The global step-down transformer market is experiencing robust growth, driven by rising electricity demand, infrastructure modernization, and the expansion of renewable energy integration. According to Grand View Research, the global transformer market size was valued at USD 118.5 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 7.3% from 2024 to 2030. Similarly, Mordor Intelligence projects a CAGR of approximately 6.8% over the same forecast period, underpinned by increasing investments in smart grids and urbanization across emerging economies. As power distribution systems evolve, the demand for efficient, reliable, and cost-effective step-down transformers has intensified. This growing need has spurred innovation and competition among manufacturers worldwide. In this context, we spotlight the top 10 step-down transformer manufacturers leading the industry through technological advancement, global reach, and strong performance metrics.

Top 10 Step Down Transformer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Transformers & Custom Magnetics

Domain Est. 1995

Website: hubbell.com

Key Highlights: Custom magnetics. We help OEMs develop, test, and manufacture transformers, inductors and filters to support their product development and exact specifications….

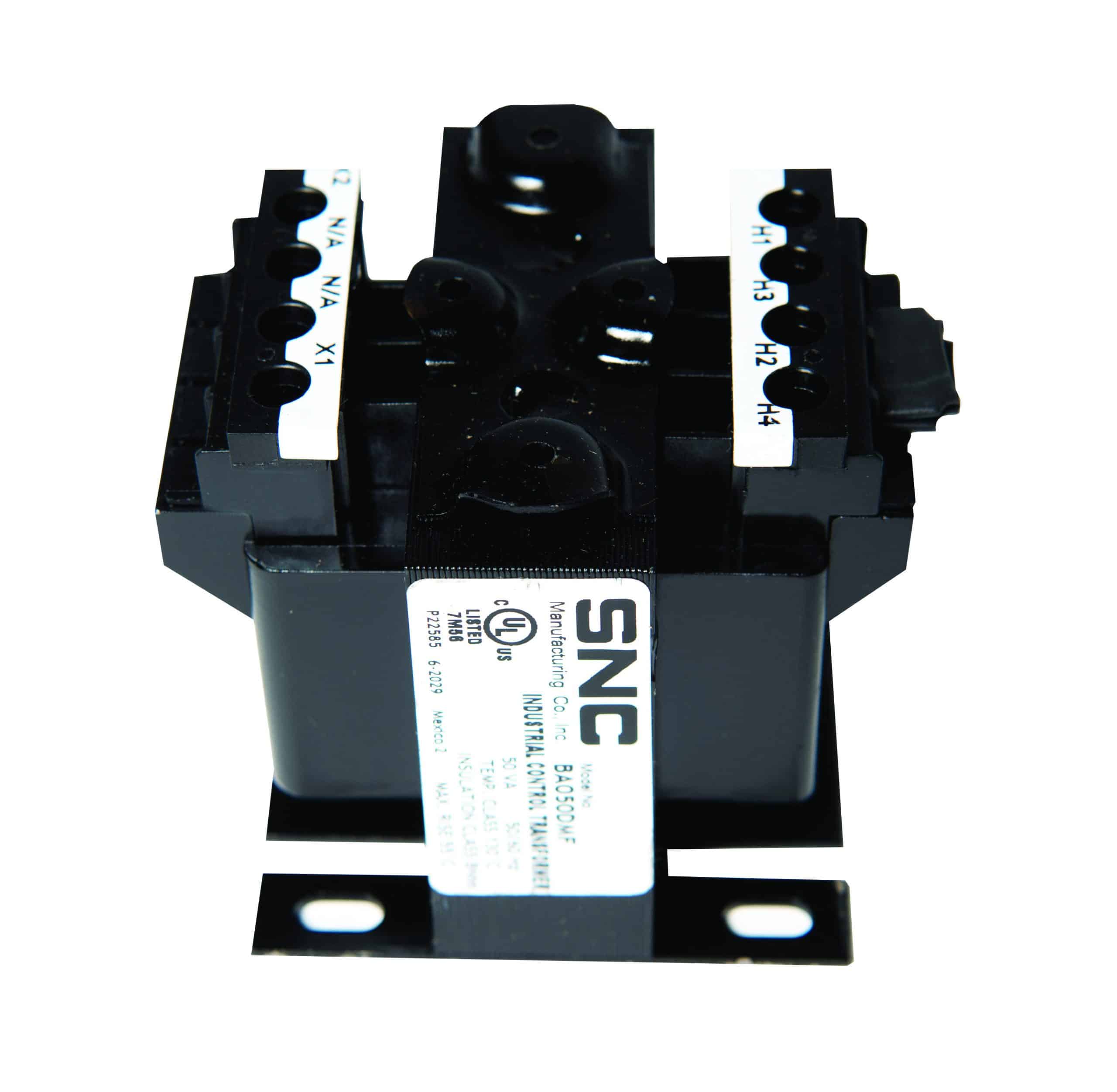

#2 SNC Manufacturing

Domain Est. 1995

Website: sncmfg.com

Key Highlights: SNC’s step-up and step-down transformers are dual frequency rated for 50/60 Hz and manufactured in a variety of configurations that range from 115 to 600 ……

#3 SGB

Domain Est. 2003

Website: sgb-smit.com

Key Highlights: The pure-play transformer specialist from Europe with the highest customer dedication. Wherever electricity is required, generated and distributed….

#4 Transformers I Power and Distribution Transformer Solutions

Domain Est. 2007

Website: siemens-energy.com

Key Highlights: Siemens Energy is a globally recognized transformer manufacturer and supplier, offering a full portfolio of power and distribution transformers. The solutions ……

#5 Step Up & Step Down Transformer Manufacturer

Domain Est. 2023

Website: steptransformer.com

Key Highlights: We are a Chinese supplier specializing in the production of step up and down transformers and support professional custom manufacturing services….

#6 Transformers

Domain Est. 1990

Website: electrification.us.abb.com

Key Highlights: ABB’s type QL K-Factor transformers are designed to withstand the additional heating that accompanies the presence of harmonics in electrical systems….

#7 Jensen Transformers

Domain Est. 1996

Website: jensen-transformers.com

Key Highlights: Jensen offers a complete range of transformers for the most demanding audio designs. Each transformer is manufactured and tested to deliver the utmost quality….

#8

Domain Est. 1997

Website: delta.xfo.com

