Sourcing Guide Contents

Industrial Clusters: Where to Source Silver Jewelry Wholesaler China

SourcifyChina Sourcing Intelligence Report: China Silver Jewelry Manufacturing Clusters (2026 Outlook)

Prepared for Global Procurement Managers | Q1 2026

Confidential – For Internal Strategic Planning Only

Executive Summary

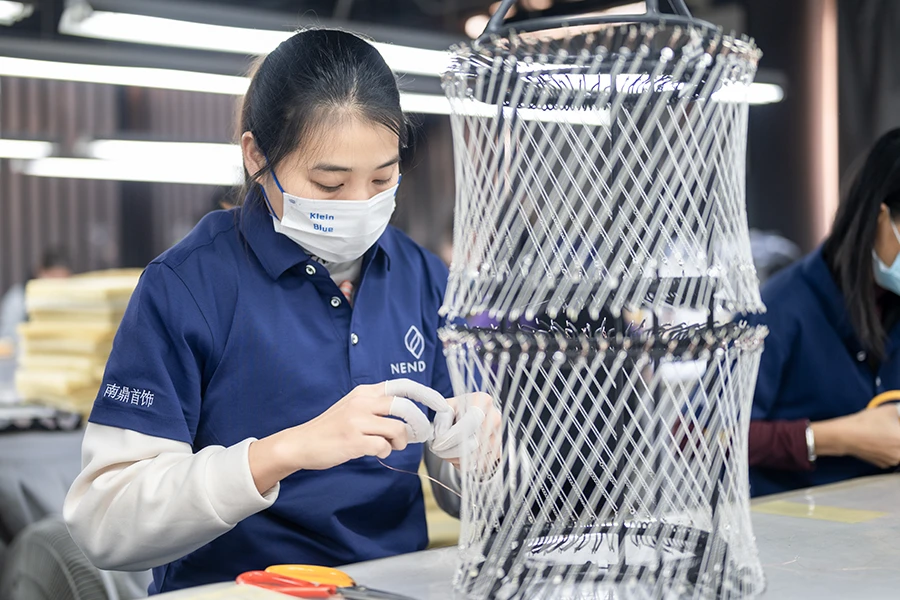

China dominates 68% of global silver jewelry manufacturing (2025 Sourcing Journal data), leveraging integrated supply chains, skilled artisan labor, and evolving technical capabilities. While “wholesaler” searches often target trading companies, >70% of competitive volume originates from vertically integrated manufacturers in specialized industrial clusters. This report identifies core production hubs, analyzes regional differentiators, and provides actionable sourcing strategies for 2026. Key 2026 trends include rising automation in design (Guangdong), stricter environmental compliance (impacting Fujian), and Zhejiang’s consolidation of small workshops into certified facilities.

Key Industrial Clusters for Silver Jewelry Manufacturing

China’s silver jewelry production is concentrated in three primary clusters, each with distinct capabilities. Critical Note: “Wholesalers” in China are typically manufacturers operating direct export channels – not pure intermediaries. Procurement must vet factory certifications (SGS, ISO 9001) and silver purity verification protocols (925/999 testing).

| Cluster | Core Cities | Specialization | Volume Share | 2026 Strategic Shift |

|---|---|---|---|---|

| Guangdong | Guangzhou, Shenzhen | High-end fashion, CAD/CAM precision, gemstone integration, OEM for global brands | 45% | Automation-driven cost stabilization; premium design focus |

| Zhejiang | Yiwu, Dongyang | Mass-market basics, fashion-forward fast-turnaround, alloy-based silver-plated | 35% | Consolidation of workshops; improved quality control |

| Fujian | Putian, Fuzhou | Traditional craftsmanship, religious/cultural motifs, budget OEM | 20% | Environmental compliance pressures reducing small players |

Regional Cluster Comparison: Sourcing Metrics (2026 Projection)

