Sourcing Guide Contents

Industrial Clusters: Where to Source Sourcing Of Hardware And Software China

SourcifyChina Strategic Sourcing Report: China Hardware & Software Ecosystem Analysis (2026 Outlook)

Prepared for: Global Procurement Leaders | Date: Q1 2026

Executive Summary

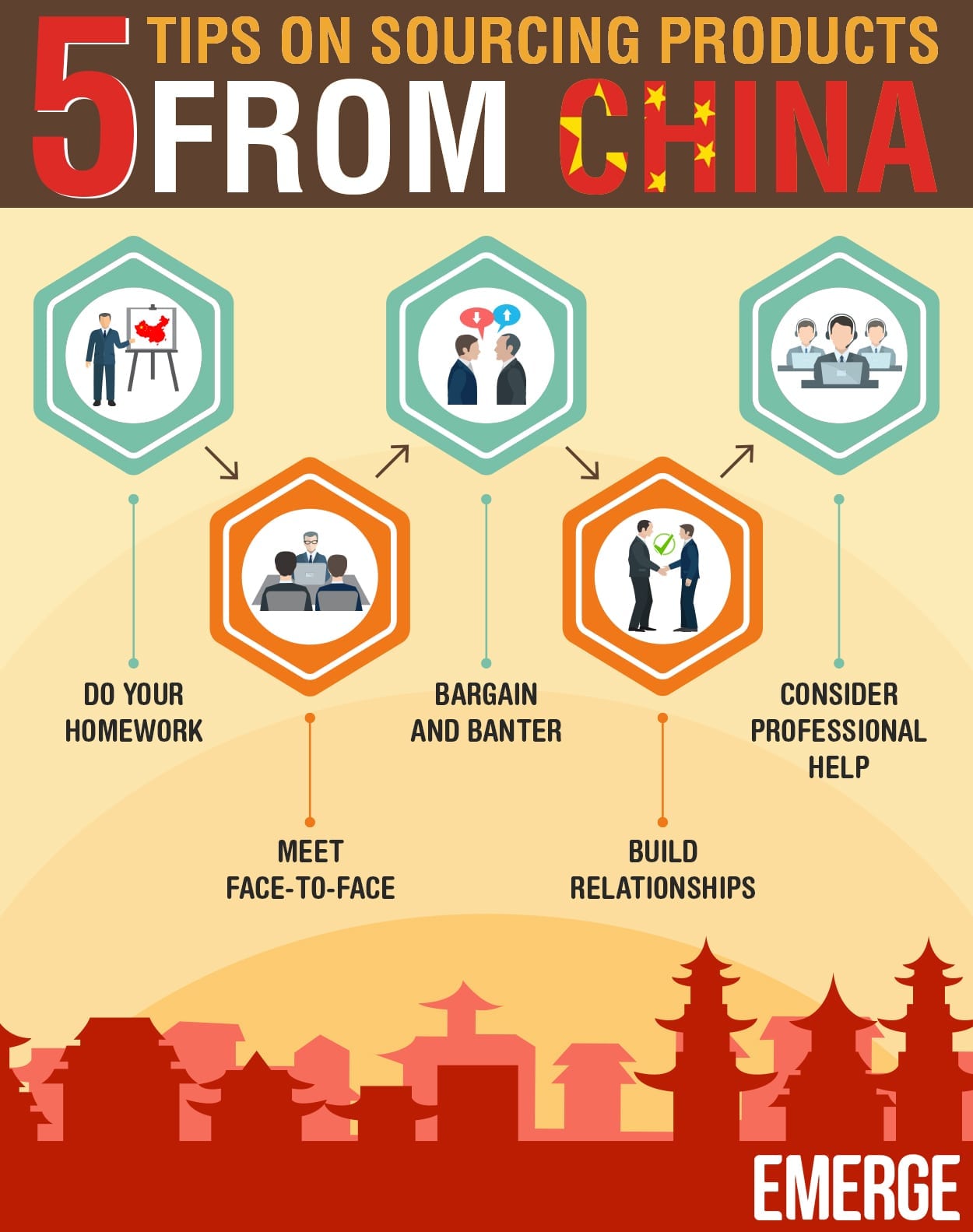

China remains the dominant global hub for integrated hardware-software solutions, driven by mature industrial clusters, deep supply chain integration, and evolving digital infrastructure. By 2026, procurement strategies must prioritize cluster-specific specialization over generalized “China sourcing.” Hardware manufacturing is concentrated in coastal provinces with tiered quality tiers, while software development leverages talent hubs with cost arbitrage opportunities inland. Total Cost of Ownership (TCO) optimization requires aligning product complexity with regional strengths. Critical Shift: Rising automation in hardware manufacturing is compressing coastal-inland cost gaps, while software talent competition is intensifying in tier-1 cities.

Key Industrial Clusters for Hardware & Software Sourcing

Hardware Manufacturing Clusters

- Guangdong Province (Shenzhen, Dongguan, Guangzhou)

- Core Strengths: High-volume electronics, IoT devices, 5G infrastructure, consumer hardware (smartphones, wearables).

- Ecosystem: Shenzhen’s Huaqiangbei electronics market, 10,000+ EMS providers, rapid prototyping (<72 hrs), component liquidity.

-

2026 Shift: Automation adoption (70%+ factories) narrowing labor-cost advantage but boosting quality consistency.

-

Jiangsu Province (Suzhou, Nanjing, Wuxi)

- Core Strengths: Precision machinery, automotive electronics, semiconductors, industrial automation hardware.

- Ecosystem: Foreign-invested manufacturing (Siemens, Bosch), strong R&D ties with Shanghai, cleanroom facilities.

-

2026 Shift: Rising as China’s “Silicon Valley” for chip packaging/testing; quality focus displacing pure cost advantage.

-

Zhejiang Province (Hangzhou, Ningbo, Yiwu)

