The global stamp printer market is experiencing steady growth, driven by increasing demand across logistics, retail, and postal services for efficient, high-precision labeling solutions. According to Mordor Intelligence, the barcode printer market—of which stamp printers are a key segment—is projected to grow at a CAGR of over 8.5% from 2024 to 2029, fueled by automation in supply chains and rising e-commerce activities. Similarly, Grand View Research estimates that the global barcode printing market was valued at USD 4.3 billion in 2023 and is expected to expand significantly in the coming decade, underpinned by advancements in thermal printing technology and integration with enterprise resource planning (ERP) systems. As organizations prioritize operational efficiency and traceability, stamp printers—known for their durability and ability to print batch codes, serial numbers, and compliance marks directly onto various surfaces—are becoming indispensable. This growing demand has spurred innovation among manufacturers, leading to a competitive landscape marked by technological differentiation and service excellence. Below are the top 9 stamp printer manufacturers shaping this dynamic industry.

Top 9 Stamp Printer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

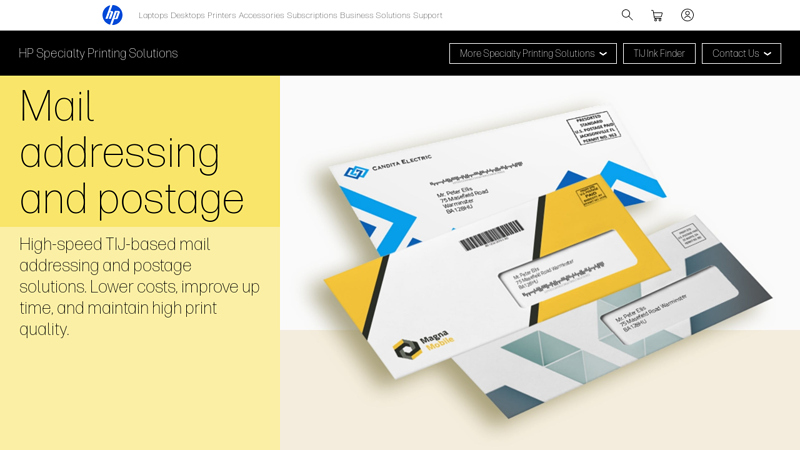

#1 Mail Addressing & Postaging Printing

Domain Est. 1986

Website: hp.com

Key Highlights: Find the right mail addressing printer for your business and connect with HP OEMs for reliable, high-speed, TIJ based mail addressing printing systems….

#2 Traditional stamps

Domain Est. 1996

Website: colop.com

Key Highlights: COLOP is one of the world’s leading manufacturers of modern stamping equipment – from office to pocket stamps, from text to date stamps and from rectangular ……

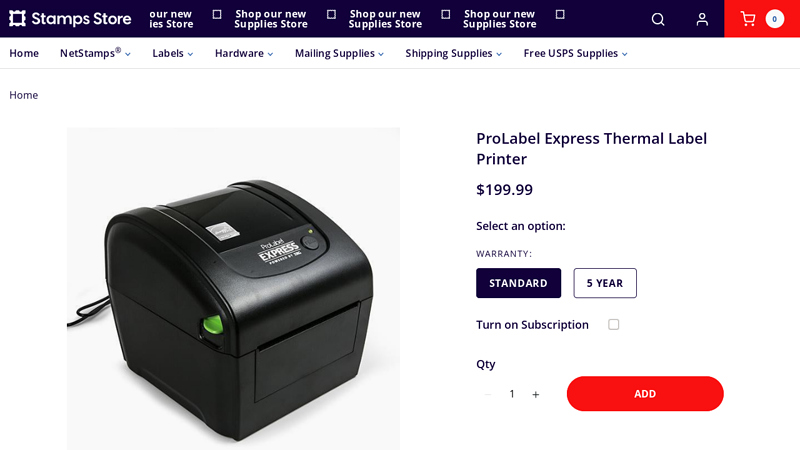

#3 ProLabel Express Thermal Label Printer

Domain Est. 1994

#4 Modern US Stamp Printers

Domain Est. 1997

Website: info.mysticstamp.com

Key Highlights: See below for information on a few of the most recent printers. Currently, stamps are printed by Ashton Potter and Banknote Corporation of America….

