The global steel stud screw market is experiencing steady growth, driven by rising construction activity and the increasing adoption of drywall and metal framing systems in both residential and commercial buildings. According to a 2023 report by Mordor Intelligence, the global drywall and metal framing market—of which steel stud screws are a critical component—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. This expansion is fueled by urbanization, demand for faster construction methods, and the shift toward sustainable building materials. Additionally, steel stud screws offer superior durability, corrosion resistance, and ease of installation compared to traditional wood framing fasteners, further accelerating their adoption. With North America and Europe leading in modern construction techniques and Asia-Pacific witnessing a construction boom, manufacturers are scaling production and innovating in screw design and coating technologies to meet evolving industry standards. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining quality, volume, and global reach to serve a growing base of contractors, distributors, and builders.

Top 10 Steel Stud Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Steel Network

Domain Est. 1997

Website: steelnetwork.com

Key Highlights: The Steel Network, Inc. (TSN) is a manufacturer of light gauge (cold-formed) steel studs and connectors based in the United States, with locations in North ……

#2 SCAFCO Steel Stud Company

Domain Est. 1997

Website: scafco.com

Key Highlights: SCAFCO Steel Stud Company is a manufacturer of a complete line of steel framing products and accessories with direct access to our engineering department….

#3 Pro-Twist

Domain Est. 2003

Website: pro-twist.com

Key Highlights: Pro-Twist is an industry-leading manufacturer of professional-grade fasteners that are used for a wide variety of applications. Get started with us today!…

#4 Global Leader in Fastening Technology

Domain Est. 2012

Website: stanleyengineeredfastening.com

Key Highlights: Stud Welding Systems. Trusted worldwide, Nelson® stud welding systems enable rapid, durable fastening in structural steel, automotive, and power applications….

#5 Metal Screws

Domain Est. 1995

Website: strongtie.com

Key Highlights: Our metal screws are designed to provide strength and superior performance in steel and other metal applications….

#6 Specialty Fastening Solutions for the Commercial Construction …

Domain Est. 1996

Website: itwbuildex.com

Key Highlights: We manufacture self-drilling and tapping screws, anchors, toggles, and other fastening systems under the Teks, Sammys, Dec-King, EZ Ancor, and Rock-On-brands….

#7 PEM – PennEngineering

Domain Est. 1996

Website: pemnet.com

Key Highlights: PEM offers innovative fastening solutions for a variety of applications across industries like Automotive Electronics, Consumer Electronics, Datacom and more….

#8 Steeler Construction Supply: Metal Stud Framing

Domain Est. 1998

Website: steeler.com

Key Highlights: Your one-stop shop for steel studs, gypsum board, drywall screws, and all-things drywall construction….