Key Highlights: Located in Granby, Quebec, Delta Transformers has been designing and manufacturing high-quality dry-type transformers and reactors for more than 40 years. Sign ……

#9 ELSCO Transformers

Domain Est. 2007

Website: elscotransformers.com

Key Highlights: ELSCO manufactures high-quality medium-voltage transformers in 500 – 2500 KVA ratings and 2400 – 34,500 primary voltages. We are committed to supplying all our ……

#10 WEG Transformers USA

Domain Est. 2015

Website: weg.us

Key Highlights: WEG Transformers USA has three facilities in Washington, Missouri and two in Mexico that manufacture distribution and power transformers….

Expert Sourcing Insights for Step Down Transformer

H2: 2026 Market Trends for Step-Down Transformers

The global step-down transformer market is poised for significant evolution by 2026, driven by technological advancements, increasing energy demands, and the global shift toward sustainable infrastructure. This analysis explores key market trends expected to shape the step-down transformer industry in 2026, focusing on demand drivers, regional dynamics, technological innovation, and regulatory influences.

-

Rising Demand from Renewable Energy Integration

The expansion of renewable energy sources such as solar and wind power is a primary driver for step-down transformers. As distributed generation systems feed into the grid at high voltages, step-down transformers are essential for safely reducing voltage levels for residential and commercial use. By 2026, increased investments in solar farms and offshore wind installations—especially in Europe, North America, and parts of Asia-Pacific—are expected to boost demand for medium and small-scale step-down transformers. -

Growth in Urbanization and Smart Grid Development

Rapid urbanization, particularly in emerging economies like India, Indonesia, and Nigeria, is driving the need for reliable power distribution networks. Step-down transformers play a critical role in last-mile power delivery. Additionally, the global push toward smart grid technology will enhance the demand for intelligent, IoT-enabled transformers capable of real-time monitoring and fault detection. By 2026, smart transformers with integrated sensors and communication modules are expected to capture a growing market share. -

Emphasis on Energy Efficiency and Eco-Friendly Materials

Regulatory standards such as the EU’s Ecodesign Directive and the U.S. DOE’s efficiency mandates are pushing manufacturers to produce energy-efficient step-down transformers. By 2026, amorphous metal core transformers—known for their lower no-load losses—are expected to gain widespread adoption, especially in regions with high electricity costs and strict environmental regulations. Increased scrutiny on SF6 (sulfur hexafluoride) emissions will also accelerate the development of dry-type and eco-friendly liquid-filled transformers. -

