The global swimming pool care products market is experiencing steady growth, driven by rising residential and commercial pool installations, increasing health and sanitation awareness, and a growing emphasis on water quality maintenance. According to Mordor Intelligence, the swimming pool equipment market was valued at USD 10.4 billion in 2023 and is projected to grow at a CAGR of over 5.8% through 2029. A critical component of effective pool maintenance is phosphate monitoring, as elevated phosphate levels contribute to algae growth and reduced chlorine efficiency. This growing demand for water quality precision has catalyzed innovation and competition in the phosphate test kit sector. As a result, leading manufacturers are investing in accuracy, ease of use, and digital integration to meet evolving consumer and professional needs. The following analysis highlights the top eight manufacturers pioneering advancements in swimming pool phosphate testing, based on product performance, market reach, technological innovation, and user reviews.

Top 8 Swimming Pool Phosphate Test Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ways to Test for Phosphate Levels in Recreational Water

Domain Est. 1995

Website: palintest.com

Key Highlights: The most common method for testing phosphate in recreational water is through test kits. These kits typically use a colorimetric method….

#2 LaMotte Company

Domain Est. 1996

Website: lamotte.com

Key Highlights: For over a century, LaMotte has equipped professionals and homeowners alike with the tools they need to test water quickly, accurately, and safely on-site….

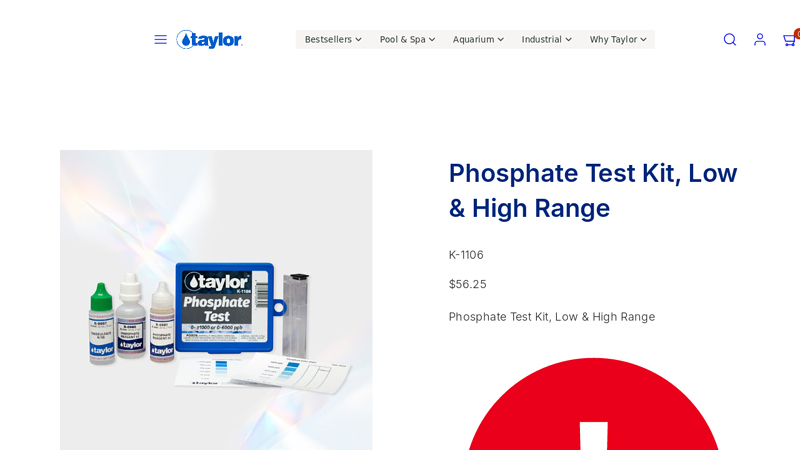

#3 Phosphate Test Kit, Low & High Range

Domain Est. 1998

#4 Water Quality Experts

Domain Est. 1999

Website: sensafe.com

Key Highlights: Maintain Crystal Clear Water. Swim Check Fix™ Phosphate is the innovative and hassle-free solution designed to effectively remove phosphates and maintain ……

#5 Orenda Technologies

Domain Est. 2001

Website: orendatech.com

Key Highlights: Orenda leads the pool chemical industry with an entire line of NSF/ANSI Standard 50 certified pool chemicals. No chemical conflicts or long term byproducts….