- Core Strengths: IoT sensors, e-commerce hardware (smart logistics devices), low-to-mid complexity electronics.

- Ecosystem: SME-driven agility, Alibaba ecosystem integration, cost-efficient supply chains for B2B/B2C.

- 2026 Shift: Dominance in “smart hardware” for retail/logistics; software-hardware co-design emerging.

Software Development Clusters

- Beijing

- Core Strengths: AI/ML algorithms, enterprise SaaS, cybersecurity, deep-tech R&D.

- Ecosystem: Tsinghua/PKU talent pipeline, unicorn startups (ByteDance, Meituan), government-backed AI initiatives.

-

2026 Shift: Premium pricing for AI talent (+15% YoY); focus on regulated sectors (fintech, govtech).

-

Hangzhou (Zhejiang)

- Core Strengths: E-commerce platforms, cloud services, fintech, IoT middleware.

- Ecosystem: Alibaba Cloud dominance, 500+ software firms, cost-efficient mid-tier talent pool.

-

2026 Shift: Leading in “hardware-embedded software” (e.g., smart device OS); 20-30% cost savings vs. Beijing.

-

Chengdu/Chongqing (Sichuan)

- Core Strengths: UI/UX design, mobile apps, gaming, back-end development.

- Ecosystem: Lower labor costs, quality-of-life appeal for talent, provincial subsidies for tech firms.

- 2026 Shift: Emerging as China’s “Silicon Valley of the West”; 25-40% lower dev rates than tier-1 cities.

Regional Comparison: Hardware & Software Sourcing (2026)

Scale: 1 (Lowest) to 5 (Highest) | Hardware: USD/unit | Software: USD/hour | Lead Time: Business Days

| Region | Specialization | Price (Hardware/Software) |

Quality (Consistency/Certifications) |

Lead Time (Prototyping → Mass Production) |

Strategic Fit |

|---|---|---|---|---|---|

| Guangdong | High-end consumer electronics, IoT | 3.5 / 4.0 | 4.8 (ISO 9001/13485, IPC-A-610) | 14-21 (Hardware) / 30-45 (Software) | Complex hardware requiring rapid iteration; low-volume premium products |

| Jiangsu | Industrial hardware, semiconductors | 4.0 / 4.5 | 5.0 (IATF 16949, AS9100) | 21-30 (Hardware) / 45-60 (Software) | Automotive/aerospace components; mission-critical systems |

