The global silicone products market is experiencing robust growth, driven by increasing demand for durable, flexible, and hypoallergenic materials across consumer electronics, healthcare, and wearable technology sectors. According to Grand View Research, the global silicone market was valued at USD 20.3 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. A key driver within this expansion is the rising popularity of custom silicone bands—used in smartwatches, fitness trackers, medical ID bracelets, and promotional merchandise. With major tech companies and lifestyle brands prioritizing personalization and user comfort, the need for reliable, high-volume custom silicone band manufacturers has surged. This growing demand has led to the emergence of specialized manufacturers across Asia, North America, and Europe, offering OEM/ODM services, rapid prototyping, and compliance with international quality standards. Below, we profile the top 10 silicone bands custom manufacturers positioned to meet this booming market demand.

Top 10 Silicone Bands Custom Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom Silicone Wristbands

Domain Est. 1997

Website: aerorubber.com

Key Highlights: High Quality Custom Silicone Wristbands | B2B Volume | Large Inventory | Est. 1973 | Call Aero Rubber @ (800) 662-1009….

#2 Custom Silicone Wristbands & Rubber Bracelets

Domain Est. 2015

Website: wristbandbuddy.com

Key Highlights: Wristbandbuddy.com is a leading wristband manufacturer, offering a great range of custom silicone wristbands, printed wristbands, rubber wristbands and ……

#3 Custom Silicone Wristbands

Domain Est. 1996

#4 Custom Silicone Wristbands & Personalised Rubber Wristbands

Domain Est. 2002

Website: idcband.com

Key Highlights: Free delivery over $100 · 31-day returnsWe offer a variety of cheap silicone wristbands that are high quality and can be custom printed with your own design or purchased in a vari…

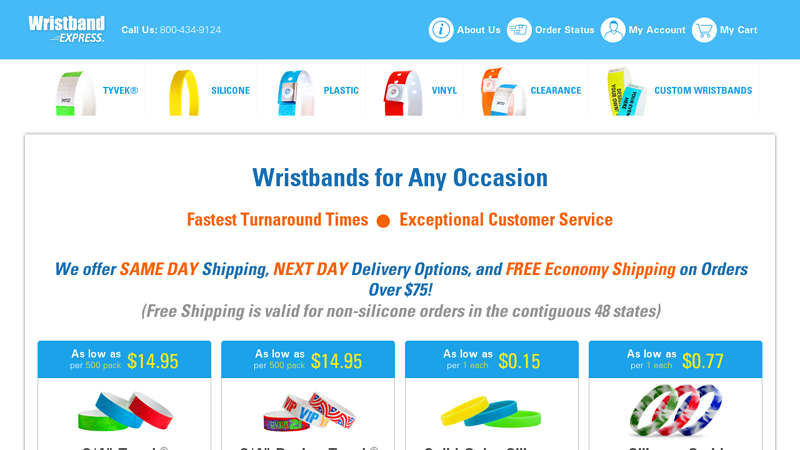

#5 Wristband Express

Domain Est. 2004

Website: wristbandexpress.com

Key Highlights: $50 delivery · 30-day returnsBuy custom & stock wristbands from Wristband Express! Shop Tyvek, silicone, plastic & vinyl wristbands for your events, parties, admissions & screenin…

#6 Reminderband: Silicone Bracelets & Custom Bracelets

Domain Est. 2004 | Founded: 2004

Website: reminderband.com

Key Highlights: Reminderband is the original custom silicone wristband company. We’ve been personalizing quality wristbands for just about any occasion since 2004….