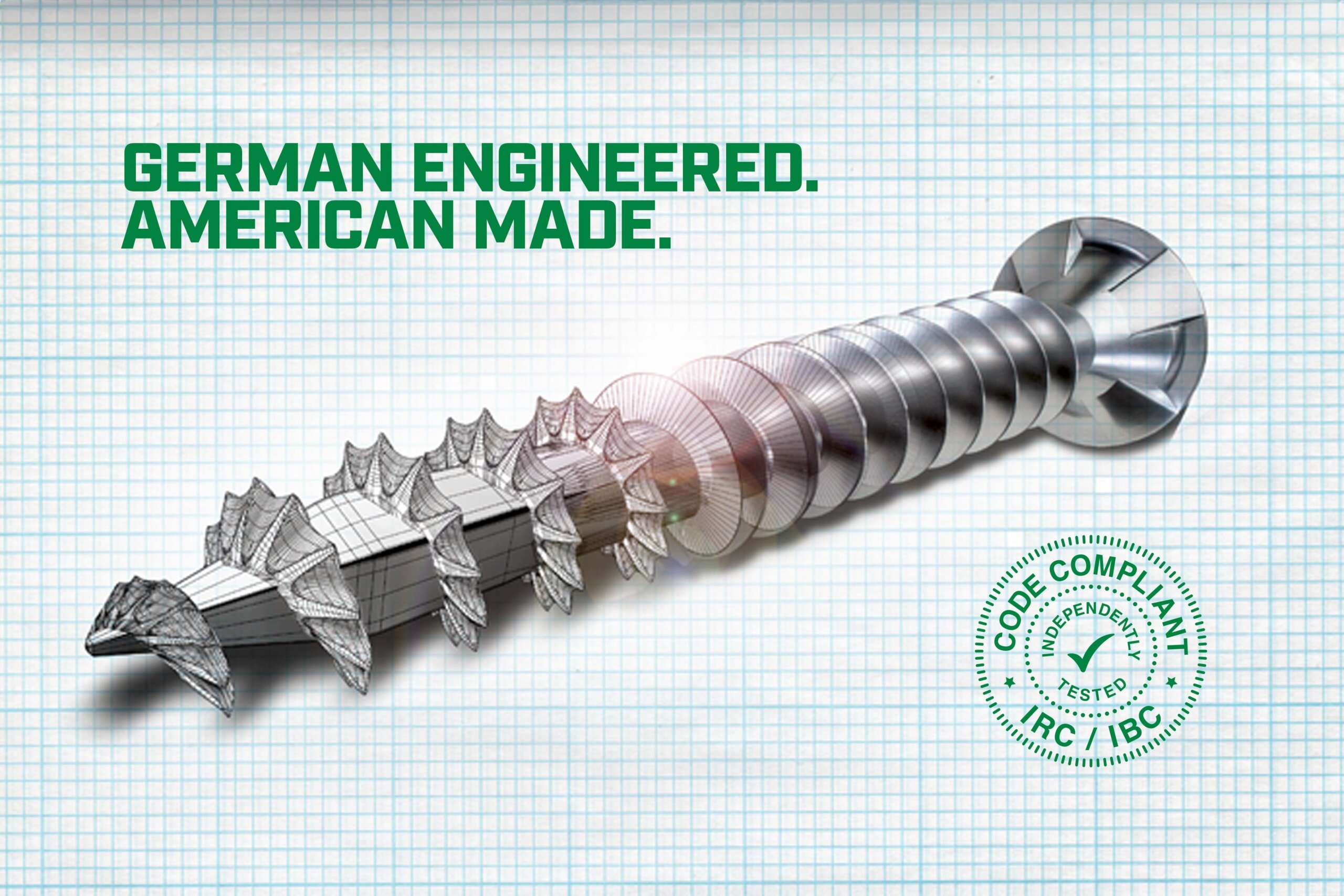

#9 SPAX US

Domain Est. 2004

Website: spax.us

Key Highlights: Our Engineered Screws & Fasteners are manufactured and rigorously tested right here in the heart of America. Rely on us to help you drive the highest quality….

#10 Teks Screws

Domain Est. 2018

Website: teksscrews.com

Key Highlights: Drill, Tap, Fasten in One Motion. Teks® Metal Fasteners are the original self-drilling screws developed to drill, tap, and fasten metal in one motion….

Expert Sourcing Insights for Steel Stud Screws

H2: 2026 Market Trends for Steel Stud Screws

The global market for steel stud screws is poised for steady growth leading into 2026, driven by expanding construction activity, technological advancements in fastening solutions, and increasing demand for lightweight and energy-efficient building systems. As part of the broader construction hardware sector, steel stud screws—used primarily in drywall and metal framing applications—are benefiting from shifts in building practices and material preferences.

One of the primary drivers shaping the 2026 outlook is the global rise in non-residential and residential construction, particularly in emerging economies across Asia-Pacific, Latin America, and Africa. Urbanization, infrastructure development, and government-backed housing programs are boosting demand for metal stud framing systems, where steel screws are essential components. In North America and Europe, renovation and retrofitting projects are also contributing to sustained demand, especially with a focus on sustainable and modular construction methods.

Another key trend is the growing adoption of light gauge steel framing (LSF) in both commercial and residential buildings. LSF offers advantages such as fire resistance, dimensional stability, and recyclability, making it a preferred alternative to traditional wood framing. This shift directly increases the need for high-performance steel stud screws designed for consistent grip, corrosion resistance, and compatibility with automated installation tools.