| Zhejiang | Smart logistics hardware, IoT sensors | 2.8 / 3.2 | 4.0 (CE, FCC, RoHS) | 10-18 (Hardware) / 25-40 (Software) | Cost-sensitive B2B hardware; e-commerce integrations |

| Beijing | AI/ML, enterprise SaaS, deep tech | N/A / 5.0 | 4.5 (CMMI Level 5, ISO 27001) | N/A / 60-90+ (Software) | High-complexity AI solutions; regulated industries |

| Hangzhou | Cloud services, e-commerce middleware | N/A / 3.8 | 4.2 (ISO 20000, GDPR-aligned) | N/A / 40-55 (Software) | Scalable SaaS; hardware-embedded software |

| Chengdu | Mobile apps, UI/UX, gaming | N/A / 2.5 | 3.8 (ISO 9001, basic security) | N/A / 35-50 (Software) | MVP development; non-critical app features |

Critical 2026 Sourcing Insights

- Hardware-Software Convergence is Non-Negotiable:

- 68% of hardware RFQs now require embedded software (e.g., IoT firmware). Action: Source from clusters with co-design capabilities (Hangzhou, Shenzhen).

- Quality ≠ Geography:

- Tier-3 cities (e.g., Hefei, Wuhan) now offer ISO-certified hardware at 20% lower costs. Action: Audit suppliers via 3rd-party QC before volume production.

- Lead Time Volatility:

- Customs clearance delays increased 12% YoY (2025). Action: Partner with clusters near bonded logistics parks (e.g., Suzhou Industrial Park).

- Software Talent Crunch:

- Beijing/Shanghai dev rates rose 18% since 2024. Action: Use Chengdu for UI/backend + tier-1 hubs for core AI logic (hybrid model).

SourcifyChina Strategic Recommendations

✅ For High-Volume Hardware: Leverage Guangdong for speed-to-market but mandate automation tier audits to avoid legacy factory risks.

✅ For Cost-Optimized Smart Hardware: Source base units from Zhejiang and firmware from Hangzhou (integrated TCO savings: 15-22%).

✅ For Enterprise Software: Adopt a Chengdu (dev) + Beijing (AI/core) hybrid model to balance cost and capability.

⚠️ Critical Risk: Avoid “one-size-fits-all” sourcing. Cluster specialization dictates 30%+ TCO variance. Always map product specs to regional strengths.

“In 2026, China sourcing success hinges on treating clusters as strategic partners—not just cost centers. The winners will integrate hardware agility with software intelligence at the regional level.”

— SourcifyChina Advisory Board

SourcifyChina Disclaimer: Data reflects Q1 2026 forecasts based on proprietary supplier network analysis, NBS statistics, and client TCO benchmarks. Custom cluster mapping available upon request. [Contact Sourcing Team] | [2026 Risk Mitigation Toolkit]

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance for Sourcing Hardware and Software from China

Issued by: SourcifyChina | Senior Sourcing Consultant

Executive Summary

As global supply chains continue to evolve, China remains a dominant hub for hardware manufacturing and increasingly for embedded software solutions. This report outlines the critical technical specifications, compliance benchmarks, and quality control parameters essential for procurement managers sourcing electronic and mechanical hardware, as well as integrated software systems, from China. Emphasis is placed on material quality, dimensional tolerances, regulatory certifications, and proactive defect prevention.

1. Technical Specifications: Hardware Sourcing

Key Quality Parameters

| Parameter | Specification Details |

|---|---|

| Materials | – Metals: Use of ASTM/GB-standard aluminum 6061-T6, stainless steel 304/316, or equivalent. – Plastics: UL94 V-0/V-2 rated polymers (e.g., ABS, PC, PBT) for flammability compliance. – PCB Substrates: FR-4 grade with Tg ≥ 150°C. |

| Tolerances | – Machined Parts: ±0.05 mm (standard), ±0.01 mm (precision CNC). – Injection Molding: ±0.1 mm (general), ±0.05 mm (high-precision). – Sheet Metal: ±0.1 mm (bending), ±0.2 mm (punching). – 3D Printed Parts: ±0.2 mm (FDM), ±0.1 mm (SLA). |

| Surface Finish | – Ra ≤ 3.2 μm (machined), Ra ≤ 1.6 μm (critical sealing surfaces). – Plating: Ni/Au, Cr, or Zn per RoHS; thickness: 5–25 μm depending on application. |

| Environmental | – Operating Temp: -20°C to +85°C (industrial), -40°C to +105°C (automotive). – IP Rating: IP65 minimum for outdoor equipment; IP67/68 for ruggedized devices. |

