The global apparel market, driven by rising consumer demand for affordable and stylish basics, continues to expand at a steady pace. According to a 2023 report by Grand View Research, the global t-shirt market size was valued at USD 53.4 billion and is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This sustained growth is fueled by increasing e-commerce penetration, fast fashion trends, and the rising preference for casual wear across demographics. As demand surges, the role of reliable S/S (short sleeve) tee manufacturers becomes increasingly critical in meeting quality, scalability, and sustainability benchmarks. From innovative fabric sourcing to on-time production and low minimum order quantities, today’s top manufacturers are setting new standards in efficiency and responsiveness. Based on production capacity, certifications, customer reviews, and market reach, the following eight manufacturers have emerged as leaders in supplying high-quality short sleeve t-shirts to brands worldwide.

Top 8 Ss Tee Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Forged Tee Pipe Fittings

Domain Est. 2022

Website: pssteel.co.in

Key Highlights: SS Forged Pipe Fittings Manufacturer comes in different sizes, wall thicknesses, and grades of stainless steel to meet specific industrial requirements….

#2 Bonney Forge

Domain Est. 1996

Website: bonneyforge.com

Key Highlights: Bonney Forge is a leading manufacturer of Forged and Cast Steel Valves,Olets*/Pipets*, Forged Steel Fittings and Unions, and Specialty Products….

#3 Seamless steel pipe

Domain Est. 2017

Website: united-steel.com

Key Highlights: As a professional manufacturer,UNITED STEEL INDUSTRY CO.,LTD offer you the best steel pipes,such as Carbon pipes,seamless steel pipe,stainless steel pipe ……

#4 Stainless Steel Forged Tee Manufacturer, Supplier

Domain Est. 2017

Website: tescosteel.com

Key Highlights: We manufacture Tee products that are available in different forms such as Stainless Steel Equal Tee, Stainless Steel Equal Tee, Stainless Steel Cross Tee and ……

#5 Eastern Steel Manufacturing Co.,Ltd

Domain Est. 2021

Website: eastern-steels.com

Key Highlights: Eastern Steel Manufacturing Co.,Ltd is a leading manufacturer and distributor of seamless steel pipe, welded steel pipe, OCTG products and fittings….

#6 ASME B16.9 Stainless Steel Tee Manufacturer.

Domain Est. 2024

Website: stainless-steel-fitting.com

Key Highlights: S&S manufactures custom stainless steel tees in equal and reducing designs, meeting ASME B16.9 and ASTM A403 standards….

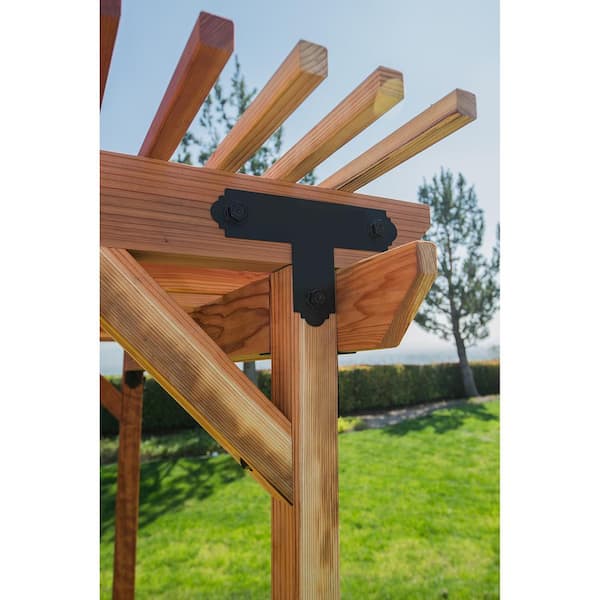

#7 Simpson Strong

Domain Est. 1995

Website: strongtie.com

Key Highlights: Welcome to the Simpson Strong-Tie homepage showcasing our resources, products and services designed to help people build safer, stronger structures….

#8 Manufacturing of stainless steel butt

Domain Est. 1997

Website: proform.fr

Key Highlights: Proform manufactures stainless steel buttweld fittings and nickel alloys elbows and tees. Discover our expertise and know-how by visiting our website….

Expert Sourcing Insights for Ss Tee

H2: Market Trends for SST (Sustainable Style Tee) in 2026

As we move closer to 2026, the market for Sustainable Style Tees (SST) is poised for transformative growth driven by evolving consumer values, technological innovation, and regulatory shifts. The H2 outlook for SST reflects a maturation of the sustainable fashion sector, with key trends shaping demand, production, and brand positioning.

1. Accelerated Demand for Circularity

By H2 2026, circular fashion models will dominate the SST market. Consumers increasingly expect brands to offer take-back programs, recycling guarantees, and transparency in material lifecycles. Leading SST brands are projected to partner with closed-loop textile recyclers, using advanced fiber-to-fiber technologies to convert old tees into new garments—reducing waste and enhancing brand loyalty.