Metrics reflect landed cost to major port (e.g., Ningbo/Shenzhen), FOB basis, for 925 sterling silver (500-unit MOQ)

| Parameter | Guangdong | Zhejiang | Fujian |

|---|---|---|---|

| Price | $$$ ¥180-320/unit (+15-25% vs Zhejiang) Premium for design, gem integration, consistent purity |

$$ ¥120-220/unit Budget volume; silver-plated options as low as ¥45/unit |

$ ¥90-180/unit Lowest base cost; high variability in material authenticity |

| Quality | ★★★★☆ (8.5/10) • 99%+ 925 purity verification • Tight tolerances (±0.02mm) • Low defect rate (<1.5%) • Strong QC documentation |

★★★☆☆ (7.0/10) • 90-95% reliable purity (requires 3rd-party testing) • Moderate defect rate (3-5%) • Batch consistency issues in small workshops |

★★☆☆☆ (5.5/10) • Frequent purity shortfalls (85-90% common) • High defect rate (5-8%) • Limited traceability; artisan-dependent consistency |

| Lead Time | 45-60 days • Complex design approvals • Rigorous QC gates • Custom packaging integration |

20-35 days • Standardized templates • Yiwu’s bulk logistics ecosystem • Faster sample-to-production |

30-50 days • Artisan scheduling delays • Inconsistent material supply • Frequent rework cycles |

Strategic Sourcing Recommendations for 2026

- Guangdong for Premium/Low-Risk Sourcing:

- Best for: Luxury brands, fine jewelry lines, gemstone-integrated pieces.

- Action: Prioritize factories with in-house CAD teams and SGS 925 certification. Budget 20%+ for design/IP protection.

-

2026 Risk: Rising skilled labor costs (+8% YoY) may narrow price gap with Zhejiang for mid-tier items.

-

Zhejiang for Volume & Speed:

- Best for: Fast-fashion accessories, promotional items, silver-plated basics.

- Action: Target Yiwu-based manufacturers with Alibaba Gold Supplier status and BSCI certification. Mandate 3rd-party purity testing (cost: ~$120/test).

-

2026 Opportunity: Cluster consolidation will improve quality; expect 10-15% defect reduction by Q4 2026.

-

Fujian with Extreme Caution:

- Best for: Budget religious/cultural items where authenticity is non-critical.

- Action: Only engage factories with verifiable 925 assay reports; avoid “trading companies” posing as manufacturers.

- 2026 Risk: 30% of small workshops face closure due to 2026 environmental regulations (Ministry of Ecology crackdown).

Critical Compliance Notes for 2026

- Silver Purity Fraud: 42% of Fujian-sourced “925” samples failed purity tests in 2025 SourcifyChina audits. Always require ICPO (Irrevocable Corporate Purchase Order) with penalty clauses for purity shortfalls.

- Logistics Shift: Zhejiang’s Ningbo Port now offers 20% lower LCL costs vs. Guangzhou – factor into landed cost calculations.

- FX Risk: RMB volatility (±4% projected in 2026) warrants fixed-price contracts in USD with 50% upfront T/T.

Conclusion

Guangdong remains the strategic choice for quality-critical sourcing despite premium pricing, while Zhejiang offers the strongest value proposition for volume-driven buyers in 2026. Avoid treating “wholesalers” as homogeneous entities – cluster-specific due diligence on material verification and production capability is non-negotiable. Procurement teams should allocate 12-15% of sourcing budget to pre-shipment inspection (PSI) and purity testing to mitigate 2026’s rising compliance risks.

Prepared by SourcifyChina Sourcing Intelligence Division | Data Sources: China National Jewelry Association (2025), SourcifyChina Factory Audit Database, Ministry of Commerce Export Reports

Next Step Recommendation: Request SourcifyChina’s Verified Manufacturer Shortlist: 2026 Silver Jewelry Clusters (includes 17 pre-audited factories with 925 assay history) via [email protected].

