The global demand for functional and durable bag closures has seen steady growth, driven by rising consumer preference for convenience, security, and design innovation in luggage, backpacks, and outdoor gear. According to a report by Mordor Intelligence, the global zippers and fasteners market—encompassing spring-loaded closures—was valued at USD 11.3 billion in 2023 and is projected to grow at a CAGR of 4.8% through 2029. Spring-loaded bag closures, in particular, have gained traction due to their reliability, ease of use, and integration into high-performance and premium segment products. Fueled by expansion in the travel and outdoor recreation industries, as well as increased e-commerce packaging needs, manufacturers specializing in these mechanisms are scaling innovation and production. This growing market landscape has led to increased competition and specialization among key players, especially in Asia-Pacific and North America. Below are eight leading spring-loaded bag closure manufacturers distinguished by engineering precision, material quality, global distribution, and industry partnerships.

Top 8 Spring Loaded Bag Closure Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bulk Bags

Domain Est. 1997

Website: kingbag.com

Key Highlights: King Bag and Manufacturing manufactures and imports bulk handling bags. We were one of the 1st US Manufacturers of Bulk bags and we remain ……

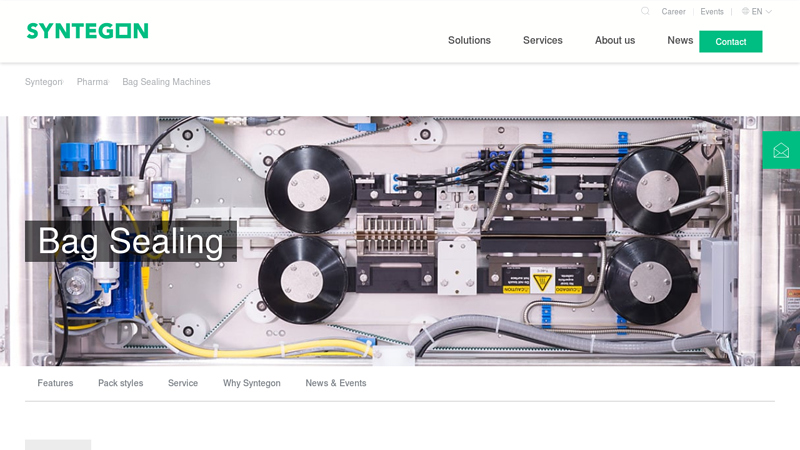

#2 Bag Sealing Machines

Domain Est. 2019

Website: syntegon.com

Key Highlights: Our bag sealing machine feature an advanced sealing technology to ensure bags are properly sealed, ideally suited for medical, food and non-food items….

#3 Closures archivos

Domain Est. 2021

Website: leatherartisanlab.com

Key Highlights: Free delivery 5-day returnsDiscover durable and stylish closures for your leathercraft projects, offering functionality and elegance in various designs and finishes.Missing: loade…

#4 Spiroflow Helps a Customer Out

Domain Est. 1996

Website: spiroflow.com

Key Highlights: The Spiroflow Type 2 bulk bag discharger at Jowat Adhesives includes spring-loaded arms to support the bag lifting frame, the integral bag dumping station, bag ……

#5 YKK FASTENING PRODUCTS GROUP / The finest zipper company …

Domain Est. 2001

Website: ykkfastening.com

Key Highlights: The YKK Fastening Products Group is trusted world-wide for their impeccable production standards and thorough quality control processes for zippers, ……

#6 Purse Locks & Clasps

Domain Est. 2002

#7 Bag Clasps & Closures

Domain Est. 2006

#8 95801 38mm Non

Domain Est. 2012

Website: cpcworldwide.com

Key Highlights: Upgrade your fluid connections with the 95801 38mm Non-Valved Bag Closures Caps & Plugs. Durable and reliable, CPC products are perfect for a wide range of ……

Expert Sourcing Insights for Spring Loaded Bag Closure

H2: Market Trends for Spring Loaded Bag Closure in 2026

As the global packaging industry evolves in response to sustainability mandates, automation demands, and shifting consumer preferences, the Spring Loaded Bag Closure (SLBC) market is poised for notable transformation by 2026. These mechanical fastening systems—commonly used in resealable plastic bags for food, pet care, medical supplies, and consumer goods—are adapting to meet new performance and environmental standards. Below are key market trends expected to shape the SLBC landscape in 2026:

Rising Demand for Sustainable and Recyclable Solutions

By 2026, environmental regulations and consumer pressure will drive significant innovation in SLBC materials. Manufacturers are increasingly replacing traditional polypropylene or polyethylene-based closures with bio-based polymers, recycled-content resins, and mono-material designs that support recyclability. Closed-loop recycling programs and compatibility with existing waste streams (e.g., store drop-off LDPE films) will become competitive differentiators. Brands aiming for “recyclable packaging” certifications will favor SLBCs engineered for compatibility with recyclable bag structures.

