The global storage cabinet market is experiencing steady growth, driven by rising demand across residential, commercial, and industrial sectors. According to Grand View Research, the global storage and organization products market was valued at USD 32.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth is fueled by urbanization, increasing home improvement activities, and the need for efficient space management in both homes and workplaces. Additionally, Mordor Intelligence projects a similar upward trend, citing expanding retail and e-commerce distribution channels as key contributors to market expansion. As demand for durable, modular, and aesthetically versatile storage solutions rises, manufacturers are innovating to meet diverse consumer needs. In this competitive landscape, nine companies have distinguished themselves through product quality, technological integration, and global reach—shaping the future of the storage cabinet industry.

Top 9 Storage Cabinet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 American Woodmark Corporation

Domain Est. 1996

Website: americanwoodmark.com

Key Highlights: The source for American Woodmark Corporation (AMWD) stockholders, investors, jobseekers, and cabinet lovers. Click here to find what you’re looking for!…

#2 Strong Hold

Domain Est. 1998

Website: strong-hold.com

Key Highlights: The most trusted brand of Industrial cabinets, storage, and workspace solutions. Strong Hold products are engineered for the toughest work environments!…

#3 KraftMaid Cabinetry

Domain Est. 1995

Website: kraftmaid.com

Key Highlights: Discover custom kitchen and bath cabinets from KraftMaid—built for style and storage. Start designing your dream space today with our easy planning tools….

#4 Storage and Organization Furniture

Domain Est. 1995

#5 Cabinets

Domain Est. 1996

Website: lista.com

Key Highlights: The extensive range of LISTA cabinets enables you to customise and add to your storage and workspace equipment….

#6 Durham Manufacturing

Domain Est. 1996

Website: durhammfg.com

Key Highlights: Durham MFG has the ability to ship your products from the US to anywhere in the world. Let us know how we can help you, help your customers worldwide….

#7 Cabinets

Domain Est. 1997

Website: edsal.com

Key Highlights: Ready-to-Assemble Storage Cabinets, Heavy Duty Welded Steel Flammable Safety Cabinets, Heavy Duty Welded Steel Flammable Safety Cabinets….

#8 Category: Storage Cabinets & Shelving

Domain Est. 1998

Website: vestil.com

Key Highlights: Vestil’s Storage Cabinets & Shelving provide reliable and efficient solutions for organizing tools, equipment, and supplies in any workspace….

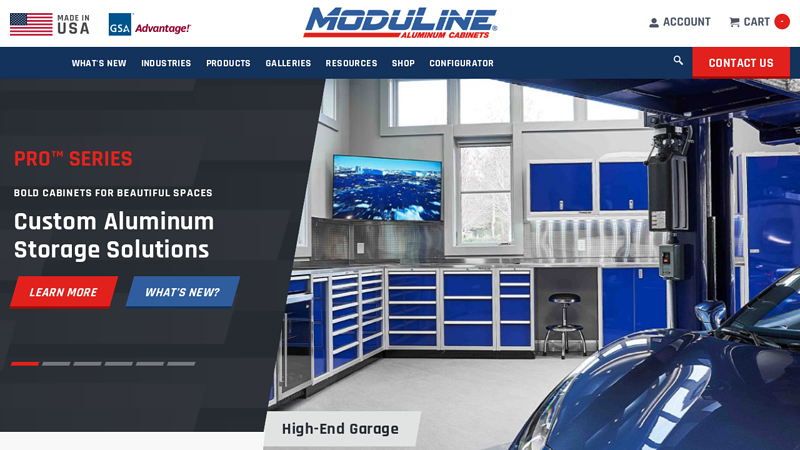

#9 Moduline® Aluminum Cabinets

Domain Est. 2000

Website: modulinecabinets.com

Key Highlights: Moduline Cabinets makes the most sought-after, high-end aluminum cabinet systems on the market today. With rugged, good looks and superior build quality….