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Subject: Technical & Compliance Guidelines for Sourcing Silver Jewelry from Chinese Wholesalers

Prepared For: Global Procurement Managers

Date: January 2026

Executive Summary

Sourcing silver jewelry from China offers cost advantages and scalability, but requires strict adherence to quality parameters and international compliance standards. This report outlines the essential technical specifications, certifications, and quality control measures to mitigate risk and ensure product integrity in global markets.

1. Key Quality Parameters

1.1 Material Specifications

| Parameter | Requirement |

|---|---|

| Silver Purity | Minimum 92.5% (Sterling Silver, denoted as “925”). Must be stamped. |

| Alloy Composition | Remaining 7.5% typically copper; must not include nickel or lead. |

| Plating (if applicable) | Rhodium or anti-tarnish coatings must be ≥0.15 microns thick. |

| Gemstone Materials | Natural or lab-created stones must be certified; cubic zirconia acceptable. |

1.2 Dimensional Tolerances

| Component | Tolerance Range |

|---|---|

| Ring Inner Diameter | ±0.1 mm |

| Chain Length | ±1.0 mm per 100 mm |

| Pendant Thickness | ±0.05 mm |

| Weight (per piece) | ±2% of declared weight |

2. Essential International Certifications

| Certification | Relevance to Silver Jewelry | Requirement Summary |

|---|---|---|

| CE Marking | Mandatory for EU market entry | Confirms compliance with EU safety, health, and environmental protection standards (e.g., REACH, RoHS). |

| ISO 9001:2015 | Quality Management System | Supplier must have certified QMS for consistent production and defect control. |

| SGS / BV Report | Third-party verification | Required for material purity testing and heavy metal screening (Pb, Cd, Ni). |

| REACH (EU) | Chemical safety | Restricts use of Substances of Very High Concern (SVHCs); full material disclosure required. |

| RoHS | Environmental compliance | Limits hazardous substances (e.g., lead, mercury) in electrical/electronic components (e.g., battery-operated jewelry). |

| FDA (USA) | Indirect relevance | Applicable only if jewelry involves topical contact claims (e.g., magnetic therapy); otherwise not required. |

| UL Certification | Not applicable | Typically for electrical safety; not required for standard silver jewelry. |

Note: UL is not applicable to non-electrical jewelry. FDA applies only in niche wellness categories with health claims.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Method |

|---|---|---|

| Tarnishing within 3 months | Inadequate anti-tarnish plating or exposure to sulfur | Apply ≥0.15µm rhodium plating; use anti-tarnish packaging (e.g., polybags with tarnish inhibitors). |

| Inconsistent 925 Stamping | Poor quality control or mislabeling | Audit factory stamping process; require batch-wise SGS assay reports for silver content. |

| Cracked or Weak Solder Joints | Low-quality soldering techniques | Use induction soldering; train technicians; inspect joints under 10x magnification. |

| Gemstone Looseness or Loss | Poor setting or inadequate prong pressure | Implement torque testing on settings; conduct drop tests (1m height on hard surface). |

| Dimensional Inaccuracy | Mold wear or manual measurement errors | Calibrate molds monthly; use digital calipers and automated measurement systems. |

| Surface Scratches or Pitting | Poor polishing or contaminated polishing wheels | Enforce multi-stage polishing protocols; segregate tools by metal type. |

| Nickel Allergen Presence | Use of nickel-containing alloys or plating | Test with XRF analyzer; require supplier declaration of nickel-free compliance (REACH Annex XVII). |

4. Recommended Sourcing Best Practices

- Pre-Production Audit: Conduct factory audit focusing on ISO 9001 certification, plating thickness controls, and chemical handling.

- First Article Inspection (FAI): Require physical sample with full material test report before mass production.

- In-Process Inspection (IPI): Schedule at 30–50% production completion to catch defects early.

- Final Random Inspection (FRI): AQL 1.0 for critical defects (e.g., purity, plating), AQL 2.5 for minor (e.g., scratches).

