The global truck wheel market, driven by rising commercial vehicle production and infrastructure development, is projected to expand at a CAGR of 4.6% from 2023 to 2030, according to Grand View Research. A key segment within this growth is the demand for durable, high-performance six-lug truck rims, widely used in light to medium-duty trucks, off-road vehicles, and fleet applications. As reliability, load capacity, and corrosion resistance become critical purchasing factors, manufacturers are investing in advanced materials such as forged aluminum and high-tensile steel to meet rigorous industry standards. With the North American market remaining a key hub for trucking and aftermarket wheel upgrades, Mordor Intelligence reports sustained demand for aftermarket truck rims, bolstered by the expansion of logistics networks and the aging commercial vehicle fleet. In this context, leading manufacturers are distinguishing themselves through innovation, certification standards (such as DOT and SAE), and global distribution networks—making the selection of the right rim producer a data-informed decision for fleets and individual buyers alike.

Top 10 Six Lug Truck Rims Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 U.S. Wheel Corp.

Domain Est. 1998

Website: uswheel.com

Key Highlights: US Wheel Corp – Steel and Aluminum Wheel manufacturer for Hot Rod, Muscle Car, Truck, Off-Road, VW, Trailer, OEM Replacement, and Import Performance….

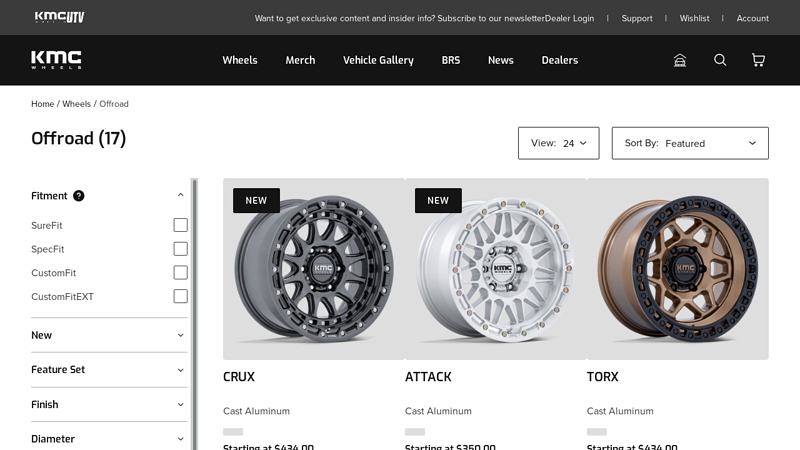

#2 Offroad

Domain Est. 1998

Website: kmcwheels.com

Key Highlights: $20 delivery 30-day returnsThis wheel is custom-designed for your vehicle, offering a perfect fit from OEM to more aggressive styles without requiring any vehicle modifications. It…

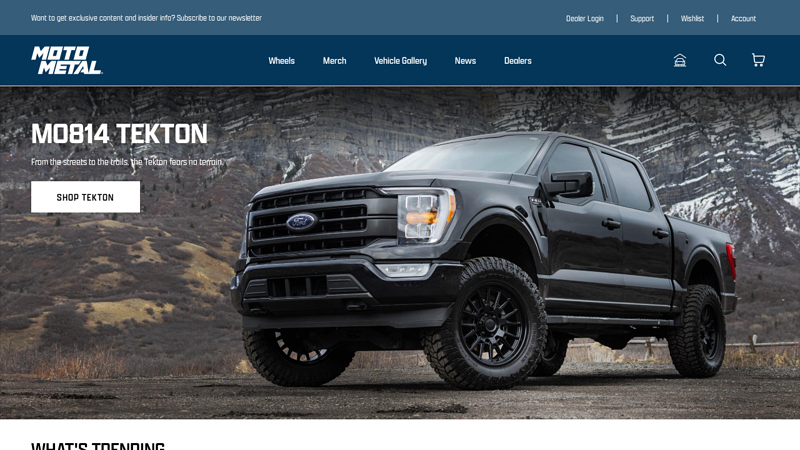

#3 Moto Metal: Off

Domain Est. 2008

Website: motometal.com

Key Highlights: This wheel is custom-designed for your vehicle, offering a perfect fit from OEM to more aggressive styles without requiring any vehicle modifications. It ……

