The sublimation printing paper market has experienced robust growth in recent years, driven by rising demand across textiles, signage, and custom décor industries. According to a 2023 report by Mordor Intelligence, the global sublimation paper market was valued at USD 1.35 billion and is projected to grow at a CAGR of 6.8% from 2024 to 2029. This expansion is fueled by the increasing adoption of digital printing technologies and the surge in personalized product offerings, particularly in e-commerce. Complementing this, Grand View Research reports that the broader dye-sublimation market—which includes paper, inks, and printers—is expected to exceed USD 10 billion by 2030, underpinned by advancements in heat-transfer efficiency and sustainable printing solutions. As demand intensifies, a select group of manufacturers has emerged as leaders in innovation, production capacity, and global distribution. Here are the top 10 sublimation printing paper manufacturers shaping the industry.

Top 10 Sublimation Printing Paper Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Beaver Paper

Domain Est. 1996

Website: beaverpaper.com

Key Highlights: Beaver Paper is a globally recognized producer of TexPrint® sublimation paper, ProTex® tissue and TexStyles® graphic fabrics for the dye-sublimation and ……

#2 ColDesi, Inc. Make Your Own Customized Products

Domain Est. 2010

Website: coldesi.com

Key Highlights: Leading provider of customized products equipment. Including: commercial embroidery machines, direct-to-garment printers, and more….

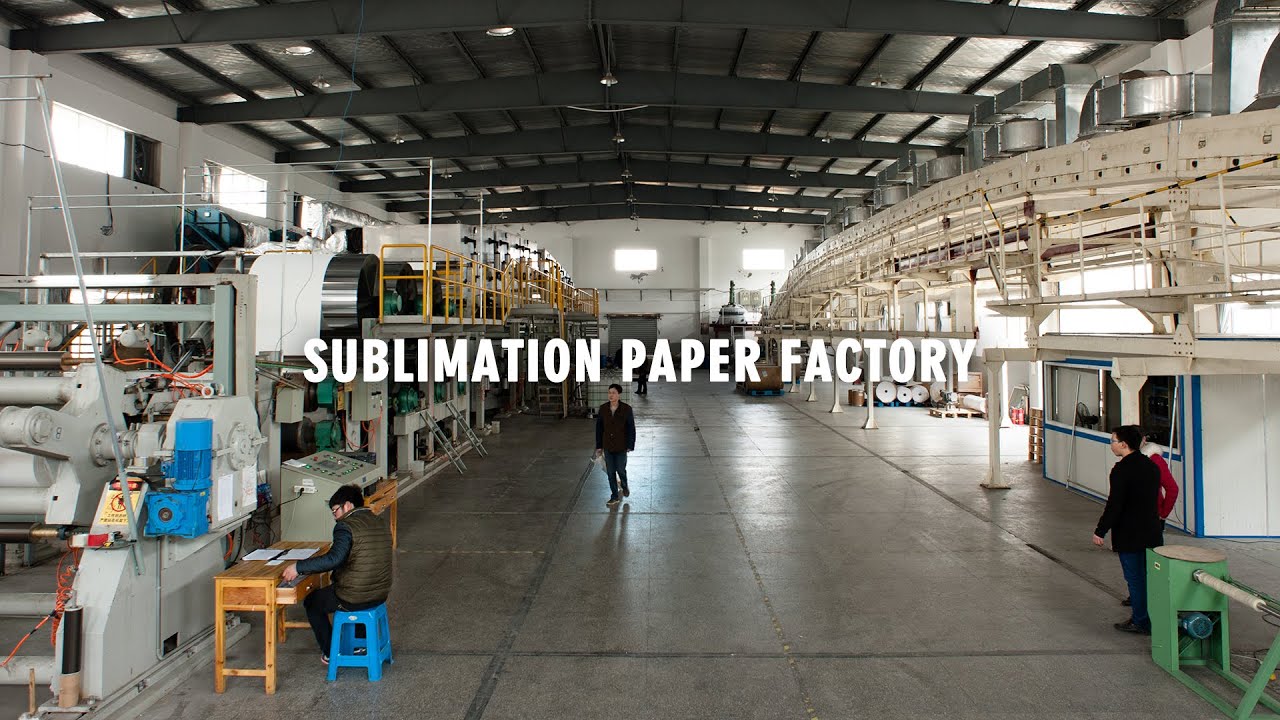

#3 Sublimation Paper Manufacturers

Domain Est. 2023

Website: xinflyinggroup.com

Key Highlights: Xinflying’s high quality wholesale bulk sublimation paper can assist in the precision, speed, and stability of your printers in maximums….

