The global silver testing equipment market is experiencing robust growth, driven by increasing demand for precision in precious metal analysis across industries such as jewelry, electronics, and recycling. According to Grand View Research, the global precious metals testing market size was valued at USD 4.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This expansion is fueled by rising scrutiny on metal purity, stricter regulatory standards, and the growth of the secondary metals recycling sector. Silver, in particular, has seen heightened testing requirements due to its widespread industrial applications and investment value. As demand for accurate, rapid, and non-destructive testing solutions grows, manufacturers of silver testing machines are innovating to deliver advanced spectrometry, X-ray fluorescence (XRF), and electronic conductivity-based solutions. In this evolving landscape, certain companies have emerged as leaders, combining cutting-edge technology with global reach and reliability. The following list highlights the top 9 silver testing machine manufacturers shaping the future of metal verification.

Top 9 Silver Testing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ashlyn Instruments

Domain Est. 2007

Website: ashlyninstruments.com

Key Highlights: Gold & Silver Testing Machines · Melting Machines · Laser Machines · Casting … Manufacturing Machines · Casting · Setting · Filling · Polishing · Rhodium · Gold ……

#2 China Gold Tester Manufacturers, Silver Tester Suppliers, Jewelry …

Domain Est. 2022

Website: napcolab.com

Key Highlights: Napco Precision Instruments Co., Ltd.: We’re professional gold tester, silver tester, jewelry tester, zinc nickel tester, alloy tester manufacturers and ……

#3 Gold, Silver and Platinum Analysis

Domain Est. 1989

Website: bruker.com

Key Highlights: Silver jewelry manufacturers can verify the purity of the silver they purchase to make jewelry as well as monitor their own process in alloying pure silver….

#4 Silver Testing Machine

Domain Est. 2015

Website: superbmelt.com

Key Highlights: We are a silver coin testing machine manufacturer that ensures your electronic silver tester gets to your doorstep on time, without retail interruptions….

#5 Our Services

Domain Est. 1995

Website: lab.chowsangsang.com

Key Highlights: We can provide testing for precious metal raw materials, semi-finished products and jewellery articles of gold, platinum and silver in either destructive or non ……

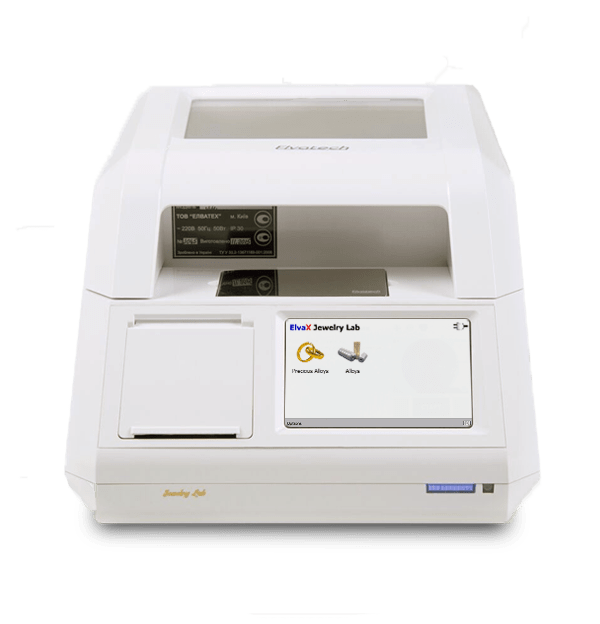

#6 ElvaX Jewelry Lab

Domain Est. 2000

Website: elvatech.com

Key Highlights: ElvaX Jewelry Lab is a perfect benchtop gold and silver testing machine which allows you to define gold and silver purity and measure gold assay….

#7 Analyzing Precious Metals

Domain Est. 2006

Website: thermofisher.com

Key Highlights: Explore technologies used in analysis and testing that help identify elements contained in precious metals….

