The global stainless steel gutters market is gaining momentum as durability, corrosion resistance, and low maintenance drive demand across residential and commercial construction sectors. According to a 2023 report by Mordor Intelligence, the global rainwater management systems market—which includes stainless steel gutters—is projected to grow at a CAGR of over 6.2% from 2023 to 2028, fueled by increasing infrastructure development and rising preference for long-lasting building materials. Stainless steel, in particular, is emerging as a preferred choice over traditional aluminum and PVC due to its superior lifespan and performance in extreme weather conditions. With expanding urbanization and stricter building codes in regions like North America and Europe, manufacturers are investing in advanced fabrication technologies to meet growing demand. As competition intensifies, a select group of producers is leading the way in innovation, quality, and market reach—shaping the future of rainwater management solutions. Here’s a look at the top 10 stainless steel gutters manufacturers shaping this evolving industry landscape.

Top 10 Stainless Steel Gutters Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Gutterglove

Domain Est. 2003

Website: gutterglove.com

Key Highlights: Gutterglove is an innovator in the home improvement space focused on people, products, programs, and technology….

#2 Gutter Systems, Gutter Guards, & Coils

Domain Est. 2019

Website: spectraguttersystems.com

Key Highlights: Largest manufacturer & distributor of gutter systems, gutter guards, & coils within the United States, offering a complete line of rain ware products….

#3

Website: metalsales.us.com

Key Highlights: Metal Sales is the nation’s largest manufacturer of metal roofing, wall, and building systems. We are the most awarded and highly recognized provider of metal ……

#4 Stainless Steel

Domain Est. 1997

Website: classicgutters.com

Key Highlights: Stainless Steel ; Hidden Half Round INTERNAL Gutter Brackets with Rods · 1.50 · 9.00 Price range: $1.50 through $9.00 ; K-Style Hidden Gutter Brackets · 1.50 · 3.50 ……

#5 Gutter Supply

Domain Est. 1998

Website: service-partners.com

Key Highlights: Service Partners is a trusted supplier of seamless rain gutters. We carry aluminum, steel, copper and galvalume, plus gutter equipment….

#6 Residential Downspouts, Residential Gutters …

Domain Est. 2001

Website: vikingmetals.com

Key Highlights: Viking Metal Products is the perfect source for residential metal products. We make residential K-Style and residential half-round gutters in any length….

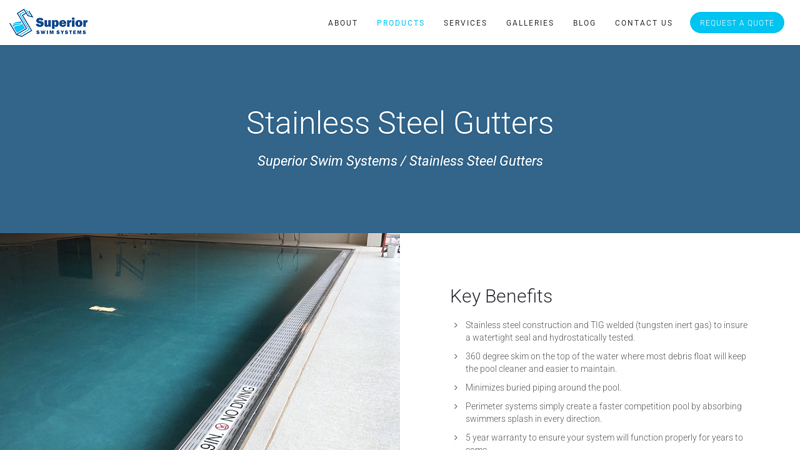

#7 Stainless Steel Gutters

Domain Est. 2003

Website: superiorswimsystems.com

Key Highlights: All gutter systems are 12 gauge type 304L or 316L stainless steel with a #3 polish. Our stainless steel gutters are custom fabricated so any special design ……

