The global solar energy storage market is experiencing robust expansion, driven by the increasing adoption of renewable energy, declining battery costs, and supportive government policies. According to Mordor Intelligence, the Solar Energy Storage Market was valued at USD 4.7 billion in 2023 and is projected to reach USD 16.8 billion by 2029, growing at a CAGR of 23.8% during the forecast period. This surge is fueled by rising demand for grid stability, enhanced energy independence, and the need for reliable backup power in both residential and commercial sectors. As solar-plus-storage systems become increasingly integral to the clean energy transition, manufacturers are scaling innovations in battery chemistry, system integration, and energy management software. Against this backdrop, identifying the top solar energy storage system manufacturers provides critical insight into the companies leading technological advancement, market penetration, and long-term sustainability in the energy storage landscape.

Top 10 Solar Energy Storage System Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Decarbonizing Industry with Solar Thermal

Domain Est. 2012

Website: heliogen.com

Key Highlights: Heliogen is an energy technology company specializing in unlocking the power of the sun for cost-effective, reliable, and dispatchable low-carbon power and heat ……

#2 AES

Domain Est. 1993

Website: aes.com

Key Highlights: AES is committed to creating greener, smarter and innovative energy solutions. Together, we can accelerate the future of clean, renewable energy….

#3 Solar & Battery Solutions

Domain Est. 1995

Website: generac.com

Key Highlights: Use energy on your own terms. Generac Solar & Battery Solutions provide a more powerful, resilient and smart way to manage your energy needs….

#4 Canadian Solar

Domain Est. 2001

Website: canadiansolar.com

Key Highlights: Over 20 solar & energy storage manufacturing facilities. in Asia & Americas. Canadian Solar closely examines our supply chains to ensure goods imported are ……

#5 Stem

Domain Est. 2001

Website: stem.com

Key Highlights: The industry-leading comprehensive suite for solar and storage assets, offering advanced analytics, remote diagnostics, and performance reporting tools, ……

#6 SolarEdge

Domain Est. 2005

Website: solaredge.com

Key Highlights: Transform your businesses and residences into an eco-friendly energy hub using the SolarEdge inverter solution and the SolarEdge energy manager platform….

#7 Sungrow US

Domain Est. 2007

Website: us.sungrowpower.com

Key Highlights: Sungrow, a global leader in renewable energy solutions in the USA, provides innovative solar power systems for diverse programs in North America….

#8 Energy Vault®

Domain Est. 2007

Website: energyvault.com

Key Highlights: We are the only energy storage company offering solutions encompassing short to long to ultra long duration needs with proprietary battery, gravity, and hybrid ……

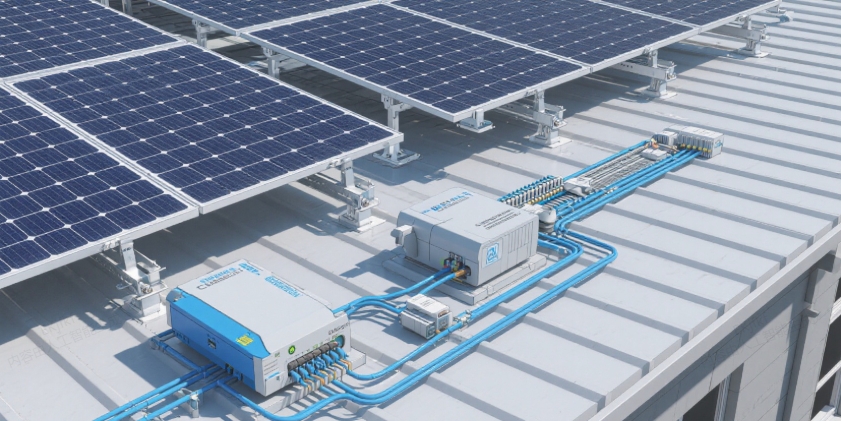

#9 Yotta Energy

Domain Est. 2012

Website: yottaenergy.com

Key Highlights: The YOTTA BLOCK (YB-1) is the perfect distributed energy storage (1 kWh) solution for reducing demand charge, integrating cost-saving techniques like peak ……

#10 Fluence

Domain Est. 2017

Website: fluenceenergy.com

Key Highlights: Fluence is a global market leader in energy storage products and services, and cloud-based software for renewables and storage assets….