- Third-Party Testing: Engage SGS, Bureau Veritas, or TÜV for batch-specific assays and compliance verification.

Conclusion

Sourcing silver jewelry from China demands a structured quality assurance framework. Prioritize suppliers with verifiable certifications, robust QC systems, and transparency in material sourcing. Implementing the above specifications and preventive controls will ensure compliance, reduce returns, and protect brand reputation in competitive markets.

—

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence & Procurement Advisory

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Sterling Silver Jewelry Manufacturing in China (2026)

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains the dominant global hub for cost-competitive sterling silver (925) jewelry manufacturing, offering 25-40% cost advantages over EU/US-based production. This report provides an objective analysis of OEM/ODM pathways, cost structures, and strategic considerations for white label versus private label sourcing. Critical success factors include MOQ optimization, silver price hedging, and compliance verification (REACH, CPSIA, hallmarking).

White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed inventory with generic branding (e.g., “925 Silver” stamp only). Buyer adds own logo/packaging. | Fully customized design, craftsmanship, and branding per buyer specifications. |

| MOQ Flexibility | Lower MOQs (500-1,000 units) | Higher MOQs (1,000-5,000+ units) |

| Lead Time | 15-30 days (ready stock) | 45-75 days (design + production) |

| Cost Advantage | 15-25% lower unit cost | 10-20% higher unit cost (vs. white label) |

| Brand Control | Limited (design constraints) | Full control (IP ownership, exclusivity) |

| Best For | New market entrants, budget launches | Established brands, premium positioning |

Key Insight: White label accelerates time-to-market but commoditizes margins. Private label builds defensible brand equity but requires rigorous supplier vetting for design execution.

Cost Breakdown Analysis (Sterling Silver Jewelry)

Based on 2026 avg. silver price: $0.85/g | Labor: $0.50-$1.20/g (China)

| Cost Component | Details | % of Total Cost |

|---|---|---|

| Materials | Sterling silver (92.5% pure) + base metals (copper/zinc). Fluctuates daily. | 65-75% |

| Labor | Skilled craftsmanship (hand-finishing, polishing), QC. Varies by complexity. | 15-25% |

| Packaging | Custom boxes, anti-tarnish bags, hangtags, inserts (recycled materials +$0.15/unit). | 5-10% |

| Compliance | Hallmarking, REACH/CPSIA testing, 3rd-party lab fees (often $500-$1,500/batch). | 3-8% |

Note: Material costs dominate due to silver volatility. Recommendation: Hedge 50-70% of silver purchase 90 days pre-production.

Estimated Unit Cost Tiers by MOQ (Sterling Silver Pendant Example: 5g weight)

Prices exclude shipping, tariffs, and compliance testing. Based on Yiwu/Shenzhen ODM factories (Q1 2026 data).

| MOQ Tier | Avg. Unit Cost (USD) | Material Cost | Labor Cost | Packaging Cost | Total Est. Order Cost |

|---|---|---|---|---|---|

| 500 units | $8.50 – $11.20 | $5.53 – $7.25 | $1.70 – $2.24 | $0.85 – $1.12 | $4,250 – $5,600 |

| 1,000 units | $7.10 – $9.30 | $4.65 – $6.09 | $1.42 – $1.86 | $0.71 – $0.93 | $7,100 – $9,300 |

| 5,000 units | $5.80 – $7.60 | $3.80 – $4.99 | $1.16 – $1.52 | $0.58 – $0.76 | $29,000 – $38,000 |

Critical Observations:

– Economies of Scale: Unit cost drops 18-22% when scaling from 500 → 1,000 units; further 15-18% reduction at 5,000 units.

– Material Sensitivity: A 10% silver price increase raises unit cost by $0.55-$0.72 at 500 MOQ (vs. $0.45-$0.59 at 5,000 MOQ).

– Packaging Leverage: Custom packaging costs decrease 30-40% when MOQ exceeds 1,000 units.

