The global market for energy-efficient heating solutions is experiencing robust growth, driven by rising energy costs and increasing demand for sustainable technologies. According to Mordor Intelligence, the global thermoelectric generator market—which encompasses heat recovery systems like Stirling cycle applications—is projected to grow at a CAGR of over 9.5% from 2024 to 2029. As decentralized, off-grid heating gains traction, Stirling cycle heat-powered fans have emerged as a reliable solution for improving heat distribution in wood stoves and biomass heaters without requiring external electricity. These fans operate entirely on the temperature differential generated by the stove, making them both environmentally friendly and cost-effective. With growing consumer awareness and technological advancements, the demand for high-performance Stirling cycle fans is on the rise. Based on market presence, product innovation, and customer reviews, the following four manufacturers stand out as leaders in the Stirling cycle heat-powered fan industry.

Top 4 Stirling Cycle Heat Powered Fans Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Heat Powered Fan For Buddy Heater

Domain Est. 2003

Website: nortonnorris.com

Key Highlights: Using advanced Stirling engine technology, this fan requires no batteries or electricity – it runs entirely on the heat from your heater. Compatible with both …Missing: cycle ma…

#2 Power Generation Technology Using Waste Heat

Domain Est. 1996

Website: yanmar.com

Key Highlights: The Stirling engine power generation system can reduce both electricity purchases and CO2 emissions. A single Stirling engine can reduce an ……

#3 Stirling Engines & Stove Fans by Kontax

Domain Est. 2004

Website: stirlingengines.co.uk

Key Highlights: We sell high & low temperature differential Stirling engines, thermo-acoustic Stirling engines and wood-burning stove fans….

#4 The Stirling Cycle

Domain Est. 2019

Website: stirlingcryogenics.com

Key Highlights: The Stirling cycle is a thermodynamic closed cycle invented in 1816 by the Scottish minister Robert Stirling. It was used as an engine….

Expert Sourcing Insights for Stirling Cycle Heat Powered Fans

As of now, projections for the 2026 market trends for Stirling Cycle Heat-Powered Fans using hydrogen (H₂) as a thermal source or energy carrier involve a confluence of technological, economic, environmental, and policy-driven factors. While Stirling cycle heat-powered fans are niche, their integration with hydrogen technologies could position them for growth in specific applications. Below is a comprehensive analysis of anticipated 2026 market trends using H₂ as a key enabler.

Market Trend Analysis: Stirling Cycle Heat-Powered Fans with H₂ Integration (2026 Outlook)