Integration with Automation and High-Speed Packaging Lines

The push for operational efficiency in manufacturing will intensify demand for SLBC systems compatible with high-speed filling and sealing equipment. By 2026, spring-loaded closures will be optimized for seamless integration with automated form-fill-seal (FFS) machines, reducing downtime and misalignment issues. Smart design improvements—such as enhanced tactile feedback, consistent spring tension, and better alignment guides—will ensure reliability at speeds exceeding 100 bags per minute, especially in food and pharmaceutical sectors.

Expansion into Premium and Health-Focused Segments

The SLBC market will see growth beyond commodity packaging into high-value niches such as organic foods, meal kits, pharmaceuticals, and medical devices. In these segments, the resealability, freshness retention, and tamper-evidence offered by spring-loaded closures add tangible value. By 2026, closures may incorporate antimicrobial additives or oxygen barriers, particularly for perishable goods, aligning with consumer demand for extended shelf life and product safety.

Focus on User Experience and Accessibility

Ergonomic design will become a key selling point. SLBCs will evolve to offer easier opening and closing for elderly and disabled users, potentially through reduced actuation force or tactile indicators. Enhanced audible and tactile feedback (“click” mechanisms) will improve user confidence in seal integrity. Branded closures with customizable colors, textures, or embossed logos will also gain traction as packaging becomes a tool for brand differentiation.

Regional Growth and Supply Chain Localization

While North America and Europe will remain strong markets due to stringent packaging regulations and high automation rates, Asia-Pacific—especially India and Southeast Asia—is expected to see the fastest growth in SLBC adoption by 2026. Rising middle-class consumption, urbanization, and modernization of retail infrastructure will drive demand for resealable packaging. Additionally, geopolitical shifts and supply chain resilience concerns will lead to increased regional manufacturing of SLBCs, reducing reliance on single-source suppliers.

Technological Innovation and Material Science Advancements

Ongoing R&D will yield next-generation SLBCs featuring shape-memory alloys, multi-position locking mechanisms, or integration with smart labels (e.g., NFC tags for traceability). While full digitization remains limited, hybrid closures combining mechanical reliability with digital tracking capabilities may emerge in specialty applications. Material science will focus on improving fatigue resistance of the spring mechanism and UV stability for outdoor or long-term storage use.

In conclusion, the Spring Loaded Bag Closure market in 2026 will be defined by sustainability, automation readiness, and user-centric design. Companies investing in eco-innovation, precision engineering, and application-specific solutions will capture growing demand across diverse verticals.

Common Pitfalls Sourcing Spring Loaded Bag Closure (Quality, IP)

Sourcing spring loaded bag closures—commonly used in packaging for resealable bags in food, medical, or consumer goods—can present several challenges, particularly concerning quality consistency and intellectual property (IP) risks. Being aware of these pitfalls helps mitigate supply chain disruptions, legal issues, and brand damage.

Poor Material Quality and Durability

One of the most frequent quality issues is the use of substandard materials in the spring mechanism or housing. Low-grade plastics or metals can degrade quickly, leading to failure in the closure’s ability to snap shut or maintain a secure seal. This is especially critical in applications requiring hygiene or long-term reusability. Sourcing from suppliers without rigorous material certifications (e.g., FDA compliance for food contact, RoHS for electronics) increases the risk of field failures and customer complaints.

Inconsistent Manufacturing Tolerances

Spring loaded closures depend on precise engineering for reliable function. Inconsistent injection molding or spring tension due to lax quality control can result in high defect rates—such as misaligned parts, weak spring return, or difficulty in opening/closing. Suppliers lacking robust process validation or statistical process control (SPC) may deliver batches with variable performance, undermining product reliability.

Lack of Intellectual Property Due Diligence

Many spring loaded closure designs are protected by patents or design rights. Sourcing generic or unbranded versions from third-party manufacturers, especially in regions with weak IP enforcement, risks infringing on existing patents. Companies may unknowingly purchase closures that replicate patented mechanisms (e.g., specific latch geometries or spring configurations), exposing them to legal action, import bans, or forced redesigns.

Supplier Transparency and Traceability Gaps

Suppliers may not fully disclose the origin of components or manufacturing processes. This lack of traceability complicates quality investigations and regulatory compliance. For instance, if a closure fails during use, determining whether the fault lies in material sourcing, assembly, or design becomes difficult without transparent supply chain data.

Inadequate Testing and Certification

Reputable closures should undergo performance testing for cycle life, tensile strength, and environmental resistance (e.g., UV, temperature). Some suppliers provide limited or falsified test data, leading buyers to assume durability that isn’t there. Always verify independent test reports and request samples for in-house validation before scaling procurement.

Copycat Designs with Hidden IP Risks

Some suppliers offer “compatible” or “universal” closures that closely resemble proprietary designs (e.g., similar to those from知名品牌 like Kwik Lok or Velcro). While marketed as generic, these may still infringe on utility or design patents. Legal exposure increases if the buyer brands or distributes these closures widely, particularly in markets with strong IP enforcement like the U.S. or EU.

Conclusion

To avoid these pitfalls, conduct thorough supplier audits, request material and IP documentation, and engage legal counsel to assess freedom-to-operate. Prototyping and third-party testing should precede mass orders. Prioritizing transparency and compliance ensures durable, legally safe closures that support brand integrity.

