The global steel mesh for concrete market is experiencing robust growth, driven by rising demand in construction and infrastructure development. According to Grand View Research, the global welded wire mesh market size was valued at USD 64.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increased urbanization, government investments in smart cities, and the need for durable, cost-effective reinforcement solutions in residential, commercial, and industrial construction. With sustainability and structural integrity becoming key priorities, manufacturers are innovating to produce high-tensile, corrosion-resistant steel mesh that meets evolving industry standards. As demand surges, especially in Asia-Pacific and North America, identifying leading suppliers becomes critical for contractors, engineers, and procurement professionals seeking reliable, high-performance materials. Based on production capacity, global footprint, technological innovation, and market reputation, the following nine companies stand out as the top steel mesh for concrete manufacturers shaping the industry’s future.

Top 9 Steel Mesh For Concrete Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Insteel Industries Inc.

Domain Est. 1996

Website: insteel.com

Key Highlights: We manufacture and market prestressed concrete strand and welded wire reinforcement, including engineered structural mesh, concrete pipe reinforcement and ……

#2 Wire Products

Domain Est. 1997

Website: nucor.com

Key Highlights: The Nucor Wire Products Group produces a wide range of steel wire products, as well as reinforcing solutions for the concrete construction industry….

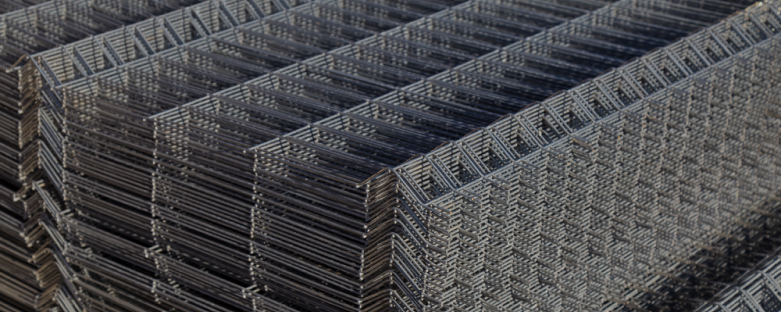

#3 Welded Wire Reinforcing (Construction Mesh)

Domain Est. 2000

Website: treeisland.com

Key Highlights: Welded wire reinforcement (construction mesh) is an efficient and economical replacement for rebar as reinforcement in concrete construction….

#4 Steel Reinforcements & Mesh

Domain Est. 2001

Website: madar.com

Key Highlights: From steel rebar to welded wire mesh, these products provide superior tensile strength and resistance to cracking, making them ideal for foundations, walls, ……

#5 Harris Supply Solutions: Steel Rebar Distributor

Domain Est. 2005

Website: harrissupplysolutions.com

Key Highlights: We proudly stock a wide variety of steel remesh sizes in sheets, rolls and finishes at all of our locations for various construction requirements our customers ……

#6 KEY STEEL WIRE

Domain Est. 2007

Website: keysteelwire.com

Key Highlights: Keysteel has been manufacturing steel wire products for concrete reinforcement for over 10 years, providing solutions to meet your customers wire mesh needs….

#7 Helix Steel

Domain Est. 2009

Website: helixsteel.com

Key Highlights: Helix Steel’s Twisted Steel Micro Rebar reinforces concrete with proven strength, speed, and durability. Replace rebar, cut costs, and build smarter today….