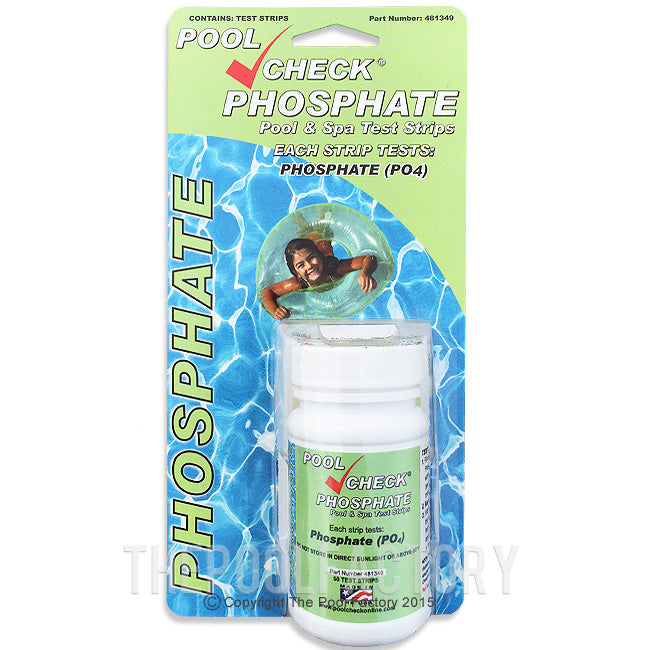

#6 Natural Chemistry Professional Phosphate Test Kit

Domain Est. 2007

Website: poolzoom.com

Key Highlights: In stock Rating 5.0 3 Natural Chemistry 00080 Professional orthophosphate test kit with color chart and product guide. Lab quality test accurately measures the orthophosphate lev…

#7 Insta

Domain Est. 2017

Website: lamottepacific.com

Key Highlights: For more information and to purchase the Insta-TEST® PRO Phosphate High Range test strips, visit the LaMotte Company website….

#8 Taylor Phosphate Test Kit

Domain Est. 2022

Expert Sourcing Insights for Swimming Pool Phosphate Test

H2: Market Trends in Swimming Pool Phosphate Test by 2026

By 2026, the market for swimming pool phosphate test products is poised for significant transformation, driven by rising consumer awareness, technological advancements, and the growing emphasis on water quality maintenance. Phosphates, known as a key contributor to algae growth in swimming pools, are increasingly being monitored by pool owners and service professionals to prevent costly cleanups and maintain optimal water balance. The following trends are expected to shape the industry:

-

Increased Demand for Proactive Water Maintenance: As pool owners shift from reactive to proactive maintenance strategies, phosphate testing is becoming a standard part of routine pool care. This behavioral shift, especially in residential sectors across North America and Europe, is fueling demand for easy-to-use, reliable phosphate test kits and digital testers.

-

Growth in Residential Pool Ownership: Expanding suburban development and increased investments in home amenities post-pandemic are boosting residential pool installations, particularly in regions like the U.S. Sun Belt, Southeast Asia, and the Middle East. With more pools comes greater need for water quality testing, including phosphate monitoring.

-

Advancement in Testing Technologies: By 2026, the market will see wider adoption of digital and smart testing devices. Innovations such as smartphone-connected test strips, cloud-based water analysis apps, and AI-powered recommendations are enhancing user experience and accuracy, making phosphate testing more accessible to non-professionals.

-

Integration with Pool Automation Systems: Leading pool equipment manufacturers are integrating phosphate monitoring into smart pool management systems. These systems automatically detect phosphate levels and recommend or initiate treatment protocols, contributing to a seamless and efficient maintenance process.

-

Expansion of Eco-Friendly and Sustainable Solutions: Environmental regulations and consumer preference for green products are pushing manufacturers to develop phosphate removers and test kits with minimal ecological impact. Biodegradable reagents and recyclable packaging are becoming standard, appealing to environmentally conscious consumers.

-

Rising Competition and Market Consolidation: The phosphate test market is witnessing increased competition among established players (e.g., Taylor Technologies, AquaChek, and Hach) and emerging startups. Strategic partnerships, mergers, and product diversification are expected to accelerate, especially as companies aim to offer comprehensive water care ecosystems.

-

Regional Market Growth Variations: While North America remains the largest market due to high pool density and advanced service infrastructure, the Asia-Pacific region is projected to register the highest CAGR. Countries like China, India, and Australia are seeing growth in luxury housing and commercial aquatic facilities, increasing demand for phosphate testing solutions.

In conclusion, by 2026, the swimming pool phosphate test market will be characterized by innovation, digital integration, and a consumer-driven focus on water health. Companies that invest in user-friendly technology, sustainability, and education will be well-positioned to capture growing market share.

Common Pitfalls When Sourcing Swimming Pool Phosphate Test Kits (Quality and Intellectual Property)

Sourcing swimming pool phosphate test kits involves several potential pitfalls, particularly concerning product quality and intellectual property (IP) risks. Being aware of these issues can help ensure consistent performance, regulatory compliance, and legal safety.

