The global stainless steel conveyor belt market is experiencing robust growth, driven by rising demand for hygienic, durable, and corrosion-resistant material handling solutions across industries such as food processing, pharmaceuticals, automotive, and logistics. According to a 2023 report by Mordor Intelligence, the conveyor belt market is projected to grow at a CAGR of over 5.2% from 2023 to 2028, with stainless steel variants gaining preference in high-sanitation and high-temperature applications. Similarly, Grand View Research valued the global conveyor systems market at USD 10.5 billion in 2022, forecasting a CAGR of 5.8% through 2030, underpinned by automation trends and expanding manufacturing footprints in Asia-Pacific and North America. As industries prioritize efficiency, compliance with food safety standards (such as FDA and EHEDG), and operational longevity, the selection of reliable stainless steel conveyor belt manufacturers has become critical. The following list highlights the top 10 manufacturers recognized for innovation, global reach, product durability, and industry-specific customization capabilities—key factors shaping the next generation of material handling infrastructure.

Top 10 Stainless Steel Conveyor Belt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ashworth Conveyor Belts

Domain Est. 1996

Website: ashworth.com

Key Highlights: The official site of Ashworth, a world leader in stainless steel, plastic, wire mesh, and spiral conveyor belts. Contact us for industrial applications, ……

#2 Esbelt

Domain Est. 1996

Website: esbelt.com

Key Highlights: We are industrial conveyor belt manufacturer of lightweight thermoplastic conveyor belts for a wide range of applications, in food, agro, or industrial ……

#3 QC Conveyors

Domain Est. 2013

Website: qcconveyors.com

Key Highlights: QC Conveyors is a trusted conveyor manufacturer providing custom systems for industrial and automation applications. Fast lead times and expert support….

#4 Wire Belt Company

Domain Est. 1996

Website: wirebelt.com

Key Highlights: At Wire Belt, we offer many styles and specifications of mesh conveyor belts to suit your needs. Call us today on (603)644-2500 to find out more….

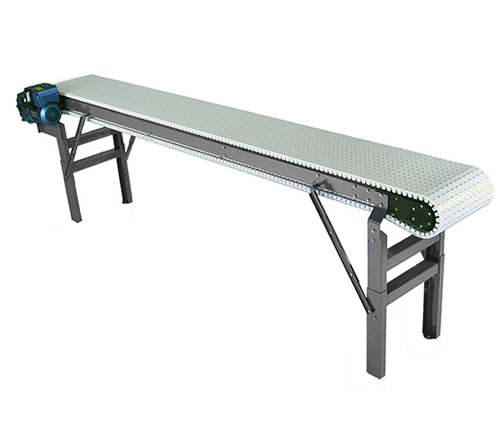

#5 Belt Conveyor Systems

Domain Est. 1998

Website: ultimationinc.com

Key Highlights: Ultimation is one of the top conveyor belt manufacturers. Our simple and versatile belt conveyor systems use two or more pulleys to drive looped belts….

#6 MAFDEL Belts

Domain Est. 2001

Website: mafdel-belts.com

Key Highlights: Mafdel: Manufacturer of thermoweldable belts and conveyor belts for 40 years · Quick and easy on-site welding eliminates the need to dismantle conveyors….

#7 Span Tech Conveyors

Domain Est. 2017

Website: spantechconveyors.com

Key Highlights: Explore Span Tech’s custom conveyors for packaging, food, pharma, and more—built for efficiency, flexibility, and increased productivity….

#8 Conveyor belts

Domain Est. 1995

Website: ipco.com

Key Highlights: IPCO | Elevate your material handling with IPCO’s stainless steel conveyor belts. Strong, hygienic, and HS options await your exploration!…

#9 Stainless Steel Belts for Food Processing and Handling

Domain Est. 1996

Website: belttechnologies.com

Key Highlights: Our highly trained and experienced engineers can design, develop and manufacture a complete, stainless steel sanitary food processing conveyor belt system to ……

#10 Shuttleworth

Domain Est. 1996

Website: shuttleworth.com

Key Highlights: Shuttleworth designs and manufactures conveyor systems & material handling systems for a variety of industries & applications….

