The global gearbox market is experiencing robust growth, driven by rising industrial automation, increasing demand for energy-efficient solutions, and advancements in material handling and robotics. According to a 2023 report by Mordor Intelligence, the global gearbox market was valued at USD 91.4 billion in 2022 and is projected to grow at a CAGR of over 5.8% from 2023 to 2028. A key differentiator in this evolving landscape is noise reduction, with industries increasingly prioritizing silent operation for applications in precision machinery, medical equipment, robotics, and consumer electronics. As operational efficiency and acoustic comfort become critical performance metrics, silent gearbox manufacturers are gaining prominence. This shift has led to significant innovation in gear design, lubrication technologies, and material engineering—culminating in highly efficient, low-noise transmission systems. Based on market presence, technological advancement, and product performance, here are the top 7 silent gearbox manufacturers shaping the future of motion control.

Top 7 Silent Gearbox Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SUMIT INDUSTRIAL GEARS LLP

Domain Est. 2021

Website: sumitgears.com

Key Highlights: SIGL is a trusted name among the gearbox manufacturers in India. We can custom design, engineer, and manufacture gearboxes catering to the requirements of your ……

#2 SILENT

Domain Est. 2011

Website: en.gdmotor.cn

Key Highlights: We are a professional manufacturer specialized in the industry of high precision gears and micro-precision planetary gearboxes for many years….

#3 Dongguan Silent Industry Co.,Ltd

Domain Est. 2013

Website: silentgearmotor.com

Key Highlights: Silent is a leading company in gear and transmission technology in China – with international presence, as a partner for globally operating customers and with ……

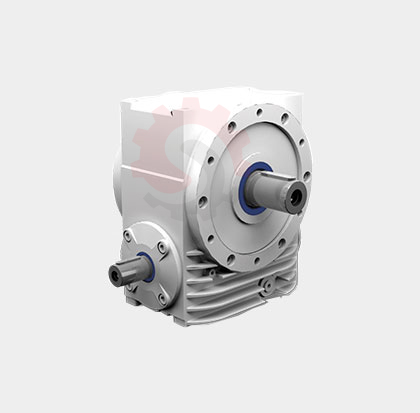

#4 Worm Gearbox Manufacturer

Domain Est. 2024

Website: sarbamangalageartransmission.com

Key Highlights: With features such as a self-locking mechanism, quiet operation, and durability, worm gearboxes stand out as one of the most reliable power transmission ……

#5 DONGGUAN SILENT

Website: stgearbox.com

Key Highlights: Silent is a manufacturer of micro drives. We build an economical and efficient micro-drive system for you. Small space · High power…

#6 Power Transmission Products

Domain Est. 1996

Website: zero-max.com

Key Highlights: We build quality and precision into each of our high-performance motion control products. From gearboxes to shaft couplings, we have the solution you need….

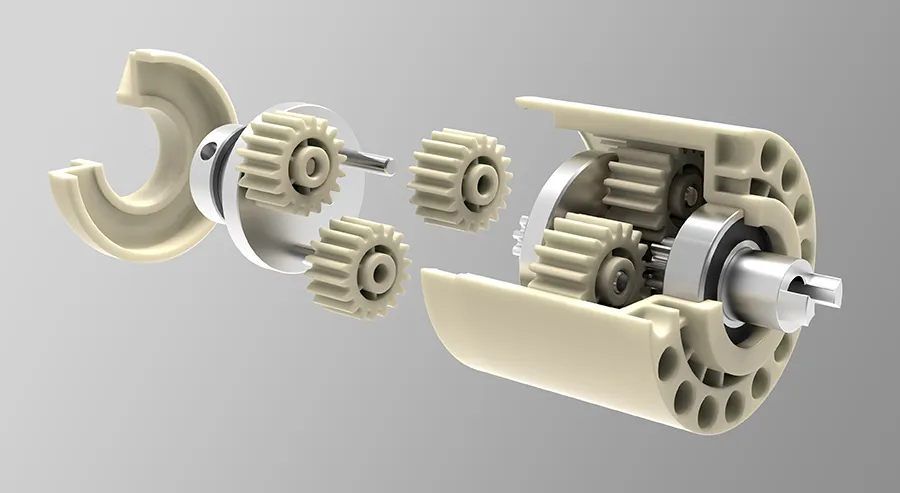

#7 Planetary Gearbox (Plastic)

Domain Est. 2015

Website: zwgearbox.com

Key Highlights: ZHAOWEI plastic planetary gear box is composed of POM planetary gear group, which has many advantages such as good self-lubrication, low noise, light weight, ……

Expert Sourcing Insights for Silent Gearbox

H2: 2026 Market Trends Forecast for Silent Gearbox Technology

The global market for silent gearbox technology is poised for significant transformation by 2026, driven by evolving industrial demands, technological innovation, and a growing emphasis on noise reduction in both consumer and industrial applications. As industries prioritize energy efficiency, automation, and user comfort, silent gearboxes are emerging as critical components across multiple sectors. Below is a comprehensive analysis of key market trends expected to shape the silent gearbox landscape in 2026.