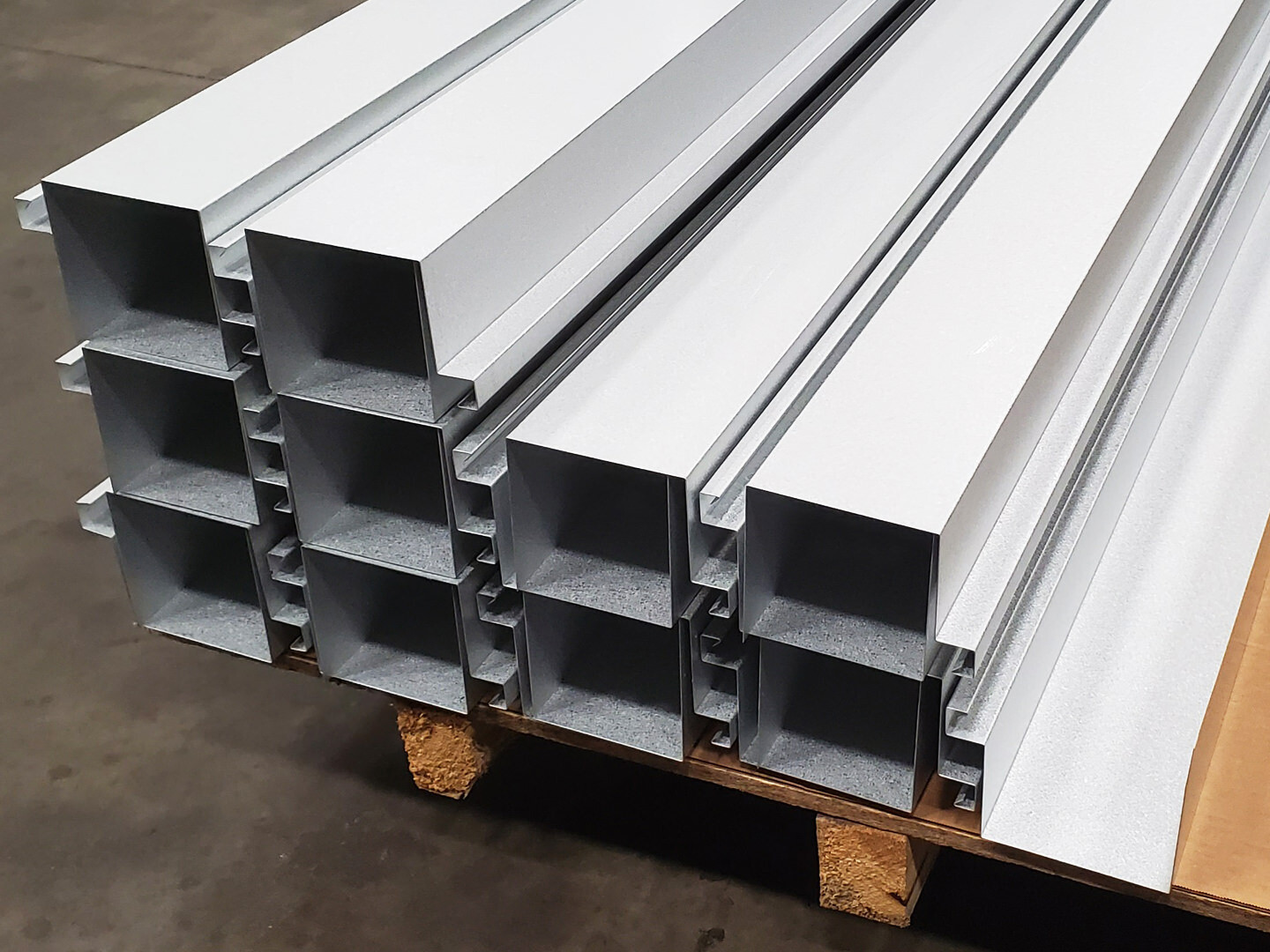

#8 Rolled material, gutters and roofing products in Stainless Steel

Domain Est. 2014

Website: mazzonettometals.com

Key Highlights: MAZZONETTO deals with trading in and processing metals for guttering, roofing and facade cladding in Stainless Steel AISI 304 – 316….