Expert Sourcing Insights for Stainless Steel Conveyor Belt

H2: Market Trends for Stainless Steel Conveyor Belts in 2026

The global stainless steel conveyor belt market is poised for significant transformation and growth by 2026, driven by rising industrial automation, stringent hygiene regulations, and expanding applications across key sectors. This analysis explores the major market trends shaping the industry in 2026.

-

Increased Demand from Food and Beverage Industry

Stringent hygiene and sanitation standards across food processing facilities are accelerating the adoption of stainless steel conveyor belts. With growing consumer awareness about food safety and regulatory bodies like the FDA and EU enforcing stricter compliance, manufacturers are replacing polymer or carbon steel belts with corrosion-resistant, easy-to-clean stainless steel variants. The trend is particularly strong in meat processing, dairy, and ready-to-eat meals production, where contamination risks are high. -

Growth in Pharmaceutical and Medical Device Manufacturing

The pharmaceutical and healthcare sectors are increasingly utilizing stainless steel conveyor belts due to their non-reactive properties, cleanroom compatibility, and resistance to sterilization processes such as autoclaving and chemical washdowns. In 2026, the push for automated, contamination-free production lines will further boost demand, especially in facilities producing injectables, tablets, and surgical instruments. -

Technological Advancements in Belt Design and Materials

Innovation in metallurgy and belt engineering is enhancing performance and durability. Trends include the development of ultra-thin, high-tensile strength belts, modular designs for easy maintenance, and surface treatments that improve slip resistance and reduce friction. Additionally, the integration of smart sensors and IoT-enabled monitoring systems into conveyor systems allows real-time tracking of belt wear, tension, and hygiene—contributing to predictive maintenance and operational efficiency. -

Expansion in Emerging Economies

Industrialization in Asia-Pacific (particularly China, India, and Southeast Asia), Latin America, and parts of Africa is creating new market opportunities. Rising investments in food processing, automotive manufacturing, and chemical industries are increasing demand for durable and hygienic conveying solutions. Local production of stainless steel components and government incentives for manufacturing modernization are also supporting market growth in these regions. -

Sustainability and Energy Efficiency Focus

Environmental regulations and corporate sustainability goals are influencing material selection and system design. Stainless steel conveyor belts, with their long service life, recyclability, and reduced need for replacements, align well with circular economy principles. In 2026, manufacturers are prioritizing energy-efficient conveyor systems that minimize power consumption, and stainless steel’s low friction variants contribute to this goal. -

Shift Toward Customization and Modular Systems

End-users are increasingly seeking customized conveyor solutions tailored to specific operational needs—such as high-temperature resistance in glass or metal heat treatment, or corrosion resistance in chemical plants. Modular stainless steel belts allow for flexible configurations, easy cleaning, and quick replacement of damaged sections, reducing downtime and maintenance costs. -

Supply Chain Resilience and Regional Manufacturing

Post-pandemic, companies are reevaluating global supply chains, leading to a shift toward localized production. In 2026, this trend supports regional manufacturing of stainless steel conveyor belts, reducing lead times and logistics costs. Strategic partnerships between belt manufacturers and industrial equipment integrators are also on the rise to offer turnkey automation solutions.

Conclusion

By 2026, the stainless steel conveyor belt market will be shaped by a convergence of regulatory demands, technological innovation, and industrial growth. Sectors emphasizing hygiene, durability, and automation will lead adoption, while sustainability and customization will differentiate competitive offerings. Companies investing in R&D, smart manufacturing, and regional supply chains are expected to gain a strategic advantage in this evolving landscape.

Common Pitfalls When Sourcing Stainless Steel Conveyor Belts (Quality & Intellectual Property)

Sourcing stainless steel conveyor belts requires careful evaluation to avoid costly mistakes related to both product quality and intellectual property (IP) risks. Overlooking these areas can lead to production downtime, safety hazards, legal disputes, and reputational damage. Below are key pitfalls to watch for:

Quality-Related Pitfalls

1. Substandard Material Composition

One of the most frequent issues is receiving belts made from inferior-grade stainless steel (e.g., non-304 or 316 when specified). Some suppliers may substitute cheaper alloys or use recycled content that doesn’t meet required corrosion resistance or strength standards. This can lead to premature rusting, pitting, or structural failure—especially in harsh or sanitary environments.

