The global speaker cable market is experiencing steady expansion, driven by rising demand for high-fidelity audio systems in residential, commercial, and automotive applications. According to Grand View Research, the global audio cable market size was valued at USD 2.1 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by advancements in audio technology, increasing consumer preference for premium sound quality, and the proliferation of home theater and immersive audio setups. As speaker cable performance heavily depends on the quality of termination, the demand for reliable, high-conductivity cable ends has risen in tandem. With manufacturers prioritizing signal integrity, durability, and ease of connectivity, a competitive landscape of specialized producers has emerged. The following list highlights the top nine speaker cable ends manufacturers shaping the industry through innovation, product consistency, and broad market reach.

Top 9 Speaker Cable Ends Types Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Types of Electrical Connectors and Wire Connectors

Domain Est. 1992

Website: te.com

Key Highlights: From USB connectors and RJ45 connectors to TE’s DEUTSCH connectors and AMP connectors, we design and manufacture the electrical connectors and wire connectors ……

#2 speakON® Cable Connectors

Domain Est. 1996

Website: neutrik.com

Key Highlights: The speakON cable connectors are the industry-standard connectors for amplifier / loudspeaker connections. The entire family of 2, 4 and 8 pole cable connectors ……

#3 Cardas Cables

Domain Est. 1996

Website: cardas.com

Key Highlights: This page allows you to browse our cables by product line (Clear, Parsec, Iridium, etc.), or by type (speaker, interconnect, power, etc.)…

#4 WBT

Domain Est. 1996

Website: wbtusa.com

Key Highlights: The product line has expanded from the first RCA type plug to include male and female RCA type connectors, binding posts, banana plugs and spade lugs with ……

#5 REAN Connectors

Domain Est. 2004

Website: rean-connectors.com

Key Highlights: REAN offers designers of audio, video and lighting products a comprehensive range of connectors featuring ultra-robust, high-reliability designs….

#6 High End Audio & Video from The Cable Company

Domain Est. 2005

#7 Cables

Domain Est. 2010

Website: warmaudio.com

Key Highlights: Premier Series Cables. Rugged cables with exacting construction, powerful EMI/RFI rejection, premium connectors and a lifetime warranty….

#8 Elite Core

Domain Est. 2010

Website: elitecoreaudio.com

Key Highlights: Free delivery 30-day returnsElite Core is headquartered in Greenbrier, Arkansas. We manufacture and distribute professional audio, video, and lighting equipment to clients around t…

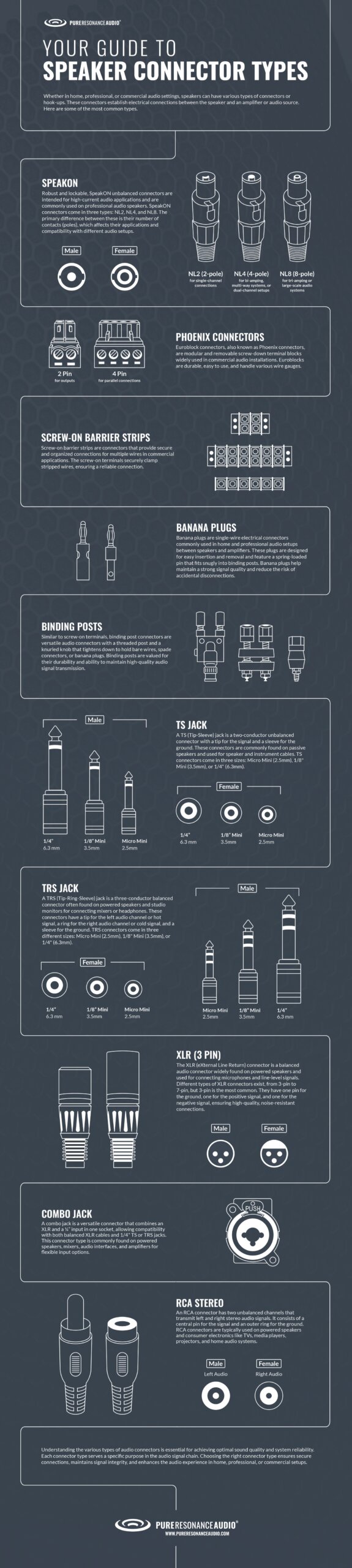

#9 A Guide to Speaker Connector Types

Domain Est. 2010

Website: seetronic.com

Key Highlights: This guide will walk you through different types of speaker connectors, explain where each type works best, and provide practical tips for ……

Expert Sourcing Insights for Speaker Cable Ends Types

H2: 2026 Market Trends for Speaker Cable Ends Types

The global market for speaker cable ends is poised for significant evolution by 2026, driven by advancements in audio technology, growing consumer demand for high-fidelity sound systems, and the proliferation of smart audio devices. As audiophiles and mainstream consumers alike seek improved connectivity and signal integrity, various types of speaker cable ends are experiencing shifts in demand, innovation, and application.

