The global stainless steel roofing market is experiencing steady growth, driven by rising demand for durable, corrosion-resistant, and sustainable building materials. According to Grand View Research, the global stainless steel market size was valued at USD 132.7 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030, with the construction sector accounting for a significant share of this demand. Similarly, Mordor Intelligence projects the stainless steel market to grow at a CAGR of over 4.8% during the forecast period 2024–2029, citing increased infrastructure development and industrial construction in emerging economies. As architects and builders prioritize longevity and environmental performance, stainless steel roofing has emerged as a preferred solution—particularly in harsh climates and high-exposure environments. This growing adoption has propelled innovation and competition among manufacturers, giving rise to a select group of industry leaders shaping the future of metal roofing. Below, we highlight the top nine stainless steel roofing manufacturers leveraging material science, sustainability, and engineering excellence to meet evolving market demands.

Top 9 Stainless Steel Roofing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Berridge Manufacturing Co.

Domain Est. 1996

Website: berridge.com

Key Highlights: For over 50 years Berridge has worked to set the standard by designing, developing and manufacturing superior architectural metal products and technology….

#2 McElroy Metal

Domain Est. 1996

Website: mcelroymetal.com

Key Highlights: McElroy Metal is the leading manufacturer of metal roofing, metal siding, and substructural components with locations across the United States. Learn more….

#3 Metal Roofing Manufacturer

Domain Est. 1997

Website: mbci.com

Key Highlights: MBCI manufactures the highest quality metal roofing & wall panels to meet your project’s aesthetic & structural standards. Request a quote today!…

#4 DECRA Metal Roofing: #1 Stone

Domain Est. 1999

Website: decra.com

Key Highlights: DECRA Metal Roofing is the #1 stone-coated steel manufacturer for residential and commercial roofing backed by a lifetime warranty to guarantee protection….

#5 Tri County Metals, Florida

Domain Est. 2003

Website: tricountymetals.com

Key Highlights: As a privately owned metal roofing manufacturer, we produce seven different metal roof panel profiles, complete custom trim solutions, specialty trim, and a ……

#6

Website: metalsales.us.com

Key Highlights: Metal Sales is the nation’s largest manufacturer of metal roofing, wall, and building systems. We are the most awarded and highly recognized provider of metal ……

#7 Sheffield Metals

Domain Est. 1998

Website: sheffieldmetals.com

Key Highlights: Sheffield Metals is a leader in the distribution of coated and bare metal products, as well as engineered standing seam metal roof (SSMR) & wall systems….

#8 Metal roofs made of HFX stainless for new builds and renovations

Domain Est. 1999

Website: roofinox.com

Key Highlights: Standing seam, shingles, roof panels and accessories for metal roofs made of HFX stainless, in the only complete stainless steel system with ROOFINOX roof ……

#9 Stainless Steel® Standing Seam Metal Roofing

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: A standing seam metal roof provides energy reduction benefits without sacrificing style. The clips and screws fasten the panels tightly to prevent leaks….

Expert Sourcing Insights for Stainless Steel Roofing

H2: 2026 Market Trends for Stainless Steel Roofing

The global stainless steel roofing market is poised for significant transformation by 2026, driven by technological advancements, increasing demand for sustainable building materials, and evolving construction practices. Below are the key trends shaping the market in this pivotal year:

1. Rising Demand for Sustainable and Energy-Efficient Materials

As environmental regulations tighten and green building certifications (such as LEED and BREEAM) gain prominence, stainless steel roofing is increasingly favored for its recyclability, longevity, and low environmental impact. Its high solar reflectance and thermal emittance contribute to energy savings in buildings, aligning with global decarbonization goals. By 2026, sustainable construction mandates in North America, Europe, and parts of Asia-Pacific are expected to boost stainless steel adoption over traditional roofing materials.

2. Growth in Commercial and Industrial Construction

Stainless steel roofing is gaining traction in commercial, industrial, and institutional infrastructure due to its durability, low maintenance, and resistance to corrosion and extreme weather. The expansion of data centers, manufacturing facilities, and cold storage units—especially in emerging economies—will drive demand. These sectors prioritize long-term performance and operational efficiency, making stainless steel a cost-effective solution despite higher initial costs.

3. Technological Innovations in Coatings and Alloys

By 2026, advancements in alloy compositions (e.g., lean duplex and high-chromium grades) and protective coatings will enhance the performance of stainless steel roofing in aggressive environments, including coastal and high-pollution areas. Innovations such as antimicrobial surface treatments and photovoltaic-integrated panels are expected to create hybrid solutions, combining energy generation with superior roofing functionality.

