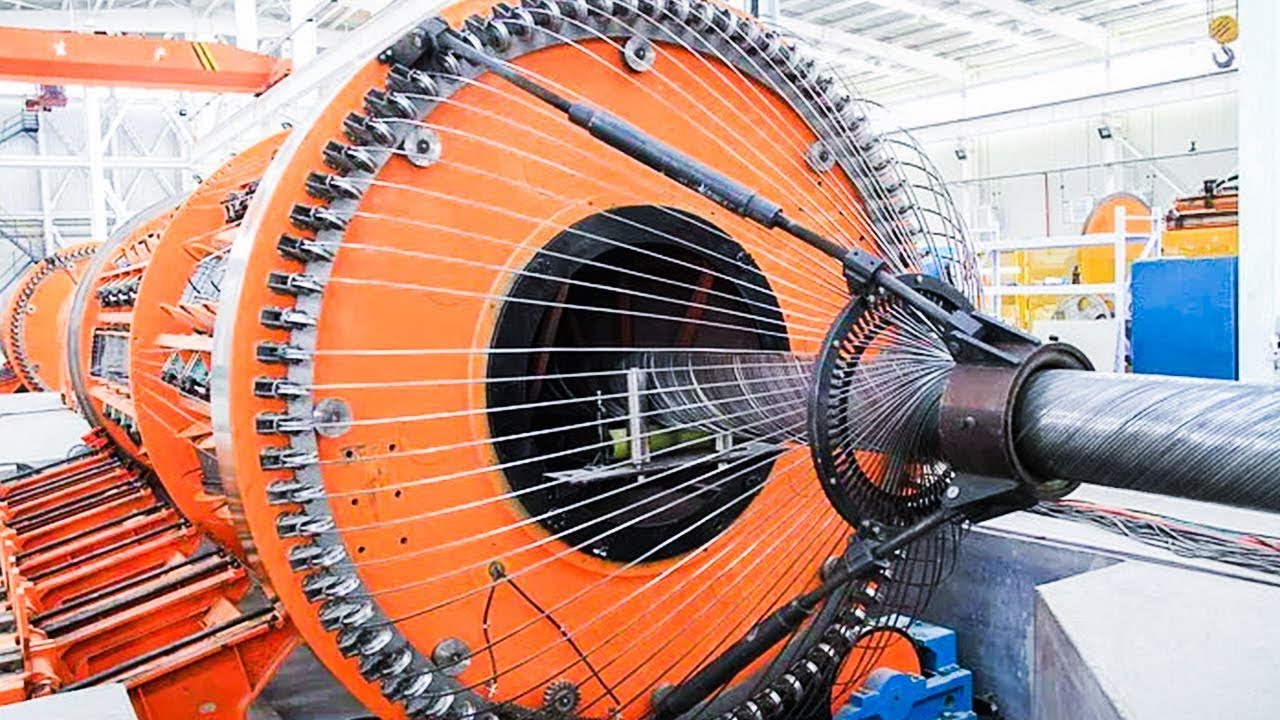

The global industrial pulley and sheave market is experiencing steady expansion, driven by rising demand across construction, material handling, and renewable energy sectors. According to Grand View Research, the global wire rope market—closely tied to sheave applications—was valued at USD 8.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This growth underscores the increasing reliance on high-performance steel cable sheaves that ensure efficiency, safety, and durability in lifting and rigging operations. As industries prioritize load-bearing reliability and operational longevity, manufacturers of precision-engineered sheaves are scaling innovation in materials, design, and corrosion resistance. In this evolving landscape, identifying leading steel cable sheave manufacturers becomes critical for sourcing partners seeking performance-validated components. Based on market presence, production capabilities, and technological advancement, the following seven companies stand out as key industry leaders.

Top 7 Steel Cable Sheaves Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 to Loos & Co., Inc.

Domain Est. 1997

Website: loosco.com

Key Highlights: Loos and Company manufactures and stocks aircraft cable to commercial and military specifications in stainless steel, galvanized carbon steel, and a variety of ……

#2 Bear Equipment

Domain Est. 2000

Website: bearequipment.com

Key Highlights: Your Standard & Custom Rope Sheave Manufacturer. Experience 40 years of precision-machined quality products, responsive service, same-day quotes, on-time ……

#3 Sheaves, Inc.: Wire Rope Sheaves From Stock

Domain Est. 2003

Website: esheaves.com

Key Highlights: We are an engineering firm. We take your technical requirements for wire rope sheaves and translate them into cost effective solutions….

