The global steel rack shelf market is experiencing robust growth, driven by rising demand for efficient warehousing and storage solutions across e-commerce, retail, and manufacturing sectors. According to a report by Mordor Intelligence, the global storage rack market was valued at USD 10.8 billion in 2023 and is projected to reach USD 14.5 billion by 2029, growing at a CAGR of 5.1% during the forecast period. This expansion is fueled by the increasing need for optimized space utilization, especially in automated distribution centers and cold storage facilities. Additionally, Grand View Research highlights that the growing trend toward industrial automation and the expansion of logistics infrastructure in emerging economies are key catalysts accelerating market demand. As supply chains become more complex and inventory turnover speeds increase, the role of high-quality, durable steel rack systems has become paramount—making the choice of manufacturer a strategic decision for businesses aiming to scale efficiently and sustainably. In this context, identifying the top 10 steel rack shelf manufacturers provides critical insight into industry leaders driving innovation, reliability, and global supply chain resilience.

Top 10 Steel Rack Shelf Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Storage Racking System, Industrial Pallet Racks, Pallet Racking …

Domain Est. 1995

Website: frazier.com

Key Highlights: Frazier is the leading manufacturer of structural steel pallet racking storage systems for warehouses in the United States, Canada and Mexico….

#2 Steel King

Domain Est. 1998

Website: steelking.com

Key Highlights: Steel King is the nation’s single-source industrial rack manufacturer. We are a qualified industrial rack supplier that provides efficient material handling ……

#3 Montel Inc.: Mobile Shelving and High

Domain Est. 1996

Website: montel.com

Key Highlights: We design and manufacture efficient mobile shelving and vertical farming systems designed to save space, improve organization, and boost productivity….

#4 Metro

Domain Est. 1997

Website: metro.com

Key Highlights: Metro is the global manufacturer for original Super Erecta wire shelving and a vast array of storage & productivity products….

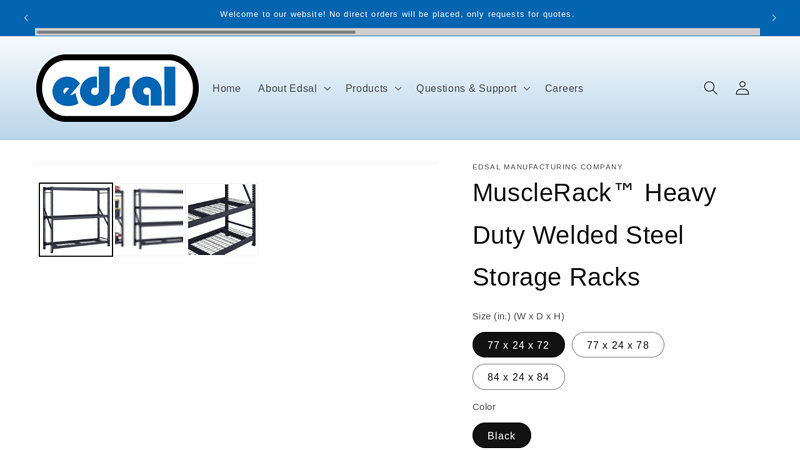

#5 MuscleRack™ Heavy Duty Welded Steel Storage Racks

Domain Est. 1997

Website: edsal.com

Key Highlights: In stockProduct Overview Features: Industrial grade welded steel frames and beams Easy to assemble in just minutes Shelves can be easily adjusted in 1-1/2” ……

#6 NSMC Steel Racks

Domain Est. 2023

Website: nsmc-steel-racks.com

Key Highlights: We specialize in fabricating heavy duty steel stacking racks and industrial wire baskets for manufacturing, distribution and warehouse customers….

#7 Commercial Shelving & Storage Racks

Website: pencoproducts.com

Key Highlights: Browse Penco’s selection of commercial shelving systems and storage rack products for warehouses and manufacturers….

#8 Rousseau Metal

Domain Est. 1998

Website: rousseau.com

Key Highlights: We design, manufacture and market cabinets, workstations and shelving tailored to the diverse needs of a wide range of industries….

#9 Garage Shelving

Domain Est. 2002

Website: gladiatorgarageworks.com

Key Highlights: Free delivery over $299 90-day returns…

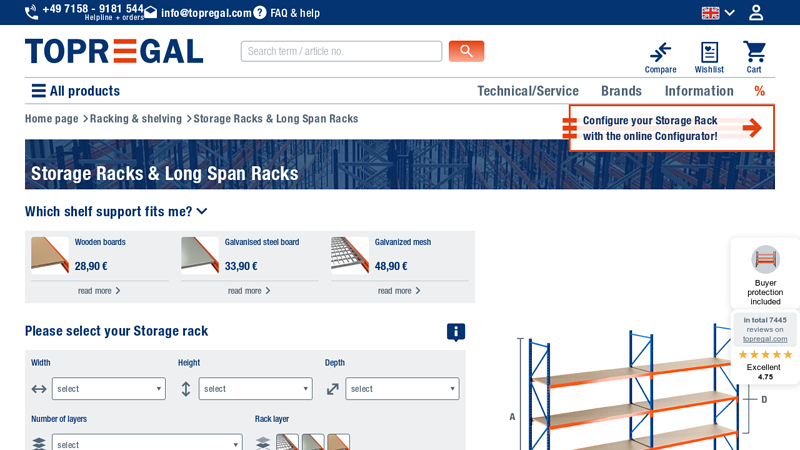

#10 Storage Racks & Long Span Racks

Domain Est. 2008

Website: topregal.com

Key Highlights: Our metal storage racks can be ordered from us as a complete offer or in individual parts, consisting of trusses, rack uprights, shelves and many more….