Regional Market Dynamics

Asia-Pacific is projected to dominate the step-down transformer market in 2026, led by China and India’s massive infrastructure and electrification projects. Government initiatives like India’s “Power for All” and China’s 14th Five-Year Plan emphasize grid modernization, creating robust demand. In contrast, mature markets in North America and Western Europe will focus on transformer replacement and grid resilience, driven by aging infrastructure and climate resilience planning. -

Technological Advancements and Digitalization

Digital twin technology, predictive maintenance algorithms, and AI-driven load management systems are being integrated into transformer design and operation. By 2026, digital step-down transformers with remote monitoring capabilities are expected to reduce operational downtime and maintenance costs, appealing to utilities and industrial users alike. -

Supply Chain and Raw Material Challenges

The availability and pricing of key materials such as copper, silicon steel, and insulating oils will continue to influence production costs. Geopolitical tensions and trade policies may disrupt supply chains, prompting manufacturers to localize production or seek alternative materials. Recycling and remanufacturing of transformers are likely to gain traction as sustainability concerns grow.

Conclusion

By 2026, the step-down transformer market will be shaped by a confluence of energy transition, digital innovation, and regulatory pressures. Companies that invest in energy-efficient designs, smart technologies, and sustainable manufacturing practices will be best positioned to capitalize on emerging opportunities. As electrification expands globally, step-down transformers will remain a cornerstone of modern power systems, evolving to meet the demands of a smarter, greener grid.

Common Pitfalls When Sourcing Step-Down Transformers (Quality, IP)

Sourcing step-down transformers involves several critical considerations, particularly regarding quality and intellectual property (IP). Overlooking these aspects can lead to performance issues, safety hazards, legal complications, and increased long-term costs. Below are key pitfalls to avoid:

Inadequate Quality Verification

Many buyers focus solely on price and specifications without validating the actual build quality. Low-cost transformers may use substandard materials such as inferior core laminations, undersized windings, or poor insulation, leading to overheating, inefficiency, and premature failure. Always verify compliance with international standards (e.g., IEC, UL, CE) and request test reports or certifications from reputable third-party labs.

Lack of IP Due Diligence

Sourcing transformers—especially from manufacturers in regions with lax IP enforcement—risks purchasing counterfeit or cloned designs. Unauthorized replication of patented transformer designs or trademarks can expose the buyer to legal liability. Ensure suppliers have legitimate rights to the designs they offer and request documentation proving original equipment manufacturer (OEM) authorization or design ownership.

Overlooking Environmental and Ingress Protection (IP) Ratings

The IP rating defines protection against dust and moisture, which is crucial for transformers used in harsh environments. Selecting a transformer with an insufficient IP rating (e.g., IP20 instead of IP54 for outdoor or industrial use) can result in internal contamination, short circuits, or corrosion. Always match the IP rating to the intended operating environment to ensure longevity and reliability.

Insufficient Testing and Quality Assurance Processes

Some suppliers may lack robust quality control systems, resulting in inconsistent product performance. Avoid vendors who do not provide factory acceptance tests (FAT), routine test reports, or access to production audits. Request sample testing under load conditions before placing bulk orders to verify thermal performance, voltage regulation, and noise levels.

Hidden Costs from Poor Efficiency

Low-quality transformers often have higher no-load and load losses, increasing energy consumption and operating costs over time. Failing to evaluate efficiency ratings (e.g., DOE 2016, EU EcoDesign) can lead to significant long-term expenses, especially in continuous-operation applications. Prioritize transformers with high energy efficiency, even if initial costs are higher.

Supply Chain and After-Sales Support Risks

Choosing suppliers without reliable after-sales support or spare parts availability can lead to extended downtimes during failures. Additionally, lack of traceability and documentation complicates warranty claims and maintenance. Partner with suppliers who offer technical support, warranty coverage, and clear documentation, including circuit diagrams and material declarations.

By addressing these pitfalls proactively, buyers can ensure they source reliable, compliant, and legally sound step-down transformers that meet both technical and operational requirements.