2. Tech-Integrated Sustainability Verification

Blockchain and QR-code traceability will become standard in the SST space. In H2 2026, consumers can scan a tee’s tag to view its full supply chain journey—from organic cotton farm to dyeing facility and carbon footprint per unit. This transparency builds trust and differentiates authentic sustainable brands from greenwashed competitors.

3. Rise of Regenerative Agriculture Sourcing

SST brands are shifting beyond “less harm” to “positive impact” by sourcing cotton from regenerative farms. By H2 2026, a growing number of premium SST lines will highlight soil health improvements, biodiversity metrics, and carbon sequestration data—appealing to eco-conscious buyers willing to pay a 15–20% price premium.

4. AI-Driven Customization and On-Demand Manufacturing

To reduce overproduction, AI-powered design platforms will enable personalized SST creation in H2 2026. Consumers co-design tees via apps, triggering local, on-demand production. This minimizes inventory waste, shortens supply chains, and aligns with the growing preference for unique, slow-fashion apparel.

5. Regulatory Pressure and Policy Incentives

The EU’s Digital Product Passport (DPP) and proposed textile waste regulations will be fully enforced by 2026. In H2, SST brands operating in Europe must comply with strict sustainability labeling and end-of-life reporting. Conversely, government subsidies for eco-textile innovation and green manufacturing will lower production costs for compliant SST producers.

6. Expansion into Emerging Markets

While Western markets remain strong, H2 2026 will see SST brands targeting urban millennials in Southeast Asia, Latin America, and Africa. Localized designs, affordable sustainable fabrics (e.g., banana or pineapple fiber blends), and mobile-first retail strategies will drive growth in these regions.

Conclusion

The H2 2026 landscape for SST is defined by deeper sustainability integration, technological enablement, and global scalability. Brands that prioritize verifiable eco-impact, circular systems, and consumer engagement will lead the market, turning the humble sustainable tee into a symbol of systemic change in fashion.

Common Pitfalls When Sourcing Stainless Steel Tees (Quality & Intellectual Property)

Sourcing stainless steel tees—especially for critical applications in industries like oil and gas, pharmaceuticals, or food processing—requires careful attention to both quality assurance and intellectual property (IP) concerns. Overlooking these aspects can lead to project delays, safety risks, legal issues, and financial losses. Below are key pitfalls to avoid:

Inadequate Material Certification and Traceability

One of the most frequent quality pitfalls is receiving stainless steel tees without proper material test reports (MTRs) or with falsified documentation. Buyers may assume compliance based on supplier claims, but without mill test certificates (e.g., EN 10204 3.1 or 3.2), verifying chemical composition and mechanical properties becomes impossible. This increases the risk of using substandard materials that fail under pressure or in corrosive environments.

Poor Weld Quality and Workmanship

Stainless steel tees, particularly welded ones, are prone to defects like incomplete penetration, porosity, or heat-affected zone (HAZ) corrosion if not manufactured to proper standards (e.g., ASME B16.9, ASTM A403). Sourcing from low-cost suppliers without rigorous quality control often results in poor weld integrity, which can compromise system safety and lead to leaks or failures.

Non-Compliance with International Standards

Suppliers may claim adherence to standards like ASTM, ASME, or ISO without actual compliance. For example, a tee may be labeled as ASTM A403 WP316 but fail to meet required chromium, nickel, or molybdenum content. Failure to verify conformance through independent testing can result in non-compliant components entering critical systems.

Counterfeit or Gray Market Products

A significant IP and quality risk involves counterfeit tees that mimic branded products. Some suppliers replicate logos, part numbers, or certifications of reputable manufacturers without authorization. These counterfeit items lack quality assurance and warranties, exposing buyers to liability and performance risks. Additionally, purchasing such items may inadvertently support IP infringement.

Lack of Intellectual Property Due Diligence

When sourcing from overseas manufacturers, especially in regions with weaker IP enforcement, there’s a risk of engaging with suppliers who produce reverse-engineered versions of patented designs. Even if the buyer is unaware, using such components could lead to legal action from original equipment manufacturers (OEMs) claiming IP violations.

Insufficient Supplier Qualification and Audits

Relying solely on price or online listings without verifying a supplier’s manufacturing capabilities, quality management systems (e.g., ISO 9001), or production facilities increases the likelihood of receiving defective or non-compliant products. Unannounced audits or third-party inspections are essential to validate claims.

Inadequate Testing and Inspection Protocols

Many buyers overlook the need for third-party inspections (e.g., by SGS, Bureau Veritas, or TÜV) at the factory or upon delivery. Skipping steps like hydrostatic testing, PMI (positive material identification), or dimensional checks can result in undetected defects reaching the job site.

Supply Chain Transparency Gaps

Complex supply chains can obscure the actual manufacturer. A supplier may act as a middleman, sourcing from unqualified foundries. Without transparency, buyers cannot ensure consistency, traceability, or accountability—critical for quality and IP integrity.