1. Technology Overview

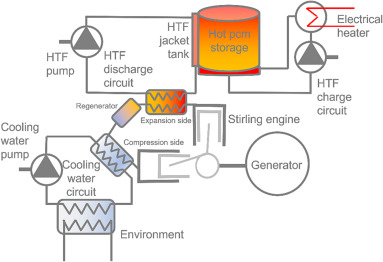

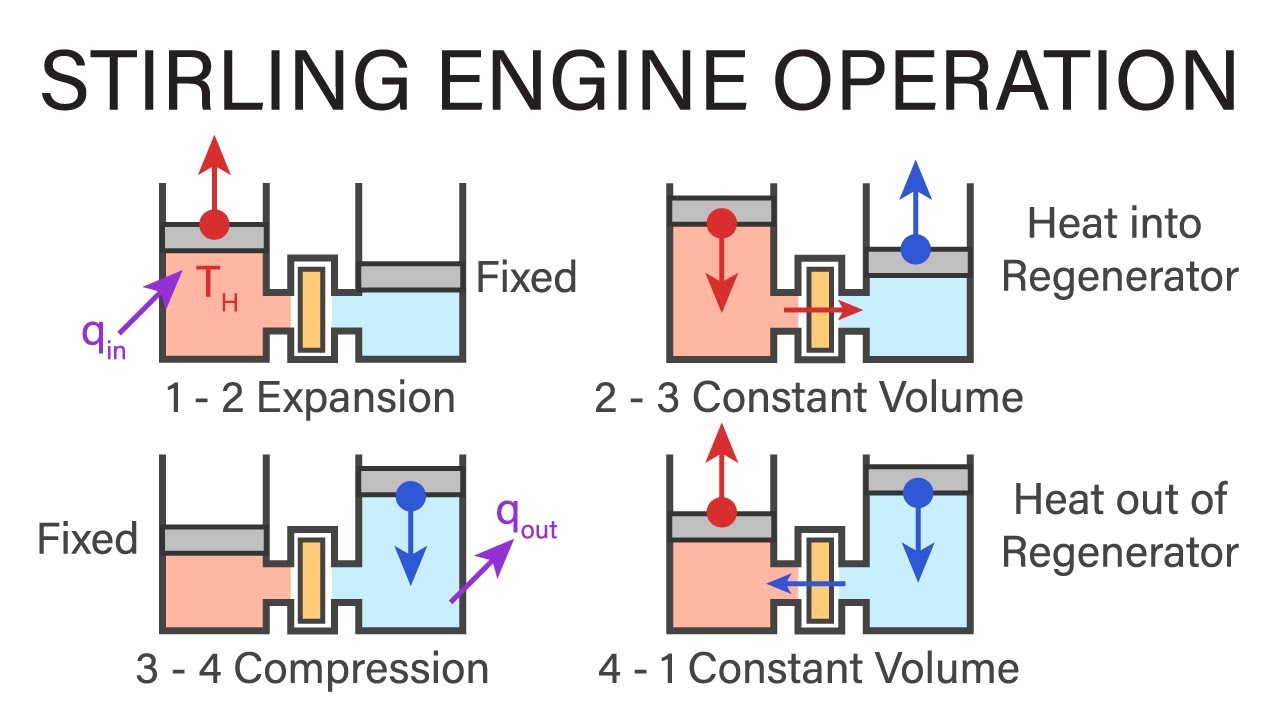

Stirling cycle heat-powered fans convert thermal energy into mechanical motion through a closed-cycle regenerative heat engine. These fans operate silently and require no electricity, making them ideal for passive ventilation in off-grid or high-heat environments.

When integrated with hydrogen combustion or hydrogen-fueled thermal systems (e.g., hydrogen boilers or reformers), the Stirling engine can utilize the heat from H₂ combustion as a clean, high-efficiency thermal source.

2. Hydrogen (H₂) as a Driver for Stirling Fan Applications (2026)

a. Clean Thermal Energy Source

- Low-Carbon Heating: By 2026, green hydrogen (produced via electrolysis using renewable energy) is expected to gain broader adoption in industrial and commercial heating.

- Hydrogen combustion produces only heat and water vapor, aligning with global net-zero goals.

- Stirling fans powered by H₂-derived heat eliminate reliance on fossil fuels and reduce operational carbon footprint.

b. Synergy with Hydrogen Infrastructure Rollout

- By 2026, pilot hydrogen distribution networks (especially in the EU, Japan, South Korea, and parts of the U.S.) will support hydrogen use in buildings and industry.

- Stirling fans can be integrated into hydrogen-heated buildings (e.g., data centers, greenhouses, or industrial dryers) to provide passive cooling or ventilation without grid dependency.

c. Energy Resilience and Decentralization

- H₂-powered Stirling fans support energy resilience in off-grid or hybrid energy systems.

- Useful in remote or disaster-prone areas where hydrogen storage provides reliable thermal energy, and Stirling fans offer passive air circulation without electrical backup.

3. Key Market Drivers (2026)

a. Regulatory and Policy Support

- The EU’s Fit for 55, U.S. Inflation Reduction Act (IRA), and Japan’s Green Growth Strategy incentivize clean hydrogen use.

- Building codes may begin to require passive ventilation solutions in zero-emission buildings — favoring Stirling fans powered by clean heat sources like H₂.

b. Industrial and Commercial Adoption

- Industries using high-temperature processes (e.g., food processing, glass manufacturing) may adopt H₂ burners for heat; Stirling fans can recover waste heat for ventilation.

- Data centers exploring hydrogen backup systems could use Stirling fans for passive cooling during outages.

c. R&D and System Integration

- By 2026, modular systems combining hydrogen burners, Stirling engines, and fan arrays are expected to emerge from R&D labs.

- Startups and cleantech firms may commercialize hybrid H₂-Stirling ventilation units.

4. Challenges and Limitations (2026)

a. Cost and Efficiency

- Green hydrogen remains expensive (~$3–6/kg in 2026 estimates), making H₂-powered systems cost-prohibitive for widespread residential use.