#9 Pre

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: A pre-hung gutter is a gutter that’s installed before the installation of the metal panels. Its purpose is to divert water off the roof and away from the walls ……

#10 Gutter Guards America

Domain Est. 2019

Website: gutterguardsamerica.com

Key Highlights: These gutter guards are designed with advanced technologies and materials that ensure optimal water flow while preventing clogs caused by leaves, debris, and ……

Expert Sourcing Insights for Stainless Steel Gutters

2026 Market Trends for Stainless Steel Gutters

Growing Demand Driven by Durability and Sustainability

The stainless steel gutter market is projected to experience significant growth by 2026, primarily fueled by increasing consumer preference for durable, long-lasting, and eco-friendly building materials. Stainless steel is inherently resistant to rust, corrosion, and extreme weather conditions, making it an ideal choice for residential and commercial gutter systems. As climate change leads to more frequent and severe weather events—such as heavy rainfall and storms—homeowners and builders are turning to stainless steel for its superior performance and reliability. Additionally, the recyclability of stainless steel aligns with global sustainability goals, appealing to environmentally conscious consumers and supporting green building certifications like LEED.

Expansion in Residential and High-End Construction Sectors

The residential construction sector, particularly luxury and custom home building, is a key driver of stainless steel gutter adoption. By 2026, growing urbanization and rising disposable incomes in regions such as North America, Western Europe, and parts of Asia-Pacific are expected to boost demand for premium building materials. Stainless steel gutters are increasingly viewed as a value-added feature due to their sleek aesthetics, low maintenance, and lifespan exceeding 50 years. Architects and designers are specifying stainless steel in modern and minimalist home designs, further accelerating market penetration.

Technological Advancements and Design Innovation

Innovation in manufacturing and design is shaping the future of stainless steel gutters. By 2026, manufacturers are expected to leverage advanced fabrication techniques—such as laser cutting and robotic welding—to produce seamless, custom-fit gutter systems with improved water flow efficiency. Integrated smart gutter solutions, including sensors for clog detection and water monitoring, may begin to emerge in high-end markets, enhancing functionality and user experience. These technological advancements not only improve performance but also reduce installation time and labor costs.

Competitive Landscape and Regional Growth

North America is anticipated to dominate the stainless steel gutter market in 2026, supported by a robust construction industry and stringent building codes emphasizing material durability. Europe follows closely, driven by strict environmental regulations and a strong renovation market. Meanwhile, the Asia-Pacific region is expected to witness the highest growth rate due to rapid urban development and increasing awareness of premium building products. Key market players are focusing on expanding production capacities, offering customization options, and investing in marketing to capture a larger share of the evolving market.

Challenges and Price Sensitivity

Despite the positive outlook, the high initial cost of stainless steel gutters compared to alternatives like aluminum or vinyl remains a barrier to mass adoption. In price-sensitive markets, this could limit growth, particularly in emerging economies. However, as production scales and supply chains become more efficient, prices are expected to stabilize, improving accessibility. Education campaigns highlighting the long-term cost savings and reduced maintenance will be crucial in shifting consumer perception.

In conclusion, the 2026 market for stainless steel gutters is poised for expansion, driven by durability, sustainability, and design innovation. While cost remains a challenge, increasing demand in high-end construction and technological improvements will likely solidify stainless steel’s position as a premium choice in the global gutter industry.

Common Pitfalls Sourcing Stainless Steel Gutters (Quality, IP)

Sourcing stainless steel gutters offers long-term durability and aesthetic appeal, but several pitfalls can compromise performance and value if not carefully addressed. Below are key quality and intellectual property (IP)-related challenges to watch for.

Poor Material Quality and Grade Misrepresentation

One of the most frequent issues is the substitution of lower-grade stainless steel. Suppliers may claim to provide high-quality grades like 304 or 316 but deliver thinner gauges or inferior alloys (e.g., 201 or 430), which are more prone to corrosion and deformation. This misrepresentation reduces lifespan and performance, especially in coastal or high-moisture environments.