Conclusion

To mitigate these risks, buyers should prioritize certified suppliers, demand full traceability, conduct regular audits, and perform independent quality testing. Additionally, legal agreements should include IP warranties and clear accountability clauses. Due diligence in sourcing stainless steel tees not only ensures product reliability but also protects against legal and operational exposure.

Logistics & Compliance Guide for SS TEE

This guide outlines essential logistics and compliance considerations for handling, shipping, and managing SS TEE (stainless steel tee fittings) in accordance with industry standards and regulatory requirements. Adherence to these guidelines ensures product integrity, safety, and legal compliance throughout the supply chain.

Product Identification & Specifications

- Material Grade: Confirm SS TEE is manufactured from specified stainless steel grade (e.g., ASTM A312/A403 for seamless/welded fittings, grades 304, 304L, 316, 316L).

- Size & Dimensions: Verify nominal pipe size (NPS), schedule, wall thickness, and center-to-end dimensions per ASME B16.9 or customer specifications.

- Marking Requirements: Each fitting must be permanently marked with manufacturer’s name or trademark, material grade, size, and applicable standard.

Packaging & Handling

- Protective Packaging: SS TEEs must be packaged to prevent mechanical damage, corrosion, and contamination. Use:

- Waterproof wrapping or plastic caps on ends

- Wooden crates or palletized bundles with corner protectors

- Desiccants in enclosed containers for long-term storage or marine transport

- Handling Procedures: Use non-abrasive lifting equipment (e.g., nylon slings). Avoid dragging or dropping to prevent dents and surface damage.

Storage Conditions

- Environment: Store indoors in a dry, well-ventilated area. Avoid exposure to chlorides, acids, and salt-laden air.

- Segregation: Keep stainless steel separate from carbon steel to prevent galvanic corrosion. Use dedicated storage racks.

- Duration: Limit outdoor storage; if unavoidable, cover completely and elevate off ground.

Transportation Requirements

- Mode-Specific Guidelines:

- Marine: Comply with IMDG Code if shipped internationally. Ensure cargo is secured to prevent shifting.

- Road/Rail: Use tarps to protect against weather. Confirm load limits and securement per local regulations.

- Documentation: Include packing list, material test reports (MTRs), and certificates of compliance (e.g., ISO 9001, PED for EU).

Regulatory Compliance

- International Standards:

- ASME B16.9 – Factory-Made Wrought Buttwelding Fittings

- ASTM A403 – Standard Specification for Wrought Stainless Steel Piping Fittings

- PED 2014/68/EU – Required for fittings used in pressure equipment within the European Union

- Country-Specific Requirements:

- USA: Comply with ASME and OSHA handling standards

- Canada: CSA B51 and Transport Canada regulations

- UAE/Saudi Arabia: SASO or SABER certification may be required

- Customs & Import: Provide accurate HS Code (e.g., 7307.22 for stainless steel pipe fittings), commercial invoice, and country of origin declaration.

Quality Assurance & Documentation

- Material Test Reports (MTRs): Must accompany each batch, certifying chemical composition and mechanical properties.

- Inspection & Testing: Perform visual, dimensional, and non-destructive testing (e.g., PMI, hydrostatic) as per project or code requirements.

- Traceability: Maintain full lot traceability from raw material to final product.

Environmental & Safety Compliance

- Hazard Communication: Although stainless steel is non-hazardous, provide Safety Data Sheet (SDS) per GHS standards.

- Waste Management: Recycle packaging materials. Handle metal swarf or cutting waste per local environmental regulations.

- Worker Safety: Enforce PPE (gloves, safety glasses) during handling and inspection.

Non-Conformance & Corrective Actions

- Quarantine: Isolate non-compliant SS TEEs and document deviations.

- Reporting: Notify customer and regulatory bodies if required (e.g., under PED Article 12).

- Root Cause Analysis: Investigate and correct process failures to prevent recurrence.

Adhering to this Logistics & Compliance Guide ensures the safe, efficient, and lawful distribution of SS TEE fittings while maintaining product quality and customer trust.

Conclusion for Sourcing Stainless Steel Tee Fittings:

Sourcing stainless steel tee fittings requires a strategic approach that balances quality, cost, compliance, and supply chain reliability. After evaluating various suppliers, certifications, material grades (such as SS304, SS316), manufacturing standards (e.g., ASME B16.9, MSS SP-75), and lead times, it is evident that selecting the right supplier is critical to ensuring product durability, corrosion resistance, and system integrity in demanding applications.

Partnering with reputable manufacturers who adhere to international quality standards and offer proper documentation, such as mill test certificates and material traceability, minimizes the risk of failure in critical systems. Additionally, considering long-term cost efficiency—factoring in maintenance, lifespan, and performance—proves more valuable than opting for the lowest initial price.

In conclusion, a successful sourcing strategy for stainless steel tees involves thorough supplier vetting, clear specification requirements, and ongoing quality assurance. By prioritizing reliability and compliance, organizations can ensure safe, efficient, and sustainable operations across industries such as oil & gas, pharmaceuticals, food processing, and water treatment.