#8 Silver Testing Machine: Test Silver Content fast

Domain Est. 2012

Website: alloytester.com

Key Highlights: Our silver testers deliver accurate silver concentration readings ranging from trace levels to 100%, whether in alloys or pure silver samples, all in less than ……

#9 Gold Testing Machine, XRF Instruments, Silver Testing Machine

Domain Est. 2020

Website: microanalytik.com

Key Highlights: Microanalytik Instruments offers a wide range of XRF instruments, including gold testing machines, hallmarking machines, and silver testing machines….

Expert Sourcing Insights for Silver Testing Machine

H2: 2026 Market Trends for Silver Testing Machines

The global market for silver testing machines is poised for significant transformation by 2026, driven by increasing industrial demand, technological advancements, and growing regulatory requirements for quality assurance in precious metals. As silver remains a critical material in electronics, jewelry, solar panels, and medical devices, the need for accurate and efficient testing solutions has intensified. The following key trends are expected to shape the silver testing machine market in 2026:

-

Rising Demand in Electronics and Renewable Energy Sectors

The proliferation of high-tech electronics and the global push toward renewable energy—particularly photovoltaic solar panels—are major catalysts for silver consumption. Silver’s superior conductivity makes it indispensable in printed circuit boards, conductive inks, and solar cell manufacturing. This surge in industrial applications will fuel demand for precision silver testing machines to ensure purity and performance standards, especially in automated production environments. -

Adoption of Advanced Technologies

By 2026, silver testing machines are expected to integrate next-generation technologies such as artificial intelligence (AI), machine learning (ML), and Internet of Things (IoT) connectivity. These innovations will enable real-time data analysis, predictive maintenance, and remote monitoring of testing equipment. Portable X-ray fluorescence (XRF) and optical emission spectrometers with enhanced accuracy and faster response times will dominate the market, offering non-destructive testing solutions ideal for on-site quality control. -

Growth in Jewelry and Bullion Markets

The global jewelry industry continues to expand, particularly in emerging markets such as India, China, and Southeast Asia, where silver is a popular choice due to its affordability compared to gold. With increasing consumer awareness and regulatory scrutiny on metal authenticity, demand for handheld and benchtop silver testing devices in retail and auction environments is expected to grow. Devices offering instant results with minimal sample preparation will be highly sought after. -

Stringent Regulatory Standards and Certification Requirements

Regulatory bodies and international standards organizations are tightening purity and traceability requirements for precious metals. In response, manufacturers of silver testing machines are aligning products with ISO, ASTM, and CEN standards. Certification-compliant testing equipment will become essential for refineries, mints, and recycling facilities, driving market growth and encouraging innovation in calibration and reporting functionalities. -

Expansion of Recycling and Urban Mining Initiatives

As sustainability gains prominence, the recycling of electronic waste (e-waste) and end-of-life products containing silver is becoming economically viable. Silver recovery from scrap materials requires precise testing to assess silver content and optimize extraction processes. This trend is expected to boost demand for cost-effective and high-throughput testing solutions in recycling plants and urban mining operations. -

Geographic Market Shifts

Asia-Pacific is projected to lead the silver testing machine market by 2026, fueled by rapid industrialization, a booming electronics manufacturing sector, and strong domestic demand for jewelry. North America and Europe will maintain steady growth, supported by advanced research infrastructure and strict quality control in high-tech industries. Meanwhile, Latin America and Africa are emerging as new markets due to expanding mining activities and improved assay infrastructure. -

Increased Competition and Market Consolidation

The silver testing machine market will witness intensified competition among key players such as Thermo Fisher Scientific, Bruker, Olympus (Evident), and Innov-X (part of Olympus). Strategic partnerships, mergers, and product diversification will be common as companies aim to capture larger market shares. Entry of regional manufacturers offering affordable, localized solutions may also disrupt pricing models and expand market accessibility.