Expert Sourcing Insights for Storage Cabinet

H2: 2026 Market Trends for Storage Cabinets

The global storage cabinet market is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and shifting work and living environments. As urbanization accelerates and space optimization becomes a priority, demand for functional and aesthetically pleasing storage solutions continues to grow. Below are key trends shaping the storage cabinet industry in 2026:

-

Rise of Smart Storage Solutions

By 2026, smart storage cabinets equipped with IoT integration are gaining traction, particularly in residential and commercial sectors. Features such as automated opening systems, inventory tracking via RFID tags, and app-based controls are increasingly common. These innovations cater to tech-savvy consumers and industries like healthcare and logistics, where efficient asset management is critical. -

Sustainable and Eco-Friendly Materials

Environmental concerns are reshaping product development. Manufacturers are prioritizing recycled wood, bamboo, and low-VOC (volatile organic compound) finishes to meet consumer demand for sustainable furniture. Certifications like FSC (Forest Stewardship Council) and Greenguard are becoming differentiators in competitive markets. -

Modular and Customizable Designs

Flexibility is a central theme in 2026. Modular storage cabinets that allow reconfiguration based on user needs are in high demand. Consumers and businesses alike seek customizable units that adapt to changing spatial requirements, especially in multifunctional homes and hybrid office environments. -

Growth in E-Commerce and Direct-to-Consumer Sales

Online retail continues to dominate the distribution landscape. Brands are investing in augmented reality (AR) tools that let customers visualize cabinets in their space before purchasing. Flat-pack designs optimized for shipping are also contributing to the popularity of DTC (direct-to-consumer) models. -

Urbanization and Space Constraints

With more people living in compact urban dwellings, space-saving storage cabinets—such as wall-mounted, under-bed, or multi-functional units—are in high demand. Designers are focusing on vertical storage and dual-purpose furniture (e.g., cabinets that double as desks or room dividers). -

Commercial and Industrial Expansion

Beyond residential use, storage cabinets are seeing increased adoption in sectors like healthcare (for medical supplies), education (for equipment management), and manufacturing (for tool organization). These applications require durable, secure, and compliant designs, driving innovation in locking mechanisms and material strength. -

Regional Market Variations

While North America and Europe emphasize design and sustainability, emerging markets in Asia-Pacific and Latin America are experiencing rapid growth due to urban development and rising disposable incomes. Localized designs that reflect cultural aesthetics and functional needs are becoming essential for global brands.

In conclusion, the 2026 storage cabinet market is characterized by innovation, sustainability, and adaptability. Companies that embrace smart technology, eco-conscious production, and flexible design are best positioned to capitalize on these evolving trends and meet the diverse needs of global consumers.

Common Pitfalls When Sourcing Storage Cabinets (Quality and IP Rating)

Sourcing storage cabinets—especially for industrial, outdoor, or mission-critical applications—requires careful attention to both build quality and Ingress Protection (IP) ratings. Overlooking these aspects can lead to premature failure, safety hazards, or non-compliance. Below are key pitfalls to avoid:

1. Overlooking IP Rating Suitability

One of the most frequent mistakes is selecting a cabinet with an IP rating that doesn’t match the environment. For example, using an IP54-rated cabinet in a washdown or outdoor setting where IP65 or higher is required can result in water and dust ingress, damaging internal components. Always assess environmental conditions (e.g., exposure to rain, dust, chemicals, or high-pressure cleaning) and choose the appropriate IP rating accordingly.

2. Assuming Higher IP Always Means Better Quality

While a higher IP rating (e.g., IP66, IP68) indicates superior protection, it doesn’t guarantee overall build quality. Some cabinets achieve high IP ratings through seals and gaskets but use thin, low-grade materials that dent easily or corrode over time. Ensure that material quality (e.g., stainless steel, powder-coated mild steel) aligns with durability requirements, not just ingress protection.

3. Ignoring Long-Term Seal Degradation

Gaskets and seals are critical for maintaining IP integrity. However, many sourced cabinets use low-quality rubber or foam seals that degrade under UV exposure, temperature swings, or chemical contact. This leads to compromised protection over time. Verify that the cabinet uses UV-resistant, temperature-stable sealing materials designed for long-term performance.

4. Inadequate Corrosion Resistance

Even with a suitable IP rating, cabinets made from poor-quality materials or with insufficient surface treatment (e.g., thin powder coating or inadequate galvanization) are prone to rust and corrosion—especially in coastal or industrial environments. Always confirm material specifications (e.g., 304 or 316 stainless steel) and protective finishes compatible with the installation site.

5. Poor Door and Hinge Design Affecting IP Integrity

Frequent opening and closing can wear out hinges or misalign doors, breaking the seal and reducing effective IP protection. Cabinets with flimsy hinges or inadequate door compression mechanisms may fail to maintain a tight seal over time. Prioritize robust hinge designs and self-aligning or latch-assisted sealing systems.