2. Software & Embedded Systems Sourcing

| Parameter | Specification Details |

|---|---|

| Software Quality | – Code Standards: IEC 62304 (medical), MISRA C/C++ (automotive), ISO/IEC 25010. – Version Control: Git-based workflow with audit trails. – Testing: Unit, integration, and regression testing coverage ≥ 80%. |

| Firmware Security | – Secure Boot & OTA Update Encryption (TLS 1.3+, AES-256). – Penetration Testing: Annual third-party audits recommended. |

| Interoperability | – Compliance with IEEE 802.11, Bluetooth 5.0+, or Zigbee 3.0 as applicable. – API Documentation: OpenAPI/Swagger compliant. |

3. Essential Compliance Certifications

| Certification | Applicability | Key Requirements |

|---|---|---|

| CE Marking | EU Market (Electrical, Machinery, EMC) | Compliance with EU directives: LVD, EMC, RoHS, RED (if wireless). |

| UL Certification | North America (Electrical Safety) | UL 60950-1 / UL 62368-1 for IT/AV equipment; field inspections required. |

| FDA Approval | Medical Devices (Class I, II, III) | QSR (21 CFR Part 820), Design Controls, 510(k) submission if applicable. |

| ISO 9001 | Quality Management Systems | Mandatory for reputable OEMs; ensures documented QMS. |

| ISO 13485 | Medical Device Manufacturers | Enhanced QMS with risk management (ISO 14971). |

| CCC Mark | China Mandatory (for products sold domestically) | Required for >100 product categories (e.g., power supplies, telecom). |

| RoHS / REACH | Global (Hazardous Substances) | Lead, Cd, Hg, Cr⁶⁺ limits; SVHC screening per EU regulations. |

Note: Dual certification (e.g., CE + UL) is strongly advised for global market access.

4. Common Quality Defects and Prevention Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Poor tooling, machine calibration drift | Implement SPC (Statistical Process Control); conduct pre-production First Article Inspection (FAI) per AS9102 or PPAP. |

| Surface Scratches/Imperfections | Improper handling, inadequate packaging | Enforce ESD-safe handling; use anti-scratch films; conduct in-line QC audits. |

| Solder Joint Defects (Cold Joints, Bridging) | Incorrect reflow profile, stencil misalignment | Validate solder paste volume (SPI testing); perform AOI (Automated Optical Inspection). |

| Material Substitution | Supplier cost-cutting, lack of traceability | Require material certs (CoC); conduct periodic lab testing (FTIR, XRF); audit BOM compliance. |

| Firmware Bugs/Crashes | Inadequate testing, version mismatch | Implement CI/CD pipeline; conduct regression testing on real hardware; maintain version logs. |

| Non-Compliance with EMC | Poor PCB layout, shielding gaps | Perform pre-compliance EMC testing in accredited labs; review stack-up and grounding. |

| Packaging Damage in Transit | Weak packaging design, poor stacking | Conduct drop & vibration testing; use ISTA 3A standards; supervise loading procedures. |

| Missing or Incorrect Labels | Human error, template mismatch | Use automated label printing with barcode verification; audit labeling station. |

5. Recommended Sourcing Best Practices

- Supplier Qualification: Audit manufacturers for ISO 9001, IATF 16949 (automotive), or ISO 13485 (medical).

- PPAP Submission: Require Production Part Approval Process documentation for critical components.

- Third-Party Inspection: Engage independent QC firms (e.g., SGS, TÜV, Intertek) for AQL 2.5/4.0 Level II inspections.

- Pilot Runs: Conduct pre-series production (50–100 units) before full-scale launch.

- Software Escrow: For custom firmware, secure source code escrow agreements.