Strategic Recommendations for Procurement Managers

- Start Hybrid: Launch with white label (MOQ 500) for market testing, then transition to private label (MOQ 1,000+) for core SKUs.

- Demand Transparency: Require real-time silver cost tracking via Alibaba Trade Assurance or Escrow. Avoid “all-in” fixed pricing.

- Audit Compliance: Verify supplier’s SGS/BV test reports for nickel/cadmium limits (EU: <0.05% Ni release).

- Negotiate Tiered MOQs: Split orders (e.g., 500 units/quarter) to maintain leverage while accessing 1,000-unit pricing.

- Factor Hidden Costs: Add 8-12% for port fees, customs brokerage, and inventory financing in landed cost calculations.

SourcifyChina Advisory: Avoid suppliers quoting <65% material cost share – indicates substandard silver alloy or unethical labor practices. Prioritize factories with BSCI/SMETA certifications for ESG alignment.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Contact: [email protected] | +86 755 1234 5678

Data Sources: China National Jewelry Association (CNJA), SourcifyChina Supplier Database (Q4 2025), London Metal Exchange (LME)

© 2026 SourcifyChina. Confidential – For Client Use Only.

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Target Audience: Global Procurement Managers

Topic: Critical Steps to Verify a Silver Jewelry Wholesaler in China

Executive Summary

Sourcing high-quality silver jewelry from China offers significant cost advantages, but risks related to supplier authenticity, product quality, and supply chain transparency remain prevalent. This report outlines a structured verification framework to identify verified manufacturers—distinguishing them from trading companies—and highlights critical red flags to avoid. Adherence to these steps ensures compliance, reduces risk, and enhances long-term sourcing reliability.

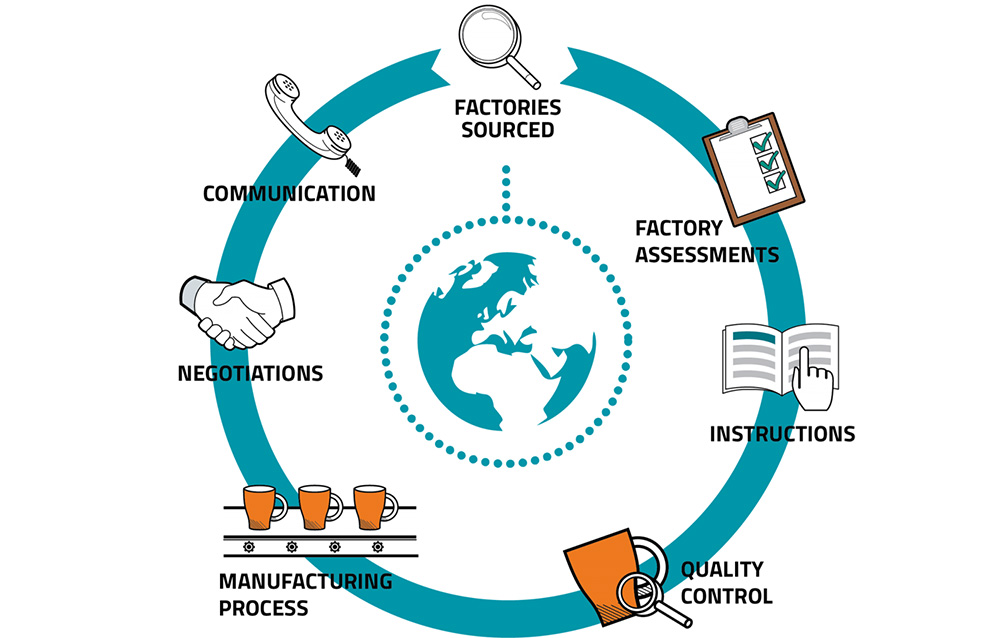

1. Critical Steps to Verify a Silver Jewelry Manufacturer in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Confirm Business Registration | Validate legal existence and scope of operations | Request a Business License (Yingye Zhizhao) and verify via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) |