In conclusion, the 2026 outlook for the silver testing machine market is characterized by technological innovation, sector-driven demand, and global expansion. Stakeholders who invest in smart, compliant, and user-friendly testing systems will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Silver Testing Machines (Quality and Intellectual Property)

Sourcing a silver testing machine, especially for accurate purity assessment and compliance, involves navigating several critical challenges related to quality assurance and intellectual property (IP) protection. Overlooking these pitfalls can lead to inaccurate results, financial losses, reputational damage, and potential legal complications.

Inadequate Quality Control and Performance Verification

One of the most frequent issues is receiving a machine that fails to deliver the precision and reliability promised. Many suppliers, particularly those from less-regulated markets, may offer equipment with unverified specifications. Buyers often assume stated accuracy (e.g., ±0.01% purity) is guaranteed, only to discover discrepancies during real-world testing. Lack of independent calibration certificates, substandard sensors, or poor build quality can compromise test results. Without third-party validation or performance testing prior to purchase, businesses risk investing in equipment that produces inconsistent or unreliable data—undermining trust in transactions and quality control processes.

Risk of Counterfeit or Clone Devices

The market for precious metal testers has seen a rise in counterfeit or reverse-engineered machines that mimic reputable brands. These clones often replicate the exterior design and branding but use inferior internal components and algorithms, leading to inaccurate readings. Sourcing from unauthorized distributors or gray-market channels increases exposure to such devices. These knockoffs not only perform poorly but may also lack essential safety certifications and software updates, posing operational and compliance risks.

Intellectual Property Infringement

Purchasing or using a testing machine that infringes on existing patents or proprietary technology can expose the buyer to legal liability. Some low-cost suppliers reproduce patented spectroscopy methods, software algorithms, or hardware designs without licensing. Even if the buyer is unaware, using such a machine could result in cease-and-desist orders, fines, or forced equipment seizure. It is essential to verify that the supplier holds legitimate rights to the technology or has appropriate IP licenses, particularly for advanced techniques like X-ray fluorescence (XRF) or electronic conductivity testing.

Lack of Software Authenticity and Support

Modern silver testers rely heavily on proprietary software for analysis and reporting. A common pitfall is receiving devices with pirated, outdated, or unsupported software. This not only violates licensing agreements but also limits functionality, prevents updates, and increases vulnerability to cybersecurity threats. Without access to official software support, users may be unable to fix bugs, comply with regulatory changes, or generate legally defensible test reports.

Insufficient After-Sales Service and Calibration

A high-quality silver testing machine requires regular calibration and technical support to maintain accuracy over time. Sourcing from suppliers without a local service presence or clear maintenance protocols can result in prolonged downtime and escalating costs. Machines that lack traceable calibration to international standards (e.g., NIST) may not be accepted in regulated environments or during audits, undermining their utility and credibility.

Hidden Costs and Misrepresented Specifications

Some suppliers advertise low upfront prices but omit critical costs such as calibration services, software licenses, spare parts, or training. Additionally, technical specifications may be misleading—such as quoting ideal lab conditions rather than real-world performance. This can result in budget overruns and performance shortfalls once the machine is deployed.

Avoiding these pitfalls requires due diligence: vetting suppliers thoroughly, requesting third-party test reports, verifying IP legitimacy, ensuring software authenticity, and securing comprehensive service agreements. Investing time in proper sourcing safeguards both operational integrity and legal compliance.

Logistics & Compliance Guide for Silver Testing Machine

Product Classification and Regulatory Overview

Silver testing machines, used for analyzing the purity and composition of silver in various forms (e.g., bullion, jewelry, scrap), are typically classified as scientific or analytical instruments. Depending on the technology used (e.g., X-ray fluorescence (XRF), fire assay, electronic testers), these devices may fall under specific regulatory frameworks related to measurement accuracy, radiation safety, and environmental compliance. Understanding the classification is essential for meeting import/export, transportation, and operational requirements.