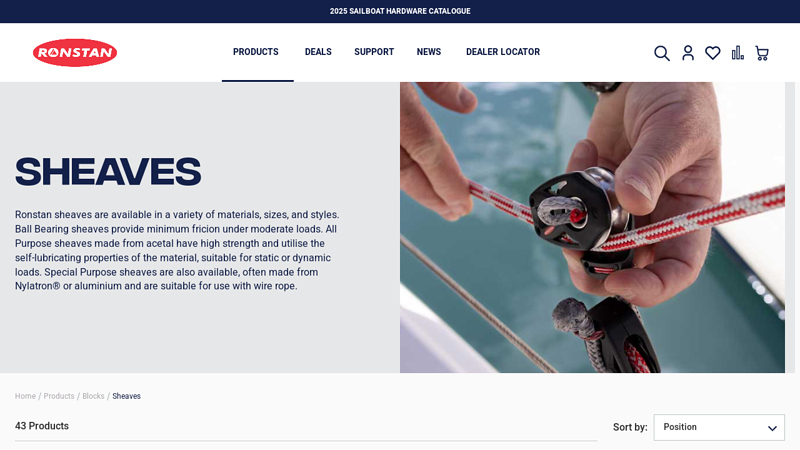

#4 Pulley Sheaves

Domain Est. 1997

Website: ronstan.com

Key Highlights: Free delivery over $75 30-day returnsRonstan sheaves are available in a variety of materials, sizes, and bearing styles, including ball bearing, roller bearing, and plain bearing….

#5 Sheaves

Domain Est. 1997

Website: americanblock.com

Key Highlights: We manufacture sheaves to API 8C, and third party certification such as ABS or DNV is available upon request. SIZES: 20″ TO 120″ FOR ANY DIAMETER OF WIRE ROPE ……

#6 Wire rope sheaves

Domain Est. 2000

Website: ropeblock.com

Key Highlights: Wire rope sheaves. Sheaves in different constructions and materials for various purposes, available from stock. NEW! THE QUICK & EASY WAY OF FINDING…

#7 Get Wire Rope Sheaves & Pulleys Here

Domain Est. 2004

Website: isheaves.com

Key Highlights: 8-day deliveryWe provide both stock and custom wire rope sheaves for many applications. Call us at 973-284-7003 for a free consultation….

Expert Sourcing Insights for Steel Cable Sheaves

H2: 2026 Market Trends for Steel Cable Sheaves

The global market for steel cable sheaves is poised for steady growth and transformation by 2026, driven by advancements in industrial automation, infrastructure development, and the increasing demand for durable lifting and rigging components across key sectors. Several strategic trends are expected to shape the market landscape:

-

Increased Demand from Renewable Energy Sectors

The expansion of wind and hydroelectric power projects globally is creating a surge in demand for high-strength, corrosion-resistant steel cable sheaves. These components are essential in turbine installation, maintenance cranes, and cable management systems, where reliability under extreme conditions is critical. As renewable energy investments rise—particularly in North America, Europe, and parts of Asia-Pacific—steel cable sheave manufacturers are adapting designs for enhanced performance in harsh environments. -

Growth in Infrastructure and Construction Activities

Major infrastructure initiatives, including urban mass transit systems, bridge construction, and port modernization, are fueling demand for heavy lifting equipment. Steel cable sheaves, integral to cranes, hoists, and material handling systems, benefit directly from this trend. Government-led infrastructure programs in China, India, the U.S., and the Middle East are expected to sustain market growth through 2026. -

Technological Advancements and Material Innovation

Manufacturers are investing in advanced metallurgy and surface treatments—such as galvanization, nitriding, and ceramic coatings—to improve wear resistance and extend service life. Integration with smart monitoring systems (IoT-enabled load sensors and condition monitoring) is also emerging, allowing predictive maintenance and real-time performance tracking of sheave systems in industrial settings. -

Shift Toward Lightweight and High-Performance Designs

While steel remains dominant for its strength and load-bearing capacity, there is growing interest in hybrid designs that reduce overall system weight without compromising durability. This trend is particularly relevant in aerospace, offshore, and mobile crane applications where efficiency and portability are paramount. -

Stringent Safety and Regulatory Standards

Regulatory bodies worldwide are tightening safety requirements for lifting and rigging equipment, prompting upgrades in sheave design and quality control. Compliance with ISO, OSHA, and ASME standards is becoming a key differentiator for suppliers, influencing procurement decisions in mining, oil & gas, and construction industries. -