2. Inadequate Surface Finish and Weld Quality

Poor surface finish (e.g., rough welds, inconsistent polishing) can harbor bacteria, making the belt unsuitable for food, pharmaceutical, or cleanroom applications. Poor welding techniques can create weak points, increasing the risk of belt breakage under load.

3. Inconsistent Tolerances and Dimensional Accuracy

Belts with inconsistent pitch, width, or link alignment may not fit existing conveyor systems properly, causing misalignment, excessive wear, and increased maintenance. This often stems from poor manufacturing controls or outdated tooling.

4. Lack of Traceability and Certification

Reputable suppliers provide material test reports (MTRs) and mill certificates verifying the stainless steel grade and compliance with standards (e.g., ASTM, ISO). Without these, buyers have no proof of quality, increasing the risk of non-compliance in regulated industries.

5. Overlooking Environmental and Load Requirements

Selecting a belt not rated for the operating environment (e.g., high temperature, acidic exposure, heavy loads) leads to rapid degradation. Buyers must ensure the belt’s specifications match application demands, including tensile strength, temperature resistance, and chemical compatibility.

Intellectual Property (IP)-Related Pitfalls

1. Unauthorized Replication of Patented Designs

Many high-performance conveyor belt patterns (e.g., modular plastic or precision metal mesh designs) are protected by patents. Sourcing from manufacturers who copy patented designs—even unknowingly—can expose the buyer to legal liability, including injunctions or damages if the IP holder takes action.

2. Use of Counterfeit or Grey-Market Products

Some suppliers offer “compatible” or “OEM-equivalent” belts that infringe on registered designs or trademarks. These products may appear cost-effective but can violate IP laws and void equipment warranties.

3. Lack of IP Due Diligence in Supplier Vetting

Buyers often fail to investigate whether a supplier holds proper licenses or owns the rights to the designs they sell. This oversight can result in purchasing infringing products, especially when sourcing from low-cost regions with weaker IP enforcement.

4. Ambiguous Contracts and IP Ownership

Custom-designed belts may involve joint development. Without clear contractual terms, disputes can arise over who owns the design rights. Buyers should ensure contracts specify IP ownership, usage rights, and restrictions on third-party manufacturing.

5. Supply Chain Transparency Gaps

Complex supply chains can obscure the origin of designs and materials. A supplier may claim originality while sourcing from a subcontractor using pirated tooling. Full transparency and audits are essential to mitigate IP risks.

Mitigation Strategies

To avoid these pitfalls, conduct thorough supplier audits, request full material and design documentation, verify compliance with industry standards, and consult legal experts when sourcing custom or high-value belt systems. Prioritize suppliers with proven quality management systems (e.g., ISO 9001) and transparent IP practices.

Logistics & Compliance Guide for Stainless Steel Conveyor Belt

Product Overview and Key Specifications

Stainless steel conveyor belts are widely used in industries such as food processing, pharmaceuticals, automotive, and chemical manufacturing due to their durability, corrosion resistance, and hygiene properties. These belts are typically made from grades such as 304 or 316 stainless steel, with construction types including modular, mesh, or flat-top. Understanding the technical specifications—such as belt width, pitch, thickness, load capacity, and temperature resistance—is essential for proper handling, transportation, and regulatory compliance.

Regulatory Compliance Requirements

Stainless steel conveyor belts must comply with industry-specific regulations depending on the application. In food and beverage industries, compliance with FDA (U.S. Food and Drug Administration) standards and EU Regulation (EC) No 1935/2004 for materials in contact with food is mandatory. For pharmaceutical use, adherence to cGMP (current Good Manufacturing Practices) and ISO 14644 (cleanroom standards) may apply. Additionally, machinery safety standards such as ISO 14120 (safety of machinery – guards) and OSHA (Occupational Safety and Health Administration) guidelines in the U.S. must be observed during installation and operation.