International Shipping and Transportation

When shipping a silver testing machine internationally, proper packaging, labeling, and documentation are critical. Ensure the device is securely packed to prevent damage during transit, especially if it contains sensitive components such as X-ray tubes or precision sensors. Use shock-absorbing materials and moisture barriers where necessary. Clearly label packages with “Fragile,” “This Side Up,” and any applicable hazard labels (e.g., for batteries or radiation sources). Air and sea freight must comply with IATA (International Air Transport Association) or IMDG (International Maritime Dangerous Goods) regulations if hazardous components are present.

Export Controls and Licensing

Silver testing machines—particularly those using XRF or other spectroscopic technologies—may be subject to export control regulations. In the United States, such devices could fall under the Export Administration Regulations (EAR) and may require a license depending on the destination country and technical specifications (e.g., energy levels of X-ray tubes). Check if the machine is listed on the Commerce Control List (CCL) under ECCN 3A999 or similar categories. Similar controls may apply under EU dual-use regulations or other national regimes.

Import Compliance and Duties

Importers must verify tariff classifications (e.g., under the Harmonized System code—typically 9027 for instruments and apparatus for physical or chemical analysis) and confirm applicable duties and taxes in the destination country. Some countries offer duty exemptions for scientific equipment; check local customs regulations. Provide complete commercial invoices, packing lists, and certificates of origin. Machines with electronic components may also need to comply with electromagnetic compatibility (EMC) and electrical safety standards.

Safety and Environmental Compliance

Devices using ionizing radiation, such as XRF analyzers, must comply with radiation safety standards (e.g., FDA 21 CFR 1020.40 in the U.S., IEC 62495 internationally). These machines typically require registration with national radiation protection agencies and may need periodic inspections. Ensure compliance with RoHS (Restriction of Hazardous Substances) and REACH regulations in the EU for electronic components. Proper end-of-life disposal must follow WEEE (Waste Electrical and Electronic Equipment) directives.

Calibration and Metrological Compliance

For accurate results, silver testing machines must be calibrated according to recognized standards (e.g., ISO/IEC 17025 for testing and calibration laboratories). Provide calibration certificates traceable to national or international standards. Some countries require in-country certification by a metrology institute before the device can be legally used for commercial assay purposes.

Documentation and Recordkeeping

Maintain comprehensive records including:

– Technical specifications and user manuals

– Calibration and maintenance logs

– Export/import licenses and customs declarations

– Radiation safety certifications (if applicable)

– Compliance declarations (CE, FCC, etc.)

These documents are essential for audits, customs clearance, and regulatory inspections.

Summary

Successful logistics and compliance for silver testing machines require attention to classification, safety standards, export controls, and customs regulations. Always consult with legal and regulatory experts in both the exporting and importing countries to ensure full compliance and avoid delays or penalties.

Conclusion for Sourcing a Silver Testing Machine

After a thorough evaluation of available options, sourcing a silver testing machine is a strategic investment that enhances accuracy, efficiency, and trust in precious metal verification. Whether for a jewelry business, refinery, pawn shop, or scrap metal operation, the right testing equipment ensures reliable results, reduces the risk of fraud, and supports compliance with quality standards.

Among the various technologies—such as X-ray Fluorescence (XRF), electronic testers, acid test kits, and optical spectrometers—XRF analyzers emerge as the most accurate, non-destructive, and user-friendly solution for high-volume and professional use. Although they require a higher initial investment, their long-term benefits in terms of precision, speed, and minimal sample damage justify the cost.

Key considerations in sourcing should include precision requirements, budget, ease of use, portability, and after-sales support. It is recommended to procure machines from reputable suppliers offering calibration services, training, and warranty coverage to ensure sustained performance.

In conclusion, acquiring a high-quality silver testing machine not only improves operational efficiency but also strengthens customer confidence and protects your business from financial loss due to counterfeit or substandard materials. The ideal choice balances performance, reliability, and cost-effectiveness to meet the specific needs of your operation.