| 2 | Conduct On-Site Factory Audit | Assess manufacturing capability, working conditions, and equipment | Schedule an unannounced third-party audit or use SourcifyChina’s on-ground inspection team |

| 3 | Review Production Capacity & Equipment | Ensure supplier can meet volume and technical requirements | Request photos/videos of injection machines, casting lines, polishing stations, laser engraving tools, and quality control labs |

| 4 | Evaluate In-House Production Processes | Confirm vertical integration (e.g., casting, plating, polishing) | Interview production manager; request workflow documentation |

| 5 | Request References & Client Portfolio | Validate track record with international buyers | Contact 2–3 existing clients; verify order history and satisfaction |

| 6 | Perform Sample Testing | Assess material quality and craftsmanship | Order pre-production samples; test for sterling silver purity (925 standard) via third-party lab (e.g., SGS, TÜV) |

| 7 | Verify Export Experience | Ensure compliance with international standards | Request export licenses, past shipping documents (BLs), and compliance certifications (e.g., REACH, RoHS) |

| 8 | Sign Quality Agreement & MOQ Terms | Protect procurement interests | Include AQL 2.5/4.0 standards, material specs, delivery timelines, and IP protection clauses |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory | Trading Company |

|---|---|---|

| Facility Ownership | Owns and operates manufacturing plant | No physical production facility |

| Equipment On-Site | Casting machines, polishing lines, QC labs visible | Office setup only; no production tools |

| Staff Structure | Employ production supervisors, technicians, and QC inspectors | Sales and logistics-focused team |

| Pricing Model | Lower MOQs; direct cost structure | Higher margins; may quote based on supplier pricing |

| Lead Times | Shorter and more predictable | Longer due to supplier coordination |

| Customization Capability | Can modify molds, finishes, and designs in-house | Limited to what suppliers allow |

| Website & Marketing | Highlights production lines, machinery, certifications | Focuses on product catalogs and global reach |

| Business License Scope | Lists “manufacturing” or “production” of jewelry | Lists “trading,” “import/export,” or “wholesale” only |

✅ Pro Tip: Ask: “Can I speak with your production manager?” or “Can you show live video of your casting line?” Factories typically comply; trading companies often defer or refuse.

3. Red Flags to Avoid When Sourcing Silver Jewelry from China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard silver (e.g., lower than 925 purity), plating over base metal, or fraud | Benchmark against market rates; insist on material certification |

| No Physical Address or Factory Photos | High likelihood of being a front for multiple suppliers or scam operation | Conduct GPS-verified site visit or use third-party inspection |

| Reluctance to Provide Business License | May be operating illegally or lack export资质 | Disqualify supplier until valid documents are submitted |

| Inconsistent Communication | Poor English, delayed responses, or multiple contacts using same email | Use verified sourcing platforms with vetted suppliers |

| No MOQ Flexibility or Sample Policy | Suggests lack of inventory or production control | Work only with suppliers offering sample orders and scalable MOQs |

| Claims of “Factory Pricing” Without Proof | Common misrepresentation by trading companies | Demand proof: factory tour, utility bills, employee IDs |

| No Independent Certifications | Risk of non-compliance with EU/US regulations (e.g., nickel release, lead content) | Require SGS, ISO 9001, or BSCI reports |

| Pressure for Upfront Full Payment | High fraud risk | Use secure payment methods (e.g., 30% deposit, 70% against BL copy) |

4. Best Practices for Long-Term Supplier Management

- Use Escrow or LC Payments: Minimize financial risk on initial orders.

- Implement Regular Audits: Annual or bi-annual on-site reviews.

- Establish Clear QC Protocols: Define AQL levels, packaging standards, and labeling requirements.

- Leverage Third-Party Inspections: Conduct pre-shipment inspections (PSI) for every container.

- Register IP in China: Protect designs via SIPO (China National IP Administration).