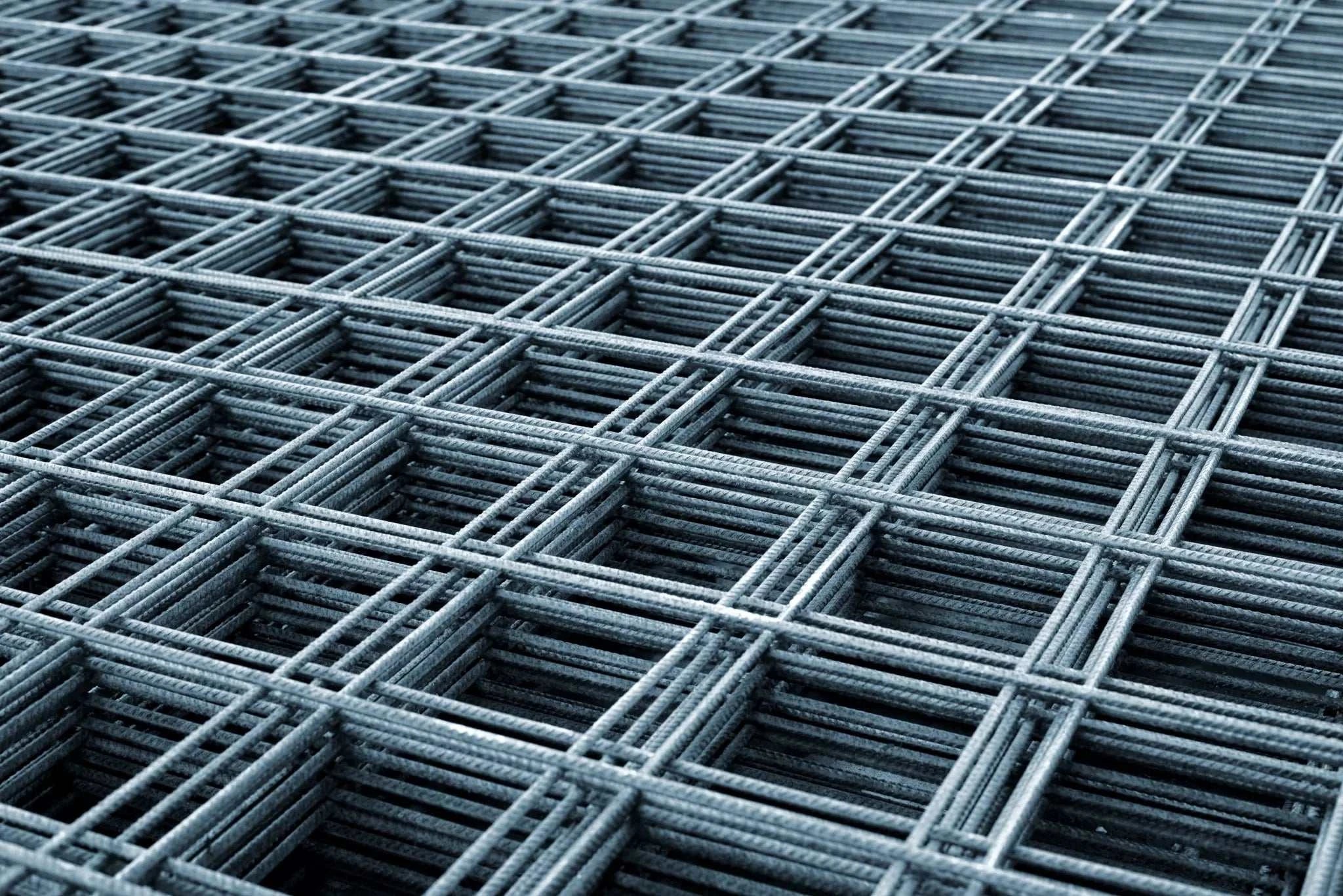

#8 Ribbed Steel Concrete Mesh for Construction Reinforcement

Domain Est. 2013

Website: concrete-mesh.com

Key Highlights: Welded mesh reinforcement bars are from 3 to 40 mm diameter, located in mutually perpendicular direction and forming a square or rectangular shape mesh….

#9 Wire Mesh for Concrete (Heavy Duty Galvanized)

Domain Est. 2023

Website: barrierbossusa.com

Key Highlights: In stock Free delivery over $2,500Crafted from galvanized steel, this heavy-duty mesh adds critical tensile reinforcement to slabs, foundations, and structural builds — helping pre…

Expert Sourcing Insights for Steel Mesh For Concrete

2026 Market Trends for Steel Mesh For Concrete

Global Demand and Market Growth

The global market for steel mesh in concrete applications is projected to experience steady growth by 2026, driven by increased infrastructure development, urbanization, and government investments in public works. According to industry forecasts, the market is expected to expand at a compound annual growth rate (CAGR) of approximately 5.2% from 2021 to 2026. This growth is particularly evident in emerging economies across Asia-Pacific, the Middle East, and Africa, where rapid construction of residential, commercial, and transportation infrastructure continues to boost demand for reinforced concrete solutions.