- Stirling engines have relatively low power density; suitable for low-torque applications like fans, but not high-performance cooling.

b. Hydrogen Storage and Safety

- H₂ requires specialized storage (compressed or cryogenic), adding complexity and cost.

- Safety regulations for indoor H₂ use may limit deployment in residential or public buildings.

c. Market Awareness and Niche Status

- Stirling fans are not widely known; consumer and industrial adoption may lag despite technical benefits.

- Competition from electric fans powered by renewable electricity (e.g., solar PV) remains strong due to lower cost and simplicity.

5. Regional Market Outlook (2026)

| Region | Outlook |

|——–|———|

| Europe | Strong growth potential due to hydrogen strategy, building decarbonization mandates, and funding for pilot projects. Germany and the Netherlands lead in H₂ integration. |

| Japan & South Korea | High interest in hydrogen society; government-backed demonstrations may include Stirling-based thermal systems. |

| North America | Moderate adoption, focused on industrial and data center applications. IRA incentives may support R&D. |

| China | Focus on hydrogen in transportation and industry; Stirling fans may be used in industrial heat recovery systems. |

| Rest of World | Limited adoption due to infrastructure gaps, but potential in off-grid applications with hydrogen microgrids. |

6. Forecasted Applications (2026)

- Hydrogen-Heated Greenhouses: Use H₂ burners for warmth; Stirling fans circulate air using waste heat.

- Backup Ventilation in H₂-Powered Facilities: Hospitals, labs, or telecom stations using hydrogen generators.

- Industrial Waste Heat Recovery: Pair H₂ combustion systems with Stirling fans to improve thermal efficiency.

- Off-Grid Housing in Cold Climates: Integrated H₂ heating and passive ventilation in eco-homes.

7. Market Size and Growth Estimate

- The global Stirling engine market is projected to reach ~$600 million by 2026 (CAGR ~6–8%).

- H₂-integrated Stirling fan systems may represent 5–10% of this segment, driven by niche industrial and demonstration projects.

- Annual installations: ~5,000–10,000 units globally by 2026, mainly in pilot and commercial facilities.

8. Conclusion: Strategic Outlook for 2026

By 2026, Stirling cycle heat-powered fans using hydrogen (H₂) as a thermal source will remain a niche but strategically growing technology. Their value lies in zero-emission, off-grid ventilation where hydrogen infrastructure is emerging. While not yet competitive with electric fans on cost, their synergy with clean hydrogen heating systems positions them as a promising solution in industrial, agricultural, and resilient infrastructure applications.

Key success factors:

– Cost reduction in green hydrogen.

– Integration into broader hydrogen energy systems.

– Support from clean energy policies and building codes.

Bottom Line: H₂-powered Stirling fans won’t dominate the ventilation market by 2026, but they will emerge as a symbol of clean thermal innovation in the expanding hydrogen economy.

Note: This analysis is forward-looking and based on current trends as of 2024. Actual market developments may vary with technological breakthroughs, policy shifts, and hydrogen cost trajectories.

Common Pitfalls When Sourcing Stirling Cycle Heat Powered Fans: Quality and Intellectual Property (IP) Risks

Sourcing Stirling cycle heat-powered fans offers an energy-efficient, maintenance-free solution for improving heat distribution. However, navigating the market presents significant challenges, particularly concerning product quality and intellectual property (IP) integrity. Being aware of these pitfalls is crucial for making informed procurement decisions.

H2: Quality-Related Pitfalls in Sourcing Stirling Cycle Fans

-

Substandard Materials and Construction:

- Problem: Many low-cost manufacturers use inferior materials (e.g., thin-gauge, non-heat-resistant plastics for housings, low-grade aluminum alloys, poor-quality bearings) to cut costs. This leads to premature failure, warping at high temperatures, or reduced efficiency.

- Impact: Shortened lifespan, potential safety hazards (melting, cracking), decreased air movement, and unreliable performance.

- Mitigation: Demand material specifications (e.g., high-temp thermoplastics like PPS or PEEK, specific aluminum grades), inspect samples rigorously, and prioritize suppliers with proven manufacturing standards.