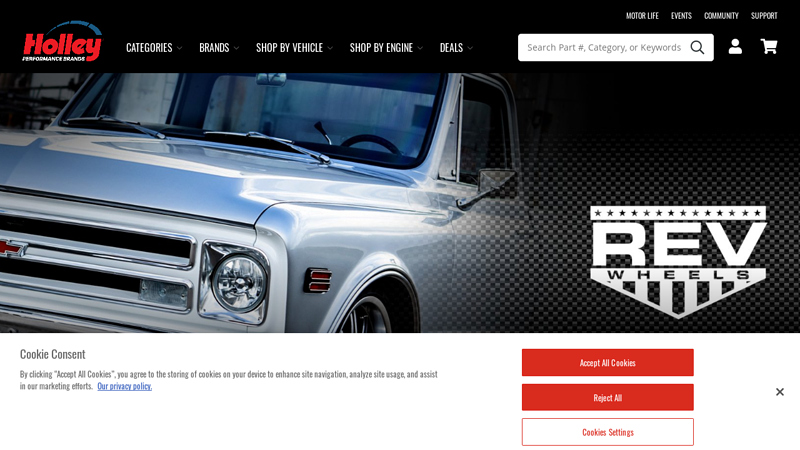

#4 REV Wheels ()

Domain Est. 1995

Website: holley.com

Key Highlights: Free delivery over $149 · 90-day returnsREV Wheels offers a full portfolio of wheels for a variety of classic vehicles and trucks including the Ford Mustang, Chevrolet Camaro, GM …

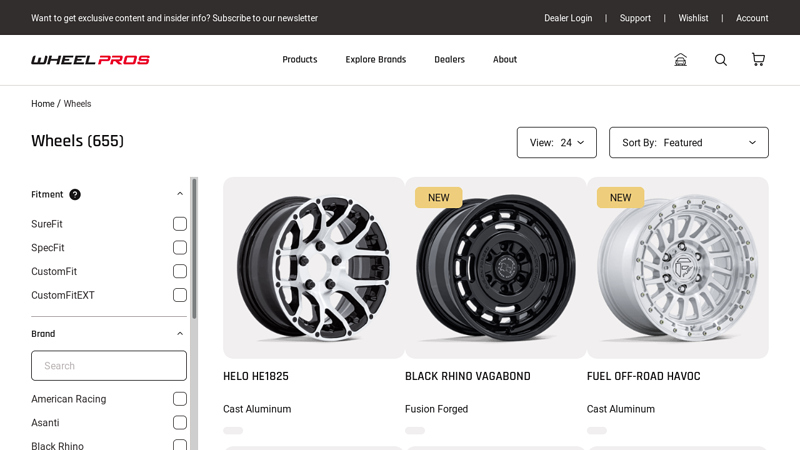

#5 Shop Wheels

Domain Est. 1998

#6 TSW Alloy Wheels

Domain Est. 1999

Website: tsw.com

Key Highlights: TSW Alloy Wheels engineers custom wheels to precisely fit your car or SUV. With 35 breathtaking designs, from 17″ to 22″, our selection is only surpassed by ……

#7 WELD Racing Wheels: Forged & Flow

Domain Est. 2000

#8 Raceline Wheels

Domain Est. 2000

#9 Method Race Wheels

Domain Est. 2009

Website: methodracewheels.com

Key Highlights: Method Race Wheels is committed to bringing you the finest quality products with the most complete lineup of wheels for off-road trucks, off-road buggies, ……

#10 US Mags

Domain Est. 2010

Website: us-mags.com

Key Highlights: $20 delivery 30-day returnsBLARE 6 LUG PRECISION SERIES. Forged Aluminum. 1 finish available. 24″. 26″. Starting at $1,247.00. BLARE ……

Expert Sourcing Insights for Six Lug Truck Rims

H2: 2026 Market Trends for Six Lug Truck Rims

The market for six lug truck rims is poised for notable evolution by 2026, driven by shifts in consumer demand, technological advancements, and broader automotive industry trends. As light-duty and heavy-duty trucks remain essential for commercial operations, personal use, and outdoor recreation, the demand for durable, high-performance wheel solutions continues to grow—particularly in the six lug segment, which strikes a balance between strength, weight, and compatibility.