Expert Sourcing Insights for Steel Rack Shelf

H2: 2026 Market Trends for Steel Rack Shelves

The global steel rack shelf market is poised for significant transformation by 2026, driven by evolving industrial demands, technological advancements, and shifting consumer behaviors across logistics, retail, and manufacturing sectors. As supply chains become more complex and space optimization remains a critical factor, steel rack shelves continue to play a pivotal role in storage and inventory management. Below are the key market trends expected to shape the steel rack shelf industry in 2026:

1. Increased Demand from E-Commerce and Warehousing

The exponential growth of e-commerce is a primary driver for steel rack shelf adoption. By 2026, the need for high-density, scalable storage solutions in automated fulfillment centers and distribution hubs will surge. Steel rack systems—particularly selective, pallet, and drive-in racks—are being optimized for fast-moving inventory cycles, supporting just-in-time logistics models. The expansion of last-mile delivery networks will further stimulate demand for durable and modular racking in urban micro-fulfillment centers.

2. Integration with Automation and Smart Warehousing

Automation is redefining warehouse operations, and steel rack shelves are being redesigned to integrate with automated guided vehicles (AGVs), robotic picking systems, and warehouse management software (WMS). By 2026, smart racking systems equipped with IoT sensors for load monitoring, real-time inventory tracking, and predictive maintenance will gain market traction. These innovations enhance safety, reduce human error, and improve space utilization—key priorities for modern logistics operators.

3. Growth in Cold Storage and Refrigerated Warehousing

With rising demand for perishable goods, pharmaceuticals, and temperature-sensitive products, the cold chain logistics sector is expanding rapidly. Steel rack shelves designed for low-temperature environments—featuring corrosion-resistant coatings and structural stability under extreme conditions—are expected to see increased adoption. The push for energy-efficient cold storage facilities will drive demand for racking systems that optimize airflow and cooling efficiency.

4. Sustainability and Recyclability Driving Material Preferences

Steel’s recyclability and durability position it favorably in a market increasingly focused on sustainability. By 2026, manufacturers will emphasize eco-friendly production processes, use of recycled steel, and modular designs that extend product lifecycles. Regulatory pressures and corporate ESG (Environmental, Social, and Governance) goals will encourage end-users to choose steel over less sustainable alternatives like wood or plastic composites.

5. Regional Market Shifts and Manufacturing Localization

Asia-Pacific, particularly China and India, will remain dominant in both production and consumption due to rapid industrialization and urbanization. However, North America and Europe will witness growth driven by warehouse automation and reshoring of manufacturing. Geopolitical factors and supply chain resilience concerns may lead to increased regional manufacturing of steel racking systems, reducing dependency on global supply chains.

6. Customization and Modular Design Innovation

As storage needs diversify across industries—from automotive parts to retail goods—customizable and modular steel rack systems will gain popularity. In 2026, manufacturers will offer configurable shelving solutions that adapt to varying load capacities, aisle widths, and warehouse layouts. This flexibility supports scalability and reduces long-term capital expenditure for businesses.

7. Price Volatility and Raw Material Challenges

Fluctuations in steel prices due to energy costs, trade policies, and geopolitical tensions could impact profit margins. By 2026, companies may adopt hedging strategies, long-term supplier contracts, or alternative materials for non-critical components to mitigate cost instability. Efficiency improvements in manufacturing, such as roll-forming and automated assembly, will help offset rising input costs.

In conclusion, the steel rack shelf market in 2026 will be characterized by technological integration, demand from high-growth sectors like e-commerce and cold storage, and a strong emphasis on sustainability and adaptability. Companies that innovate in design, embrace automation, and respond to regional market dynamics will be best positioned to capitalize on emerging opportunities.

Common Pitfalls When Sourcing Steel Rack Shelves: Quality and Intellectual Property Issues

Logistics & Compliance Guide for Steel Rack Shelf

Product Overview and Specifications

Steel rack shelves are essential storage solutions in warehouses, distribution centers, and industrial facilities. They are typically constructed from high-strength steel and designed to support heavy loads. Standard configurations include selective, pallet, drive-in, push-back, and cantilever racking systems. Key specifications include load capacity (per shelf or per level), dimensions (height, depth, width), beam length, upright frame gauge, and finish (e.g., powder-coated, galvanized). Understanding these specifications is critical for safe and compliant installation and use.

