The global spring lock washer market is experiencing steady growth, driven by rising demand across automotive, industrial machinery, construction, and aerospace sectors. According to a report by Mordor Intelligence, the global lock washer market was valued at USD 1.2 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This expansion is fueled by increasing industrialization, stringent safety regulations requiring reliable fastening solutions, and the growing emphasis on vibration-resistant components in critical applications. Spring lock washers, known for their ability to maintain tension and prevent loosening under dynamic loads, are becoming essential in high-performance environments. With manufacturing hubs expanding in Asia-Pacific and Latin America, and technological advancements improving material durability and corrosion resistance, the competitive landscape is evolving rapidly. In this context, identifying the leading manufacturers who combine innovation, quality, and global reach is crucial for procurement teams and engineering professionals alike. Based on production capacity, certifications, market presence, and customer reviews, we’ve compiled a data-driven list of the top 9 spring lock washer manufacturers shaping the industry in 2024.

Top 9 Spring Lock Washer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Double Coil Spring Lock Washers

Domain Est. 1996

Website: tengco.com

Key Highlights: We will custom manufacture double coil spring lock washers to your exact specifications. Request a Quote · Phone(714) 676-8200 · [email protected]. Sort ……

#2 Lock Washers

Domain Est. 1997

Website: shakeproof.com

Key Highlights: The Helical Spring Lock Washers we offer at ITW Shakeproof Industrial have been among the most popular structural anti-loosening products on the market….

#3 Split Lock Washers

Domain Est. 1999

Website: fastcoinc.com

Key Highlights: Order split lock washers in bulk and get fast shipping on all orders. Helical spring lock washers are available in various sizes, ……

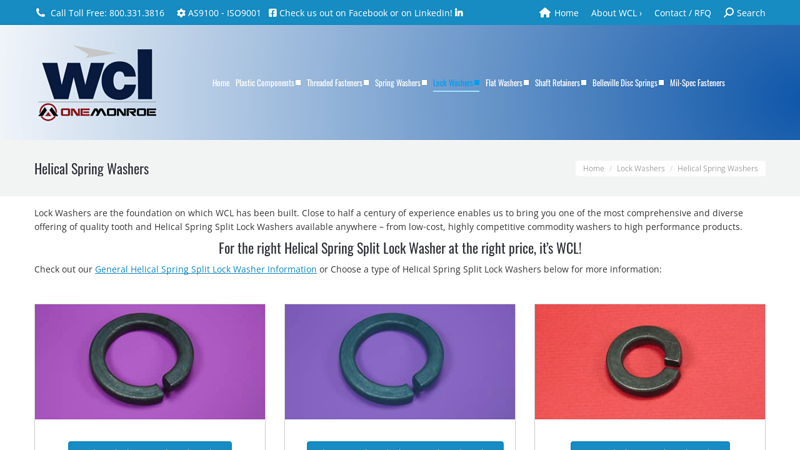

#4 Helical Spring Washers

Domain Est. 1997

Website: wclco.com

Key Highlights: Quality tooth and Helical Spring Split Lock Washers available anywhere – from low-cost, highly competitive commodity washers to high performance products….

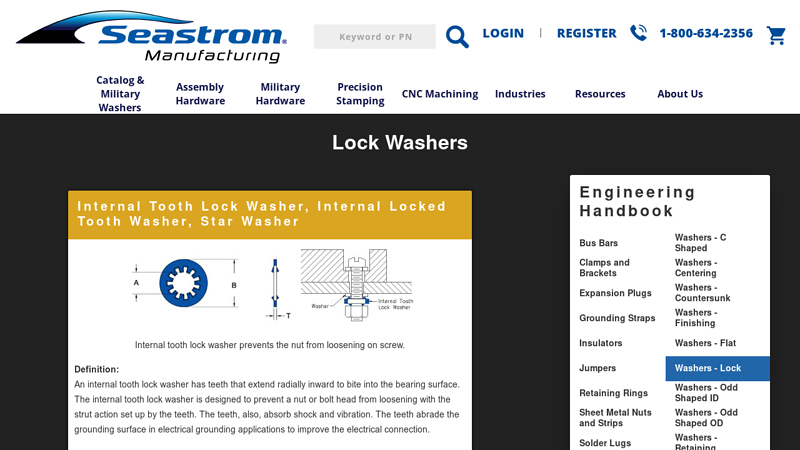

#5 Lock Washers

Domain Est. 1997

Website: seastrom-mfg.com

Key Highlights: Internal Tooth Lock Washers are available in the following materials and finishes: Spring Steel: Baking, Black Oxide, Cadmium types I & II, Chrome, Degreasing, ……