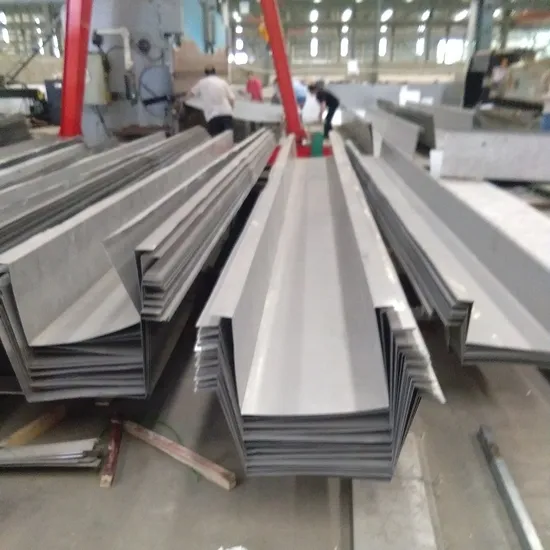

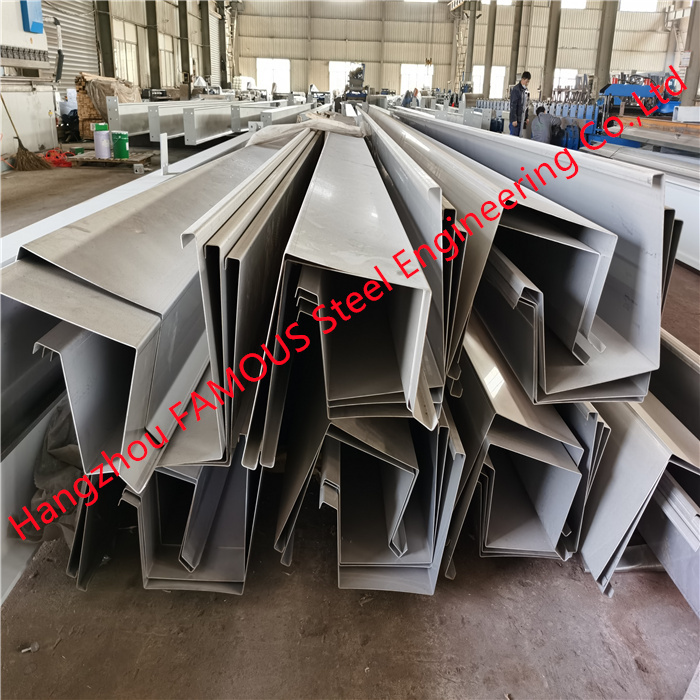

Inadequate Thickness (Gauge) and Structural Integrity

Stainless steel gutters must meet minimum thickness standards (typically 0.5mm to 0.7mm) to handle water load and resist denting. Sourcing from unverified suppliers may result in under-gauged materials that sag, collapse under debris, or fail during heavy rainfall. Always verify material certifications and conduct physical inspections.

Lack of Proper Surface Finish and Corrosion Resistance

A poor surface finish not only affects appearance but can accelerate corrosion. Look for consistent passivation and proper finishing (e.g., brushed or satin). Inferior finishing processes leave surface contaminants that compromise the protective chromium oxide layer, leading to premature rusting—especially in polluted or saline environments.

Non-Compliance with IP and Design Infringement

Many premium gutter systems are protected by design patents, trademarks, or technical IP. Sourcing from manufacturers that replicate patented profiles, hangers, or joint systems without authorization exposes buyers to legal risks and potential product recalls. Always confirm that the supplier owns or is licensed to produce the design.

Inconsistent Manufacturing and Poor Welding

Low-cost manufacturers may use inconsistent roll-forming or substandard welding techniques, leading to weak seams, misaligned joints, and leaks. Poor craftsmanship undermines the inherent strength of stainless steel and increases installation challenges and long-term maintenance costs.

Inaccurate IP Documentation and Certification

Some suppliers provide forged or incomplete material test reports (MTRs), mill certificates, or IP ownership documentation. Relying on falsified paperwork can result in non-compliant installations, project delays, and liability issues. Always request verifiable, third-party-certified documentation.

Supply Chain Transparency and Traceability Gaps

Without traceable supply chains, it’s difficult to confirm the origin of materials or adherence to ethical and environmental standards. Lack of transparency increases the risk of counterfeit products and complicates quality assurance, particularly in large-scale or regulated construction projects.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: verify material grades and thickness, audit supplier credentials, confirm IP rights, and insist on certified documentation. Partnering with reputable, transparent suppliers ensures you receive durable, compliant, and legally sound stainless steel gutter systems.

Logistics & Compliance Guide for Stainless Steel Gutters

Product Overview and Specifications

Stainless steel gutters are durable, corrosion-resistant components used in rainwater management systems for residential and commercial buildings. Common grades include 304 and 316 stainless steel, with 316 offering enhanced resistance to chlorides and coastal environments. Typical gauges range from 26 to 24, with standard lengths of 10 to 20 feet. Understanding these specifications is essential for proper handling, storage, and compliance throughout the supply chain.