1. Rising Demand for High-Purity and Oxygen-Free Copper (OFC) Terminations

By 2026, speaker cable ends made with oxygen-free copper (OFC) are expected to dominate premium audio markets. These terminations minimize signal loss and resist oxidation, ensuring long-term performance. Manufacturers are increasingly integrating OFC-compatible connectors such as banana plugs and spade connectors, especially in high-end home theater and studio environments.

2. Growth of Banana Plugs as the Preferred Connector Type

Banana plugs are projected to maintain their position as the most popular speaker cable end due to their ease of use, secure fit, and compatibility with most modern AV receivers and speakers. The trend toward sleek, gold-plated banana plugs with insulation sleeves is accelerating, driven by both performance benefits and aesthetic appeal. The DIY audio community and custom installers are key drivers of this trend.

3. Increased Adoption of Spade Connectors in High-Fidelity Setups

Spade connectors are gaining traction in audiophile circles for their superior surface contact and ability to handle high power loads. As high-resolution audio and lossless streaming become mainstream, the need for reliable, low-resistance connections is pushing demand for high-quality spade terminals. Innovations such as dual-spade designs and anti-loosening mechanisms are expected to enhance their market appeal by 2026.

4. Expansion of Pin Connectors in Compact and Portable Audio Systems

With the rise of compact Bluetooth speakers, soundbars, and mini amplifiers, pin connectors are seeing renewed interest. These small-form-factor terminations are ideal for space-constrained applications. Advances in miniaturization and corrosion-resistant plating (e.g., nickel or rhodium) are improving their durability and signal consistency, making them more attractive for OEM audio equipment.

5. Emergence of Smart and Modular Connector Systems

By 2026, smart speaker cable ends with integrated diagnostics or modular designs are expected to enter the market. These connectors may feature built-in contact sensors or quick-swap mechanisms, allowing users to reconfigure setups easily. While still in early stages, such innovations are likely to appeal to tech-savvy consumers and professional installers seeking plug-and-play convenience.

6. Sustainability and Material Innovation

Environmental concerns are influencing material choices in cable end manufacturing. Recyclable metals, lead-free soldering, and bio-based insulation materials are becoming more common. Brands emphasizing eco-friendly production processes are likely to gain market share, particularly in Europe and North America.

7. Regional Market Dynamics

North America and Europe will remain key markets for premium speaker cable ends, fueled by home automation and high-end audio investments. Meanwhile, the Asia-Pacific region, especially China and India, is expected to see rapid growth in mid-tier connector sales due to rising disposable incomes and urbanization.

In conclusion, the 2026 speaker cable ends market will be shaped by a convergence of performance demands, aesthetic preferences, and technological innovation. Banana and spade connectors will lead in performance segments, while material quality, smart features, and sustainability will increasingly influence purchasing decisions across all consumer tiers.

Common Pitfalls When Sourcing Speaker Cable Ends: Quality and Intellectual Property Concerns