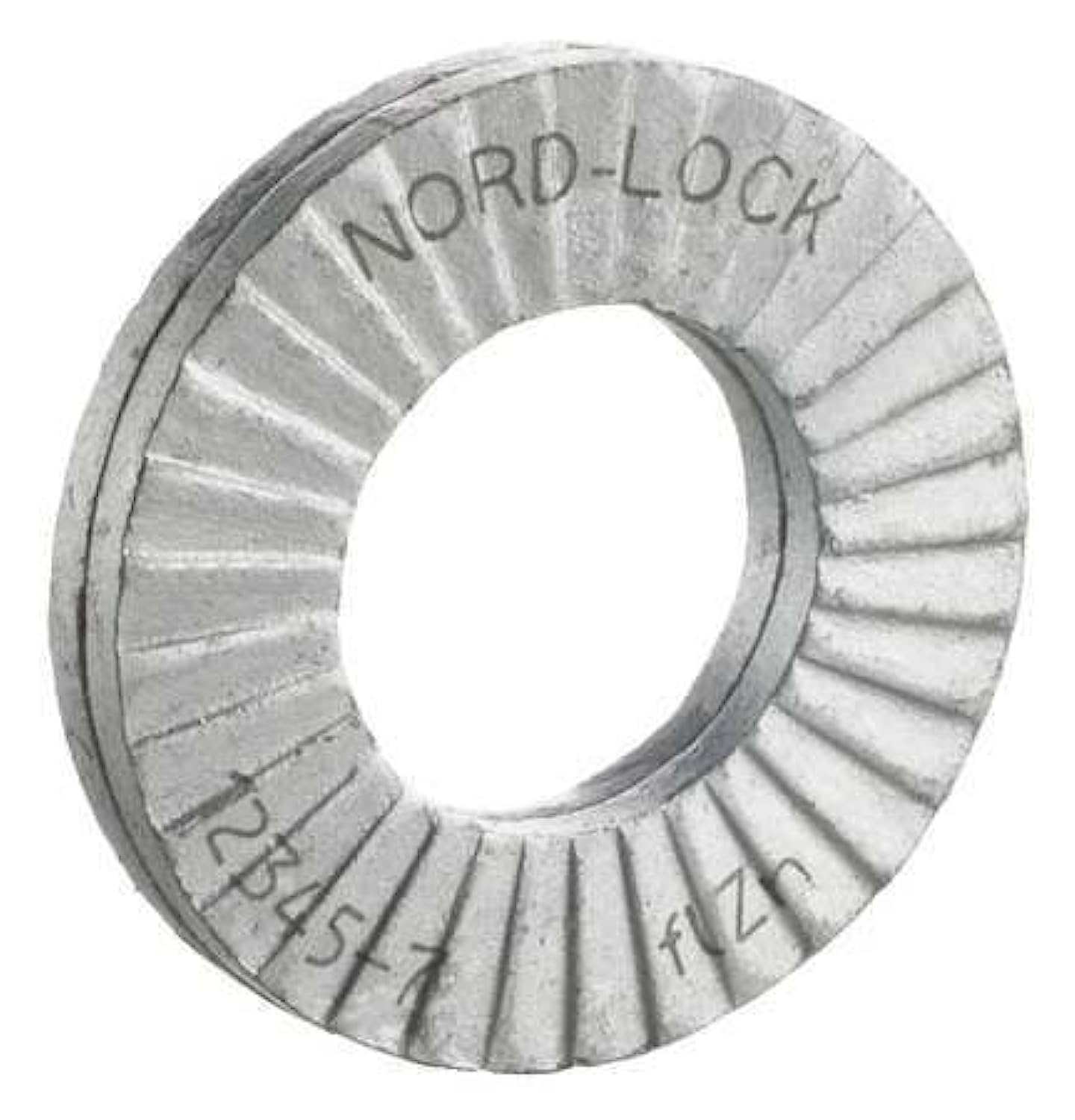

#6 Nord-Lock Original Washers

Domain Est. 1997

Website: nord-lock.com

Key Highlights: Nord-Lock® Original Washer. Nord-Lock original wedge-locking washers secures bolted joints, even when exposed to severe vibration and dynamic loads….

