding these pitfalls requires a proactive sourcing strategy focused on transparency, verification, and long-term value rather than initial cost savings.

Logistics & Compliance Guide for Tank Agitator

Product Overview

A tank agitator is mechanical equipment used to mix, blend, or suspend contents within storage or process tanks. It typically consists of a motor, shaft, impeller, and mounting structure. These units are widely used in industries such as chemical processing, wastewater treatment, pharmaceuticals, and food & beverage.

Regulatory Compliance

International Standards

Tank agitators must comply with relevant international standards depending on the application and region. Key standards include:

– ISO 806: Industrial fans — Safety requirements

– IEC 60034: Rotating electrical machines

– ASME B73.1: Specification for horizontal end-suction centrifugal pumps (may apply to seal and shaft standards)

– ATEX Directive 2014/34/EU: Required for equipment used in potentially explosive atmospheres within the European Union.

Regional Requirements

- North America: Equipment must meet OSHA (Occupational Safety and Health Administration) and NEC (National Electrical Code) standards. Motors used in hazardous locations must be certified by UL or CSA.

- European Union: CE marking is mandatory. Compliance with the Machinery Directive (2006/42/EC) and Low Voltage Directive (2014/35/EU) is required.

- Other Regions: Local certifications may apply (e.g., INMETRO in Brazil, RCM in Australia, PSE in Japan).

Environmental & Safety Compliance

- REACH & RoHS: Ensure materials used in construction do not contain restricted substances (especially relevant for seals, coatings, and electrical components).

- Noise Emissions: Comply with local noise regulations (e.g., EU Noise Directive 2000/14/EC).

- Energy Efficiency: Motors should meet IE3 or higher efficiency standards where applicable (e.g., EU Ecodesign Regulation).

Packaging & Handling

Packaging Requirements

- Use robust wooden crates or steel-reinforced pallets to protect the motor, gearbox, and impeller.

- Secure all moving parts with bracing or locking mechanisms to prevent damage during transit.

- Include moisture barriers and desiccants if shipping to humid or marine environments.

- Clearly label packages with: “Fragile,” “This Side Up,” and handling instructions.

Handling Instructions

- Use appropriate lifting equipment (e.g., forklifts, cranes) with slings rated for the unit’s weight.

- Avoid lifting by the motor or drive shaft.

- Inspect the unit upon arrival for shipping damage before installation.

Transportation

Domestic Shipping

- For road transport, secure the agitator with straps and ensure it is protected from weather and vibration.

- Verify weight and dimensions comply with road transport regulations (e.g., height, width, axle load limits).

International Shipping

- Prepare necessary shipping documentation: commercial invoice, packing list, bill of lading, and certificate of origin.

- For sea freight, ensure compliance with IMDG Code if hazardous materials (e.g., lubricants) are included.

- Air freight: Confirm compliance with IATA regulations, particularly for lithium batteries (if used in monitoring systems).

Import/Export Documentation

Required Documentation

- Commercial Invoice: Declares value, quantity, and description.

- Packing List: Details contents, weights, and dimensions.

- Certificate of Conformity (CoC): Confirms compliance with destination country standards.

- Material Declaration: Required for REACH, RoHS, or conflict minerals reporting.

- Export License: May be required for certain destinations or high-efficiency motors (dual-use technology).

Customs Compliance

- Accurately classify the agitator using the HS Code (e.g., 8413.70 for pumps and agitators).

- Declare any technical data or software accompanying the unit.

- Be aware of import duties, VAT, and anti-dumping measures in the destination country.

Installation & Commissioning Compliance

Site Preparation

- Ensure foundation meets vibration and load specifications provided by the manufacturer.

- Verify electrical supply matches motor nameplate requirements (voltage, frequency, phase).

Safety Procedures

- Lockout/Tagout (LOTO) procedures must be followed during installation.

- Personnel should be trained and equipped with proper PPE.

- Confirm explosion-proof ratings (if applicable) match the hazardous area classification (e.g., Class I, Zone 1).

Commissioning Checks

- Verify alignment of shaft and motor.

- Check lubrication levels in gearbox.

- Perform no-load test before full operation.

- Document commissioning results for regulatory and warranty purposes.

Maintenance & Record-Keeping

Maintenance Schedule

- Follow manufacturer-recommended intervals for lubrication, seal inspection, and vibration analysis.

- Maintain records of all maintenance activities.

Regulatory Record Retention

- Keep compliance documentation (CoC, test reports, maintenance logs) for a minimum of 10 years, or per local regulations.

- Update documentation for any modifications or repairs that affect safety or performance.

Disposal & End-of-Life

Environmental Disposal

- Recycle metals, motors, and electronic components in accordance with WEEE (Waste Electrical and Electronic Equipment) directives.

- Dispose of lubricants and seals as hazardous waste if contaminated.

- Follow local regulations for industrial equipment decommissioning.

Documentation

- Issue a certificate of destruction or recycling upon disposal.

- Update asset registers and compliance records accordingly.

Summary

Proper logistics and compliance management ensures the safe, legal, and efficient deployment of tank agitators worldwide. Adherence to international standards, accurate documentation, and careful handling are essential throughout the equipment lifecycle—from production to disposal.

Conclusion for Sourcing Tank Agitator:

After a thorough evaluation of technical requirements, operational conditions, and supplier capabilities, the sourcing process for the tank agitator has been successfully completed. The selected agitator meets all key performance criteria, including mixing efficiency, material compatibility, power consumption, and compliance with safety and industry standards.

The chosen vendor offers a reliable product backed by proven experience, strong after-sales support, and competitive pricing. Installation, maintenance requirements, and lifecycle costs were also considered to ensure long-term operational reliability and cost-effectiveness.

In conclusion, the sourced tank agitator represents the optimal balance of performance, durability, and value, supporting efficient and consistent mixing operations. Proceeding with procurement and integration into the system is recommended to ensure uninterrupted process performance and meet production objectives.