Expert Sourcing Insights for Solar Energy Storage System

H2: 2026 Market Trends for Solar Energy Storage Systems

As the global energy landscape evolves toward sustainability and resilience, the solar energy storage system market is poised for transformative growth by 2026. Driven by technological advancements, supportive policies, and increasing demand for energy independence, several key trends are shaping the trajectory of this sector.

-

Accelerated Adoption of Residential and Commercial Storage Solutions

By 2026, residential and commercial solar-plus-storage systems are expected to dominate market growth. Homeowners and businesses are increasingly investing in battery storage to maximize self-consumption of solar energy, reduce grid dependence, and ensure backup power during outages. Falling battery costs—particularly lithium-ion—combined with rising electricity prices are making these systems more economically viable. -

Declining Battery Costs and Technological Innovation

The cost of lithium-ion batteries has decreased by over 80% in the last decade, and this downward trend is projected to continue through 2026. Innovations in battery chemistry, such as lithium iron phosphate (LFP) and solid-state batteries, are enhancing safety, cycle life, and energy density. These improvements are expanding storage applications and reducing levelized cost of storage (LCOS), making solar storage accessible across diverse markets. -

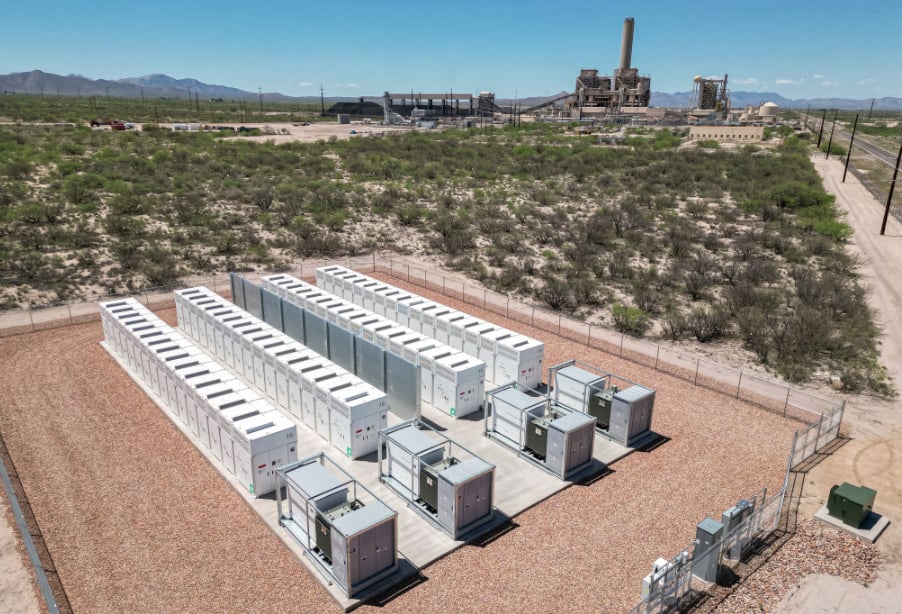

Grid-Scale Storage Integration

Utility-scale solar farms are increasingly integrating large battery energy storage systems (BESS) to manage intermittency and support grid stability. By 2026, grid operators in North America, Europe, and parts of Asia-Pacific are expected to deploy multi-gigawatt storage capacity paired with solar installations. This trend is fueled by renewable integration mandates, frequency regulation needs, and the growing use of storage in capacity markets. -

Policy and Regulatory Support

Government incentives and regulatory frameworks are playing a pivotal role in market expansion. In the U.S., the Inflation Reduction Act (IRA) extends tax credits for standalone energy storage, effectively decoupling storage eligibility from generation assets. Similar policies in the European Union (e.g., Clean Energy for All Europeans package) and emerging markets in Southeast Asia and Latin America are accelerating deployment. -

Energy-as-a-Service (EaaS) and Virtual Power Plants (VPPs)