#5

Domain Est. 1998

Website: trodat.net

Key Highlights: The diverse product world from Trodat. Whether at work, at home or on the go – you will always find the right stamp in the large Trodat stamp range….

#6 American Stamp

Domain Est. 1999

Website: americanstamp.com

Key Highlights: American Stamp & Marking Products is your source for all your marking and engraving needs, located in Maryland Heights, Missouri….

#7 Hot Stamp Marking & Thermal Printing Machines|CTK Corporation

Domain Est. 2000

Website: en.hotmarker.com

Key Highlights: CTK’s Hotmarker is a reliable and efficient marking solution for a wide range of applications. They are used in industries like electric power, auto, aircraft, ……

#8 Quality Rubber Stamp Co., LLC

Domain Est. 2006

Website: qstamps.com

Key Highlights: QUALITY RUBBER STAMP CO., LLC manufactures a wide range of GENUINE rubber stamps, such as date stamps, number stamps, and band stamps….

#9 SHINY AMERICA, LLC

Domain Est. 2015

Website: shinyamerica.com

Key Highlights: Home; Self-Inking Printer Line; 850 Series Printers; Help Save the Oceans; Handy Pocket Stamps; Heavy-Duty Self-Inking Daters; Heavy-Duty Self-Inking Daters ……

Expert Sourcing Insights for Stamp Printer

H2: 2026 Market Trends for Stamp Printers

As we look toward 2026, the stamp printer market is poised for significant transformation, driven by evolving regulatory demands, technological advancements, and shifting logistics needs. Below is an analysis of key market trends expected to shape the industry in the coming years:

1. Increased Demand for Digital Integration and Smart Labels

By 2026, stamp printers are no longer standalone devices but integrated components of broader digital shipping and logistics ecosystems. Cloud-connected stamp printers that sync with e-commerce platforms, ERP systems, and shipping software will dominate. Features such as automatic rate comparison, real-time postage updates, and digital audit trails will become standard, enhancing operational efficiency for businesses.

2. Growth in E-Commerce and Direct-to-Consumer Shipping

The continued rise of e-commerce, particularly in small and medium-sized businesses (SMBs), will fuel demand for desktop and mobile stamp printers. As more brands adopt direct-to-consumer (DTC) models, the need for on-demand, in-house postage solutions will grow. Portable and wireless stamp printers will gain traction among remote sellers and fulfillment centers seeking flexibility and scalability.

3. Sustainability and Eco-Friendly Printing Solutions

Environmental concerns will drive innovation in stamp printing technology. By 2026, manufacturers will prioritize energy-efficient models, recyclable materials, and low-impact ink formulations. Water-based inks and biodegradable label substrates will become more common, aligning with corporate sustainability goals and regulatory pressures in regions like the EU and North America.

4. Expansion of Mobile and On-the-Go Printing

Mobile stamp printing—enabled by Bluetooth and app-based solutions—will see increased adoption, especially in last-mile delivery and field service operations. Delivery drivers, couriers, and mobile postal workers will rely on compact, battery-powered printers to issue valid postage at the point of pickup or delivery, reducing delays and improving customer experience.

5. Regulatory Compliance and Security Enhancements

Postal authorities worldwide are expected to implement stricter anti-fraud measures and digital authentication protocols. By 2026, stamp printers will incorporate advanced security features such as encrypted digital signatures, tamper-proof logs, and blockchain-based verification to ensure postage integrity and compliance with evolving postal regulations.

6. AI and Predictive Maintenance

Artificial intelligence will begin playing a role in predictive maintenance for commercial-grade stamp printers. By analyzing usage patterns and performance data, AI-enabled systems will anticipate maintenance needs, reduce downtime, and optimize print quality—crucial for high-volume logistics operations.

7. Consolidation and Service-Based Business Models

The market may see consolidation among stamp printer manufacturers and service providers. Companies like Pitney Bowes and Datalogic could expand their offerings into subscription-based models, bundling hardware, software, and postage credits into unified logistics-as-a-service (LaaS) platforms. This shift will lower entry barriers for SMBs and increase customer retention.