Technological innovation is also influencing product development. Manufacturers are focusing on enhanced coatings—such as zinc flake, ceramic, and thermoset coatings—to improve corrosion resistance and extend the lifespan of screws in humid or coastal environments. Additionally, smart packaging, torque-optimized screw designs, and compatibility with cordless power tools are improving installation efficiency, appealing to contractors seeking time and labor savings.

Sustainability and regulatory standards are becoming increasingly important. By 2026, stricter building codes and green certification requirements (e.g., LEED, BREEAM) are expected to favor durable, recyclable materials like steel. This creates a favorable environment for steel stud screws, especially those made with recycled content or low-carbon manufacturing processes.

Regionally, Asia-Pacific is anticipated to dominate market growth due to rapid urbanization in countries like India, Vietnam, and Indonesia. Meanwhile, North America remains a mature but stable market, supported by ongoing remodeling activity and the popularity of metal framing in multifamily and commercial construction.

In summary, the 2026 steel stud screw market will be shaped by rising construction volumes, the proliferation of metal framing systems, product innovation, and sustainability demands. Companies that invest in R&D, expand distribution in high-growth regions, and align with green building standards are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Steel Stud Screws (Quality, IP)

Sourcing steel stud screws may seem straightforward, but overlooking key quality and intellectual property (IP) aspects can lead to costly failures, safety hazards, and legal complications. Being aware of these common pitfalls helps ensure you select reliable, compliant, and legally sound products.

Inadequate Material and Coating Quality

One of the most frequent issues is assuming all steel screws are equal. Low-quality screws may use substandard steel alloys or insufficient zinc coating, leading to premature corrosion—especially in humid or coastal environments. This compromises structural integrity over time. Always verify material specifications (e.g., Grade 8.8 steel) and coating thickness (e.g., minimum 5µm for zinc), and request test certifications.

Lack of Compliance with Building Standards

Steel stud screws must meet regional building codes and performance standards (e.g., ASTM, EN, or local structural requirements). Sourcing non-compliant screws—especially those lacking proper load rating data or fire resistance certifications—can result in failed inspections, project delays, and liability in case of structural failure. Ensure suppliers provide documentation proving compliance.

Poor Thread Design and Drive Compatibility

Inferior thread geometry or mismatched drive types (e.g., Phillips vs. Pozi vs. Torx) can cause installation issues such as cam-out, stripped heads, or incomplete fastening. This not only slows down work but can weaken connections. Confirm that screw design is optimized for steel-to-steel applications and compatible with standard power tools used on-site.

Counterfeit or Unbranded Products

Gray-market or counterfeit screws may imitate reputable brands but fail to meet performance claims. These often lack traceability, making it difficult to verify origin or quality. Avoid unbranded or suspiciously low-priced screws; instead, source from authorized distributors and verify authenticity through batch numbers or manufacturer databases.

Intellectual Property (IP) Infringement Risks

Using screws that copy patented designs (e.g., proprietary thread configurations, head profiles, or coating technologies) can expose your project or company to legal action. Some suppliers may offer “compatible” or “equivalent” screws that infringe on IP rights. Always confirm that the product does not violate existing patents and, when in doubt, consult legal counsel or choose licensed alternatives.

Inconsistent Dimensional Tolerances

Low-cost manufacturers may produce screws with inconsistent lengths, diameters, or thread pitches. These variations can lead to improper fit, reduced pull-out strength, or difficulty in automated installation processes. Request dimensional inspection reports and conduct spot checks upon delivery to ensure uniformity.

Insufficient Technical Support and Documentation

Reliable suppliers provide detailed technical data, including load charts, installation guidelines, and compatibility information. Sourcing from vendors who lack this support increases the risk of incorrect application and performance failures. Prioritize suppliers with accessible engineering support and comprehensive product documentation.

By addressing these pitfalls early, you ensure that the steel stud screws you source deliver long-term performance, comply with regulations, and avoid legal or structural risks.

Logistics & Compliance Guide for Steel Stud Screws

Product Classification and Specifications

Steel stud screws are typically classified under construction fasteners and are essential in drywall, framing, and structural applications. Common specifications include:

– Material: Carbon steel, often zinc-plated or coated for corrosion resistance.

– Drive Type: Phillips, square, or combination drive.