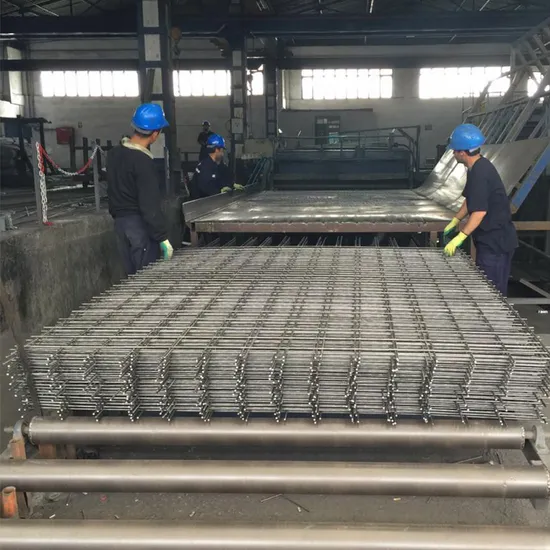

Technological Advancements and Product Innovation

By 2026, technological advancements are anticipated to significantly influence the steel mesh for concrete sector. Manufacturers are increasingly adopting automation and digital design tools, such as Building Information Modeling (BIM), to enhance precision in mesh fabrication and placement. Innovations like pre-fabricated modular steel mesh systems and corrosion-resistant coatings (e.g., epoxy-coated or galvanized steel) are becoming standard, improving durability and reducing long-term maintenance costs. Additionally, the integration of smart reinforcement technologies, including embedded sensors for structural health monitoring, is beginning to emerge in high-end construction projects.

Sustainability and Environmental Considerations

Sustainability is becoming a key market driver. With growing emphasis on green building practices and carbon footprint reduction, the steel mesh industry is shifting toward recycled steel content and energy-efficient production methods. By 2026, regulatory frameworks and green certification programs (e.g., LEED, BREEAM) are expected to encourage the use of sustainable steel products. Furthermore, the development of hybrid reinforcement systems—combining steel mesh with fiber-reinforced polymers (FRP)—is gaining traction as a way to reduce material weight and improve corrosion resistance, particularly in coastal or chemically aggressive environments.

Regional Market Dynamics

Asia-Pacific is expected to dominate the steel mesh for concrete market by 2026, led by China, India, and Southeast Asian nations undergoing massive infrastructure expansion. China’s continued focus on high-speed rail, urban housing, and smart cities supports strong domestic demand. In India, government initiatives such as “Smart Cities Mission” and “Housing for All” are driving construction activity. Meanwhile, North America and Europe are witnessing steady growth, primarily due to infrastructure rehabilitation projects and stricter building codes. The Middle East is also emerging as a key market, fueled by large-scale developments in Saudi Arabia’s Vision 2030 and UAE’s Expo 2020 legacy projects.

Competitive Landscape and Key Players

The market is characterized by a mix of large multinational corporations and regional manufacturers. Key players such as Anping County Ya Li Lian Hua Wire Mesh Co., Ltd., Wanzek Manufacturing, Inc., and Tata Steel are investing in R&D and geographic expansion to strengthen their market positions. Consolidation through mergers and acquisitions is expected to increase by 2026, as companies aim to enhance production capabilities and supply chain efficiency. Competitive advantages are increasingly derived from customization, just-in-time delivery, and technical support services.

Challenges and Risks

Despite positive growth prospects, the steel mesh for concrete market faces challenges, including fluctuating raw material prices, particularly for iron ore and scrap steel. Trade policies and tariffs, especially between major economies like the U.S. and China, may impact supply chain stability. Additionally, labor shortages and rising construction costs in some regions could temper demand. Alternative reinforcement materials, such as fiberglass and basalt rebar, also pose a long-term competitive threat, particularly in niche applications requiring non-conductive or non-magnetic properties.