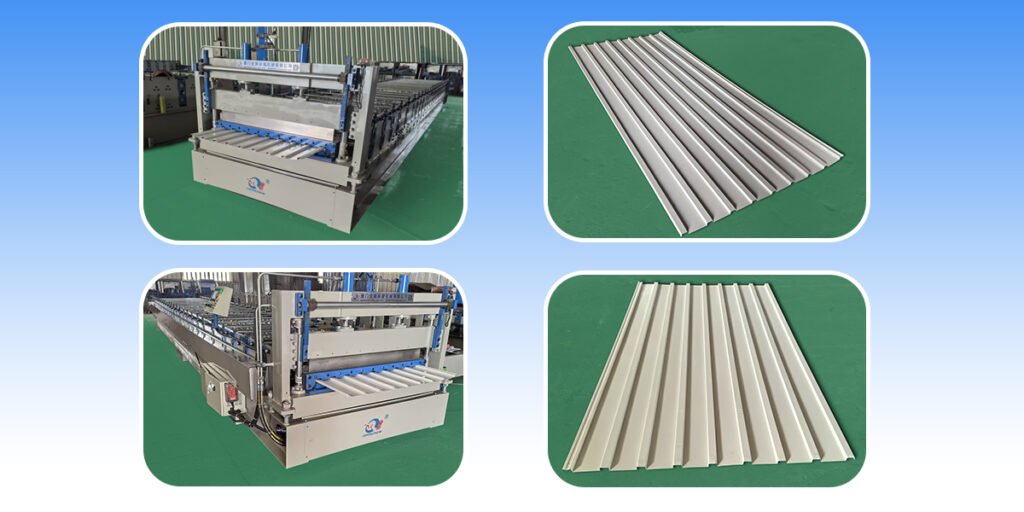

4. Regional Market Shifts and Urbanization

Asia-Pacific, particularly China, India, and Southeast Asia, will be the fastest-growing market due to rapid urbanization, infrastructure development, and government investments in smart cities. Meanwhile, North America and Western Europe will focus on retrofitting aging infrastructure with durable, low-maintenance materials, further supporting stainless steel roofing adoption.

5. Price Volatility and Supply Chain Resilience

Fluctuations in raw material prices—especially nickel and chromium—may impact profitability. However, by 2026, manufacturers are expected to adopt more resilient supply chains, including localized production and recycled content utilization, to mitigate risks and meet growing demand sustainably.

6. Integration with Building-Integrated Photovoltaics (BIPV)

A notable trend is the integration of stainless steel roofing with solar technology. Lightweight, corrosion-resistant stainless substrates are being used as support structures for BIPV systems. This synergy supports net-zero energy building designs and is expected to gain regulatory support in several key markets.

In conclusion, the 2026 stainless steel roofing market will be defined by sustainability, innovation, and regional diversification. Stakeholders who invest in advanced materials, eco-friendly manufacturing, and integrated building solutions will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Stainless Steel Roofing (Quality, IP)

Sourcing stainless steel roofing requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance failures, legal issues, and significant financial losses.

Poor Material Quality and Misrepresentation

One of the most frequent pitfalls is receiving substandard stainless steel that fails to meet specified grades or performance requirements. Suppliers may misrepresent lower-grade alloys (e.g., 201 or 304L as 316) to cut costs, leading to premature corrosion, staining, or structural failure—especially in harsh environments like coastal or industrial areas. Buyers must verify mill test certificates (MTCs), conduct independent material testing, and ensure compliance with international standards (e.g., ASTM, ISO) to avoid compromised durability and lifespan.

Lack of IP Protection and Design Infringement

Stainless steel roofing systems often incorporate patented profiles, fastening methods, or installation techniques. Sourcing from unauthorized manufacturers or copycat suppliers risks infringing on intellectual property rights, potentially resulting in legal action, project delays, or forced removal of installed materials. Buyers should verify that suppliers hold proper licensing for proprietary designs and avoid “generic” alternatives that mimic patented systems without authorization.

Inadequate Surface Finish and Aesthetic Consistency

Stainless steel roofing relies heavily on surface finish for both appearance and corrosion resistance. Pitfalls include inconsistent finishes (e.g., variable grain in brushed finishes) or damage during fabrication and transport. Poor surface quality can accelerate pitting corrosion and detract from architectural intent. Ensure suppliers adhere to specified finish standards (e.g., ASTM A480) and provide sample panels for approval before full production.