#7 Wristband Connection: Customized Silicone Wristbands

Domain Est. 2010

Website: thewristbandconnection.com

Key Highlights: 15-day returnsWristband Connection sells customized silicone wristbands and rubber bracelets. Start designing your silicone bracelet with your message, color & clipart!…

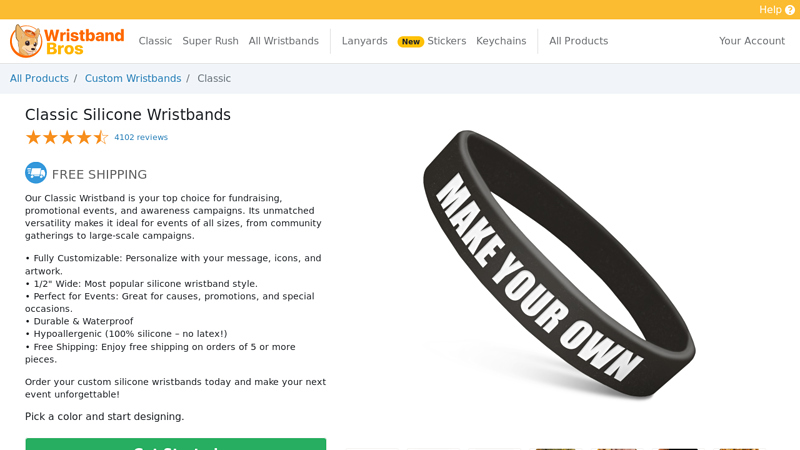

#8 The Classic Rubber Wristband

Domain Est. 2011

Website: wristbandbros.com

Key Highlights: In stock Rating 4.7 (4,101) The Classic is our most popular custom wristband. This item is made from 100% silicone and available in Youth (7″), Adult (8″) and Large (8.5″) sizes….

#9 Wristband Creation

Domain Est. 2012

Website: wristbandcreation.com

Key Highlights: $7.99 delivery · 30-day returnsWristbandCreation.com is your leading source for customized silicone wristbands. You can design your own wristbands and choose your own message, col…

#10 Silicone Wristbands

Domain Est. 1996

Website: wristband.com

Key Highlights: Need cheap silicone wristbands for a fundraiser or event? Wristband Resources is your best source for personalized silicone wristbands made in the USA….

Expert Sourcing Insights for Silicone Bands Custom

2026 Market Trends for Silicone Bands Custom

Rising Demand for Personalization and Branding

In 2026, the custom silicone bands market will continue to be driven by a strong consumer preference for personalized products. Individuals and organizations increasingly seek unique designs that reflect identity, affiliation, or cause awareness. Businesses leverage custom bands for branding, promotional events, and employee engagement, while consumers use them for fashion, fitness tracking, and commemorative purposes. Advanced digital printing and laser etching technologies will enable more intricate designs and faster turnaround, supporting mass customization at scale.

Expansion in Healthcare and Safety Applications

The healthcare sector is expected to adopt custom silicone bands more widely by 2026, particularly in patient identification and medical alerts. Hospitals and clinics are shifting toward durable, hypoallergenic silicone wristbands with QR codes or RFID integration for secure data access. Additionally, safety-conscious industries such as construction and manufacturing may adopt customized silicone bands embedded with safety certifications or emergency contact information, enhancing workplace safety protocols.

Sustainability and Eco-Friendly Materials

Environmental concerns will push manufacturers toward sustainable production methods and recyclable silicone materials. In 2026, consumers and corporate clients will increasingly demand eco-certified silicone bands made from non-toxic, recyclable, or bio-based silicones. Brands emphasizing green manufacturing processes and carbon-neutral shipping will gain a competitive edge, aligning with global sustainability goals and consumer values.

Integration with Wearable Technology

While traditional silicone bands remain popular, a growing trend involves hybrid models combining aesthetic customization with smart features. In 2026, expect to see more custom bands compatible with fitness trackers and health monitors, offering interchangeable, branded silicone straps. This convergence allows users to personalize their wearable tech while maintaining functionality, appealing to tech-savvy and fashion-conscious demographics.

Growth in E-Commerce and Direct-to-Consumer Models

Online platforms will dominate custom silicone band distribution by 2026, enabling instant design uploads, real-time previews, and rapid fulfillment. Small businesses, nonprofits, and individuals benefit from user-friendly design tools and low minimum order quantities. Subscription models for recurring events (e.g., monthly charity bands) and AI-driven design recommendations will enhance customer engagement and retention in the e-commerce space.