6. Incomplete or Misleading IP Certification

Some suppliers claim IP ratings without third-party testing or certification. This can result in cabinets that don’t perform as advertised. Always request test reports or certification from recognized standards bodies (e.g., IEC 60529) to verify the claimed IP rating.

7. Neglecting Internal Quality and Fit-Out Options

A cabinet may have excellent IP protection externally but lack proper internal organization—such as mounting rails, cable entries, or ventilation options. Poor internal design can lead to inefficient space use, heat buildup, or difficulty servicing equipment. Evaluate internal features and customization options during sourcing.

8. Cost-Driven Selection Compromising Quality

Opting for the lowest-cost option often results in subpar materials, weak construction, or unreliable IP performance. The initial savings can be outweighed by maintenance, replacement, or downtime costs. Invest in a total cost of ownership (TCO) analysis to justify higher-quality cabinets where needed.

By proactively addressing these pitfalls, buyers can ensure they source storage cabinets that deliver both reliable environmental protection and long-term durability.

Logistics & Compliance Guide for Storage Cabinets

This guide outlines key considerations for the logistics and regulatory compliance associated with the shipment, handling, installation, and use of storage cabinets. Adhering to these guidelines ensures safety, legal compliance, and efficient operations.

Shipping and Transportation

Ensure storage cabinets are securely packaged to prevent damage during transit. Use palletized shipments with corner protectors and stretch wrap to stabilize loads. When transporting, secure cabinets upright in vehicles to avoid tipping. Verify that shipping documentation includes weight, dimensions, and handling instructions (e.g., “This Side Up,” “Fragile”). Coordinate with carriers experienced in handling industrial or heavy goods, especially for large metal or hazardous material storage cabinets.

Import/Export Compliance

For international shipments, confirm compliance with destination country regulations. This includes proper HS (Harmonized System) code classification—typically under headings such as 9403 (furniture) or 7323 (steel storage units). Obtain necessary export licenses if applicable, and ensure all required documentation (commercial invoice, packing list, bill of lading) is accurate and complete. Be aware of import duties, tariffs, and restrictions on materials (e.g., certain coatings or treated metals).

Hazardous Materials Storage Compliance

If the storage cabinet is intended for hazardous substances (e.g., flammable liquids, chemicals), it must meet local and international safety standards. In the U.S., cabinets should comply with OSHA 29 CFR 1910.106 and NFPA 30 requirements, including self-closing doors, proper labeling, and grounding provisions. In the EU, adherence to EN 14470-1 (flammable liquids) or EN 14470-2 (toxic/ corrosive substances) is required. Always verify compliance markings and certification labels on the product.

Environmental and Safety Regulations

Storage cabinets must align with environmental health and safety (EHS) standards. Ensure compliance with REACH and RoHS regulations in the EU regarding restricted substances in materials. In workplaces, cabinets should support spill containment (e.g., leak-tight sumps) and be placed in well-ventilated areas when storing volatile chemicals. Follow local fire codes regarding cabinet placement, clearance from exits, and proximity to ignition sources.

Installation and Workplace Safety

Install cabinets on stable, level surfaces to prevent tipping. Anchor heavy or tall units to walls if required by manufacturer instructions or safety codes. Maintain clear access and aisle space per OSHA or local regulations (typically at least 28–36 inches). Train personnel on proper cabinet use, including weight limits, chemical compatibility, and emergency procedures. Label cabinets clearly to indicate contents and hazards.

Documentation and Auditing

Maintain records of cabinet compliance certifications, safety data sheets (SDS) for stored materials, inspection logs, and maintenance activities. Regular audits should verify that cabinets remain in good condition, are used appropriately, and continue to meet regulatory requirements. Update documentation as regulations or cabinet usage changes occur.

By following this guide, organizations can ensure safe, compliant, and efficient handling and use of storage cabinets across their operations.

Conclusion for Sourcing Storage Cabinets:

After a comprehensive evaluation of available suppliers, product specifications, cost structures, and quality standards, it is concluded that sourcing storage cabinets from [Selected Supplier/Option] offers the optimal balance between durability, functionality, cost-efficiency, and timely delivery. The chosen cabinets meet the required organizational needs, comply with safety and environmental standards, and provide long-term value for money. Implementing this sourcing decision will enhance storage efficiency, improve workspace organization, and support operational effectiveness across departments. It is recommended to proceed with the selected supplier under the agreed terms, with periodic performance reviews to ensure continued satisfaction and service quality.