-

Inconsistent or Inaccurate Performance Claims:

- Problem: Suppliers may exaggerate key metrics like CFM (Cubic Feet per Minute), temperature thresholds for activation, heat source compatibility, or noise levels. Testing conditions are often non-standard or unrealistic.

- Impact: Fans may fail to move sufficient air, activate too late, or be excessively noisy, defeating their purpose.

- Mitigation: Require independent test reports (e.g., from accredited labs) using standardized testing methods (e.g., simulating wood stove surfaces). Verify claims against real-world user reviews and ask for demonstrable performance data.

-

Poor Thermal Design and Efficiency:

- Problem: Inefficient heat transfer design (e.g., inadequate baseplate conductivity, poor fin design, suboptimal displacer mechanism) results in low conversion of heat into mechanical motion.

- Impact: Reduced fan speed, slower response time, higher minimum operating temperature, and overall poor performance compared to well-designed units.

- Mitigation: Evaluate the design (thickness/quality of baseplate, fin surface area, displacer seal quality) and seek suppliers who can explain their thermal optimization strategies.

-

Lack of Durability and Reliability Testing:

- Problem: Many sourced fans undergo minimal or no rigorous testing (e.g., thermal cycling, long-duration operation, vibration testing) to ensure reliability over years of use.

- Impact: High failure rates in the field, leading to customer dissatisfaction, warranty claims, and reputational damage.

- Mitigation: Ask for detailed reliability test data (MTBF – Mean Time Between Failures, thermal cycle count passed). Favor suppliers with established track records and robust quality control processes (e.g., ISO 9001 certification).

-

Inadequate Safety Features:

- Problem: Missing or poorly implemented safety features like tip-over switches (to stop the fan if the stove is unstable) or overheat protection.

- Impact: Potential fire hazard or damage if the fan falls onto a flammable surface or operates beyond safe temperature limits.

- Mitigation: Explicitly require safety certifications (e.g., ETL, CE with relevant directives) and verify the presence and function of critical safety mechanisms.

H2: Intellectual Property (IP) Pitfalls in Sourcing Stirling Cycle Fans

-

Sourcing Counterfeit or Direct Copies:

- Problem: A significant portion of the market, especially online and from certain regions, consists of fans that are blatant copies of patented, trademarked, or design-protected models from reputable innovators. These often lack proper licensing.

- Impact: Legal liability for the buyer (contributory infringement), association with poor quality, damage to brand reputation, and potential seizure of goods by customs. Undermines investment in genuine innovation.

- Mitigation: Conduct thorough IP due diligence. Research known patents (utility and design) in your target markets. Ask suppliers for proof of IP ownership or valid licensing agreements for the specific design/technology. Be wary of near-identical products at suspiciously low prices.

-

Infringement of Core Stirling Engine Technology:

- Problem: While basic Stirling cycle principles are public domain, specific, efficient implementations (e.g., unique displacer mechanisms, regenerator designs, low-friction seals, specific bearing arrangements) are often protected by active utility patents.

- Impact: Sourcing fans utilizing these patented technologies without a license exposes the buyer to significant patent infringement lawsuits, potentially leading to injunctions, damages, and recall costs.

- Mitigation: Identify key patent holders in the heat-powered fan space. Perform a Freedom-to-Operate (FTO) analysis, especially for large-scale or branded distribution. Require suppliers to warrant they do not infringe third-party IP.

-

Trademark and Brand Infringement:

- Problem: Suppliers may produce fans with logos, names, or packaging confusingly similar to established brands, attempting to capitalize on their reputation.

- Impact: Consumer confusion, dilution of genuine brand value, and potential legal action from the rights holder against both the supplier and potentially the buyer for contributing to the infringement.

- Mitigation: Verify the supplier’s brand and trademarks are legitimate and registered. Avoid products with names or logos suspiciously close to major brands. Ensure packaging doesn’t mimic protected branding.

-

Design Patent Infringement:

- Problem: The distinctive aesthetic appearance of successful fan models (overall shape, fin configuration, base design) is often protected by design patents or registered designs.

- Impact: Sourcing visually identical or substantially similar designs without permission constitutes infringement, leading to legal risks and potential product seizures.

- Mitigation: Compare the design of the sourced fan against known design patents. Be cautious of designs that are mere copies of market leaders. Seek legal advice if the design appears too close.