Conclusion

By 2026, the steel mesh for concrete market will be shaped by increasing infrastructure demand, technological innovation, and sustainability imperatives. While challenges remain, the outlook remains positive, especially in developing regions. Companies that invest in advanced manufacturing, eco-friendly products, and strategic global partnerships are likely to lead the market in the coming years.

Common Pitfalls When Sourcing Steel Mesh for Concrete (Quality and Intellectual Property)

Sourcing steel mesh for concrete reinforcement involves several critical considerations to ensure structural integrity, compliance, and cost-effectiveness. Overlooking key factors related to quality and intellectual property (IP) can lead to project delays, safety risks, and legal complications. Below are the most common pitfalls to avoid:

Inadequate Quality Control and Certification

One of the most frequent issues is sourcing steel mesh without proper quality assurance. Buyers may accept products without verified mill test certificates (MTCs), chemical composition reports, or mechanical property validations. This can result in substandard mesh that fails to meet required tensile strength, weld integrity, or ductility standards—jeopardizing the structural performance of the concrete.

Non-Compliance with Regional Standards

Steel mesh must comply with local and international standards such as ASTM (e.g., ASTM A185, A496, A970), BS (e.g., BS 4482), or ISO specifications. Sourcing mesh that meets only generic or outdated standards can lead to rejection during site inspections or regulatory audits. Always confirm that the mesh conforms to the project’s specified codes and has been tested accordingly.

Poor Weld Quality and Spacing Inconsistencies

Low-quality manufacturing processes can result in inconsistent weld points or inaccurate bar spacing. Weak welds reduce load transfer efficiency and may lead to premature cracking or failure under stress. Visual inspection alone is insufficient—demand third-party testing reports that validate weld shear strength and dimensional tolerances.

Use of Substandard or Recycled Materials

Some suppliers may use recycled or off-spec steel to cut costs, leading to reduced corrosion resistance and mechanical performance. Without proper material traceability and certification, it’s difficult to verify the origin and suitability of the steel. Always require documentation that confirms the use of virgin or approved recycled content meeting industry standards.

Lack of Intellectual Property Due Diligence

When sourcing proprietary welded wire mesh systems (e.g., branded reinforcement solutions with patented designs or manufacturing methods), failing to verify IP rights can result in legal exposure. Unauthorized use of patented mesh patterns, connection systems, or production techniques may lead to infringement claims, project stoppages, or financial penalties.

Ignoring Supply Chain Transparency

Opaqueness in the supply chain increases the risk of counterfeit or mislabeled products. Without clear traceability from manufacturer to delivery, it’s difficult to verify authenticity or respond effectively to quality issues. Insist on full documentation, batch tracking, and direct supplier engagement to mitigate these risks.

Overlooking Corrosion Protection Requirements

For projects in aggressive environments (e.g., coastal or de-icing salt exposure), inadequate corrosion protection—such as insufficient epoxy coating or galvanization—can drastically shorten service life. Ensure the mesh coating meets specified thickness and adhesion standards (e.g., ASTM A884 for epoxy, ASTM A1064 for galvanized mesh).

Failure to Conduct Pre-Delivery Inspections

Assuming quality based on past performance or supplier reputation can be risky. Always conduct pre-shipment inspections or audits, especially for large or critical orders. This includes verifying dimensions, weld quality, surface finish, and packaging to prevent on-site rejections.

By proactively addressing these pitfalls, stakeholders can ensure the steel mesh used in concrete applications meets both technical requirements and legal obligations, safeguarding project outcomes and long-term structural performance.

Logistics & Compliance Guide for Steel Mesh For Concrete

Overview

Steel mesh for concrete, also known as welded wire fabric (WWF) or reinforcement mesh, plays a critical role in enhancing the structural integrity of concrete elements in construction projects. Effective logistics and compliance management are essential to ensure timely delivery, product quality, safety, and adherence to regulatory standards.

Transportation & Handling

Packaging and Protection

Steel mesh panels are typically bundled and secured using steel strapping or bands. Protective coatings (e.g., epoxy or galvanization) must remain intact during transit. Use moisture-resistant wrapping or tarps to prevent corrosion during transport, especially in humid or coastal environments.