Regional Market Expansion and Niche Targeting

While North America and Europe remain key markets, growth in Asia-Pacific and Latin America will accelerate due to rising disposable incomes and digital adoption. Niche markets—including fitness challenges, wedding favors, school spirit bands, and religious outreach—will see targeted marketing and product innovations. Localization of designs, multilingual packaging, and culturally relevant themes will be critical for international success.

Common Pitfalls When Sourcing Custom Silicone Bands (Quality & IP)

Sourcing custom silicone bands can be a cost-effective way to create branded merchandise, fitness trackers, or promotional items. However, businesses often encounter challenges related to quality control and intellectual property (IP) protection. Being aware of these common pitfalls helps ensure a successful sourcing experience.

Poor Material Quality and Inconsistent Durability

One of the most frequent issues is receiving silicone bands made from substandard materials. Low-quality silicone may contain fillers that reduce flexibility, cause discoloration, or lead to cracking over time. Buyers might receive bands that feel brittle, have an unpleasant odor, or degrade quickly with regular use—damaging brand reputation.

Inaccurate Color Matching and Printing Defects

Custom silicone bands often rely on precise color matching (e.g., Pantone colors) and clear branding. Suppliers may deliver inconsistent shades due to poor pigment control or use low-resolution printing methods that result in smudging, fading, or misaligned logos. This undermines the professional look and reduces product appeal.

Lack of Product Certification and Safety Compliance

Many silicone band applications—especially wearables—require compliance with safety standards such as FDA, RoHS, or REACH. Some suppliers may claim compliance without proper documentation. Sourcing from non-certified manufacturers risks legal issues, product recalls, or rejection by customs authorities in regulated markets.

Inadequate Quality Control Processes

Suppliers with weak quality assurance systems may ship batches containing defects like flash (excess silicone at mold seams), air bubbles, uneven thickness, or incorrect dimensions. Without third-party inspections or clear QC checklists, these flaws may go unnoticed until the product reaches end customers.

Intellectual Property Infringement Risks

When providing custom designs, logos, or unique molds, there’s a risk that suppliers may duplicate your design for other clients or sell it independently. Without robust IP agreements, businesses may lose exclusivity over their custom designs, leading to counterfeit products or market dilution.

Weak or Unclear Contracts Protecting IP Rights

Many sourcing agreements fail to explicitly address ownership of molds, artwork, and product designs. Suppliers might retain rights to use your design for other customers unless a formal Intellectual Property Assignment clause is included. Always ensure contracts specify that all IP developed for your order belongs solely to your company.

Hidden Costs and Minimum Order Quantity (MOQ) Traps

Suppliers may advertise low per-unit prices but impose high MOQs or charge separately for mold creation, design setup, and shipping. These hidden costs can significantly increase the total investment, especially for small businesses or startups testing a product.

Communication and Language Barriers

Misunderstandings due to language differences or time zone gaps can lead to incorrect specifications, delayed timelines, or unmet expectations. Lack of responsive communication makes resolving issues more difficult and can delay product launches.

No Prototype or Sampling Before Mass Production

Skipping the sampling phase is a common mistake. Without reviewing a physical prototype, you risk mass-producing bands with design, fit, or quality issues that are costly to fix post-production. Always request and approve a sample before full-scale manufacturing.

Failure to Audit or Verify Supplier Credentials

Not all suppliers are who they claim to be. Businesses may fall victim to fraudulent suppliers or middlemen with no real manufacturing capability. Always verify certifications, conduct factory audits (in-person or via third party), and check references before placing large orders.

Logistics & Compliance Guide for Custom Silicone Bands

Order Fulfillment & Production Timeline

Custom silicone band production typically involves several stages: design approval, material sourcing, mold creation (if applicable), production, quality inspection, and packaging. Standard lead times range from 10 to 21 business days after design confirmation. Rush services may be available for an additional fee. Ensure clear communication with your supplier regarding deadlines, especially for time-sensitive events or promotional campaigns.

Shipping Methods & Delivery Options

Available shipping options depend on order size, destination, and urgency. Common choices include:

– Standard Ground Shipping: Economical for domestic orders; delivery in 3–7 business days.

