The skid loader sweeper market is experiencing robust growth, driven by increasing demand for efficient, multi-purpose cleaning and material handling solutions across construction, municipal, and industrial sectors. According to Grand View Research, the global skid steer loader market size was valued at USD 11.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is supported by rising infrastructure development, urbanization, and the need for compact, versatile equipment in confined environments. Mordor Intelligence also projects steady expansion in the compact equipment sector, citing heightened emphasis on operational efficiency and labor cost reduction as key contributing factors. As demand for attachments like sweeper units grows—often exceeding 30% of total skid steer attachments revenue—manufacturers specializing in high-performance, durable sweepers are gaining strategic importance. In this competitive landscape, the following ten companies have emerged as leaders, combining innovation, global reach, and data-backed product reliability to meet evolving industry needs.

Top 10 Skid Loader Sweeper Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Broce Broom

Domain Est. 2002

Website: brocebroom.com

Key Highlights: Broce Broom is the leading producer of construction & industrial street sweepers to help accommodate any milling & surface treatment projects….

#2 Sweeper Attachment

Domain Est. 1997

Website: bobcat.com

Key Highlights: Free delivery over $99 30-day returnsThe sweeper’s hydraulic motor spins durable bristles mounted to its rotating drum. Powerful flicking action sends dirt and debris flying into t…

#3 Skid Steer Pick Up Broom

Domain Est. 2000

Website: mclarenindustries.com

Key Highlights: Our pick-up broom for skid steers will easily handle the job. Our reinforced 8” hub and durable 26” poly wafers sweep material into the bucket….

#4 Brooms & Sweepers

Domain Est. 2002

Website: virnigmfg.com

Key Highlights: Virnig’s skid steer broom attachment lineup features the angle broom and pick-up (hopper) broom. The angle broom quickly sweeps dirt, snow, and other debris….

#5 Brooms

Domain Est. 2003

Website: skidsteersolutions.com

Key Highlights: Free delivery over $5,000 · 30-day returns…

#6 Skid Steer Angle Broom & Sweeper

Domain Est. 2007

Website: skidpro.com

Key Highlights: Our Skid Steer Angle Broom allows you to sweep powerfully in both directions. This versatile angle broom attachment makes cleanup easy and efficient….

#7 Skid Steer Brooms

Domain Est. 2008

Website: bluediamondattachments.com

Key Highlights: We manufacture one of the industry’s most comprehensive broom lineups, with solutions for any application and any host machine; Our skid steer sweeper ……

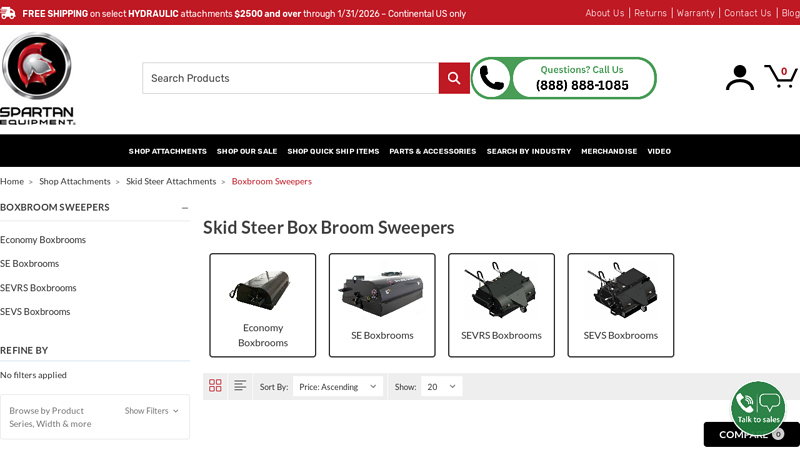

#8 Skid Steer Box Broom Sweepers

Domain Est. 2010

Website: spartanequipment.com

Key Highlights: 4–30 day deliveryShop our extensive selection of Skid Steer Box Broom Sweepers to find one that fits your equipment and makes your Skid Steer the powerful, efficient surface ……

#9 Product Overview

Domain Est. 2011

Website: smithchallenger.com

Key Highlights: The SCM 200 Skid Steer Mount Sweeper is designed for bucket replacement applications and is equipped with a manual Quick-Change Brush System, allowing the brush ……

#10 72

Domain Est. 2022

Website: igniteattachments.com

Key Highlights: In stock Free deliveryClean jobsites fast with this 72-inch skid steer sweeper bucket. A broom bucket attachment with built-in hopper for efficient dirt and debris collection….

Expert Sourcing Insights for Skid Loader Sweeper

2026 Market Trends for Skid Loader Sweepers

The skid loader sweeper market is poised for transformation by 2026, driven by evolving industry demands, technological advancements, and a heightened focus on sustainability. As attachments for versatile skid steer loaders, these sweepers are increasingly critical for efficient site cleanup across construction, municipal, industrial, and commercial sectors. Key trends shaping the market include:

Growing Emphasis on Efficiency and Productivity

Contractors and municipalities face increasing pressure to complete tasks faster with fewer resources. Skid loader sweepers are becoming integral to streamlining cleanup operations, reducing labor costs, and minimizing downtime. By 2026, demand will rise for high-capacity, quick-change sweepers that integrate seamlessly with existing fleets. Models featuring rapid attachment systems, improved debris containment, and enhanced maneuverability in tight spaces will dominate, particularly in urban construction and facility maintenance.