Regional Market Dynamics

Asia-Pacific is expected to lead global market share due to rapid industrialization and infrastructure development, particularly in China and India. North America and Europe will maintain strong demand, supported by modernization of aging infrastructure and growth in offshore energy projects. Latin America and Africa show emerging potential, driven by mining and energy sector investments. -

Sustainability and Circular Economy Initiatives

By 2026, environmental considerations are increasingly influencing procurement. Manufacturers are adopting sustainable production practices, including energy-efficient manufacturing and recycling of scrap steel. Reconditioned and remanufactured sheaves are gaining traction in cost-sensitive markets, promoting circular economy models.

In conclusion, the steel cable sheave market in 2026 will be characterized by innovation, regulatory compliance, and sector-specific customization. Companies that invest in R&D, sustainability, and digital integration are likely to gain competitive advantage in this evolving landscape.

Common Pitfalls When Sourcing Steel Cable Sheaves: Quality and Intellectual Property Risks

Poor Material Quality and Inadequate Heat Treatment

One of the most frequent issues when sourcing steel cable sheaves is receiving products made from substandard materials or without proper heat treatment. Low-grade steel or insufficient hardening of the sheave groove can lead to premature wear, deformation, and failure under load. This compromises lifting safety and increases downtime and replacement costs. Buyers must verify material certifications (e.g., ASTM or ISO standards) and request proof of heat treatment processes such as induction hardening or through-hardening.

Inaccurate Machining and Dimensional Tolerances

Inconsistent machining can result in sheaves with incorrect groove profiles, misaligned bore holes, or uneven surfaces. These defects increase cable friction, accelerate rope wear, and can cause cable slippage or derailment. Sourcing from manufacturers without strict quality control (QC) systems—such as ISO 9001 certification—heightens the risk of receiving non-conforming parts. Conducting first-article inspections or third-party QC audits is essential to mitigate this pitfall.

Lack of Load and Fatigue Testing Documentation

Reputable sheave manufacturers perform load and fatigue testing to validate performance under real-world conditions. Many low-cost suppliers cannot or will not provide test reports or FEA (Finite Element Analysis) data. Without this documentation, buyers risk deploying sheaves that may fail catastrophically under operational stress. Always request performance validation data and verify compliance with industry standards like ASME B30.26 or ISO 4308.

Counterfeit or IP-Infringing Designs

Sourcing from unauthorized or unverified suppliers increases the risk of receiving sheaves that infringe on patented designs or trademarks. Some manufacturers replicate branded sheaves (e.g., those from established OEMs) without licensing, offering “compatible” versions that may look identical but lack engineering integrity. This exposes the buyer to legal liability and potential supply chain disruptions. Ensure suppliers have proper IP licenses or offer original, non-infringing designs with verifiable design ownership.

Insufficient Surface Protection and Corrosion Resistance

Steel sheaves used in outdoor or corrosive environments require proper surface treatments—such as galvanization, powder coating, or specialized paint systems. Many budget suppliers omit or shortcut these processes, leading to rapid rust formation, pitting, and reduced service life. Confirm surface treatment specifications and request salt spray test results (e.g., ASTM B117) to verify corrosion resistance.

Inadequate Traceability and Documentation

High-integrity applications (e.g., in offshore, mining, or crane operations) demand full traceability, including material test reports (MTRs), manufacturing records, and heat lot numbers. Suppliers with poor documentation practices may not provide these, making compliance with regulatory or safety audits difficult. Prioritize vendors that offer comprehensive traceability and maintain digital quality records.

Overlooking Custom Design Ownership and IP Rights

When sourcing custom-engineered sheaves, buyers may assume they own the design rights. However, without a clear contractual agreement, the supplier may retain intellectual property, restricting the buyer’s ability to source from alternate manufacturers or modify the design. Always include IP assignment clauses in procurement contracts to secure full ownership of custom designs.

By proactively addressing these quality and intellectual property pitfalls, procurement teams can ensure reliable, safe, and legally compliant sourcing of steel cable sheaves.

Logistics & Compliance Guide for Steel Cable Sheaves

Proper logistics and regulatory compliance are essential when transporting and handling steel cable sheaves to ensure safety, avoid delays, and meet international and local requirements. This guide outlines key considerations for the efficient and compliant movement of these industrial components.