#7 Spring Washer

Domain Est. 1999

Website: asraymond.com

Key Highlights: 6-day deliveryASRaymond offers various Spring Washer products such as Belleville, Clover®Dome, DIN, Disc, and more. Designed to provide an axial force in a limited amount ……

#8 Spring washers

Domain Est. 2000

Website: boellhoff.com

Key Highlights: Spring washers behave like compression springs and increase the flexibility in a screw connection. Find out more here….

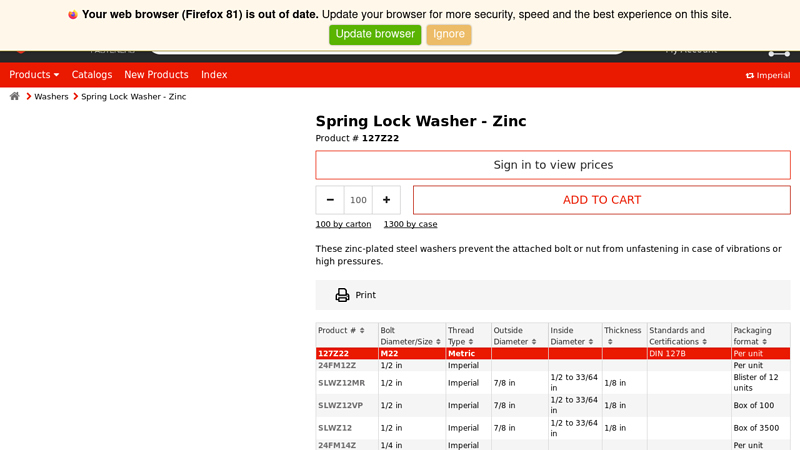

#9 Spring Lock Washer

Domain Est. 2005

Website: reliablefasteners.com

Key Highlights: These zinc-plated steel washers prevent the attached bolt or nut from unfastening in case of vibrations or high pressures….

Expert Sourcing Insights for Spring Lock Washer

H2: 2026 Market Trends for Spring Lock Washers

The global spring lock washer market in 2026 is poised for steady growth, driven by underlying industrial demand and technological evolution, though facing challenges from alternative fastening solutions. Key trends shaping the landscape include:

1. Steady Growth in Core Industrial Sectors:

Demand will remain anchored in traditional heavy industries—automotive manufacturing, construction machinery, industrial equipment, and aerospace. As global infrastructure development continues, particularly in emerging economies, the need for reliable, cost-effective anti-loosening solutions like spring lock washers will sustain market momentum. Electric vehicle (EV) production, while introducing new fastening demands, will still utilize spring lock washers in non-critical or cost-sensitive applications, supporting overall volume.

2. Material and Coating Innovations Enhancing Performance:

To meet stricter performance and durability standards, manufacturers are investing in advanced materials and surface treatments. High-strength alloys, stainless steel variants (e.g., 17-4 PH), and improved corrosion-resistant coatings (such as zinc-nickel, Dacromet, or eco-friendly alternatives) will gain traction. These enhancements extend service life in harsh environments (e.g., marine, chemical, outdoor infrastructure), boosting demand in high-reliability applications.

3. Rising Competition from Alternative Locking Technologies:

Spring lock washers face increasing competition from more effective solutions like prevailing torque lock nuts, toothed lock washers, Nord-Lock wedge systems, and chemical thread lockers. These alternatives often offer superior vibration resistance and reliability. As industries prioritize safety and maintenance reduction—especially in aerospace, energy, and transportation—adoption of these higher-performance options may limit spring lock washer growth in critical applications.

4. Regional Shifts and Supply Chain Optimization:

Asia-Pacific, led by China and India, will remain the dominant production and consumption hub due to robust manufacturing activity. However, geopolitical factors and supply chain resilience concerns will drive regional diversification. Companies may pursue nearshoring or regional sourcing strategies, benefiting local manufacturers in North America and Europe. Automation in production will also increase to improve precision and reduce labor costs.