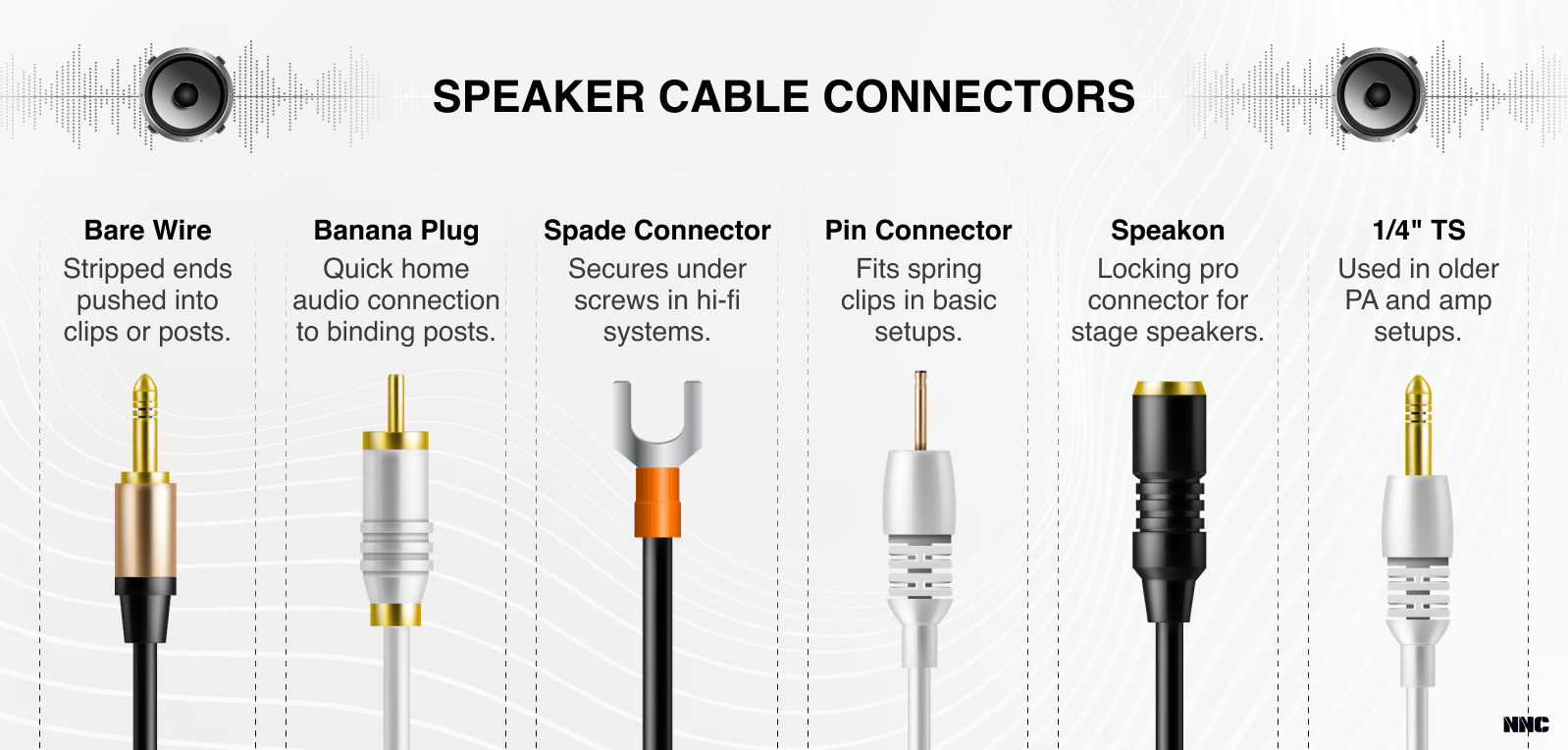

Sourcing speaker cable ends—such as banana plugs, spade connectors, pin connectors, and spades—may seem straightforward, but several pitfalls can impact both performance and legal compliance. Overlooking quality and intellectual property (IP) issues can lead to poor audio performance, customer dissatisfaction, safety hazards, or even legal disputes. Below are critical considerations to avoid common mistakes.

Poor Material Quality and Construction

One of the most frequent pitfalls is selecting speaker cable ends made from substandard materials. Low-quality connectors often use brass with high zinc content, aluminum, or even plastic-coated metal, which increase electrical resistance and degrade signal transmission. Poor plating (e.g., thin or non-uniform gold, nickel, or silver coatings) leads to oxidation and corrosion over time, resulting in intermittent connections and reduced audio fidelity. Additionally, weak clamping mechanisms or poorly designed strain relief can cause loose connections or cable damage.

Tip: Always verify material specifications—look for oxygen-free copper (OFC), robust plating thickness (e.g., 24k gold over nickel barrier), and secure crimp or screw terminals.

Inconsistent Tolerances and Fit

Low-cost connectors often suffer from inconsistent manufacturing tolerances. This can lead to poor fit with binding posts or sockets, resulting in wobbling, partial contact, or difficulty inserting/removing connectors. Incompatibility with specific amplifier or speaker terminals may frustrate end users and reflect poorly on the brand sourcing them.

Tip: Request samples and test-fit connectors with common industry-standard terminals before bulk ordering.

Misrepresentation of IP and Trademark Violations

A major legal pitfall involves sourcing counterfeit or IP-infringing products. Some suppliers offer “compatible” versions of well-known branded connectors (e.g., those resembling brands like Furutech, WBT, or Neutrik). However, these may infringe on design patents, trademarks, or utility models. Using such components exposes the buyer to intellectual property litigation, customs seizures, and brand reputation damage.

Tip: Conduct due diligence on supplier legitimacy. Avoid products labeled with names or designs too similar to established brands. Request proof of IP clearance or licensing when in doubt.

Lack of Compliance and Safety Certification

Speaker cable ends—especially those used in consumer or commercial AV systems—may need to meet safety and regulatory standards (e.g., UL, CE, RoHS). Inferior connectors may use flammable plastics or fail to meet temperature and current rating requirements, posing fire or electrical hazards. Sourcing non-compliant parts can lead to product recall and liability issues.

Tip: Ensure connectors are rated for appropriate current and voltage, and confirm compliance with regional safety standards relevant to your market.

Hidden Costs from High Failure Rates

While low-cost connectors may appear economical upfront, poor quality often results in higher long-term costs due to returns, warranty claims, and labor for replacements. High failure rates damage brand reputation and erode customer trust.

Tip: Calculate total cost of ownership (TCO), factoring in expected lifespan, failure rates, and customer support needs, rather than focusing solely on unit price.