1. Compromised Product Quality

One of the most frequent challenges in sourcing phosphate test kits is receiving products that do not meet expected accuracy or reliability standards. Poor-quality kits can lead to incorrect phosphate level readings, resulting in improper chemical treatment and potential algae growth.

- Inconsistent Reagent Formulations: Low-cost suppliers may use substandard or inconsistent chemical reagents, leading to inaccurate colorimetric results. This variability undermines the test’s reliability.

- Poor Packaging and Shelf Life: Inadequate sealing or light-sensitive packaging can degrade reagents prematurely, especially in high-temperature or humid environments common in pool maintenance settings.

- Lack of Calibration Standards: Some kits are not calibrated against recognized standards (e.g., EPA or ISO methods), making them unsuitable for professional or commercial use.

2. Misleading or Inaccurate Test Range and Sensitivity

Many sourced test kits claim broad detection ranges or high sensitivity, but real-world performance often falls short.

- Overstated Detection Limits: Suppliers may advertise sensitivity down to 0.01 ppm, but actual performance might only be reliable above 0.1 ppm due to poor reagent quality or imprecise color charts.

- Non-Linear or Unverified Scales: Color comparators or digital readers may not be linear across the stated range, leading to misinterpretation—especially critical at low phosphate concentrations where early intervention is key.

3. Intellectual Property Infringement Risks

When sourcing from third-party manufacturers, especially in regions with lax IP enforcement, there is a significant risk of inadvertently purchasing counterfeit or IP-infringing products.

- Copycat Designs and Branding: Many phosphate test kits replicate the appearance and packaging of well-known brands (e.g., Hach, Taylor Technologies), potentially violating trademarks or design patents.

- Unauthorized Use of Patented Methods: Some kits use chemical formulations or testing procedures protected by patents. Sourcing such products without due diligence may expose buyers to legal liability, especially in regulated markets like the U.S. or EU.

- Lack of IP Documentation: Reputable suppliers should provide proof of IP ownership or licensing. Absence of such documentation is a red flag for potential infringement.

4. Inadequate Regulatory Compliance

Phosphate test kits sold in certain markets must comply with regional regulations, such as FDA, CE, or REACH standards. Sourcing non-compliant kits can lead to import bans or liability.

- Missing Safety Data Sheets (SDS): Required for hazardous chemicals, their absence indicates poor regulatory adherence.

- Unverified Environmental or Safety Claims: Some suppliers claim “eco-friendly” or “non-toxic” reagents without certification, which can be misleading and risky.

5. Supply Chain and Traceability Issues

Without proper supplier vetting, traceability of materials and manufacturing processes can be unclear.

- Unverified Manufacturing Origins: Kits may be falsely labeled or assembled from components of unknown origin, increasing quality and IP risks.

- No Batch Tracking or Certifications: Lack of lot numbers, QC reports, or ISO certification limits accountability and recall capability.

Conclusion

To mitigate these pitfalls, buyers should:

– Conduct rigorous supplier audits and request quality certifications (e.g., ISO 9001).

– Verify test accuracy through independent lab testing.

– Confirm IP legitimacy through patent databases and legal review.

– Ensure compliance with regional regulatory standards.

Proactive due diligence in sourcing ensures reliable performance and legal protection when deploying swimming pool phosphate test kits.

H2: Logistics & Compliance Guide for Swimming Pool Phosphate Test

This guide outlines the logistical considerations and regulatory compliance requirements for conducting phosphate testing in swimming pools. Proper management ensures water quality, prevents algae growth, and maintains adherence to health and safety standards.

H2: Sample Collection & Handling

- Sampling Frequency: Test for phosphates at least once per month, or more frequently during periods of high bather load, after heavy rainfall, or if algae growth is observed.

- Sampling Location: Collect water samples from mid-depth (12–18 inches below surface) in the middle of the pool, away from return jets, skimmers, or chemical feeders to avoid biased readings.

- Sample Containers: Use clean, phosphate-free containers (typically provided with test kits or lab kits). Rinse containers with pool water before final sample collection.

