The global sublimation printing market is experiencing robust growth, driven by rising demand for customized products across apparel, home décor, and promotional items. According to Grand View Research, the market was valued at USD 6.5 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.1% from 2023 to 2030. This surge is attributed to advancements in digital printing technology, increasing consumer preference for personalization, and the scalability offered by sublimation blanks in on-demand manufacturing. As brands and entrepreneurs seek reliable sources for high-quality sublimation blank slates—ranging from mugs and phone cases to tiles and apparel—the role of specialized manufacturers becomes increasingly critical. In this evolving landscape, identifying partners with consistent quality, diverse product offerings, and efficient production capabilities is key to maintaining a competitive edge. Here’s a data-driven look at the top 9 sublimation blank slates manufacturers shaping the industry’s future.

Top 9 Sublimation Blank Slates Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sublimation Photo Slates

Domain Est. 2005

#2 Premium Photo Slate for Sublimation

Domain Est. 2005

#3 Sublimation Photo Slate

Domain Est. 2011

Website: longforte.com

Key Highlights: In stock Rating 4.8 41 Designed with a smooth, glossy white coating, it allows for vibrant, detailed image transfers, making it ideal for personalised gifts, home décor, or corpo…

#4 Keepwaters Sublimation Slate Blanks, Sublimate Slates With …

Domain Est. 2017

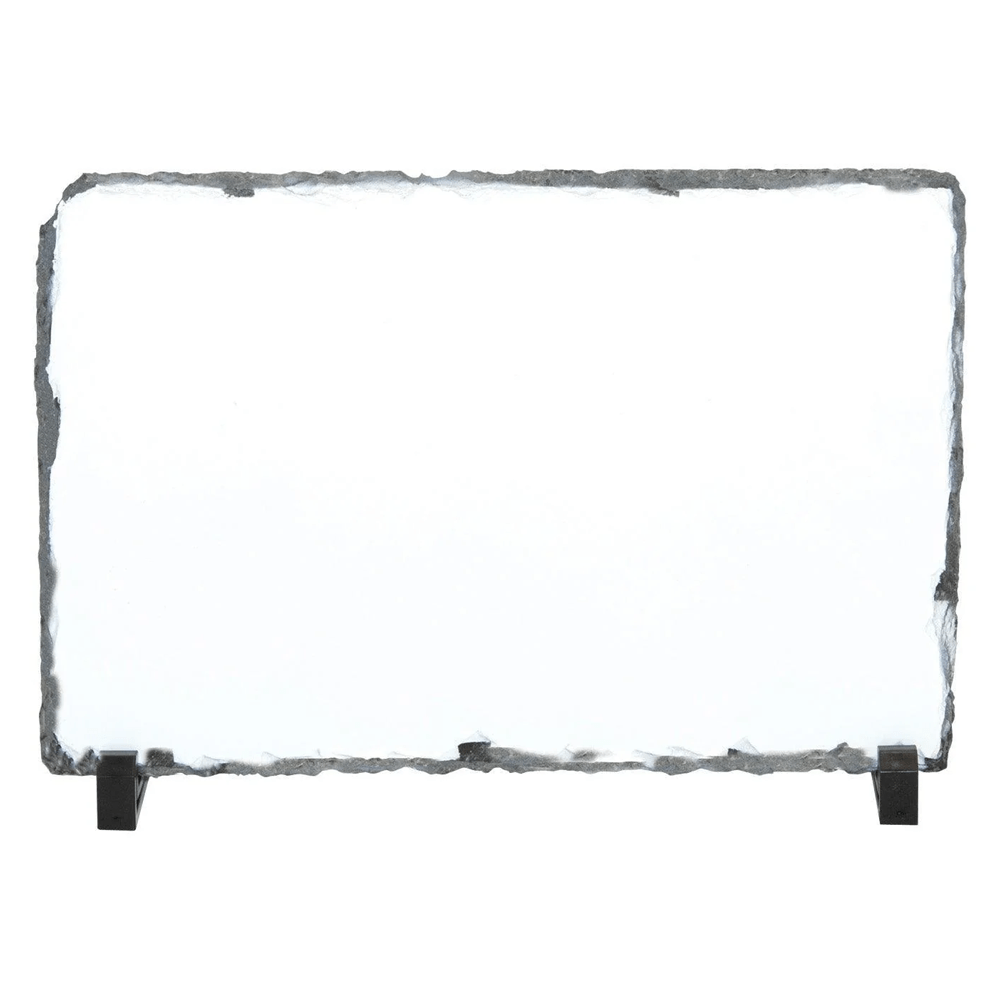

#5 PATIKIL Sublimation Slate Blanks, 6 Pcs Heart Stone Sublimation …

Domain Est. 2017

Website: leonardiandpartners.com

Key Highlights: In stock Rating 5.0 (149) 6 days ago · Size: The Sublimation Slate Blank comes with 6 pcs sublimated blank photo frames with display stands, which measure 6 x 6 x 0.31 inches/15 …