Conclusion:

By 2026, the stamp printer market will transition from a niche office tool to a critical node in the digital supply chain. Success will depend on adaptability, connectivity, and sustainability. Companies that embrace integration, security, and eco-conscious innovation will lead the market, while legacy models risk obsolescence in the face of rapid digital transformation.

Common Pitfalls When Sourcing Stamp Printers: Quality and Intellectual Property Risks

Sourcing stamp printers—particularly for applications like postal services, logistics, or product labeling—can present significant challenges if not approached carefully. Two of the most critical areas where companies encounter problems are product quality and intellectual property (IP) concerns. Overlooking these aspects can lead to operational inefficiencies, legal disputes, and reputational damage.

Quality-Related Pitfalls

Inconsistent Print Clarity and Durability

One of the most frequent quality issues is inconsistent print output. Low-quality stamp printers may produce smudged, faded, or misaligned impressions, especially under high-volume use. This is often due to substandard ink formulations, poorly calibrated print heads, or inadequate pressure mechanisms. Over time, this reduces the legibility of stamped information, potentially leading to compliance failures or rejection of marked items.

Poor Build Quality and Reliability

Many budget-friendly stamp printers sourced from unverified suppliers suffer from fragile components and short lifespans. Plastic housings, weak mechanical parts, or low-grade electronics can result in frequent breakdowns, increased maintenance costs, and unplanned downtime. It’s essential to assess the build materials, motor quality, and overall engineering before committing to a supplier.

Lack of Standard Compliance

Stamp printers used in regulated industries (e.g., postal or pharmaceutical sectors) must meet specific standards for print permanence, ink safety, and environmental resistance. Sourcing from suppliers who do not adhere to ISO, ASTM, or industry-specific standards can result in non-compliant equipment that fails inspections or causes liability issues.

Inadequate After-Sales Support and Spare Parts

Even if a stamp printer performs well initially, poor vendor support can undermine long-term operations. Suppliers may not offer readily available replacement parts, technical documentation, or responsive service, making repairs difficult and costly—especially for specialized or proprietary models.

Intellectual Property (IP) Risks

Use of Counterfeit or Cloned Technology

Some manufacturers, particularly in regions with lax IP enforcement, produce stamp printers that copy patented designs, firmware, or mechanical components from established brands. Purchasing such equipment exposes the buyer to legal risks, including potential infringement claims from original equipment manufacturers (OEMs), especially when importing across borders.

Unauthorized Firmware and Software

Stamp printers often rely on proprietary software for configuration, calibration, and integration with enterprise systems. Sourcing devices with pirated or reverse-engineered firmware not only violates copyright laws but can also introduce cybersecurity vulnerabilities, data leakage risks, and compatibility issues.

Lack of IP Documentation and Warranty

Reputable suppliers provide clear documentation regarding IP ownership, licensing agreements, and warranty terms. When sourcing from obscure vendors, buyers may receive no proof of legitimate technology use, leaving them exposed in case of legal challenges. This also complicates warranty claims and technical support.

Customization Without Licensing

Businesses sometimes request customized stamp printers with unique features or branding. If the supplier implements these changes using unlicensed components or patented technologies, the buyer could become complicit in IP violations—even unintentionally.

Mitigation Strategies

To avoid these pitfalls, organizations should:

– Conduct thorough due diligence on suppliers, including site visits and reference checks.

– Request product certifications and test samples before bulk purchasing.

– Verify IP ownership through legal documentation and third-party validation.

– Engage legal counsel to review contracts for IP indemnification clauses.

– Prioritize suppliers with transparent supply chains and established reputations.

By proactively addressing quality and IP concerns, businesses can ensure reliable performance and reduce legal and operational risks associated with stamp printer procurement.

Logistics & Compliance Guide for Stamp Printers

This guide outlines essential logistics and compliance considerations for businesses involved in the printing and distribution of postage and fiscal stamps. Adhering to these guidelines ensures operational efficiency, regulatory compliance, and the integrity of stamp products.