Packaging and Handling Guidelines

Proper packaging is crucial to prevent damage during transit. Stainless steel conveyor belts should be wrapped in anti-corrosion paper or VCI (Vapor Corrosion Inhibitor) film and secured on wooden pallets or in crates. For long or flexible belts, they must be coiled or folded carefully to avoid kinking or deformation. Handling should be performed using appropriate lifting equipment, such as forklifts or overhead cranes with soft slings, to avoid scratching or denting the belt surface. Workers should wear gloves to prevent fingerprints and contamination, especially for belts used in sterile environments.

Transportation and Shipping Considerations

When shipping stainless steel conveyor belts, carriers must be informed of the cargo’s weight, dimensions, and sensitivity to moisture and physical impact. International shipments should comply with IMDG (International Maritime Dangerous Goods) Code if applicable, though stainless steel belts are generally non-hazardous. For air freight, IATA packaging regulations should be followed. Documentation, including a commercial invoice, packing list, and certificate of conformance, must be complete and accurate. Consider using climate-controlled or covered transport to prevent exposure to corrosive environments, particularly in coastal or industrial regions.

Import and Export Compliance

Exporters and importers must ensure compliance with customs regulations in both origin and destination countries. Key documentation includes a Certificate of Origin, Material Test Reports (MTRs), and REACH/SVHC (Registration, Evaluation, Authorization, and Restriction of Chemicals) compliance statements where applicable. For exports from the U.S., compliance with EAR (Export Administration Regulations) may be required. Import duties, tariffs, and local standards (e.g., CE marking in the EU, CCC in China) must be verified in advance. Sanitary and phytosanitary (SPS) measures may apply if wooden packaging is used, requiring ISPM 15 treatment certification.

Installation and On-Site Compliance

Prior to installation, verify that the conveyor belt meets the equipment manufacturer’s specifications and site safety standards. Installation should be performed by trained personnel following lockout-tagout (LOTO) procedures per OSHA or equivalent local regulations. After installation, conduct safety inspections and functional tests to ensure alignment, tension, and operational integrity. Maintain records of installation, maintenance, and compliance certifications for audit purposes.

Maintenance, Traceability, and Recordkeeping

Establish a routine maintenance schedule to inspect for wear, corrosion, and mechanical failure. Use traceable lot numbers or serial tags on belts to support quality control and recalls if needed. Retain all compliance documentation—including material certifications, inspection reports, and safety data sheets (SDS) if lubricants are involved—for a minimum of 5–10 years, depending on industry requirements. Digital recordkeeping systems are recommended for efficient audit preparation and regulatory reporting.

Environmental and Disposal Regulations

At end-of-life, stainless steel conveyor belts can typically be recycled. Disposal must comply with local environmental regulations such as EPA (U.S. Environmental Protection Agency) or WEEE (Waste Electrical and Electronic Equipment) directives in the EU. Avoid landfill disposal when possible due to the recyclable nature of stainless steel. Ensure that any cleaning residues or contaminants are handled as hazardous waste if applicable.

Conclusion for Sourcing Stainless Steel Conveyor Belts

Sourcing stainless steel conveyor belts requires a thorough evaluation of material quality, application requirements, supplier reliability, and total cost of ownership. Stainless steel belts offer superior durability, corrosion resistance, and hygiene, making them ideal for industries such as food processing, pharmaceuticals, and chemical manufacturing. When selecting a supplier, it is essential to consider factors such as compliance with industry standards (e.g., FDA, USDA, ISO), customization capabilities, lead times, and after-sales support.

A strategic sourcing approach that includes supplier audits, sample testing, and long-term partnership development ensures consistent product performance and operational efficiency. Additionally, investing in high-grade stainless steel (such as 304 or 316) tailored to specific environmental conditions enhances belt longevity and reduces maintenance costs.

In conclusion, successful sourcing of stainless steel conveyor belts hinges on balancing quality, cost, and reliability. By partnering with reputable suppliers and aligning technical specifications with operational needs, businesses can achieve optimal performance, improve safety, and support sustainable manufacturing practices.