Non-Compliance with Regional Standards and Certifications

Different regions have specific requirements for fire resistance, wind uplift, and environmental performance. Sourcing stainless steel roofing without verifying compliance with local building codes (e.g., CE marking in Europe, ICC-ES in the U.S.) can lead to rejected installations or liability issues. Always confirm that products carry necessary third-party certifications and are suitable for the project’s geographic and climatic conditions.

Supply Chain Transparency and Traceability Gaps

A lack of transparency in the supply chain increases the risk of counterfeit materials or unethical sourcing practices. Without full traceability—from raw material origin to final product—buyers cannot ensure responsible sourcing or validate claims about recycled content and environmental impact. Demand full documentation and consider suppliers who offer blockchain or digital traceability solutions.

Overlooking Long-Term Maintenance and Lifecycle Costs

While stainless steel is low-maintenance, improper sourcing can lead to higher lifecycle costs. Inferior edge treatments, poor welding practices, or incompatible accessories (e.g., fasteners) may necessitate premature repairs. Evaluate the total cost of ownership, including installation complexity and expected service life, rather than focusing solely on initial price.

Logistics & Compliance Guide for Stainless Steel Roofing

Material Handling and Transportation

Stainless steel roofing materials require careful handling to prevent damage during transit and on-site movement. Coils, sheets, and panels should be transported on flatbed trucks secured with straps and protective padding to avoid scratching or deformation. Avoid dragging materials; use lifting equipment with soft slings or vacuum lifters. Store materials elevated off the ground on clean, dry wooden bearers, and cover them with waterproof, breathable tarps to protect against moisture and debris.

Storage and Site Management

Upon delivery, store stainless steel roofing components in a dry, well-ventilated area away from corrosive substances such as chloride-based cleaners, carbon steel debris, or galvanized materials to prevent galvanic corrosion. Keep packaging intact until installation. Segregate stainless steel from other metals to avoid cross-contamination. On-site, limit foot traffic on stored materials and use protective mats during installation to prevent surface abrasions.

Installation Best Practices

Use tools dedicated to stainless steel to avoid iron contamination, which can lead to rust. Always wear clean gloves when handling materials. Follow manufacturer guidelines for fastener selection—typically non-ferrous or stainless steel fasteners compatible with the roofing grade. Ensure proper expansion gaps are maintained to accommodate thermal movement. Avoid mixing stainless steel with dissimilar metals in direct contact; use insulating washers or coatings if necessary.

Regulatory Compliance

Ensure all stainless steel roofing products comply with relevant international and local standards such as ASTM A240 (for material quality), ASTM A480 (general requirements), and EN 10088 (European standards). In the U.S., compliance with International Building Code (IBC) and local fire, wind, and snow load requirements is essential. Verify that the chosen grade (e.g., 304, 316) meets environmental exposure standards, especially in coastal or industrial areas where chloride resistance is critical.

Environmental and Safety Regulations

Adhere to OSHA safety protocols during installation, including fall protection, proper lifting techniques, and use of personal protective equipment (PPE). Manage waste responsibly—recycle offcuts and packaging per local regulations. Stainless steel is 100% recyclable, supporting LEED and other green building certifications. Ensure material sourcing aligns with environmental management systems (e.g., ISO 14001) and conflict mineral policies where applicable.

Documentation and Certification

Maintain records of material test reports (MTRs), mill certificates, and compliance documentation for traceability. Provide as-built drawings and operation/maintenance manuals to the client. Confirm that installers are certified by the manufacturer or a recognized trade body, ensuring warranty validity and long-term performance.

Warranty and Maintenance Compliance

Follow the manufacturer’s maintenance guidelines to preserve finish and corrosion resistance. Regularly inspect for debris accumulation, drainage blockages, and signs of abrasion or staining. Clean with mild detergent and water; avoid chlorinated or abrasive cleaners. Document inspections and maintenance to uphold warranty conditions and ensure compliance with long-term performance standards.

In conclusion, sourcing stainless steel roofing requires careful consideration of quality, durability, cost, and supplier reliability. Stainless steel offers exceptional resistance to corrosion, extreme weather conditions, and physical damage, making it an ideal long-term investment for both residential and commercial buildings. When selecting a source, it is essential to partner with reputable suppliers who provide certified materials, consistent product standards (such as ASTM or ISO certifications), and transparent documentation. Evaluating factors such as grade selection (e.g., 304 or 316 stainless steel), finish, gauge thickness, and local availability can significantly impact performance and cost-efficiency. Additionally, considering logistical aspects like lead times, shipping costs, and after-sales support ensures a smooth procurement process. Ultimately, sourcing high-quality stainless steel roofing not only enhances structural integrity and aesthetics but also reduces maintenance and replacement costs over time, delivering long-term value and sustainability.