-

Lack of IP Warranty and Indemnification:

- Problem: Standard supply contracts may not include clauses where the supplier warrants they own the IP or have the right to sell the product, nor do they indemnify the buyer against third-party IP infringement claims.

- Impact: The buyer bears the full legal and financial risk if an IP dispute arises.

- Mitigation: Negotiate and include strong IP warranty and indemnification clauses in the sourcing contract. The supplier should guarantee non-infringement and agree to defend and cover costs if a valid claim is made.

Conclusion: Sourcing Stirling cycle fans requires moving beyond just price and specifications. Rigorous assessment of both quality (materials, performance verification, durability, safety) and IP integrity (avoiding counterfeits, verifying patents/trademarks, securing contractual protections) is essential to ensure a reliable, safe, legally compliant, and ultimately successful product offering. Due diligence in these areas mitigates significant financial, operational, and reputational risks.

Logistics & Compliance Guide: Stirling Cycle Heat-Powered Fans (H2)

1. Introduction

This guide outlines the logistics and compliance requirements for the international shipment, import, and distribution of Stirling Cycle Heat-Powered Fans, with a focus on H2 classification under the Harmonized System (HS) Code framework. These fans are mechanical devices that convert thermal energy into mechanical motion using the Stirling cycle principle and do not require external electrical power.

This document is designed for manufacturers, exporters, importers, freight forwarders, and compliance officers involved in the global trade of these products.

2. Product Overview

Product: Stirling Cycle Heat-Powered Fan

Function: Converts waste heat (e.g., from stoves, furnaces, heaters) into rotational energy to drive a fan blade, improving air circulation and heat distribution.

Power Source: Thermal energy (no electricity required)

Components:

– Sealed Stirling engine (typically using air or helium as working fluid)

– Fan blades

– Heat exchangers (hot and cold ends)

– Mounting hardware

– No batteries or external power supply

Key Features:

– Energy-efficient

– Off-grid operation

– Low maintenance

– Environmentally friendly (no emissions during operation)

3. HS Code Classification (H2)

3.1. Harmonized System (HS) Code

The Harmonized System (HS) is an internationally standardized system for classifying traded products. Accurate classification ensures proper duties, taxation, and regulatory compliance.

Recommended HS Code: 8414.59.00

Chapter 84: Nuclear reactors, boilers, machinery and mechanical appliances; parts thereof

Heading 8414: Air or vacuum pumps, air or other gas compressors, fans, blowers, and ventilating or recycling hoods

Subheading 8414.59: Fans and blowers, other than those of heading 8414.30

8414.59.00: Other fans and blowers (applicable to non-electric, heat-powered fans not elsewhere specified)

Note: Some countries may interpret Stirling devices under 8412.80 (Other engines and motors), but 8414.59.00 is more appropriate due to the primary function as a fan.

H2 Classification Context

- “H2” refers to a customs tariff or statistical subcategory used in certain national tariff schedules (e.g., EU TARIC, U.S. HTS, Canada’s HS).

- In the U.S. Harmonized Tariff Schedule (HTS), the full code would be: 8414.59.70 – “Other fans: Other: Other”

- In the EU, TARIC code: 8414590090

Always verify with the destination country’s customs authority or use binding tariff information (BTI) for certainty.

4. Export & Import Compliance

4.1. Export Controls

- No ITAR/EAR controls: Stirling fans are generally not subject to U.S. export controls (ITAR or EAR) as they are commercial, non-sensitive devices.

- No dual-use concerns: These fans do not meet criteria under the Wassenaar Arrangement unless modified for military or surveillance use.

4.2. Import Regulations by Region

| Region | HS Code | Import Duty Rate | Key Compliance Notes |

|——-|——–|——————|————————|

| United States | 8414.59.70 | 4.0% | No import license required; CBP may request product description |

| European Union | 84145900 | 0%–2.7% (varies by member state) | CE marking not required unless incorporating electrical components |

| Canada | 8414.59.00 | 0% (under USMCA) | Subject to CBSA verification; English/French labeling |

| Australia | 8414.59.00 | 5% | No special permits; comply with AS/NZS labeling standards |

| United Kingdom | 84145900 | 2.0% | Post-Brexit: UKCA marking not required for mechanical-only devices |

Tip: Duty rates may be reduced or eliminated under free trade agreements (e.g., USMCA, CETA, RCEP) — ensure Certificate of Origin is provided.