Inadequate Supply Chain Transparency

Many suppliers, especially those based in regions with less stringent IP enforcement, may lack transparency about manufacturing origins or material sources. This opacity increases the risk of receiving non-compliant or counterfeit parts and makes it difficult to verify quality control processes.

Tip: Work with reputable suppliers who provide traceability, audit reports, and clear documentation of materials and manufacturing practices.

By proactively addressing these pitfalls—prioritizing material quality, fit precision, IP compliance, safety certification, and supply chain integrity—businesses can source speaker cable ends that ensure reliable performance and legal safety.

Logistics & Compliance Guide for Speaker Cable Ends Types

When managing the logistics and compliance of speaker cable ends, it’s essential to understand the various connector types, their international shipping requirements, regulatory standards, and handling protocols. This guide outlines key considerations for manufacturers, distributors, and installers to ensure safe, legal, and efficient handling of speaker cable ends.

Connector Types and Material Considerations

Different speaker cable end types—such as banana plugs, spade connectors, pin connectors, and bare wire terminations—require specific handling and packaging due to their materials (e.g., copper, gold plating, nickel, or tin). Conductive metals may be subject to RoHS (Restriction of Hazardous Substances) compliance in the EU and similar regulations globally. Ensure all finishes and materials meet RoHS, REACH, and IPC standards where applicable.

Packaging and Labeling Requirements

Proper packaging is critical to prevent damage during transit. Individual connectors should be sealed in anti-static bags or blister packs, especially if gold or silver-plated. Bulk quantities must be packed in rigid containers to avoid crushing. Labels must include:

- Product type (e.g., “1/4″ Banana Plug, Gold-Plated”)

- Material composition

- Compliance markings (e.g., CE, RoHS)

- Country of origin

- Quantity and part number

Use multilingual labels when shipping internationally to comply with local customs requirements.

International Shipping and Customs Documentation

When shipping speaker cable ends across borders:

- Provide a detailed commercial invoice specifying HTS (Harmonized Tariff Schedule) code. For most speaker connectors, this may fall under 8536.90 (electrical apparatus for switching or protecting electrical circuits).

- Declare accurate product value, weight, and quantity.

- Include a packing list and, if required, a certificate of conformity (CoC) for EU or UKCA markets.

- Be aware of import restrictions on certain metals in specific countries (e.g., conflict minerals regulations in the U.S. under Dodd-Frank Act Section 1502).

Regulatory Compliance

Ensure all speaker cable end products comply with relevant regional and international standards:

- North America: UL 62 (Standard for Flexible Cords and Cables), FCC Part 15 (for any shielded or data-capable cables)

- European Union: Low Voltage Directive (LVD), Electromagnetic Compatibility (EMC) Directive, RoHS, REACH

- UK: UKCA marking (post-Brexit compliance)

- Australia/New Zealand: RCM (Regulatory Compliance Mark)

Third-party testing and certification may be required; retain documentation for audits.

Storage and Handling Protocols

- Store in a dry, temperature-controlled environment to prevent oxidation of metal contacts.

- Avoid exposure to corrosive chemicals or high humidity.

- Use ESD-safe handling procedures in manufacturing and warehousing to protect sensitive plating.

Environmental and Disposal Compliance

Dispose of defective or excess speaker cable ends as electronic waste (e-waste) in accordance with local environmental regulations. Recycle metals through certified e-waste processors to comply with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions.

By adhering to these logistics and compliance guidelines, businesses can ensure the safe, legal, and efficient distribution of speaker cable ends globally while minimizing risk and maintaining product integrity.

Conclusion on Sourcing Speaker Cable Ends (Connectors)

When sourcing speaker cable ends, the choice of connector type should be guided by the specific application, equipment compatibility, desired audio performance, and ease of use. Common options such as banana plugs, spade connectors, pin connectors, and bare wire each offer distinct advantages and limitations.

Banana plugs provide a secure, reliable connection with excellent conductivity and are ideal for frequent setup changes or high-end audio systems. Spade connectors offer strong, stable contact—especially useful for binding posts that cannot accommodate banana plugs. Pin connectors are simple and compact but less secure than other types, making them better suited for semi-permanent installations. Bare wire connections, while the most basic and cost-effective, are prone to fraying and short circuits, and are best reserved for systems where connectors are not supported.

Ultimately, banana plugs represent the optimal balance of performance, convenience, and durability for most modern audio setups. When sourcing connectors, prioritize high-quality materials—such as oxygen-free copper and gold plating—to minimize resistance and prevent corrosion. Additionally, ensure compatibility with both cable gauge and speaker/receiver terminal types to achieve a safe and efficient connection. Properly selected and installed speaker cable ends enhance signal integrity, simplify installation, and contribute to a clean, professional audio system setup.