#6 6 Pack Sublimation Slate Blanks,Heat Thermal Transfer Sheet Stone …

Domain Est. 2018

#7 WANZELONYO Sublimation Slate Blanks 4×6 Inch …

Domain Est. 2021

#8 ORJ 4 Pack Sublimation Slate Blanks Custom Stone Slate Picture …

Domain Est. 2023

#9

Domain Est. 2014

Website: bestsub.com

Key Highlights: BestSub is the leading supplier of 25 years in 8000+ sublimation blanks, js coatings ceramic sublimation mugs, stainless steel sublimation tumblers, ……

Expert Sourcing Insights for Sublimation Blank Slates

2026 Market Trends for Sublimation Blank Slates

The sublimation blank slates market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and the expansion of the custom printing industry. These blank substrates—used in dye-sublimation printing for personalized products like mugs, tiles, phone cases, and apparel—are becoming increasingly vital in both small-scale entrepreneurial ventures and large manufacturing operations. This analysis explores key trends expected to shape the industry in 2026.

Growing Demand for Personalization

One of the most influential trends shaping the 2026 sublimation blanks market is the rising consumer appetite for personalized products. As e-commerce platforms and social media fuel individual expression, customers are increasingly seeking unique, customized items. Sublimation blank slates serve as the foundation for this customization, enabling businesses to offer tailored merchandise. The do-it-yourself (DIY) and print-on-demand (POD) sectors are expected to drive substantial demand, particularly among small businesses and independent creators.

Expansion of E-Commerce and POD Platforms

By 2026, the integration of sublimation blanks with major e-commerce and print-on-demand platforms is expected to deepen. Platforms like Etsy, Amazon, and Shopify are facilitating easier access to sublimation products, allowing sellers to scale without holding inventory. This trend promotes low-barrier entrepreneurship and increases the need for high-quality, compatible blank slates. Suppliers are responding by offering standardized, printer-friendly blanks that integrate seamlessly with digital workflows.

Technological Advancements in Sublimation Materials

Innovation in coating technologies and substrate materials is enhancing the quality and versatility of sublimation blank slates. By 2026, expect to see more durable, eco-friendly, and multi-surface compatible blanks. Developments in polymer coatings allow for better ink adhesion and vibrant color reproduction across a broader range of materials, including wood, metal, and glass. Additionally, advancements in heat press technology are improving transfer efficiency, reducing errors, and expanding the types of items that can be sublimated.

Sustainability and Eco-Conscious Production

Environmental concerns are reshaping the sublimation industry. Consumers and regulators are pushing for greener manufacturing processes. In response, manufacturers of sublimation blanks are investing in recyclable materials, non-toxic coatings, and energy-efficient production methods. By 2026, eco-certified blank slates are expected to become a competitive advantage, particularly in environmentally conscious markets such as Europe and North America.

Diversification of Product Offerings

The sublimation blank slate market is expanding beyond traditional items like mugs and tiles. By 2026, expect increased availability of niche and unconventional blanks, such as sublimation-compatible eyewear, footwear, pet tags, and home décor elements. This diversification is opening new revenue streams for suppliers and enabling creative applications in advertising, gifting, and branding.

Global Supply Chain Optimization

As demand grows, manufacturers are optimizing global supply chains to reduce costs and improve delivery times. China remains a dominant producer, but regional manufacturing hubs in Southeast Asia, Eastern Europe, and North America are gaining traction. By 2026, localized production and inventory warehousing are expected to enhance supply chain resilience, especially in response to geopolitical and logistical disruptions.

Increased Competition and Market Consolidation

The sublimation blank slate market is becoming increasingly competitive, with new entrants and established players vying for market share. This competition is driving innovation and lowering prices, benefiting end-users. However, it may also lead to market consolidation, with larger companies acquiring smaller brands to expand their product lines and distribution networks.

Conclusion

The 2026 outlook for sublimation blank slates is robust, fueled by personalization trends, technological innovation, and the growth of e-commerce. As the market matures, success will depend on adaptability, product quality, and sustainability. Businesses that invest in R&D, supply chain efficiency, and customer-centric offerings are likely to thrive in this dynamic landscape.

Common Pitfalls When Sourcing Sublimation Blank Slates

Poor Print Quality Due to Low-Grade Materials

One of the most frequent issues when sourcing sublimation blanks is receiving products made from substandard materials. Low-quality substrates—such as cheap ceramics, metals with improper coatings, or low-density fiberboard—can result in faded, blurry, or uneven prints. These materials often fail to properly absorb sublimation ink, leading to poor color vibrancy and durability. Always verify the substrate composition and coating quality, and consider requesting samples before placing bulk orders.

Inconsistent Product Dimensions and Surface Finish

Inconsistencies in size, thickness, or surface smoothness across blank slates can cause misalignment during printing and pressing, resulting in wasted materials and customer dissatisfaction. Some suppliers, especially those with lax quality control, may ship batches with noticeable variations. To avoid this, work with reputable manufacturers that provide detailed specifications and maintain consistent production standards.

Intellectual Property (IP) Infringement Risks

Sourcing sublimation blanks with pre-applied designs or licensed shapes (e.g., branded shapes, character-inspired forms) can inadvertently expose you to intellectual property violations. Some suppliers may offer blanks that mimic patented or trademarked designs (e.g., puzzle piece layouts, branded mug shapes). Always confirm that the blank products are generic and free of protected designs. When in doubt, consult legal counsel to avoid costly infringement claims.