Advancements in Smart Technology and Automation

Technology integration is accelerating in compact equipment. By 2026, expect wider adoption of smart sweepers equipped with sensors, telematics, and performance monitoring systems. These features allow fleet managers to track usage, optimize maintenance schedules, and monitor sweeping effectiveness in real time. While full autonomy remains limited for attachments, compatibility with semi-automated or GPS-guided skid loaders will enhance precision and repeatability, especially in large-scale industrial or municipal applications.

Sustainability and Emissions Regulations

Stricter environmental regulations, particularly in North America and Europe, are pushing demand toward eco-friendly solutions. The shift toward electric and hybrid skid steer loaders will directly influence sweeper design. Manufacturers will respond with lightweight, energy-efficient sweeper attachments optimized for electric platforms. Additionally, features such as dust suppression systems and recyclable material handling will gain importance, aligning with corporate sustainability goals and regulatory compliance.

Urbanization and Infrastructure Development

Rapid urbanization, especially in emerging markets, is fueling construction and municipal cleaning needs. Skid loader sweepers offer a cost-effective, adaptable solution for maintaining cleanliness in densely populated areas. By 2026, increased public and private investment in infrastructure projects will drive demand for compact, multi-functional equipment. Municipalities will prioritize sweepers with low noise emissions and zero tailpipe emissions—further boosting adoption on electric carriers.

Expansion of Rental and Fleet Management Models

The equipment rental market continues to grow, offering businesses flexibility and reduced capital expenditure. Skid loader sweepers are well-suited for rental fleets due to their versatility and ease of use. By 2026, rental companies will expand their offerings of specialized sweepers, including combo units (sweep-vac) and models tailored for specific materials like asphalt debris or fine particulates. Digital fleet management platforms will enhance utilization tracking and customer service.

Material Innovation and Customization

To meet diverse application needs, manufacturers are investing in durable, lightweight materials such as advanced polymers and high-strength composites. These materials extend service life and reduce wear on the host machine. Additionally, customization—such as adjustable brush stiffness, variable speed controls, and modular designs—will become standard, enabling operators to adapt sweepers for specific environments, from indoor warehouses to rugged construction sites.

In conclusion, the 2026 skid loader sweeper market will be defined by smarter, cleaner, and more efficient solutions. Success will depend on manufacturers’ ability to innovate in response to automation trends, environmental standards, and the growing need for operational versatility across global markets.

Common Pitfalls When Sourcing Skid Loader Sweepers (Quality and Intellectual Property)

Sourcing skid loader sweepers—especially from international suppliers—can present several challenges related to product quality and intellectual property (IP) protection. Being aware of these pitfalls helps buyers make informed decisions and avoid costly issues down the line.

Poor Build Quality and Material Standards

One of the most frequent issues when sourcing skid loader sweepers is substandard build quality. Many suppliers, particularly in low-cost manufacturing regions, use inferior materials such as thin-gauge steel or low-grade components to cut costs. This compromises durability, safety, and performance in demanding environments. Buyers may receive sweepers that rust quickly, suffer structural failures, or fail to meet industry load and wear requirements.

Lack of Compliance with Industry Standards

Skid loader attachments must meet specific safety and performance standards (e.g., ISO, ANSI, or CE marking in Europe). Some suppliers may not adhere to these regulations or provide false certifications. Non-compliant sweepers can lead to equipment damage, safety hazards, and legal liabilities—especially if used in regulated industries.

Inadequate Testing and Quality Control Processes

Many sourced sweepers are manufactured without rigorous testing protocols. Suppliers may skip fatigue testing, stress analysis, or real-world operational trials. As a result, units may fail prematurely under normal operating conditions. A lack of documented quality control processes makes it difficult to verify reliability before purchase.

Misrepresentation of Compatibility and Specifications

Suppliers may exaggerate compatibility with major skid steer brands (e.g., Bobcat, John Deere, Caterpillar) or misstate critical specs such as weight capacity, hydraulic requirements, or sweeping width. This leads to integration issues, reduced efficiency, and potential damage to the host machine.

Intellectual Property Infringement Risks

Sourcing from manufacturers that copy patented designs—especially attachment mounting systems, brush mechanisms, or hydraulic circuits—can expose buyers to IP infringement claims. Even if the buyer is unaware, using or importing a product that violates existing patents may result in legal action, customs seizures, or forced product recalls.

No Clear Ownership or Licensing of Design

Some suppliers offer “OEM” or “compatible” sweepers that closely mimic branded models. However, without proper licensing or original design documentation, these products may be counterfeit or unauthorized replicas. Buyers risk reputational damage and legal exposure when distributing or using such equipment.