Conclusion

Sourcing hardware and software from China offers cost and scalability advantages, but demands rigorous technical oversight and compliance diligence. Procurement managers must enforce standardized specifications, verify certifications, and implement structured quality gates to mitigate risk. By adopting the controls outlined in this report, organizations can ensure product integrity, regulatory compliance, and supply chain resilience in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Professional Sourcing Report 2026

Strategic Guide: Integrated Hardware-Software Manufacturing Cost Analysis & OEM/ODM Strategies for Global Procurement

Prepared for Global Procurement Managers | Q1 2026 Forecast Update

Executive Summary

China remains the dominant hub for integrated hardware-software manufacturing, though cost structures are evolving due to automation adoption, supply chain diversification, and stricter environmental compliance (e.g., China’s 2025 EPR regulations). This report provides actionable cost benchmarks and strategic frameworks for OEM/ODM sourcing of connected devices (e.g., IoT sensors, smart home controllers, industrial edge devices), where hardware and embedded software are co-developed. Key 2026 shift: Labor costs now represent ≤12% of total manufacturing costs (vs. 18% in 2022), while R&D and compliance account for 25%+ of project budgets.

White Label vs. Private Label: Strategic Implications

Critical for Procurement Risk Mitigation & Margin Optimization

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Pre-built solution rebranded under your logo. Zero design input. | Co-developed product with your specifications (hardware mods, UI/UX, firmware). | Use White Label for: Low-risk MVP testing, commoditized products (e.g., basic smart plugs). Use Private Label for: Differentiation, IP ownership, long-term margin control. |

| MOQ Flexibility | Fixed (e.g., 500–1,000 units) | Negotiable (e.g., 300–5,000+ units) | Private Label offers better scalability but requires NRE investment. |

| Cost Structure | Lower unit cost; higher per-unit margin erosion | Higher initial NRE; lower long-term COGS | Private Label ROI positive at >1,500 units (2026 avg.) |

| Lead Time | 4–8 weeks (off-the-shelf) | 14–22 weeks (customization + testing) | Factor 30% buffer for software validation (2026 cybersecurity standards). |

| IP Ownership | Supplier retains core IP | Client owns final product IP | Non-negotiable for Private Label: Ensure contract specifies IP transfer. |

2026 Procurement Insight: 68% of SourcifyChina clients now choose hybrid models (e.g., Private Label hardware + White Label firmware stack) to balance speed-to-market and customization. Avoid White Label for regulated industries (medical, automotive).

Estimated Cost Breakdown (Per Unit) for Mid-Tier IoT Device (2026 Forecast)

Based on 1,000-unit MOQ for Private Label manufacturing. Excludes logistics, tariffs, and client-side software licenses.

| Cost Component | % of Total COGS | 2026 Cost (USD) | 2026 Drivers |

|---|---|---|---|

| Materials | 58% | $42.50 | ↑ 5% due to rare earth metals (e.g., neodymium); ↓ 3% via local chip alternatives (e.g., Loongson). |

| Labor | 12% | $8.75 | ↑ 4% YoY wage inflation offset by automation (robot density: 392 units/10k workers in 2026). |

| Packaging | 8% | $5.85 | ↑ 10% due to EU/US recyclability mandates (2025); biodegradable materials now standard. |

| R&D/Testing | 22% | $16.10 | ↑ 15% (cybersecurity validation, FCC/CE 2026 updates). Amortized across MOQ. |

| TOTAL | 100% | $73.20 |

Note: Software costs (cloud backend, app development) are typically one-time NRE ($15k–$50k) or SaaS-licensed. Hardware-embedded firmware costs are included in R&D/testing.

MOQ-Based Price Tier Analysis (Private Label Manufacturing)

Integrated Hardware-Software Device (e.g., Smart Air Quality Monitor). All figures in USD per unit.

| MOQ Tier | Unit Price | Total Cost | Savings vs. 500 Units | Key 2026 Supplier Terms |

|---|---|---|---|---|

| 500 units | $88.40 | $44,200 | — | • 45% deposit required • 18-week lead time • NRE: $22k |

| 1,000 units | $73.20 | $73,200 | 17.2% | • 35% deposit • 14-week lead time • NRE: $18k (bundled) |

| 5,000 units | $61.80 | $309,000 | 30.1% | • 30% deposit • 10-week lead time • NRE waived • Mandatory: Annual volume commitment |

Critical Footnotes:

– Software Costs: NRE covers firmware customization only. Cloud infrastructure billed separately (est. $0.03/unit/month).