Loading and Securing

Panels must be loaded flat on trucks or flatbed trailers to prevent bending or warping. Use dunnage (wooden spacers) between layers to avoid deformation. Secure loads with straps or chains to prevent shifting during transit. Overhanging loads must comply with local transportation regulations.

Forklift and Crane Operations

Use appropriate lifting equipment with spreader bars or slings to avoid damaging mesh panels during offloading. Never lift by the edges or corners, as this can distort the mesh geometry. Ensure personnel are trained in safe material handling procedures.

Storage Requirements

On-Site Storage

Store steel mesh on elevated, level platforms to prevent contact with standing water or soil. Cover with waterproof tarpaulins if stored outdoors. Keep away from chloride sources (e.g., de-icing salts) to minimize corrosion risk.

Inventory Management

Use a first-in, first-out (FIFO) system to manage stock rotation. Clearly label bundles with specifications (e.g., wire diameter, spacing, grade, coating type) for traceability and quality control.

Regulatory Compliance

Material Standards

Ensure steel mesh complies with relevant international and local standards, such as:

– ASTM A1064/A1064M (Standard Specification for Carbon-Steel Wire and Welded Wire Reinforcement)

– BS 4483 (Specification for Steel Fabric for Concrete Reinforcement)

– AS/NZS 4671 (Steel Reinforcing Materials)

– EN 10080 (Steel for Reinforced Concrete)

Verify mill test certificates (MTCs) accompany each shipment, certifying chemical composition, mechanical properties, and weld integrity.

Coating and Corrosion Protection

Galvanized or epoxy-coated mesh must meet coating thickness standards (e.g., ASTM A767 for galvanizing, ASTM A884 for epoxy). Inspect for coating damage upon delivery and reject compromised batches.

Environmental and Safety Regulations

Adhere to OSHA (or equivalent) safety requirements during handling and installation. Provide personal protective equipment (PPE) such as gloves and safety glasses. Manage waste (e.g., offcuts, packaging) in accordance with local environmental laws.

Import/Export Considerations

Customs Documentation

For international shipments, ensure accurate preparation of:

– Commercial invoice

– Packing list

– Certificate of Origin

– Bill of Lading/Air Waybill

– Compliance certificates (e.g., ISO, ASTM)

Tariff Classification

Steel mesh typically falls under HS Code 7314.29 (other non-coated steel wire mesh). Confirm classification with local customs authorities to avoid delays or incorrect duties.

Anti-Dumping and Trade Compliance

Be aware of anti-dumping duties or trade restrictions in the destination country. Verify supplier eligibility under free trade agreements (e.g., USMCA, EU agreements).

Quality Assurance & Traceability

Incoming Inspection

Verify dimensions, weld spacing, wire diameter, and surface condition upon receipt. Conduct random sampling for tensile and bend testing if required.

Batch Traceability

Maintain records linking each mesh batch to its MTC, delivery note, and project application. This supports quality audits and defect investigations.

Sustainability and Disposal

Recycling

Steel mesh is 100% recyclable. Coordinate with certified metal recyclers for scrap disposal. Document recycling activities for sustainability reporting.

Carbon Footprint

Optimize transport routes and consolidate shipments to reduce emissions. Choose suppliers with environmental management systems (e.g., ISO 14001) to support green procurement goals.

Conclusion

Proper logistics and compliance practices for steel mesh for concrete ensure structural performance, regulatory adherence, and project efficiency. From secure transportation to rigorous quality control and documentation, each step contributes to safe and sustainable construction outcomes. Always consult local building codes and project specifications to meet all requirements.

In conclusion, sourcing steel mesh for concrete applications requires careful consideration of several key factors to ensure structural integrity, durability, and cost-effectiveness. It is essential to evaluate the quality standards and specifications—such as weld integrity, wire diameter, spacing, and corrosion resistance—based on the project’s engineering requirements. Choosing reputable suppliers with certifications (e.g., ASTM, BS, or ISO standards) ensures consistent product quality and compliance with building codes. Additionally, comparing pricing, lead times, and logistical capabilities helps in making a cost-efficient and timely procurement decision. Sustainable sourcing practices and material traceability are also increasingly important in modern construction. Overall, a well-informed sourcing strategy for steel mesh contributes to the safety, performance, and longevity of concrete structures.