5. Sustainability and Regulatory Pressures:

Environmental regulations will influence material selection and coating processes. Demand for RoHS and REACH-compliant products will grow, pushing manufacturers to phase out hazardous substances like hexavalent chromium. Recyclability and reduced environmental impact throughout the product lifecycle will become more important in procurement decisions, especially among large industrial clients.

6. Price Sensitivity and Cost-Effectiveness as Key Advantages:

Despite technological alternatives, the low cost, simplicity, and ease of installation of spring lock washers will ensure their continued use in non-critical, high-volume applications. In cost-sensitive markets and maintenance/repair operations (MRO), their affordability will remain a significant competitive advantage.

Conclusion:

By 2026, the spring lock washer market will experience moderate growth, supported by enduring industrial demand and material innovations. However, its role may gradually shift toward less critical or cost-driven applications as higher-performance locking technologies gain ground. Manufacturers who invest in advanced materials, sustainable practices, and operational efficiency will be best positioned to maintain competitiveness in an evolving fastening solutions landscape.

Common Pitfalls When Sourcing Spring Lock Washers (Quality, IP)

Sourcing Spring Lock Washers may seem straightforward, but several critical pitfalls related to quality and intellectual property (IP) can lead to performance failures, compliance risks, and legal exposure. Being aware of these issues is essential for reliable supply chain management.

Inconsistent Material Quality and Specifications

One of the most frequent pitfalls is receiving washers made from substandard materials or with non-compliant dimensions. Suppliers—especially low-cost or uncertified ones—may use inferior-grade spring steel that lacks the necessary tensile strength and elasticity. This can result in premature washer failure, leading to loosening of fastened joints in critical applications. Always verify material certifications (e.g., ASTM, DIN, or ISO standards) and conduct incoming quality inspections to ensure compliance.

Lack of Traceability and Certification

Reputable sourcing requires full traceability, including mill test certificates and compliance documentation. Without proper documentation, it becomes impossible to verify whether the washers meet required specifications or have been tested for performance (e.g., load retention, fatigue resistance). This is particularly crucial in regulated industries like aerospace, automotive, or medical devices, where non-compliance can result in product recalls or liability.

Counterfeit or Non-Genuine Products

The market for fasteners is rife with counterfeit goods, including Spring Lock Washers falsely labeled as meeting international standards. These counterfeit items may look identical but fail under stress due to poor heat treatment or incorrect alloy composition. Sourcing from unauthorized distributors or gray-market channels increases the risk of receiving such products, undermining system reliability and safety.

Intellectual Property (IP) Infringement Risks

Some Spring Lock Washer designs—especially proprietary or patented profiles (e.g., split ring, toothed, or wave washers with unique geometries)—are protected by intellectual property rights. Sourcing generic copies of patented designs from unlicensed manufacturers can expose your company to IP infringement claims, especially in export markets with strong IP enforcement. Always confirm that the supplier has the right to manufacture and sell the design, or opt for standard, non-proprietary configurations.

Inadequate Testing and Quality Control Processes

Many suppliers, particularly smaller or offshore manufacturers, lack robust quality assurance systems. Without proper batch testing, load cycling validation, or surface finish inspection, washers may not perform as expected under dynamic loads or corrosive environments. Insist on documented QC procedures, such as ISO 9001 certification, and request sample testing reports before placing large orders.

Misrepresentation of Standards Compliance

Suppliers may claim compliance with industry standards (e.g., ISO 7009, ASME B18.21.1) without actual conformance. This can include incorrect hardness ratings, improper coating thickness (e.g., zinc plating), or deviations in outer/inner diameter and thickness. Third-party audits or independent lab testing can help verify these claims and prevent integration of non-conforming parts.

Avoiding these pitfalls requires due diligence: vetting suppliers thoroughly, demanding certifications, conducting audits, and protecting your business from both quality failures and legal risks.