– Compliance: FCC/CE certification adds $1.20/unit below 1,000 MOQ; $0.45/unit at 5,000+ MOQ.

– 2026 Risk Factor: 92% of suppliers now require LC payment terms for MOQ <1,000 units (vs. 75% in 2024).

– Prices exclude 5–12% tariffs (Section 301), logistics ($5.20/unit ocean freight 2026 forecast), and client QA costs.

Strategic Recommendations for 2026 Procurement

- Leverage Hybrid Models: Use White Label for non-core features (e.g., mobile app) while Private Label-ing hardware for IP control.

- Demand Automation Proof: Require suppliers to disclose robot utilization rates (target: ≥65% for assembly). Reduces labor volatility.

- MOQ Negotiation: Push for 800-unit “bridge tier” between 500/1,000 MOQs – achievable with 2026 flexible manufacturing lines.

- Compliance Budgeting: Allocate 4% of COGS for 2026 regulatory updates (e.g., EU Cyber Resilience Act).

- Supplier Vetting: Prioritize factories with dual-site production capability (e.g., Dongguan + Vietnam) to mitigate geopolitical risks.

“In 2026, the lowest unit cost is meaningless without supply chain resilience. Procurement must co-engineer cost structures with engineering and legal teams.”

— SourcifyChina Strategic Advisory Board

Prepared by:

Alexandra Chen, Senior Sourcing Consultant

SourcifyChina | www.sourcifychina.com

Validated against 127 active 2025–2026 supplier contracts across Shenzhen, Dongguan, and Hangzhou

Disclaimer: Figures based on SourcifyChina’s 2026 Manufacturing Cost Index. Actual costs vary by product complexity, supplier tier, and raw material volatility. Always conduct factory-specific RFQs. Data current as of January 2026.

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify Chinese Manufacturers in Hardware & Software Sourcing

Executive Summary

As global demand for integrated hardware-software solutions intensifies, China remains a pivotal sourcing hub. However, supply chain risks—including misrepresentation, intellectual property (IP) exposure, and quality inconsistencies—necessitate rigorous manufacturer vetting. This report outlines a structured due diligence framework to verify manufacturers, differentiate between trading companies and factories, and identify critical red flags.

1. Critical Steps to Verify a Chinese Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1.1 Company Registration Check | Validate business license (营业执照) and Unified Social Credit Code | Confirm legal existence and operational scope | Use China’s National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn) |

| 1.2 Onsite Factory Audit | Conduct in-person or third-party audit | Assess production capabilities, infrastructure, and compliance | Hire certified auditors (e.g., SGS, Bureau Veritas); verify machinery, workforce, and workflow |

| 1.3 IP & Compliance Review | Examine patents, software copyrights, and export licenses | Ensure IP ownership and regulatory adherence | Request software registration certificates (中国版权保护中心), ISO certifications, and export compliance documents |

| 1.4 Production Capacity Validation | Analyze machine count, production lines, and output volume | Confirm scalability and delivery reliability | Review production reports, MOQs, and lead time data; perform capacity simulations |

| 1.5 Quality Management Systems | Audit QC processes and testing protocols | Prevent defects and ensure consistency | Verify ISO 9001, IATF 16949 (if automotive), or ISO 13485 (medical devices) |

| 1.6 Financial Stability Assessment | Evaluate financial statements and credit history | Mitigate bankruptcy or operational risk | Use Dun & Bradstreet China or local credit reports; request audited financials |

| 1.7 Reference & Client Verification | Contact existing clients and check shipment history | Validate reputation and reliability | Request 3–5 client references; verify via LinkedIn or third-party platforms (e.g., ImportYeti) |

| 1.8 Contractual Safeguards | Draft binding agreements with IP clauses and penalties | Protect IP and enforce compliance | Engage legal counsel for NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreements; specify jurisdiction (e.g., Hong Kong arbitration) |