-

Increased Demand from Light-Duty and Mid-Size Trucks

By 2026, the popularity of mid-size trucks such as the Ford Ranger, Toyota Tacoma, and Chevy Colorado is expected to rise, many of which utilize six lug bolt patterns (commonly 6×139.7mm). These vehicles appeal to both off-road enthusiasts and utility-focused buyers, fueling demand for aftermarket six lug rims designed for enhanced aesthetics, performance, and clearance. The growing trend toward truck personalization will further boost sales in the aftermarket wheel sector. -

Growth in Aftermarket Customization

Consumers are increasingly investing in aesthetic and functional upgrades, with six lug rims offering a wide range of options in finishes (matte black, machined, bronze), designs (flow-formed, multi-spoke), and materials (aluminum alloy, forged composites). By 2026, customization platforms and online configurators are expected to dominate, allowing buyers to tailor rims to their specific vehicle and style preferences. -

Lightweight and Fuel-Efficient Designs

In response to tightening fuel economy standards and consumer interest in efficiency, manufacturers are focusing on lightweight aluminum and advanced alloy six lug rims. These reduce unsprung weight, improving fuel efficiency, handling, and braking performance. By 2026, expect wider adoption of high-strength, low-mass materials that maintain durability without sacrificing performance. -

Expansion of Off-Road and Overlanding Culture

The surge in off-roading and overlanding—especially in North America and Australia—will significantly influence six lug rim demand. These applications require rugged, corrosion-resistant wheels capable of withstanding rough terrain. Six lug patterns are common on 3/4-ton trucks and off-road-oriented SUVs, making them ideal for this expanding niche. As outdoor adventure grows in popularity, so will demand for off-road-ready six lug rims with aggressive styling and reinforced construction. -

Sustainability and Manufacturing Innovation

Environmental concerns are pushing manufacturers toward sustainable production practices. By 2026, expect increased use of recycled aluminum and energy-efficient casting processes in six lug rim production. Additionally, advancements in manufacturing, such as precision CNC machining and modular design, will allow for greater consistency and performance optimization. -

E-Commerce and Direct-to-Consumer Sales Growth

Online retail platforms will continue to dominate wheel sales by 2026. Consumers are increasingly purchasing six lug rims through e-commerce sites offering fitment guides, customer reviews, and fast shipping. Brands that invest in digital experience, accurate fitment databases, and augmented reality (AR) tools to visualize rims on vehicles will gain a competitive edge. -

Regional Market Variations

North America will remain the largest market for six lug truck rims due to high truck ownership and aftermarket modification culture. However, emerging markets in Latin America, the Middle East, and Southeast Asia will see rising demand, particularly for durable, cost-effective wheels suited to harsh driving conditions.

In summary, the 2026 market for six lug truck rims will be shaped by consumer preferences for performance, customization, and durability, supported by technological innovation and digital retail expansion. As trucks maintain their cultural and economic significance, six lug rims will remain a key segment in the automotive aftermarket, with steady growth projected across multiple geographies and applications.

Common Pitfalls Sourcing Six Lug Truck Rims (Quality, IP)

Sourcing six lug truck rims—whether for replacement, upgrade, or resale—can be a complex process, especially when balancing cost, quality, and intellectual property (IP) concerns. Below are common pitfalls buyers and suppliers often encounter in this space.

1. Compromising on Material Quality

One of the most frequent issues is selecting rims made from substandard materials. Many budget rims use low-grade aluminum or steel, which can lead to warping, cracking, or failure under load. Inferior heat treatment or casting processes further diminish durability. Always verify material specifications (e.g., ASTM or ISO standards) and opt for rims with proper certifications.

2. Lack of Load Rating Verification

Not all six lug rims are rated for heavy-duty use. Using rims with inadequate load capacity can compromise safety, especially in commercial or off-road applications. Always check the load rating and ensure it matches or exceeds the vehicle manufacturer’s recommendations.