Product Classification and HS Code

Steel cable sheaves are typically classified under Harmonized System (HS) codes related to pulleys and industrial machinery components. The most common HS code is 8483.60, which covers transmission shafts, cranks, bearing housings, pulleys, and sheaves. However, final classification may vary based on design, material composition, and intended use. Always verify the correct HS code with customs authorities or a certified trade advisor in the destination country to ensure accurate tariff application and avoid penalties.

Packaging and Handling Requirements

Steel cable sheaves must be packaged to prevent damage during transit, especially given their weight and potential for surface corrosion. Best practices include:

– Use of wooden crates or reinforced pallets for large or heavy units.

– Application of protective coatings (e.g., rust-inhibitive oils) and vapor corrosion inhibitors (VCI) for long-term storage or sea transport.

– Secure fastening within containers to prevent shifting during transport.

– Clearly labeled packages with handling instructions such as “Heavy,” “Do Not Tilt,” and “Protect from Moisture.”

Shipping and Transportation

Transportation of steel cable sheaves can involve road, rail, sea, or air freight, depending on size, weight, and destination:

– Sea Freight: Most cost-effective for large volumes. Use 20′ or 40′ dry or flat-rack containers based on dimensions. Ensure compliance with IMO and SOLAS container weight verification (VGM).

– Air Freight: Suitable for urgent, smaller shipments. Confirm weight and dimensional restrictions with the carrier.

– Overland Transport: Use heavy-duty trailers with appropriate load securement. Comply with local axle weight and dimensional regulations (e.g., AASHTO in the U.S., EU directives in Europe).

Import/Export Documentation

Accurate documentation is critical for customs clearance:

– Commercial Invoice

– Packing List

– Bill of Lading (for sea) or Air Waybill (for air)

– Certificate of Origin (may be required for preferential tariff treatment under trade agreements)

– Material Test Reports (MTRs) upon request

– Export Declaration (e.g., EEI via AES in the U.S.)

– Import License (if required by destination country)

Regulatory Compliance

Compliance with international and regional standards ensures product safety and market access:

– ISO Standards: ISO 4308 (cranes – wire ropes), ISO 16625 (sheaves for lifting appliances)

– ASME B30.21: Safety standard for below-the-hook lifting devices (U.S.)

– CE Marking: Required for sale in the European Economic Area under the Machinery Directive (2006/42/EC) or Lifts Directive (2014/33/EU), as applicable

– RoHS and REACH Compliance: Confirm absence of restricted substances, especially in coatings or lubricants

Customs Clearance and Duties

Customs authorities may inspect shipments to verify product classification, value, and compliance. Be prepared for:

– Payment of applicable import duties and VAT/GST

– Anti-dumping or countervailing duties if applicable (e.g., steel-related tariffs)

– Product conformity assessments in certain jurisdictions (e.g., notified body involvement in EU)

Environmental and Safety Considerations

- Recyclable packaging is encouraged to meet sustainability goals.

- Discarded sheaves should be recycled as scrap metal in accordance with local environmental regulations.

- Provide Safety Data Sheets (SDS) if protective coatings or lubricants are applied.

Certification and Traceability

Maintain full traceability of materials and manufacturing processes:

– Retain heat numbers and MTRs for raw materials.

– Implement a quality management system (e.g., ISO 9001) to support compliance audits.

– Include batch or serial numbers on sheaves when required by customer or regulation.

Following this guide ensures efficient, compliant, and safe logistics for steel cable sheaves across global supply chains. Always consult with logistics providers and regulatory experts to address destination-specific requirements.

Conclusion for Sourcing Steel Cable Sheaves

In conclusion, sourcing steel cable sheaves requires a strategic approach that balances quality, durability, cost-efficiency, and supplier reliability. Given the critical role sheaves play in lifting, rigging, and material handling applications, selecting components made from high-grade steel with proper heat treatment and precision machining is essential to ensure safety, performance, and longevity.

A thorough supplier evaluation—considering certifications, manufacturing capabilities, quality control processes, and track record—helps mitigate risks associated with mechanical failure and downtime. Additionally, factors such as lead times, customization options, and after-sales support should be weighed to align procurement with operational requirements.

Ultimately, investing time in due diligence during the sourcing process results in long-term cost savings, improved system efficiency, and enhanced operational safety. By prioritizing reputable suppliers and adhering to industry standards, organizations can secure steel cable sheaves that meet performance expectations and support reliable, efficient operations across their lifting and hauling systems.