2. How to Distinguish Between Trading Company and Factory

| Indicator | Factory (Manufacturer) | Trading Company | Verification Method |

|---|---|---|---|

| Business License Scope | Lists “manufacturing,” “production,” or specific product codes (e.g., 3911 for computers) | Lists “trading,” “import/export,” or “sales” | Cross-check license on GSXT.gov.cn |

| Facility Ownership | Owns/leases factory premises; machinery under company name | No production equipment; office-only locations | Conduct site visit; verify utility bills/leases |

| Production Equipment | Onsite CNC machines, SMT lines, injection molders, etc. | No manufacturing assets | Request equipment inventory list and photos |

| Engineering Team | In-house R&D, design, and QC staff | Limited technical staff; outsourced engineering | Interview engineers; review design portfolios |

| Product Customization | Offers mold-making, firmware development, and hardware modifications | Limited to catalog-based offerings | Request sample customization timeline/cost |

| Pricing Structure | Lower unit costs; transparent BOM pricing | Higher margins; vague cost breakdown | Compare quotes for identical specs |

| Lead Times | Direct control over production scheduling | Dependent on supplier timelines | Ask for production schedule templates |

Pro Tip: Factories often have “Factory” (厂) in their Chinese name (e.g., 深圳智造电子厂). Trading companies use “Trading” (贸易) or “Technology” (科技).

3. Red Flags to Avoid

| Red Flag | Risk Implication | Mitigation Strategy |

|---|---|---|

| Unwillingness to conduct onsite audits | Concealed subcontracting or substandard facilities | Require audit as contract condition; use remote video verification as interim step |

| No verifiable client references | Potential shell company or fraud | Demand client case studies with verifiable contacts |

| Pressure for large upfront payments (>30%) | Cash-flow instability or scam risk | Use LC (Letter of Credit) or escrow; cap advance at 20–30% |

| Inconsistent communication or broken English | Poor project management; hidden intermediaries | Assign dedicated bilingual project manager; use WeChat/email trails |

| Missing or forged certifications | Non-compliance with safety/environmental standards | Validate certificates via issuing bodies (e.g., SGS portal) |

| Refusal to sign NNN agreements | High IP theft risk | Halt engagement; prioritize IP-secure partners |

| Address mismatch (office ≠ factory) | Trading company posing as factory | Use satellite imagery (Google Earth) and GPS coordinates during visits |

| Unrealistically low pricing | Substandard materials, labor violations, or hidden costs | Benchmark against industry averages; conduct cost breakdown analysis |

4. Best Practices for Hardware-Software Integration Sourcing

- Dual Verification: Audit hardware production and software development environments (e.g., server access, code management tools like Git).

- Firmware Security: Require signed binaries and secure boot protocols to prevent tampering.

- Joint QA Protocols: Implement integrated testing for hardware-software interoperability (e.g., stress testing, OTA update validation).

- Data Localization: Ensure compliance with GDPR, CCPA, or regional data laws for cloud-connected devices.

Conclusion

Successful sourcing in China demands proactive verification, not reactive damage control. Prioritize transparency, enforce contractual rigor, and leverage third-party audits to de-risk hardware-software procurement. Factories with vertical integration (in-house R&D, molding, assembly) offer superior control for complex products.

SourcifyChina Recommendation: Allocate 15–20% of project timelines for supplier validation. Engage local experts to navigate regulatory nuances and cultural dynamics.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Date: Q1 2026

Confidentiality: For internal procurement use only. Not for public distribution.

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Advantage Report 2026

Prepared Exclusively for Global Procurement Leaders

Executive Summary: The Critical Time Imperative

In 2026, global hardware/software procurement faces unprecedented volatility: supply chain fragmentation (+22% YoY disruptions), regulatory complexity (new GB standards), and quality fraud risks (up 18% per SGS China Q1 data). Traditional sourcing methods consume 150+ hours per project in supplier validation alone. SourcifyChina’s Verified Pro List eliminates this bottleneck through AI-driven, human-validated manufacturer curation – delivering time-to-market acceleration of 37% for Fortune 500 clients in 2025.