Regulatory Compliance

Stamp printers must operate within strict legal frameworks established by national postal authorities (e.g., USPS, Royal Mail, PostNord) and tax/fiscal agencies. Key compliance areas include:

- Licensing and Accreditation: Obtain required permits from postal and/or government revenue authorities to produce official stamps.

- Security Standards: Implement physical and digital security measures such as secure facilities, access controls, surveillance, and encrypted design files to prevent counterfeiting.

- Anti-Counterfeiting Measures: Integrate security features like holograms, watermarks, microprinting, and specialized inks as mandated by issuing authorities.

- Audit and Reporting: Maintain detailed records of production volumes, serial numbers, and distribution. Be prepared for regular audits by regulatory bodies.

- Data Protection: Safeguard sensitive design and production data in compliance with data privacy laws (e.g., GDPR, CCPA).

Secure Production Environment

The stamp printing facility must meet high security standards:

- Controlled Access: Restrict entry to authorized personnel only, using biometric or keycard systems.

- Secure Storage: Store raw materials, printed sheets, and finished products in tamper-evident, locked vaults.

- Monitoring Systems: Install 24/7 surveillance with video retention policies compliant with legal standards.

- Background Checks: Conduct thorough vetting of all employees involved in stamp production.

Logistics and Distribution

Transportation and delivery of stamps must ensure security and traceability:

- Secure Transportation: Use insured, GPS-tracked vehicles with armed or monitored escort when required.

- Chain of Custody: Document every transfer point with signed handover records to maintain accountability.

- Tamper-Evident Packaging: Employ sealed, numbered containers that show evidence of unauthorized access.

- Destination Verification: Deliver only to pre-authorized postal or government facilities with verified receiving protocols.

Inventory and Traceability

Robust inventory management ensures accountability:

- Serial Number Tracking: Assign unique serial numbers to stamp sheets or rolls and log them in a secure database.

- Real-Time Inventory Systems: Use digital tracking systems to monitor stock levels and detect discrepancies immediately.

- Reconciliation Procedures: Conduct regular physical audits to verify system records against actual inventory.

Environmental and Workplace Compliance

Maintain adherence to health, safety, and environmental regulations:

- Hazardous Materials Handling: Safely manage inks, solvents, and other chemicals per OSHA, REACH, or local regulations.

- Waste Disposal: Dispose of waste materials (especially security inks and substrates) through approved, secure channels.

- Workplace Safety: Follow standard safety protocols, including fire prevention, emergency exits, and employee training.

Incident Reporting and Response

Establish procedures for handling breaches:

- Security Breach Protocol: Define immediate actions for theft, unauthorized access, or suspected counterfeiting.

- Regulatory Notification: Report incidents to relevant authorities within required timeframes.

- Crisis Management Team: Designate personnel responsible for managing and mitigating compliance or security incidents.

Continuous Improvement and Training

Ensure ongoing compliance through education and process refinement:

- Staff Training: Regularly train employees on compliance requirements, security protocols, and ethical standards.

- Policy Updates: Review and update internal procedures to reflect changes in regulations or technology.

- Third-Party Audits: Engage independent auditors to assess compliance and recommend improvements.

Adherence to this guide helps stamp printers maintain trust, ensure legal operation, and support the integrity of national postal and fiscal systems.

Conclusion for Sourcing a Stamp Printer

After a thorough evaluation of available options, suppliers, technical specifications, cost implications, and long-term operational needs, sourcing a stamp printer has proven to be a strategic decision to enhance efficiency, accuracy, and consistency in product labeling, document processing, or packaging operations. The selected stamp printer meets key criteria including print quality, durability, compatibility with existing systems, ease of maintenance, and cost-effectiveness.

By partnering with a reliable supplier offering strong technical support and warranty coverage, the organization ensures minimal downtime and sustainable performance. Additionally, considerations for scalability and future needs position the company to adapt quickly to increased demand or evolving requirements.

In conclusion, the acquisition of the recommended stamp printer aligns with operational goals, improves workflow automation, and contributes to overall productivity. It is a justified investment that delivers both immediate benefits and long-term value.