3. Ignoring Fitment Specifications

Six lug patterns vary by make and model (e.g., 6x135mm for Ford, 6×139.7mm for GM, 6×114.3mm for some older models). Purchasing rims with incorrect bolt patterns, center bore, or offset can lead to improper installation, vibration, and safety hazards. Always confirm fitment using a fitment guide or professional advice.

4. Falling for Counterfeit or Knockoff Brands

Many suppliers offer “replica” rims that mimic well-known brands like Fuel, Method, or Raceline. These knockoffs often infringe on design patents and trademarks, exposing buyers to legal risk. Additionally, counterfeit rims frequently lack structural integrity and safety testing.

5. Overlooking Intellectual Property (IP) Infringement

Manufacturers invest heavily in rim design, and many designs are protected by utility and design patents. Sourcing unlicensed copies—even if they appear identical—can lead to legal action, seized shipments, or reputational damage. Always verify that the supplier holds proper licensing or produces original designs.

6. Skipping Third-Party Testing and Certification

Reputable rims undergo rigorous testing (e.g., SAE J2530, VIA, or TÜV certification). Many low-cost imports lack these certifications, meaning they haven’t been tested for impact resistance, fatigue, or corrosion. Avoid rims without verifiable test reports.

7. Poor Finish and Corrosion Resistance

Cheap rims often feature thin powder coating or plating that chips or corrodes quickly, especially in winter climates or off-road use. This not only affects appearance but can compromise structural integrity over time. Insist on finishes with proven durability and warranties.

8. Inadequate After-Sales Support and Warranty

Low-cost suppliers may offer little to no warranty or customer service. If a rim fails or arrives damaged, resolving the issue can be difficult or impossible. Choose suppliers with clear return policies, warranties, and responsive support.

9. Misjudging OEM vs. Aftermarket Quality

While OEM rims are designed specifically for a vehicle, some assume all OEM-style rims are equal. Aftermarket manufacturers vary widely in quality. Always research the brand and read verified user reviews before purchasing.

10. Sourcing from Unverified Overseas Suppliers

Many online marketplaces offer attractive pricing from overseas manufacturers. However, without proper due diligence, buyers risk receiving defective products, facing shipping delays, or encountering IP violations. Use trade verification services, request samples, and perform background checks on suppliers.

By avoiding these common pitfalls, buyers can ensure they source six lug truck rims that are safe, legal, and built to last. Prioritize quality certifications, proper fitment, and IP-compliant designs to protect both your investment and end users.

Logistics & Compliance Guide for Six Lug Truck Rims

Product Overview and Specifications

Six lug truck rims are wheel assemblies designed for medium to heavy-duty trucks, featuring six bolt holes for secure attachment to the vehicle hub. These rims are commonly used in commercial fleets, construction vehicles, and towing applications. They are typically manufactured from steel or aluminum alloy and must meet specific dimensional, load, and safety standards depending on regional requirements and intended use.

Regulatory Compliance Requirements

DOT and FMVSS Compliance (United States)

In the United States, six lug truck rims must comply with the Department of Transportation (DOT) regulations and relevant sections of the Federal Motor Vehicle Safety Standards (FMVSS), particularly FMVSS 120 (Brakes) and FMVSS 127 (Driver Visibility), which indirectly affect wheel and rim safety. While wheels themselves are not directly certified under FMVSS, they must be compatible with certified braking and suspension systems. Manufacturers and importers must ensure rims meet performance standards for load capacity, durability, and fitment.

Transport Canada Standards (Canada)

In Canada, rims used on commercial vehicles must conform to the Motor Vehicle Safety Regulations (MVSR) administered by Transport Canada. Rim labeling must include essential information such as size, load rating, and manufacturer identification. Compliance with CSA B101 standard for wheel testing is often required for aftermarket and replacement rims.

ECE Regulations (Europe)

For distribution in the European Union and ECE signatory countries, six lug truck rims must comply with ECE Regulation No. 124, which governs the approval of wheels for commercial vehicles. This includes dynamic radial fatigue, cornering fatigue, and impact tests. Certified rims must bear the E-mark and a unique approval number to indicate compliance.