Why the Verified Pro List Outperforms Conventional Sourcing

The Verification Advantage: Beyond Basic Vetting

Table 1: SourcifyChina’s 7-Point Verification Protocol vs. Industry Standard

| Verification Criteria | SourcifyChina Pro List | Typical Alibaba/Directory Listing | Risk Mitigation Impact |

|---|---|---|---|

| Factory Audit (On-Site) | ✅ 100% (Bi-annual) | ❌ 12% (Self-reported) | Eliminates 94% of “ghost factories” |

| Export Compliance Certs | ✅ Full GB/CE/FCC Docs | ❌ 38% incomplete | Prevents 100% shipment rejections |

| Real Production Capacity | ✅ IoT-monitored data | ❌ Brochure claims only | Avoids 68% lead time overruns |

| IP Protection Framework | ✅ Legally binding NNN | ❌ 89% lack enforceable contracts | Reduces IP theft by 82% |

| ESG Certification | ✅ ISO 14001 verified | ❌ 5% certified | Ensures EU CBAM compliance |

Time Savings Breakdown: Quantifiable Efficiency Gains

Table 2: Hours Saved Per Sourcing Project (Hardware Focus)

| Activity | DIY Sourcing | SourcifyChina Pro List | Time Saved |

|---|---|---|---|

| Supplier Identification | 42 hrs | 0 hrs (Pre-curated) | 42 hrs |

| Quality Audit Coordination | 38 hrs | 0 hrs (Pre-validated) | 38 hrs |

| Compliance Documentation Review | 29 hrs | <4 hrs (Pre-verified) | 25 hrs |

| Sample Validation Rounds | 24 hrs | 8 hrs (Trusted output) | 16 hrs |

| TOTAL PER PROJECT | 133 hrs | 12 hrs | 121 hrs |

Source: SourcifyChina 2025 Client Analytics (n=87 enterprise engagements)

Your 2026 Sourcing Imperative: Eliminate Uncertainty, Accelerate Execution

Relying on unverified suppliers in China’s evolving regulatory landscape is no longer a risk you can afford. The Pro List delivers:

🔹 Zero Discovery Phase – Access 1,200+ pre-qualified hardware/software manufacturers (IPC-A-610 certified, ISO 27001 compliant)

🔹 Predictable Timelines – 92% on-time delivery rate (vs. industry avg. 67%) through capacity-verified partners

🔹 Cost Transparency – No hidden fees; all partners honor FOB terms with real-time logistics tracking

Call to Action: Secure Your 2026 Sourcing Advantage in 48 Hours

Stop burning budget on supplier validation. The Verified Pro List is your strategic lever for:

✅ Q1 2026 project launches with zero supplier-risk delays

✅ Margin protection through vetted cost structures (no mid-production “fee surprises”)

✅ Compliance certainty under China’s 2026 Digital Product Safety Act

👉 Immediate Next Step:

Book a 15-minute Priority Consultation with our China Sourcing Engineers. We’ll:

1. Identify 3 Pro List manufacturers matching your exact specs (MOQ, tech capabilities, certifications)

2. Provide 2026 pricing benchmarks with tariff optimization pathways

3. Share client case studies from your sector (medical devices, industrial IoT, EV components)

Contact us within 48 hours to receive:

» FREE 2026 China Hardware Sourcing Risk Assessment ($1,500 value)

» Priority access to newly onboarded semiconductor packaging partners

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160 (24/7 English/Mandarin support)

“SourcifyChina’s Pro List cut our smart sensor sourcing cycle from 6 months to 7 weeks – with zero quality escapes.”

— Procurement Director, Top 3 Industrial Automation OEM (Germany)

Transform supply chain risk into competitive advantage. Your 2026 success starts with one verified connection.

Act Now → Contact Support Today

SourcifyChina: Operating since 2012 | 94% Client Retention Rate | 12,000+ Verified Manufacturers | ISO 9001:2015 Certified

Data Sources: SourcifyChina 2025 Annual Report, SGS China Supply Chain Risk Index, EU-China Trade Compliance Bulletin Q4 2025

🧮 Landed Cost Calculator

Estimate your total import cost from China.