Logistics & Compliance Guide for Spring Lock Washers

Overview of Spring Lock Washers

Spring lock washers, also known as split lock washers, are mechanical fastener components designed to prevent loosening due to vibration or thermal expansion. They are typically made from hardened steel, stainless steel, or other corrosion-resistant materials. Proper logistics and compliance handling ensures product integrity, regulatory adherence, and customer satisfaction.

Material and Packaging Requirements

Spring lock washers must be packaged to prevent corrosion, deformation, and contamination during transit. Common packaging includes:

– Bulk packaging: For large orders, washers are placed in moisture-resistant bags inside sturdy corrugated boxes.

– Vial or blister packaging: For retail or small quantities, individual or pre-counted units are sealed to maintain cleanliness.

– Anti-corrosion protection: Use vapor corrosion inhibitors (VCI) or desiccants when shipping in humid environments.

– Labeling: Each package should include part number, material specification (e.g., ASTM A123), quantity, batch/lot number, and handling instructions.

Storage Conditions

Store spring lock washers in a dry, temperature-controlled environment (15–25°C, 30–60% RH) to prevent rust and material degradation. Avoid direct contact with concrete floors; use pallets or shelving. Segregate different materials (e.g., carbon steel vs. stainless steel) to prevent galvanic corrosion.

Transportation and Shipping

- Domestic shipments: Use enclosed, dry trucks. Secure packages to prevent shifting.

- International shipments: Comply with ISPM 15 regulations for wooden pallets. Use waterproof containers for sea freight.

- Hazard classification: Spring lock washers are generally non-hazardous but must be declared accurately under HS Code 7318.29 (other washers, of iron or steel).

- Documentation: Include commercial invoice, packing list, and certificate of origin if required.

Regulatory Compliance

- RoHS (EU): Ensure washers made for electronic applications comply with Restriction of Hazardous Substances directives.

- REACH (EU): Confirm no restricted substances (e.g., SVHCs) are present above thresholds.

- ASTM/ISO Standards: Adhere to relevant specifications such as ASTM F436 (hardened steel washers) or ISO 7093.

- Conflict Minerals (US): If applicable, verify sourcing from non-conflict regions per Dodd-Frank Act Section 1502.

Import/Export Considerations

- Customs clearance: Provide accurate Harmonized System (HS) codes and country of origin.

- Tariff implications: Be aware of tariffs on steel fasteners, especially from countries subject to anti-dumping duties.

- Export controls: While typically not controlled, verify with EAR (Export Administration Regulations) if intended for military or dual-use applications.

Quality Assurance and Traceability

Maintain full traceability from raw material to final product. Retain batch records, inspection reports, and test certifications (e.g., tensile strength, hardness) for a minimum of 5 years. Conduct periodic audits of suppliers and logistics partners.

Environmental and Sustainability Practices

- Recyclability: Steel washers are 100% recyclable; promote end-of-life recycling.

- Packaging waste reduction: Use recyclable or biodegradable materials where possible.

- Carbon footprint: Optimize shipping routes and consolidate loads to minimize emissions.

Handling and Safety

- Use gloves when handling carbon steel washers to prevent fingerprint corrosion.

- Follow standard warehouse safety protocols (e.g., proper lifting, storage heights).

- Ensure material safety data sheets (MSDS/SDS) are available, though washers typically pose minimal health risks.

Conclusion

Effective logistics and compliance management for spring lock washers ensures product reliability, legal conformity, and supply chain efficiency. Adherence to international standards, proper documentation, and sustainable practices are key to successful distribution and customer trust.

Conclusion for Sourcing Spring Lock Washers:

Sourcing spring lock washers requires a strategic approach that balances quality, cost, availability, and compliance with technical specifications. After evaluating potential suppliers, it is evident that selecting a reliable manufacturer or distributor is crucial to ensuring consistent performance and reliability in applications where vibration resistance and secure fastening are essential. Key considerations include material grade (such as carbon steel, stainless steel, or specialty alloys), dimensional accuracy, load capacity, and adherence to international standards (e.g., ISO, DIN, or ANSI). Additionally, establishing long-term partnerships with suppliers who offer just-in-time delivery, robust quality control processes, and competitive pricing can significantly enhance supply chain efficiency. In conclusion, a well-structured sourcing strategy for spring lock washers not only supports operational reliability but also contributes to cost savings and improved product durability across various industrial applications.