New business models are emerging, with third-party providers offering solar storage as a service. These EaaS models lower upfront costs for consumers and enable participation in demand response programs. By 2026, virtual power plants—aggregations of distributed energy resources—are expected to play a critical role in grid management, with AI-driven platforms optimizing energy dispatch and monetizing stored energy. -

Focus on Sustainability and Second-Life Batteries

As environmental concerns grow, the industry is prioritizing sustainable practices. Repurposing electric vehicle (EV) batteries for stationary storage is gaining momentum, offering a cost-effective and eco-friendly solution. By 2026, second-life battery applications are projected to capture a notable share of the storage market, supported by advancements in battery diagnostics and modular system design. -

Regional Market Diversification

While North America and Europe remain key markets, Asia-Pacific—led by China, India, and South Korea—is expected to witness the highest growth rates. Emerging economies are leveraging solar storage to address energy access challenges and reduce reliance on diesel generators. Australia continues to lead in per-capita residential storage adoption, setting a benchmark for decentralized energy systems.

In conclusion, the 2026 solar energy storage market is characterized by rapid innovation, declining costs, and strong policy tailwinds. As integration with smart grids and renewable ecosystems deepens, solar energy storage systems are set to become a cornerstone of the global clean energy transition.

H2: Common Pitfalls When Sourcing Solar Energy Storage Systems (Quality & Intellectual Property)

Sourcing a Solar Energy Storage System (SESS) involves critical decisions beyond just price and capacity. Overlooking quality and intellectual property (IP) risks can lead to system failures, safety hazards, performance shortfalls, and legal liabilities. Here are the key pitfalls to avoid:

H2: Quality-Related Pitfalls

-

Prioritizing Price Over Proven Performance & Safety:

- Pitfall: Selecting the cheapest option without rigorous due diligence on cell chemistry, battery management system (BMS) sophistication, safety certifications, and real-world performance data.

- Consequences: Higher risk of thermal runaway, fire, premature degradation (reduced cycle life), lower round-trip efficiency, and system downtime. Cheap BMS may fail to protect the battery adequately.

- Mitigation: Demand detailed technical specifications, independent test reports (e.g., UL 9540, IEC 62619, UN 38.3), third-party safety certifications, and performance warranties backed by reputable manufacturers. Evaluate the BMS architecture and safety features (e.g., cell-level monitoring, robust thermal management).

-

Ignoring Component & System Integration Quality:

- Pitfall: Focusing solely on the battery pack while neglecting the quality and compatibility of the inverter, BMS, thermal management system, and enclosure.

- Consequences: Poor integration leads to inefficiencies, communication failures, reduced lifespan, and potential safety issues. A weak link (e.g., low-quality inverter or BMS) can compromise the entire system.

- Mitigation: Source integrated systems from single vendors where possible, or ensure rigorous compatibility testing and clear responsibility delineation between component suppliers. Verify inverter compatibility (AC/DC coupling, communication protocols).

-

Overlooking Real-World Degradation & Cycle Life Data:

- Pitfall: Relying solely on manufacturer-provided cycle life claims under ideal lab conditions (e.g., 100% depth of discharge, 25°C).

- Consequences: Actual system lifespan and performance in real-world conditions (temperature swings, partial cycling, varying loads) fall significantly short of expectations, impacting ROI.

- Mitigation: Demand accelerated aging test data, real-world field performance data from similar installations, and warranty terms that specify degradation rates under realistic operating conditions (e.g., retained capacity after 10 years at X cycles).

-

Underestimating Thermal Management & Environmental Resilience:

- Pitfall: Choosing systems without adequate or robust thermal management (air vs. liquid cooling) or failing to assess performance in the specific installation environment (extreme heat, cold, humidity, dust).

- Consequences: Accelerated battery degradation, reduced capacity, safety risks (especially in high temperatures), and potential system shutdowns in extreme conditions.

- Mitigation: Select systems with appropriate cooling technology for the climate, verify operating temperature ranges, and ensure enclosures are rated for the installation environment (e.g., IP65 for outdoor use).