#4 EcoJet® Dye Sublimation Paper

Domain Est. 1993

Website: ahlstrom.com

Key Highlights: Ahlstrom’s EcoJet™ Series sets a new standard in dye-sublimation transfer paper, combining exceptional ink absorption with unmatched flatness and stability ……

#5 Dye Sublimation Papers

Domain Est. 1995

Website: sappi.com

Key Highlights: Our portfolio of tried and tested dye sublimation papers includes coated and uncoated papers for digital transfer printing with water-based dye sublimation inks ……

#6 Sublimation Transfer Paper

Domain Est. 1996

Website: grimco.com

Key Highlights: Free delivery 30-day returnsGrimco provides sublimation transfer paper rolls and sublimation supplies at wholesale prices….

#7 Ready Printed Transfer Paper

Domain Est. 2004

Website: contrado.com

Key Highlights: In stock Rating 4.9 (8) Contrado supplies dye sublimation printed transfer paper for your sublimation fabric printing. Upload your design or logo. Express delivery….

#8 JPPlus: Engraving, Sublimation, Heat Transfer & UV-LED

Domain Est. 2005

Website: jpplus.com

Key Highlights: Johnson Plastics Plus is your home for products and equipment for laser and rotary engraving, sublimation, heat transfer printing and UV-LED printing….

#9 S-RACE® Sublimation Papers

Domain Est. 2016

Website: s-race.com

Key Highlights: Dye sublimation paper by S-RACE® is impressively fast, efficient and precise. Our Portfolio is covering dye sublimation papers for any kind of application….

#10 V

Domain Est. 2018

Website: replicasublimationpaper.com

Key Highlights: We offer a wide range of dye sublimation papers, from 44”inch (111.76cm) to 64″inch (162.56cm) in 58GSM to 105GSM. Making you able to source all the items you ……

Expert Sourcing Insights for Sublimation Printing Paper

H2: 2026 Market Trends for Sublimation Printing Paper

The sublimation printing paper market is poised for significant transformation by 2026, driven by technological advancements, rising demand in personalized and eco-conscious printing, and expanding applications across industries. As digital customization becomes increasingly mainstream, sublimation printing—known for its vibrant, durable, and high-resolution output—continues to gain traction, directly influencing the demand for sublimation transfer paper.

A key trend shaping the 2026 landscape is the growing adoption of sublimation printing in the textile and apparel sector, especially within the fast-expanding market for custom sportswear, fashion, and home décor. The rise of e-commerce platforms and on-demand printing services has empowered small businesses and entrepreneurs to offer personalized products with minimal inventory, fueling consistent demand for high-quality sublimation paper.

Additionally, sustainability is emerging as a critical market driver. By 2026, manufacturers are expected to prioritize eco-friendly sublimation papers made from recyclable or biodegradable materials, responding to both consumer demand and tightening environmental regulations. Innovations in low-ink-bleed and high-ink-absorption papers will enhance print precision and reduce waste, further supporting green initiatives.

Technological improvements in digital printing equipment—such as faster printers with higher resolution—are also increasing efficiency and lowering production costs, thereby expanding access to sublimation technology in emerging markets. This trend is particularly evident in regions like Asia-Pacific and Latin America, where rising disposable incomes and increasing investments in manufacturing are accelerating market growth.

Moreover, the integration of Industry 4.0 principles, including automation and data-driven production, is expected to optimize supply chains and improve consistency in sublimation paper quality. Leading suppliers are likely to adopt smart manufacturing techniques to meet the growing demand for customized, just-in-time paper solutions.

In summary, by 2026, the sublimation printing paper market will be shaped by innovation, sustainability, and globalization. Companies that invest in R&D, embrace eco-friendly practices, and adapt to evolving customer needs across diverse sectors will be best positioned to capitalize on these dynamic trends.

Common Pitfalls When Sourcing Sublimation Printing Paper

Sourcing sublimation printing paper is critical to achieving high-quality prints, but it comes with several common pitfalls—especially related to quality inconsistencies and intellectual property (IP) concerns. Being aware of these challenges can help avoid costly mistakes and protect your brand.