Logistics & Compliance Guide for Step-Down Transformers

Overview

Step-down transformers are critical electrical components used to reduce voltage levels for safe and efficient power distribution. Proper logistics and compliance management are essential to ensure safe handling, legal import/export, and adherence to technical standards. This guide outlines key considerations for transporting and complying with regulations related to step-down transformers.

Packaging and Handling Requirements

Step-down transformers must be packaged to prevent mechanical shock, moisture ingress, and contamination during transit. Use robust wooden crates with internal bracing and anti-vibration materials. Ensure bushings, terminals, and cooling systems are adequately protected. Always follow manufacturer handling instructions, including proper lifting points and orientation labels (e.g., “Do Not Tilt”).

Transportation Modes and Constraints

Transformers are typically transported via flatbed trucks, rail, or specialized heavy-haul vehicles due to their weight and size. For international shipments, containerized ocean freight may be used for smaller units, while larger units often require break-bulk or Ro-Ro (Roll-on/Roll-off) shipping. Air freight is rare due to cost and size limitations. Verify route clearance, bridge weight limits, and permit requirements for oversized loads.

Storage Conditions Before Deployment

Store transformers in a clean, dry, and well-ventilated area, preferably indoors. If stored outdoors, use a waterproof tarp and elevate the unit to prevent water accumulation. Monitor for condensation, especially in humid environments. For long-term storage, maintain internal dryness using desiccants or nitrogen pressure, as specified by the manufacturer.

Import/Export Documentation

Accurate documentation is vital for international shipments. Required documents typically include: commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and technical specifications. For regulated markets, additional forms such as an export declaration or import license may be required. Always declare the Harmonized System (HS) code—commonly 8504.23 or 8504.29 for transformers.

Regulatory Compliance Standards

Step-down transformers must comply with regional and international electrical safety and performance standards. Key certifications include:

– IEC 60076 (International standard for power transformers)

– IEEE C57.12.00 (North American standard)

– EN 50464 (European standard for distribution transformers)

– CSA C88 (Canadian standard)

Ensure transformers bear necessary marks such as CE, UKCA, or UL listing, depending on the destination market.

Environmental and Hazardous Material Considerations

Many transformers contain insulating oil (e.g., mineral oil) that may be classified as hazardous for transport under regulations like ADR (road), IMDG (sea), or IATA (air). PCB-free declarations are mandatory; units containing PCBs are restricted or banned in most countries. For dry-type transformers, confirm absence of hazardous materials and compliance with RoHS and REACH regulations in the EU.

Customs Clearance and Duties

Work with a licensed customs broker to ensure smooth clearance. Provide complete technical documentation, including kVA rating, voltage ratio, cooling type, and core material. Duties vary by country and transformer specifications. Some regions offer reduced tariffs for energy-efficient models meeting local eco-design directives (e.g., EU Ecodesign Regulation 548/2014).

On-Site Receiving and Inspection

Upon delivery, inspect the transformer for visible damage, seal integrity, and proper documentation. Check oil levels (if applicable) and perform a basic insulation resistance test before energizing. Report any discrepancies immediately to the carrier and supplier. Retain shipping records and inspection reports for compliance audits.

Disposal and End-of-Life Compliance

At end-of-life, dispose of transformers in accordance with local environmental regulations. Oil-filled units require certified recycling or reclamation of insulating oil and metals. Follow WEEE (Waste Electrical and Electronic Equipment) directives in Europe or equivalent programs elsewhere. Maintain records of disposal for regulatory compliance.

Conclusion for Sourcing a Step-Down Transformer

Sourcing a step-down transformer requires careful consideration of technical specifications, quality standards, supplier reliability, and cost-effectiveness. It is essential to clearly define the required voltage transformation ratio, power capacity (kVA), frequency, cooling method, insulation class, and environmental conditions to ensure compatibility with the intended application. Conducting thorough market research, evaluating multiple suppliers, and verifying certifications (such as ISO, CE, or IEC standards) help in selecting a reliable and durable transformer.

Additionally, considering lead times, after-sales service, warranty, and long-term maintenance support contributes to a successful procurement process. By aligning technical needs with supplier capabilities and performing due diligence, organizations can secure a high-performing step-down transformer that ensures efficient, safe, and uninterrupted power distribution. Ultimately, a well-sourced transformer enhances system reliability, reduces downtime, and supports operational efficiency.