H2: Intellectual Property (IP) Pitfalls

-

Sourcing from Suppliers with Questionable IP Ownership:

- Pitfall: Procuring systems from manufacturers whose core technology (cell chemistry, BMS software, system design) may infringe on patents held by established players (e.g., Tesla, LG, CATL, BYD).

- Consequences: Risk of the installed system being subject to injunctions, recalls, or forced shutdowns if the supplier loses an IP lawsuit. The end-user/owner could face significant disruption and financial loss, even if not the direct infringer.

- Mitigation: Conduct thorough due diligence on the supplier’s reputation, R&D background, and IP portfolio. Request evidence of freedom-to-operate (FTO) analyses or indemnification clauses in contracts covering IP infringement.

-

Lack of Clear Software Ownership and Update Rights:

- Pitfall: Assuming ownership or control over the BMS and system control software, only to find the supplier retains all rights and controls updates, access, and features.

- Consequences: Vendor lock-in, inability to integrate with other systems, dependency on the supplier for critical updates (security, performance), potential loss of functionality if the supplier goes out of business, and limited data access.

- Mitigation: Negotiate clear contractual terms regarding software licenses, update obligations, data ownership/access, and long-term support (LTS) guarantees. Prefer suppliers offering open communication protocols (e.g., SunSpec, Modbus) where possible.

-

Ambiguous Warranty and Support Structure:

- Pitfall: Warranties that are complex, cover only specific components (e.g., cells but not BMS or inverter), or are difficult to enforce, especially with offshore suppliers.

- Consequences: Difficulty obtaining repairs or replacements when issues arise, leading to prolonged downtime and high costs. IP disputes can further complicate warranty claims.

- Mitigation: Insist on clear, comprehensive, and transferable warranties covering the entire system (battery, BMS, inverter, enclosure) for a defined period, including performance (capacity retention) and workmanship. Verify the supplier’s local service and support network or establish clear support pathways.

-

Ignoring Future-Proofing and Scalability IP:

- Pitfall: Choosing a system where expansion or integration with future technologies (e.g., EV charging, different inverters) is restricted by proprietary hardware or software.

- Consequences: Inability to scale the system cost-effectively or integrate new technologies, leading to stranded assets and reduced long-term value.

- Mitigation: Prioritize systems designed with open standards and modular architectures. Verify compatibility pathways and upgrade options before procurement.

By proactively addressing these quality and IP pitfalls during the sourcing process, organizations can significantly reduce risks, ensure system safety and reliability, protect their investment, and achieve the desired long-term performance and return on their solar energy storage system.

Logistics & Compliance Guide for Solar Energy Storage Systems

Overview

Solar Energy Storage Systems (SESS) combine photovoltaic (PV) energy generation with battery storage to provide reliable, renewable power. Due to their complex nature—incorporating electrical, chemical, and mechanical components—shipping, handling, and deploying these systems require strict adherence to logistics best practices and regulatory compliance. This guide outlines key considerations to ensure safe, legal, and efficient movement and installation of SESS.

International & Domestic Regulations

UN/DOT Classification

Most battery-based storage systems contain lithium-ion batteries, which are classified as hazardous materials under UN/DOT regulations. Key points include:

– UN 3480: Lithium-ion batteries (when shipped separately).

– UN 3536: Lithium-ion batteries contained in equipment.

– Proper classification determines packaging, labeling, and documentation requirements.

IATA & IMDG Compliance

- Air Transport (IATA): Strict rules apply; state of charge (SoC) typically limited to ≤30% for safety.

- Maritime Transport (IMDG Code): Requires proper stowage, segregation, and emergency response information.

- Both require certified dangerous goods declarations and trained personnel for shipment preparation.

Local Electrical & Safety Codes

- UL 9540: Standard for Energy Storage Systems and Equipment (U.S.).

- IEC 62619: Safety requirements for industrial lithium-ion batteries (international).

- National Electrical Code (NEC) Article 706: U.S. standard covering installation of dedicated onsite energy storage systems.

- Compliance ensures fire safety, electrical integrity, and interoperability.