– Head Style: Bugle head, wafer head, or flat head.

– Thread Type: Coarse or fine threads, self-drilling or self-tapping.

– Standards Compliance: ASTM C1002 (for metal framing screws), ASTM F548 (for bugle head drywall screws), and/or ICC-ES evaluation reports.

Ensure product specifications align with project requirements and regional building codes.

Packaging and Labeling Requirements

Proper packaging ensures product integrity during transportation and storage:

– Primary Packaging: Screws should be sealed in moisture-resistant bags or blister packs.

– Secondary Packaging: Packaged in labeled cardboard boxes or pails with clear quantity and specification details.

– Labeling Must Include:

– Product name and model number

– Screw dimensions (length, diameter, thread type)

– Material and finish (e.g., zinc-plated steel)

– Quantity per package

– Manufacturer or supplier name and contact

– Compliance markings (e.g., ASTM, ICC-ES)

– Country of origin

– Safety warnings (if applicable)

Transportation and Storage Guidelines

To maintain quality and performance:

– Transportation: Use enclosed, dry vehicles to prevent moisture exposure. Avoid extreme temperatures that may compromise coatings.

– Handling: Use appropriate lifting equipment for bulk shipments. Avoid dropping or crushing packages.

– Storage: Store in a dry, indoor environment with stable temperature and humidity. Keep off the ground (use pallets) and away from corrosive substances.

– Shelf Life: While steel screws have a long shelf life, inspect periodically for signs of rust or coating degradation, especially in humid climates.

Regulatory and Compliance Standards

Steel stud screws must meet relevant regional and international standards:

– United States:

– Comply with ASTM standards (e.g., ASTM C1002)

– Meet International Building Code (IBC) requirements

– May require ICC-ES Evaluation Reports for structural use

– European Union:

– CE marking under Construction Products Regulation (CPR) when applicable

– Compliance with EN 14592 (for timber fasteners, if used in hybrid systems)

– Canada:

– Must meet CSA standards and National Building Code of Canada (NBCC)

– Other Regions: Verify local building codes and import regulations.

Import/Export Documentation

For international trade, ensure the following documentation:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– Certificate of Origin

– Product test reports (ASTM, ICC-ES, etc.)

– Customs classification (HS Code: Typically 7318.15 or 7318.16 for screws)

– Import permits or certifications, if required by destination country

Environmental and Safety Compliance

- RoHS Compliance: Ensure no restricted hazardous substances (e.g., lead, cadmium) exceed limits, especially for coated screws.

- REACH (EU): Declare Substances of Very High Concern (SVHC) if present above thresholds.

- Safety Data Sheet (SDS): Provide SDS if required under local regulations (especially for zinc-coated or chemically treated screws).

Quality Assurance and Traceability

- Maintain batch/lot tracking for full traceability.

- Conduct regular quality audits and third-party testing.

- Provide mill test certificates or material certifications upon request.

Supplier and Certification Verification

- Source from certified manufacturers with ISO 9001 or equivalent quality management systems.

- Verify that product certifications (e.g., ICC-ES, CE) are current and valid.

- Retain all compliance documentation for audit readiness.

Following this guide ensures efficient logistics operations and full compliance with regulatory requirements for steel stud screws across global markets.

Conclusion for Sourcing Steel Stud Screws

Sourcing steel stud screws requires a strategic approach that balances quality, cost, availability, and compliance with industry standards. After evaluating suppliers, materials, and specifications, it is clear that selecting the right fasteners involves more than just price comparison. Key factors such as screw strength, corrosion resistance (e.g., through galvanization or stainless steel composition), dimensional accuracy, and adherence to construction codes are critical to ensuring structural integrity and long-term durability in stud framing applications.

Establishing relationships with reliable suppliers who provide certified products and consistent quality control helps mitigate risks associated with material failure or project delays. Additionally, considering lead times, bulk pricing, and sustainable sourcing practices can enhance supply chain efficiency and support project timelines.

In conclusion, a well-informed sourcing strategy for steel stud screws—grounded in technical requirements, supplier reliability, and total cost of ownership—ensures optimal performance in construction projects while supporting safety, efficiency, and cost-effectiveness.