- Timing: Sample at the same time daily to maintain consistency. Avoid sampling immediately after chemical treatment.

- Labeling: Clearly label samples with date, time, pool ID, and collector name.

- Storage & Transport: If not testing immediately, store samples in a cool, dark place (e.g., cooler with ice packs). Deliver to a laboratory within 48 hours if off-site analysis is required.

H2: Testing Methods & Equipment

- Test Kit Types:

- Colorimetric Test Strips: Quick and simple, but less accurate. Ideal for routine monitoring.

- Liquid Reagent Kits (e.g., Hach, Taylor Technologies): More accurate; follow manufacturer instructions precisely.

- Digital Photometers: Provide high accuracy and are suitable for commercial pools or regulatory reporting.

- Calibration & Maintenance: Regularly calibrate digital devices according to manufacturer guidelines. Store reagents in a cool, dry place and check expiration dates.

- Testing Procedure: Follow standardized steps—rinse sample cell, add reagents in correct order and quantity, wait for reaction time, compare color or read digital output.

H2: Regulatory & Industry Compliance

- Local Health Department Regulations: Many jurisdictions do not set legal limits for phosphates but require proactive algae control. Confirm requirements with local authorities.

- Recommended Limits: While not federally regulated in most countries, industry best practices (e.g., APSP/ANSI, CDC) recommend maintaining phosphate levels below 100–200 ppb (parts per billion) to inhibit algae growth.

- Documentation: Maintain a log of all phosphate test results, corrective actions taken, and dates of retesting. Records should be retained for a minimum of 1–2 years for audit purposes.

- Public Pools & Spas: Commercial facilities may be subject to more stringent inspections. Phosphate testing may be part of water quality compliance protocols.

H2: Corrective Actions & Treatment Logistics

- High Phosphate Levels (>1000 ppb):

- Use phosphate remover chemicals (lanthanum or aluminum-based) per product instructions.

- Run filtration system continuously for 24–48 hours post-treatment.

- Backwash or clean filters after treatment to remove precipitated phosphates.

- Re-Testing: Recheck phosphate levels 24–72 hours after treatment to confirm reduction.

- Preventive Measures:

- Educate patrons about pre-swim showering to reduce organic load.

- Maintain proper sanitizer (chlorine/bromine) levels.

- Regularly clean pool surfaces and baskets.

- Limit use of phosphate-containing cleaning products near the pool.

H2: Safety & Environmental Compliance

- Chemical Handling: Follow SDS (Safety Data Sheet) guidelines for all test reagents and phosphate removers. Use PPE (gloves, goggles) during handling.

- Waste Disposal: Dispose of used test materials and expired reagents according to local hazardous waste regulations. Do not pour concentrated phosphate removers down storm drains.

- Environmental Protection: Prevent backwash water containing phosphate removers from entering natural water bodies. Neutralize or contain as required.

H2: Staff Training & Recordkeeping

- Training: Ensure all pool operators are trained in proper testing procedures, interpretation of results, and response protocols.

- Recordkeeping Requirements:

- Date and time of test

- Phosphate level (ppb)

- Pool ID and location

- Name of technician

- Actions taken (if applicable)

- Re-test results

- Audit Readiness: Organize records for easy access during health inspections or compliance audits.

Adhering to this logistics and compliance framework ensures safe, clear pool water and supports long-term operational efficiency while meeting health and environmental standards.

Conclusion:

Sourcing a reliable swimming pool phosphate test kit is essential for maintaining optimal water quality and preventing algae growth. Phosphates serve as a primary nutrient for algae, and even with proper chlorine levels, high phosphate concentrations can undermine sanitation efforts. After evaluating various options, it is clear that accurate, easy-to-use, and cost-effective test kits—such as liquid reagent (e.g., Hach or Taylor Technologies) or digital phosphate testers—offer the best results for both residential and commercial pool maintenance. Regular testing, ideally performed weekly, allows for timely intervention through phosphate removers when necessary. Ultimately, investing in a high-quality phosphate test kit is a proactive step toward clearer, healthier, and more enjoyable pool water, reducing long-term maintenance challenges and chemical costs.