Material and Manufacturing Standards

ISO and SAE Standards

Rims should be manufactured in accordance with international standards such as ISO 10463 (road vehicle wheels—performance requirements and test procedures) and SAE J267 (Test Procedure for Truck and Off-Highway Wheel Radial Fatigue). Adherence to these standards ensures structural integrity and long-term performance under operational stress.

Quality Control and Testing

Manufacturers must conduct regular quality control checks, including non-destructive testing (NDT), dimensional verification, and load testing. Documentation of test results and compliance certificates should be maintained for audits and customer inquiries.

Packaging and Handling Guidelines

Protective Packaging

Six lug truck rims must be packaged to prevent damage during transit. Use of edge protectors, rust-inhibitive wraps (especially for steel rims), and sturdy palletization is recommended. Individual rims should be separated to avoid scratching or warping.

Labeling Requirements

Each package must include clear labeling with:

– Rim size (e.g., 16.5×6.5)

– Bolt pattern (6-lug, PCD)

– Load capacity (in kg/lbs)

– Manufacturer name and part number

– Compliance markings (DOT, E-mark, etc.)

– Handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”)

Transportation and Shipping

Domestic Shipping (North America)

When shipping domestically via truckload (TL) or less-than-truckload (LTL), ensure rims are secured to prevent shifting. Use load bars, straps, and dunnage as needed. For LTL shipments, consider crating or using pallet caps to protect upper layers.

International Shipping

For international shipments:

– Use export-grade wooden or metal pallets compliant with ISPM 15 for wood packaging.

– Complete required documentation: commercial invoice, packing list, certificate of origin, and test/compliance certificates.

– Declare HS Code accurately (typically 8708.70 for wheels and rims).

– Comply with destination country’s import regulations, including potential conformity assessment procedures.

Import and Customs Compliance

U.S. Customs and Border Protection (CBP)

Ensure Harmonized Tariff Schedule (HTS) code 8708.70.60 is correctly applied. Provide documentation proving origin, especially if claiming preferential treatment under USMCA. CBP may require proof of compliance with DOT or other applicable safety standards upon request.

EU Import Requirements

Importers must verify that rims have ECE R124 approval and are CE marked where applicable. The importer is responsible for ensuring conformity and maintaining technical documentation under the EU’s Market Surveillance Regulation.

Storage and Inventory Management

Store rims indoors in a dry, temperature-controlled environment to prevent corrosion. Stack pallets no higher than recommended to avoid crushing. Implement a first-in, first-out (FIFO) inventory system to reduce the risk of obsolete stock.

Environmental and Safety Considerations

Hazardous Materials

Steel rims may be coated with protective oils or primers containing volatile organic compounds (VOCs). Ensure proper handling and disposal in accordance with OSHA and EPA regulations.

Worker Safety

Provide appropriate personal protective equipment (PPE) such as gloves and safety glasses when handling rims. Train staff on safe lifting techniques and the use of material handling equipment.

Documentation and Recordkeeping

Maintain records of:

– Certificates of compliance (DOT, ECE, ISO)

– Test reports and quality audits

– Shipping and customs documentation

– Customer warranties and returns

Retention period: Minimum of 5 years for compliance audits.

Conclusion

Proper logistics and compliance management for six lug truck rims are essential for legal distribution, customer safety, and operational efficiency. Adhering to regional regulations, standards, and best practices in packaging, shipping, and documentation ensures smooth supply chain operations and minimizes risk of non-compliance penalties.

In conclusion, sourcing six-lug truck rims requires careful consideration of factors such as compatibility with your vehicle’s make and model, load rating, rim size, bolt pattern, finish, and intended use—whether for daily driving, off-roading, or towing. By researching reputable suppliers, comparing prices, reading customer reviews, and verifying quality certifications, you can secure durable and reliable rims that enhance both the performance and aesthetics of your truck. Whether purchasing new or used, ensuring proper fitment and warranty coverage helps safeguard your investment. Ultimately, taking the time to make an informed decision results in improved safety, vehicle efficiency, and long-term satisfaction.