Coating Defects Leading to Print Failures

A critical but often overlooked aspect is the quality of the polymer coating applied to sublimation blanks. Poor or uneven coating can result in ink bleeding, poor adhesion, or ghosting. Coating that’s too thin may not hold the image, while overly thick coatings can crack under heat. Ensure your supplier uses a reliable, durable coating process designed specifically for sublimation, and test for durability under standard heat press conditions.

Lack of Compliance and Safety Certifications

Some sublimation blanks—especially drinkware or children’s items—must meet safety standards such as FDA approval for food contact or CPSIA compliance. Sourcing from suppliers that don’t provide these certifications can lead to legal issues or product recalls. Always request documentation proving compliance with relevant regulations, particularly when selling in regulated markets like the U.S. or EU.

Hidden Minimum Order Quantities (MOQs) and Supplier Reliability

Many overseas or budget suppliers advertise attractive pricing but enforce high MOQs or fail to deliver consistent quality over time. This can tie up capital and result in inventory waste. Vet suppliers thoroughly by checking reviews, requesting samples, and starting with small test orders. Prioritize transparent communication and reliable shipping timelines to avoid supply chain disruptions.

Logistics & Compliance Guide for Sublimation Blank Slates

Product Overview and Handling

Sublimation blank slates are typically rigid substrates—such as ceramic tiles, wood panels, metal sheets, or coated boards—designed to accept dye-sublimation printing. These products are intended for use with heat presses and sublimation inks to produce customized décor, signage, or personalized gifts. Proper handling, storage, and transportation are critical to maintaining surface integrity and print quality.

Storage Requirements

Store blank slates in a cool, dry environment away from direct sunlight and sources of humidity. Keep products flat and protected from dust, scratches, and physical impact. Use original packaging or protective interleaving (e.g., tissue paper or foam) when stacking to prevent surface damage. Avoid storing near volatile organic compounds (VOCs) or strong odors that could affect coating integrity.

Packaging and Shipping

Ensure blank slates are securely packaged to prevent shifting or breakage during transit. Use edge protectors, corner guards, and rigid outer cartons for rigid materials. For international shipments, comply with ISPM 15 regulations if using wooden pallets or crates—use only heat-treated lumber with proper certification markings. Clearly label packages with “Fragile,” “This Side Up,” and handling instructions.

Import/Export Compliance

Verify that sublimation blanks meet destination country import regulations. Ceramic and stone-based slates may fall under HTS codes related to building materials or finished goods (e.g., 6908.90 for ceramic plates). Coated metal or wood panels may be classified under 7326 or 4421, respectively. Confirm correct Harmonized System (HS) codes and applicable tariffs. Some countries may require product safety, labeling, or environmental compliance documentation.

Regulatory and Safety Standards

Ensure substrates comply with relevant safety standards, especially if intended for consumer use. For products sold in the U.S., compliance with CPSIA (Consumer Product Safety Improvement Act) may apply if marketed for children. EU-bound goods should meet REACH and RoHS directives, particularly regarding restricted substances in coatings or substrates. Provide Safety Data Sheets (SDS) if materials contain regulated chemicals.

Environmental and Sustainability Considerations

Source blank slates from suppliers practicing sustainable forestry (for wood) or using recyclable materials. Communicate environmental attributes such as low VOC coatings or FSC-certified wood. Properly label recyclability or disposal instructions, especially for composite or coated materials that may not be curbside recyclable.

Labeling and Documentation

Clearly label each product or package with SKU, material type, dimensions, care instructions, and sublimation guidelines (e.g., recommended temperature, pressure, and time). Include manufacturer details, country of origin, and compliance markings where required (e.g., CE, UKCA). Maintain accurate records of supplier certifications, test reports, and shipping documentation.

Returns and Reverse Logistics

Establish a returns policy that addresses damaged, defective, or misshipped items. Inspect returned blanks for usability and determine whether recycling, refurbishment, or disposal is appropriate. Follow local waste regulations when disposing of non-reusable coated or composite materials.

Conclusion for Sourcing Sublimation Blank Slates

Sourcing high-quality sublimation blank slates is a critical step in ensuring the success and professionalism of your printed products. After evaluating various suppliers, materials, and printing compatibility, it is clear that the key factors in effective sourcing include material consistency, coating quality, dimensional accuracy, and reliable supply chain performance.

Opting for blanks that are specifically designed for sublimation ensures vibrant, durable, and long-lasting prints with minimal waste or rework. Additionally, building relationships with reputable suppliers—whether domestic or international—can lead to better pricing, faster turnaround times, and access to innovative products. Sustainability and ethical manufacturing practices are also becoming increasingly important considerations for both businesses and consumers.

In conclusion, a strategic and well-researched approach to sourcing sublimation blanks not only enhances print quality and production efficiency but also supports brand credibility and customer satisfaction. By prioritizing quality, reliability, and scalability, businesses can maintain a competitive edge in the growing custom merchandise market.