Limited After-Sales Support and Warranty Enforcement

Low-cost suppliers often lack reliable customer service, spare parts availability, or enforceable warranty terms. If a sweeper fails, obtaining replacements or repairs can be time-consuming and expensive—undermining the initial cost savings.

Recommendations to Mitigate Risks

- Conduct factory audits and request third-party inspection reports.

- Verify certifications and request test data.

- Use legal agreements that address IP indemnity and compliance.

- Prioritize suppliers with proven track records and original designs.

- Consult legal experts when importing to assess IP risks.

Avoiding these common pitfalls requires due diligence, technical vetting, and attention to both quality and legal considerations.

Logistics & Compliance Guide for Skid Loader Sweeper

Overview

This guide outlines the essential logistics and compliance considerations for the transport, operation, and maintenance of a Skid Loader Sweeper. Adhering to these guidelines ensures safe handling, regulatory compliance, and efficient performance across job sites and transportation routes.

Transportation Logistics

Secure Loading and Unloading

Ensure the Skid Loader Sweeper is properly secured on flatbed trailers or lowboys using rated tie-down straps or chains. Use wheel chocks and support stands during loading/unloading via ramps or tilt beds. Only certified personnel should operate loading equipment.

Dimension and Weight Compliance

Verify the sweeper’s dimensions (length, width, height) and operating weight against local and interstate transportation regulations. Oversized loads may require:

– Permits from state transportation departments

– Escort vehicles

– Posted route approvals

– Compliance with time-of-day travel restrictions

Transport Configuration

Remove or secure attachments (brushes, hoppers, etc.) to minimize transport profile. Engage parking brakes and lock hydraulic systems to prevent movement. Cover sensitive components to protect from weather and debris during transit.

Regulatory Compliance

DOT and FMCSA Regulations (U.S.)

If transported on public roads, ensure compliance with Department of Transportation (DOT) and Federal Motor Carrier Safety Administration (FMCSA) rules, including:

– Commercial Driver’s License (CDL) requirements for operators, if applicable

– Vehicle inspection, repair, and maintenance (IRVM) standards

– Hours-of-Service (HOS) tracking for commercial drivers

Local and State Requirements

Check with local authorities for:

– Road use permits

– Noise ordinances for operation near residential areas

– Emission standards (especially in low-emission zones)

Operational Compliance

OSHA Safety Standards

When operating on job sites, follow OSHA regulations including:

– Proper personal protective equipment (PPE): hard hats, safety glasses, high-visibility vests, steel-toed boots

– Machine guarding for rotating brushes and moving parts

– Training and certification for all operators

– Pre-shift inspection logs (fluids, tires, lights, safety devices)

Environmental Regulations

Adhere to EPA and local environmental rules:

– Prevent fuel or hydraulic fluid leaks during operation and maintenance

– Capture and dispose of collected debris in accordance with waste management laws

– Use sweepers with dust suppression systems if required in high-particulate environments

Maintenance and Documentation

Scheduled Maintenance

Follow the manufacturer’s maintenance schedule for:

– Filter replacements (air, oil, hydraulic)

– Lubrication of moving parts

– Inspections of belts, hoses, and electrical systems

– Battery maintenance for electric or hybrid models

Record Keeping

Maintain detailed logs for:

– Service and repair history

– Operator certifications

– Daily pre-use inspection reports

– Incident or near-miss reports

Operator Training and Certification

Ensure all personnel operating the Skid Loader Sweeper complete:

– Manufacturer-specific training

– Site-specific safety orientation

– Refresher courses annually or after incidents

– Documentation of training completion for audit purposes

Conclusion

Proper logistics planning and regulatory compliance are critical for the safe and legal use of Skid Loader Sweepers. By following this guide, operators and fleet managers can reduce risks, avoid fines, and maintain productivity across diverse environments. Always consult local regulations and equipment manuals for the most accurate and up-to-date requirements.

Conclusion for Sourcing a Skid Loader Sweeper

In conclusion, sourcing a skid loader sweeper requires a strategic evaluation of operational needs, equipment compatibility, budget constraints, and long-term maintenance considerations. Selecting the right sweeper attachment involves assessing key factors such as sweeping width, debris capacity, filtration systems, ease of attachment and detachment, and durability under specific working conditions. It is essential to choose a model that integrates seamlessly with existing skid steer loaders to maximize efficiency and productivity.

Additionally, considering reputable suppliers and manufacturers ensures access to quality construction, reliable warranties, and responsive technical support. Evaluating both upfront costs and lifecycle expenses—including fuel efficiency, maintenance, and downtime—leads to a more informed and cost-effective decision.

Ultimately, investing in the appropriate skid loader sweeper enhances site cleanliness, improves safety, and supports regulatory compliance across industries such as construction, municipal services, and facilities management. By aligning equipment specifications with operational goals, organizations can achieve optimal performance, reduce labor costs, and extend the lifespan of their machinery—making the sourcing process a critical step toward long-term operational success.