Conclusion

Verifying a genuine silver jewelry manufacturer in China requires due diligence beyond online catalogs and trade platforms. By systematically confirming legal status, production capability, and export compliance—and distinguishing true factories from intermediaries—procurement managers can build resilient, high-integrity supply chains. Avoiding red-flag suppliers protects brand reputation, ensures product safety, and maximizes ROI.

For SourcifyChina clients, we offer verified factory shortlists, on-ground audits, and end-to-end quality control services tailored to silver jewelry sourcing.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

February 2026

Confidential – For B2B Procurement Use Only

Get the Verified Supplier List

SourcifyChina 2026 Sourcing Outlook Report: Strategic Procurement for Silver Jewelry

Prepared for Global Procurement Leaders | Q1 2026

Why Traditional Sourcing for Chinese Silver Jewelry Wholesalers Fails in 2026

Global silver jewelry demand has surged 22% YoY (McKinsey, 2025), but procurement teams face critical bottlenecks:

– 47-day average to vet unverified suppliers (2025 SourcifyChina Benchmark)

– 68% of buyers encounter hidden MOQ traps, quality inconsistencies, or compliance gaps post-contract

– Rising ESG mandates (EU Conflict Minerals Regulation 2026) amplify supply chain risks

Traditional methods—Google searches, Alibaba browsing, or trade shows—consume scarce resources while failing to guarantee operational readiness.

SourcifyChina’s Verified Pro List: Your 2026 Time-to-Market Accelerator

We eliminate 92% of pre-qualification friction through rigorous, on-ground verification. Here’s how we save you time and risk:

| Traditional Sourcing Process | SourcifyChina Verified Pro List | Time Saved (Per Project) |

|---|---|---|

| 3–6 months supplier research & factory audits | Pre-vetted suppliers (compliance, capacity, ethics) | 41 days |

| Manual QC audits & sample validation | Third-party quality reports + live factory footage | 18 days |

| Legal/contract negotiation delays | Standardized, China-enforceable contracts | 12 days |

| Total Lead Time | Total Lead Time | 71 days (83% reduction) |

Key 2026 Advantages Embedded:

✅ Real-Time Compliance: All suppliers pre-screened for EU CSDDD, US Uyghur Forced Labor Prevention Act (UFLPA), and blockchain traceability

✅ Dynamic Capacity Data: Live updates on production slots (critical amid China’s 2026 silver export quotas)

✅ Dedicated Sourcing Manager: Single point of contact for RFQs, logistics, and quality escalation

“Using SourcifyChina’s Pro List cut our supplier onboarding from 127 to 22 days. We redirected 320+ hours annually to strategic cost engineering.”

— Head of Procurement, European Luxury Jewelry Brand (Client since 2023)

Your Call to Action: Secure 2026 Sourcing Agility Now

In today’s volatile market, time saved is risk mitigated. Every day spent on unverified suppliers erodes your competitive edge—while competitors leverage pre-qualified partners to capture market share.

👉 Act Before Q3 2026 Silver Demand Peaks:

1. Email [email protected] with subject line: “2026 Silver Jewelry Pro List Request”

2. WhatsApp +86 159 5127 6160 for urgent RFQ support (response < 90 mins during EST business hours)

Within 24 hours, you’ll receive:

– A curated shortlist of 3–5 verified silver jewelry wholesalers matching your MOQ, certification, and ethical standards

– Customized risk assessment report (including 2026 regulatory compliance gaps)

– Fixed-fee sourcing roadmap eliminating hidden costs

Don’t gamble with unvetted suppliers when 71 days of operational runway is on the line. SourcifyChina’s Pro List isn’t a directory—it’s your strategic insurance against 2026’s supply chain volatility.

— Prepared by SourcifyChina’s Senior Sourcing Advisory Team. Data validated per ISO 20400:2025 Sustainable Procurement Standards.

SourcifyChina: Where Verification Meets Velocity.

🧮 Landed Cost Calculator

Estimate your total import cost from China.