5. Packaging & Labeling Requirements

5.1. Packaging

- Use durable, recyclable materials to prevent damage during transit.

- Protect moving parts (e.g., fan blades, displacer rod) with foam inserts or restraints.

- Clearly label packages: “Fragile,” “This Side Up,” and product identification.

5.2. Labeling (Per Shipment)

Mandatory labels must include:

– Product name: “Stirling Cycle Heat-Powered Fan”

– Model and serial number

– Manufacturer name and address

– HS Code: 8414.59.00

– Country of Origin (e.g., “Made in Germany”)

– Weight and dimensions

– Safety warnings (e.g., “Hot surface during operation”)

Note: No electrical safety labels required if fully passive and non-electric.

6. Shipping & Logistics

6.1. Mode of Transport

- Air Freight: Suitable for high-value or time-sensitive shipments. IATA regulations do not restrict these devices.

- Ocean Freight: Most cost-effective for bulk shipments. Use standard 20’ or 40’ dry containers.

- Land Freight: Ideal for regional distribution (e.g., EU, North America).

6.2. Documentation

Required documents for international shipment:

– Commercial Invoice

– Packing List

– Bill of Lading (or Air Waybill)

– Certificate of Origin (for preferential tariffs)

– Export Declaration (if required by origin country)

6.3. Incoterms Recommendations

- FOB (Free on Board): Common for ocean freight; exporter clears for export, risk transfers at port.

- DAP (Delivered at Place): For full-service delivery to buyer’s location.

- Avoid EXW unless buyer manages full logistics.

7. Safety & Environmental Compliance

7.1. Safety

- No risk of explosion or flammable materials under normal conditions.

- Working fluid (if helium) is sealed and non-toxic.

- Warn end-users about surface temperatures during operation.

7.2. Environmental

- No hazardous materials (RoHS compliant by design).

- Fully recyclable metal components (aluminum, steel).

- No batteries or electronic waste (WEEE exemption applies).

8. Certification & Testing (Optional but Recommended)

While not mandatory in most markets, consider:

– CE Marking: Only if integrating sensors or low-voltage electronics.

– ISO 9001: For quality management (manufacturing credibility).

– Third-party testing: For durability, thermal efficiency, and noise levels.

9. Risk Mitigation

| Risk | Mitigation Strategy |

|——|———————|

| Customs delays | Provide detailed product descriptions and HS code justification |

| Duty misclassification | Obtain a Binding Tariff Information (BTI) ruling from EU or CBP |

| Damage in transit | Use robust packaging and insure high-value shipments |

| Regulatory rejection | Verify local requirements with in-country agent |

10. Conclusion

Stirling Cycle Heat-Powered Fans are low-risk, energy-efficient devices with straightforward logistics and favorable tariff treatment under HS 8414.59.00. Proper classification, clear documentation, and adherence to packaging standards ensure smooth global distribution. Always consult local customs authorities or a licensed customs broker when entering new markets.

Prepared by: [Your Company Name]

Date: April 2025

Contact: [email protected]

Revision: 1.0

This guide is for informational purposes and does not constitute legal advice.

Conclusion: Sourcing Stirling Cycle Heat-Powered Fans

Stirling cycle heat-powered fans present a compelling solution for passive, off-grid cooling in environments where conventional electrical systems are impractical or undesirable. By harnessing thermal differentials—often from wood stoves, fireplaces, or industrial heat sources—these fans operate without electricity, offering energy efficiency, quiet operation, and environmental sustainability.

When sourcing such fans, key considerations include build quality, thermal efficiency, durability of materials, and suitability for specific heat sources. It is important to select models from reputable manufacturers that adhere to safety standards and provide reliable performance over time. While initial costs may be higher than electric alternatives, the long-term benefits of zero operating costs and low maintenance make them a cost-effective investment in appropriate settings.

In conclusion, sourcing Stirling cycle heat-powered fans is a smart choice for sustainable, reliable air circulation in off-grid homes, cabins, or industrial applications with waste heat availability. With careful selection based on technical specifications and user reviews, these devices offer an elegant fusion of thermodynamic innovation and practical utility.