– Expedited Shipping: 2–3 business days for urgent domestic needs.

– International Air Freight: 5–10 business days; recommended for overseas deliveries.

– Courier Services (e.g., DHL, FedEx): Ideal for urgent or tracked international shipments.

Always confirm Incoterms (e.g., FOB, DDP) with your supplier to clarify responsibility for shipping costs and risks.

Packaging & Labeling Requirements

Custom silicone bands are typically packaged in bulk polybags or individual retail-ready packaging. Ensure packaging complies with destination country regulations, including:

– Clear product identification

– Manufacturer or supplier information

– Compliance marks (e.g., CE, UKCA, if applicable)

For branded items, include accurate branding and avoid trademark infringement. Eco-friendly packaging options may be available upon request.

Regulatory Compliance & Safety Standards

Silicone bands must meet relevant safety and material regulations:

– REACH (EU): Compliance with chemical restrictions under Regulation (EC) No 1907/2006.

– RoHS (EU): Restriction of hazardous substances in electrical and electronic equipment (relevant if bands include electronic components).

– CPSIA (USA): For bands marketed as children’s products, compliance with lead, phthalates, and testing requirements is mandatory.

– FDA (USA): If bands are marketed for food contact or medical use, FDA-compliant silicone must be used.

Ensure your supplier provides material compliance documentation (e.g., Certificate of Compliance, SVHC statement).

Import/Export Documentation

International shipments require proper documentation to avoid customs delays:

– Commercial Invoice (with HS code 3926.30 for other articles of plastics)

– Packing List

– Certificate of Origin

– Any applicable permits or test reports (e.g., CPSIA Children’s Product Certificate)

Verify import duties and taxes with local customs authorities—some countries may exempt promotional items under specific conditions.

Quality Assurance & Inspection

Establish a quality control process prior to shipment:

– Request pre-shipment samples for approval

– Define acceptable defect rates (common standard: AQL 2.5)

– Conduct final random inspections for color accuracy, print quality, and band integrity

Document any discrepancies and work with the supplier to resolve issues.

Returns, Defects & Warranty

Clarify the supplier’s policy on defective or incorrect orders:

– Timeframe for reporting issues (e.g., 14 days post-delivery)

– Process for replacements or refunds

– Responsibility for return shipping costs

Custom-made items may be non-returnable unless defective.

Environmental & Ethical Considerations

Choose suppliers committed to sustainable practices:

– Use of recyclable or biodegradable packaging

– ISO 14001 certification for environmental management

– Ethical labor practices (e.g., BSCI or SA8000 compliance)

Recycling programs for silicone waste may be available through select manufacturers.

Final Recommendations

To ensure a smooth logistics and compliance process:

– Finalize designs and compliance requirements early

– Maintain clear communication with your supplier

– Request all necessary compliance documentation

– Plan sufficient lead time for production and shipping

– Verify local regulations in the destination country before placing large orders

Conclusion on Sourcing Custom Silicone Bands

Sourcing custom silicone bands offers a cost-effective, versatile, and impactful solution for branding, promotional campaigns, event merchandise, or product accessories. The durability, comfort, and wide range of customization options—such as colors, shapes, printing techniques, and finishes—make silicone bands an attractive choice for businesses and organizations across industries.

When sourcing, it is essential to partner with a reliable manufacturer or supplier that ensures high-quality materials (preferably food-grade or medical-grade silicone), consistent production standards, and compliance with safety regulations. Careful consideration of minimum order quantities (MOQs), lead times, packaging options, and shipping logistics will help optimize costs and timelines.

Additionally, requesting samples before full production can prevent potential issues and ensure the final product meets expectations. With thoughtful planning and a reputable supplier, custom silicone bands can serve as a powerful tool for marketing, fundraising, awareness campaigns, or team identification—delivering long-lasting visibility and brand engagement.

In summary, custom silicone bands are a practical and customizable promotional product, and successful sourcing depends on balancing quality, cost, and communication with your supplier to achieve the desired outcome.