Packaging & Handling Requirements

Packaging Standards

- Use UN-certified packaging for battery shipments.

- Include internal cushioning, short-circuit protection, and thermal insulation.

- Systems must be secured against movement during transit.

Handling Procedures

- Trained personnel only; use appropriate PPE (gloves, eye protection).

- Avoid dropping, puncturing, or exposing batteries to extreme temperatures.

- Maintain vertical orientation if specified by manufacturer.

Transportation Modes & Considerations

Road Transport

- Vehicles must comply with ADR regulations (Europe) or 49 CFR (U.S.) for hazardous materials.

- Proper placarding and documentation required.

- Temperature-controlled transport recommended in extreme climates.

Sea Freight

- Lithium batteries often subject to “Dangerous Goods” surcharges and special container requirements.

- Ensure accurate declaration to avoid port delays or rejection.

- Use containers with ventilation if required.

Air Freight

- Most restrictive due to fire risk; many carriers impose limits or bans on high-capacity lithium batteries.

- Pre-approval and detailed documentation mandatory.

- Lower SoC and robust packaging essential.

Import/Export Documentation

Required Documents

- Commercial Invoice

- Packing List

- Bill of Lading/Air Waybill

- Material Safety Data Sheet (MSDS/SDS)

- Dangerous Goods Declaration (for batteries)

- Certificate of Conformity (e.g., UL, CE, IEC)

- Import licenses or permits (country-specific)

Country-Specific Requirements

- EU: CE marking, adherence to WEEE and RoHS directives.

- USA: FCC compliance for communication modules, UL certification.

- China: CCC certification may apply; GB standards for batteries.

- Australia: RCMA approval, AS/NZS standards compliance.

Onsite Installation & Grid Interconnection

Site Preparation

- Ensure proper ventilation, fire suppression (e.g., smoke detectors, thermal monitoring), and physical security.

- Follow manufacturer’s installation manual and local building codes.

Electrical Integration

- Must comply with grid interconnection standards (e.g., IEEE 1547 in the U.S.).

- Requires inspection and approval by local utility or authority having jurisdiction (AHJ).

Commissioning & Testing

- Perform insulation resistance, grounding, and functional safety tests.

- Validate communication with inverters and energy management systems.

Environmental & End-of-Life Compliance

Recycling & Disposal

- Follow WEEE (EU), state-level (e.g., California) or national e-waste regulations.

- Partner with certified recyclers for battery end-of-life management.

- Maintain chain-of-custody records.

Sustainability Reporting

- Track carbon footprint of transport and lifecycle impacts.

- Consider EPR (Extended Producer Responsibility) obligations in target markets.

Risk Mitigation & Best Practices

- Conduct a logistics risk assessment for each shipment.

- Use third-party logistics (3PL) providers experienced in energy storage systems.

- Insure shipments for full replacement value.

- Maintain up-to-date compliance documentation and train staff regularly.

Conclusion

Successful deployment of Solar Energy Storage Systems hinges on meticulous attention to logistics and compliance across the supply chain. Proactive planning, adherence to international standards, and collaboration with certified partners minimize delays, ensure safety, and support regulatory approval. Always consult with legal, technical, and logistics experts when entering new markets or scaling operations.

Conclusion:

In conclusion, sourcing a solar energy storage system is a strategic and forward-thinking decision that enhances energy independence, improves grid resilience, and maximizes the utilization of renewable solar power. With advancements in battery technologies—such as lithium-ion, flow batteries, and emerging solid-state options—there are now diverse solutions tailored to residential, commercial, and utility-scale applications. Careful evaluation of factors such as capacity, efficiency, lifespan, cost, safety, and compatibility with existing solar installations is essential to selecting the right system.

Additionally, favorable government incentives, decreasing battery costs, and growing environmental awareness further strengthen the economic and ecological case for energy storage adoption. As renewable energy continues to expand globally, integrating solar with effective storage solutions will play a critical role in building a sustainable, reliable, and decentralized energy future. Ultimately, sourcing the right solar energy storage system not only supports long-term energy cost savings but also contributes to a cleaner, more resilient energy ecosystem.