Packaging and Handling Requirements

Proper packaging ensures that steel rack components arrive undamaged. Components such as upright frames, beams, shelves, and accessories are typically bundled and secured on wooden pallets or in crates. Protective corner guards and plastic wrapping help prevent scratches and corrosion during transit. Handling must be performed using forklifts or pallet jacks with appropriate load ratings. Manual handling of heavy beams or frames should be avoided to prevent injury. All components should be stored indoors or under cover upon delivery to prevent moisture exposure and rust.

Transportation Guidelines

Steel rack shelves are generally transported via flatbed trucks or enclosed freight trailers. Loads must be securely strapped and braced to prevent shifting during transit. Overhang beyond the trailer must comply with local transportation regulations (e.g., marked with flags or lights if exceeding limits). When shipping internationally, shipments must comply with International Maritime Organization (IMO) and carrier-specific guidelines. Use of dunnage and edge protectors prevents damage during loading and unloading.

Import/Export Compliance

For cross-border shipments, ensure compliance with relevant customs regulations. Steel rack shelves may be classified under HS Code 7308.90 (structures and parts of structures, of iron or steel). Accurate documentation—including commercial invoices, packing lists, and certificates of origin—is required. Import duties, anti-dumping measures (where applicable), and country-specific tariffs (e.g., U.S. Section 232 steel tariffs) must be accounted for. Export controls may apply depending on destination, especially for military or dual-use applications.

Safety and Installation Standards

Installation must follow recognized safety standards such as:

– FEM 10.2.02 (European Material Handling Federation)

– ANSI/MH16.1 (U.S. Rack Manufacturers Institute – RMI)

– AS 4084 (Australia/New Zealand)

These standards govern design, load capacity, seismic considerations, and aisle clearance. Only trained personnel should assemble racks using specified hardware and tools. Anchor bolts must be properly installed into concrete floors meeting minimum strength requirements. Load signage indicating maximum capacity per shelf level must be clearly displayed.

Load Capacity and Usage Compliance

Each rack system must be labeled with its load capacity per level and overall. Never exceed the manufacturer’s specified weight limits. Loads should be evenly distributed and centered on beams to prevent tipping or deformation. Dynamic loads from forklift impacts require protective accessories such as column guards and row spacers. Regular load audits help ensure ongoing compliance.

Inspection and Maintenance Protocols

Routine inspections are mandatory to ensure ongoing safety and compliance. A formal inspection program should include:

– Daily visual checks by operators for obvious damage

– Monthly professional inspections by trained personnel

– Annual comprehensive audits by qualified engineers

Document all inspections and repairs. Damaged components (e.g., bent uprights, cracked welds) must be repaired or replaced immediately using OEM parts.

Regulatory and Certification Requirements

Ensure that the steel rack shelves are certified by recognized bodies such as:

– RMI Certification (in North America)

– SEMMA or independent notified bodies (in Europe)

Certification confirms that the product meets structural and safety standards. Fire safety compliance may also be required, especially in facilities with sprinkler systems — ensure rack design allows for proper sprinkler coverage per NFPA 13 (U.S.) or equivalent local codes.

Environmental and Sustainability Considerations

Steel rack shelves are 100% recyclable at end-of-life. Opt for suppliers with ISO 14001 certification for environmental management. Use of powder-coated finishes reduces VOC emissions compared to solvent-based paints. Consider modular designs that allow reconfiguration instead of replacement to extend product life and reduce waste.

Documentation and Recordkeeping

Maintain comprehensive records including:

– As-built drawings and layout plans

– Load capacity charts

– Inspection and maintenance logs

– Certification documents

– Anchor bolt installation reports

These records are essential for compliance audits, insurance claims, and accident investigations.

Emergency Response and Incident Reporting

In case of rack damage due to forklift impact or structural failure:

1. Immediately cordon off the affected area

2. Remove all loads from compromised sections

3. Report the incident to facility management

4. Engage a qualified engineer for assessment

5. Do not reuse damaged components without professional approval

Establish clear protocols for incident reporting and corrective action to prevent recurrence.

Conclusion for Sourcing Steel Rack Shelving:

After a thorough evaluation of suppliers, product quality, pricing, lead times, and after-sales support, sourcing steel rack shelving from selected vendors presents a cost-effective and durable solution for efficient storage and inventory management. High-quality, load-bearing steel racks offer long-term durability, adaptability to various storage needs, and compliance with safety standards, ultimately enhancing operational efficiency.

Strategic partnerships with reputable suppliers—both domestic and international—ensure competitive pricing without compromising on structural integrity or customization options. Additionally, considering factors such as corrosion resistance, ease of assembly, and warranty terms further supports a wise investment decision.

In conclusion, sourcing steel rack shelving from qualified suppliers not only meets current storage demands but also provides scalability for future growth, making it a reliable and sustainable choice for warehouses, retail spaces, and industrial facilities.