Quality Inconsistencies

One of the most frequent issues when sourcing sublimation paper is inconsistent quality, particularly from low-cost or unverified suppliers. Variations in coating thickness, paper weight, absorbency, and drying time can lead to poor ink transfer, blotching, or ghosting during the heat press process. Lower-grade papers may also cause printhead clogging or produce faded, uneven prints. To mitigate this, always request samples, verify technical specifications, and prioritize suppliers with consistent quality control and third-party testing.

Intellectual Property Risks

Another major pitfall involves intellectual property concerns, especially when sourcing from overseas manufacturers. Some suppliers may use patented coating technologies or formulations without proper licensing, exposing buyers to legal risks. Additionally, there’s a risk of counterfeit or rebranded paper being sold as premium brands. To protect against IP violations, conduct due diligence on suppliers, request documentation of proprietary technology or licensing agreements, and consider working with reputable manufacturers who respect IP rights and offer legally compliant products.

Logistics & Compliance Guide for Sublimation Printing Paper

Product Overview and Handling

Sublimation printing paper is a specialized transfer medium used in dye-sublimation printing processes, primarily for transferring vibrant, full-color designs onto polyester-based materials and polymer-coated substrates. Proper logistics and compliance handling are essential to maintain product quality, ensure safety, and meet regulatory requirements throughout the supply chain.

Storage and Environmental Conditions

Store sublimation paper in a cool, dry environment with controlled temperature and humidity. Ideal conditions are between 15–25°C (59–77°F) and 40–60% relative humidity. Exposure to excessive heat, cold, or moisture can cause curling, ink bleeding, or poor transfer performance. Keep rolls and reams sealed in original packaging until ready for use, and avoid direct sunlight or proximity to heating/cooling vents.

Packaging and Transportation

Sublimation paper must be securely packaged to prevent damage during transit. Rolls should be enclosed in rigid cardboard cores and protected with end caps and stretch wrap or sealed poly bags. Flat sheets should be interleaved and packed in sturdy cartons to avoid bending or creasing. Use palletized shipments for bulk orders, ensuring stable stacking and protection from moisture. Label packages as “Fragile” and “Keep Dry” to alert handlers.

Regulatory Compliance

Sublimation paper itself is typically free of hazardous chemicals and is not classified as dangerous goods for transport under major international regulations (e.g., IATA, IMDG, ADR). However, compliance with local and international standards is required. Ensure products meet REACH (EU) and RoHS directives regarding restricted substances. In the U.S., follow guidelines from the Consumer Product Safety Commission (CPSC) if used in consumer goods applications.

Import and Export Documentation

When shipping internationally, accurate customs documentation is critical. Provide a detailed commercial invoice listing product description (e.g., “Sublimation Transfer Paper for Digital Printing”), HS Code (commonly 4802.56 or 4802.62, depending on composition), country of origin, and value. Include packing lists and, if required, certificates of origin. Verify destination country regulations—some may require conformity assessments or labeling in local language.

Labeling and Safety Information

While sublimation paper is generally non-hazardous, proper labeling enhances safety and traceability. Include product name, batch/lot number, manufacturing and expiry dates, net quantity, and storage instructions on packaging. Although not typically classified as hazardous, include a Safety Data Sheet (SDS) upon request per GHS (Globally Harmonized System) standards, especially if bundled with inks or sold as part of a printing kit.

Waste Disposal and Environmental Responsibility

Dispose of used or defective sublimation paper in accordance with local waste management regulations. The paper is typically recyclable if uncontaminated by ink; however, ink-saturated sheets may require disposal as mixed waste. Encourage customers to follow sustainable practices, such as recycling packaging materials and minimizing paper waste through efficient design layout.

Quality Assurance and Traceability

Implement a batch tracking system to ensure full traceability from manufacturing to delivery. This supports quality control and enables effective recalls if necessary. Conduct regular audits of storage and shipping practices to ensure consistency and compliance across the supply chain.

In conclusion, sourcing high-quality sublimation printing paper is a critical step in ensuring excellent print results, vibrant colors, and durable transfers in dye-sublimation printing applications. When selecting a supplier, factors such as paper weight, coating quality, heat resistance, consistency, and compatibility with your printer and inks must be carefully evaluated. Reliable suppliers offering certifications, environmental compliance, and strong technical support contribute to long-term success and customer satisfaction. By prioritizing reputable sources and conducting thorough product testing, businesses can optimize their sublimation process, reduce waste, and deliver professional-grade products across apparel, promotional items, and custom décor markets. Ultimately, strategic sourcing of sublimation paper enhances both efficiency and print quality, providing a strong foundation for growth in the competitive printing industry.