Logistics & Compliance Guide for Spring Loaded Bag Closure

This guide outlines the key logistics and compliance considerations for the distribution, handling, and regulatory adherence of Spring Loaded Bag Closure products. Adherence to these guidelines ensures product safety, legal compliance, and efficient supply chain operations.

Product Specifications and Handling Requirements

- Material Composition: The Spring Loaded Bag Closure is constructed from food-grade polypropylene (PP) and stainless steel spring components, meeting FDA 21 CFR §177.1520 and EU Regulation (EC) No 10/2011 for food contact materials.

- Temperature Tolerance: Store and transport between 0°C and 45°C (32°F to 113°F). Avoid prolonged exposure to direct sunlight or extreme cold.

- Handling Instructions: Handle with clean, dry hands or gloves. Avoid dropping or applying excessive force to prevent spring mechanism damage.

- Packaging: Units are shipped in recyclable corrugated cardboard master cases (dimensions: 30 x 20 x 15 cm). Each case contains 10 inner boxes of 100 closures (1,000 units per case).

Shipping and Transportation

- Domestic Shipments (US): Compliant with DOT 49 CFR for non-hazardous goods. Use standard parcel or LTL freight depending on volume. Label with appropriate handling symbols: “Fragile,” “Keep Dry,” and “Do Not Stack Over 5 Cases.”

- International Shipments:

- Ensure compliance with IATA and IMDG regulations (non-hazardous classification).

- Provide MSDS/SDS upon request (product classified as non-regulated).

- Include customs documentation: Commercial invoice, packing list, and Certificate of Origin (preferably Form A for GSP-eligible countries).

- Cold Chain Requirements: Not applicable.

Regulatory Compliance

- FDA Compliance (USA): Product is registered under FDA Device Listing (if applicable to closure use in medical packaging) and complies with food contact substance regulations.

- REACH & RoHS (EU): Fully compliant with EU REACH (EC 1907/2006) and RoHS 2 (2011/65/EU). No SVHCs above threshold; lead and heavy metal content within limits.

- UKCA Marking: Required for UK market; technical documentation available upon request.

- Proposition 65 (California): Product does not contain chemicals listed under California Proposition 65 requiring warning labels.

Import/Export Documentation

- Harmonized System (HS) Code: 3926.30.00 (Plastic articles of stationery or office supplies – other).

- Export Control Classification Number (ECCN): EAR99 (No license required for most destinations).

- Required Documentation:

- Commercial Invoice

- Packing List

- Bill of Lading/Air Waybill

- Certificate of Conformity (available on request)

- Certificate of Origin (for preferential tariffs)

Storage and Inventory Management

- Warehouse Conditions: Store in dry, well-ventilated areas away from chemicals and moisture. Max stacking height: 5 cases (75 cm / 2.5 ft).

- Shelf Life: Indefinite under proper storage conditions. Inspect closures periodically for spring tension and housing integrity.

- Inventory Rotation: Implement FIFO (First In, First Out) protocol to maintain product quality.

Product Labeling and Traceability

- Unit Labeling: Each closure is marked with batch/lot number and manufacturing date (YYMMDD format).

- Case Labeling: Includes product name, SKU, quantity, lot number, manufacturing date, expiry (if applicable), HS code, and handling symbols.

- Traceability System: Batch tracking via ERP system. Full traceability from raw material to finished goods available for 5 years.

Environmental and Disposal Compliance

- Recyclability: Polypropylene housing is recyclable (Resin Identification Code 5). Stainless steel spring should be separated before recycling.

- WEEE Directive: Not applicable (not electrical/electronic equipment).

- Disposal: Follow local municipal waste regulations. Do not incinerate without proper filtration due to potential particulates.

Customer Support and Incident Reporting

- Compliance Inquiries: Direct to [email protected].

- Product Defects or Non-Conformances: Report immediately using the online Non-Conformance Report (NCR) form.

- Recall Procedure: In the event of a product recall, follow ISO 1041:2023 labeling and communication protocols. Notify distributor and end-user within 24 hours of issue identification.

Adherence to this guide ensures safe, legal, and efficient movement of Spring Loaded Bag Closure products across global markets. For updates or specific regional requirements, consult the Compliance Department.

Conclusion: Sourcing Spring-Loaded Bag Closure

After a thorough evaluation of suppliers, materials, functionality, and cost considerations, sourcing spring-loaded bag closures presents a reliable and efficient solution for enhancing bag security, convenience, and reusability. These closures offer consistent performance, durability, and ease of use across various applications, including food packaging, medical supplies, and consumer goods.

Key findings indicate that sourcing from manufacturers with strong quality control, competitive pricing, and customization capabilities ensures optimal product integration and long-term value. Additionally, prioritizing suppliers who use sustainable materials and ethical production practices supports environmental and corporate social responsibility goals.

In conclusion, investing in high-quality spring-loaded bag closures from reputable suppliers not only improves product functionality and customer satisfaction but also contributes to operational efficiency and brand reputation. A strategic sourcing approach will enable long-term cost savings and supply chain resilience, making spring-loaded closures a worthwhile addition to packaging solutions.