International Shipping and Export Compliance

When exporting stainless steel gutters, ensure compliance with international trade regulations. Key considerations include:

– Harmonized System (HS) Code: Use HS Code 7308.90 (Other prefabricated structural units of iron or steel) for accurate classification.

– Export Documentation: Prepare commercial invoices, packing lists, certificates of origin, and bills of lading.

– Customs Clearance: Comply with destination country requirements. Some regions may require conformity assessments or product certifications.

– Restricted Destinations: Be aware of trade sanctions or embargoes affecting certain countries.

Domestic Transportation and Handling

Proper logistics practices ensure product integrity during domestic transit:

– Packing: Secure gutters in bundled form with protective end caps and moisture-resistant wrapping to prevent scratches and corrosion.

– Loading: Use cradles or racks to avoid deformation. Avoid stacking heavy materials on top.

– Transport Mode: Choose flatbed trucks for long lengths; ensure secure tie-downs to prevent shifting.

– Handling: Use lifting straps or slings—never chains or hooks that can damage surfaces.

Storage and Inventory Management

Stainless steel gutters must be stored under controlled conditions:

– Environment: Store indoors in a dry, well-ventilated area to prevent moisture accumulation and surface staining.

– Elevation: Keep materials off the ground using pallets or racks to avoid contact with contaminants.

– Segregation: Separate from carbon steel or other metals to prevent galvanic corrosion.

– Inventory Rotation: Implement a first-in, first-out (FIFO) system to minimize long-term storage risks.

Regulatory and Environmental Compliance

Adherence to environmental and safety standards is mandatory:

– REACH and RoHS: Confirm stainless steel composition complies with EU regulations on restricted substances (though typically not an issue for pure stainless steel).

– OSHA Guidelines: Follow safety protocols for handling heavy materials, including proper lifting techniques and personal protective equipment (PPE).

– Recycling and Disposal: Stainless steel is fully recyclable. Maintain records for end-of-life recycling to support sustainability claims.

Certification and Quality Assurance

Ensure all products meet industry standards:

– ASTM Standards: Verify compliance with ASTM A240 (Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip).

– ISO Certification: Suppliers should hold ISO 9001 certification for quality management.

– Mill Test Reports (MTRs): Request MTRs for each batch to confirm material grade, chemical composition, and mechanical properties.

Installation and End-User Compliance

Support downstream compliance by providing clear guidance:

– Installation Standards: Recommend adherence to local building codes and practices (e.g., International Building Code – IBC).

– Fastener Compatibility: Specify the use of stainless steel fasteners to prevent galvanic corrosion.

– Slope and Pitch Requirements: Provide technical data to ensure proper water flow and system performance.

Documentation and Traceability

Maintain complete records throughout the supply chain:

– Batch Traceability: Track material lots from supplier to end customer.

– Compliance Documentation: Archive test reports, certifications, and shipping records for audits.

– Labeling: Clearly label packages with product type, grade, length, batch number, and handling instructions.

Risk Management and Contingency Planning

Prepare for potential disruptions:

– Supply Chain Diversification: Source from multiple certified suppliers to mitigate risk.

– Insurance: Carry cargo insurance covering damage, theft, and delays.

– Incident Response: Establish procedures for addressing non-compliant shipments or customer claims.

By following this logistics and compliance guide, stakeholders can ensure the safe, efficient, and regulation-compliant handling of stainless steel gutters from manufacturing through to installation.

In conclusion, sourcing stainless steel gutters offers a durable, long-term solution for efficient water management in both residential and commercial buildings. While the initial investment may be higher compared to other materials, the exceptional resistance to corrosion, minimal maintenance requirements, and extended lifespan make stainless steel a cost-effective choice over time. When sourcing, it is essential to consider factors such as material grade (e.g., 304 or 316 stainless steel), supplier reliability, fabrication quality, and adherence to industry standards. Partnering with reputable suppliers who offer warranties and technical support can ensure product performance and longevity. Overall, stainless steel gutters represent a smart investment in property protection, sustainability, and aesthetic appeal, especially in harsh or coastal environments where durability is paramount.