-

Rising Demand in Electric and Hybrid Vehicles

The automotive sector, particularly electric (EV) and hybrid vehicle manufacturing, will be a primary growth driver for silent gearboxes. With EVs operating at lower noise levels than internal combustion engines, any mechanical noise—especially from gear systems—becomes more noticeable. Silent gearboxes with advanced noise-dampening materials, precision engineering, and optimized gear tooth profiles will be essential to maintain the quiet operation expected by consumers. By 2026, increasing EV adoption worldwide will significantly boost demand for low-noise transmission systems. -

Expansion in Industrial Automation and Robotics

Industrial automation and robotics are rapidly advancing, with a focus on precision, reliability, and operational quietness—especially in cleanroom environments, healthcare facilities, and collaborative robotics (cobots). Silent gearboxes, particularly harmonic and planetary gear systems with low backlash and high efficiency, are increasingly preferred in robotic joints and automated assembly lines. The trend toward smart factories (Industry 4.0) will further accelerate adoption, as silent operation supports human-robot collaboration and reduces workplace noise pollution. -

Focus on Energy Efficiency and Sustainability

Regulatory pressures and corporate sustainability goals are pushing industries to adopt energy-efficient technologies. Silent gearboxes often feature reduced friction and optimized lubrication systems, which not only minimize noise but also improve energy efficiency. By 2026, environmental standards in Europe, North America, and parts of Asia are expected to mandate lower noise emissions and higher efficiency in industrial machinery, favoring the adoption of silent gearbox solutions. -

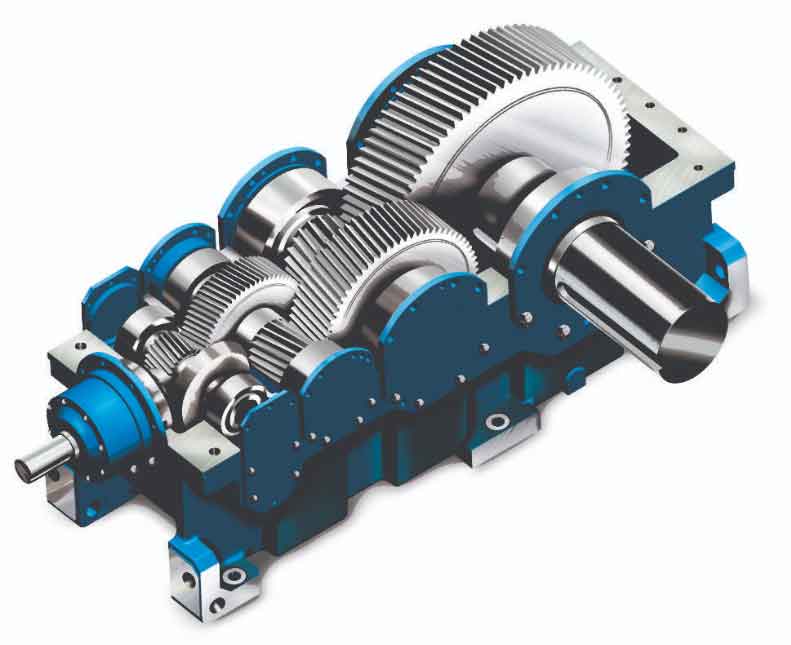

Advancements in Materials and Design

Innovation in materials such as high-performance polymers, composite alloys, and surface coatings (e.g., DLC – Diamond-Like Carbon) will enable lighter, quieter, and more durable gearboxes. Additive manufacturing (3D printing) will allow for complex internal geometries that reduce vibration and noise at the source. Simulation tools using AI and finite element analysis (FEA) will become standard in gearbox design, enabling predictive optimization of acoustic performance before prototyping. -

Growth in Consumer and Domestic Applications

Beyond industrial and automotive markets, silent gearboxes are gaining traction in consumer products such as home appliances (e.g., washing machines, HVAC systems), electric scooters, and smart home devices. As consumers demand quieter, more comfortable living environments, manufacturers will integrate silent gear technology to enhance product competitiveness. By 2026, noise levels will increasingly serve as a differentiating factor in consumer electronics and domestic machinery. -

Regional Market Dynamics

Asia-Pacific, led by China, Japan, and South Korea, will remain a dominant market due to robust manufacturing, EV production, and automation investments. Europe will follow closely, driven by stringent noise regulations (e.g., EU Machinery Directive) and green technology initiatives. North America will see steady growth, particularly in aerospace, medical robotics, and high-performance industrial equipment. -

Competitive Landscape and Strategic Partnerships

By 2026, competition in the silent gearbox market will intensify, prompting consolidation and strategic collaborations between gearbox manufacturers, material scientists, and end-users. Companies investing in R&D for noise reduction technologies and modular designs will gain a competitive edge. Integration with IoT-enabled condition monitoring systems will also become a differentiator, allowing predictive maintenance and real-time noise performance tracking.

Conclusion

The 2026 outlook for the silent gearbox market is highly positive, characterized by strong cross-sector demand, technological innovation, and regulatory support. Silent gearboxes will transition from niche solutions to standard components in high-performance systems where noise, efficiency, and precision are paramount. Companies that align with these trends through innovation, sustainability, and strategic market positioning will be well-placed to capture significant growth opportunities.

Common Pitfalls When Sourcing Silent Gearboxes: Quality and IP Concerns

Poor Build Quality Leading to Noise and Premature Failure

One of the most frequent issues when sourcing silent gearboxes is compromised build quality. Suppliers may cut corners by using low-grade materials, imprecise machining, or substandard lubricants, which directly impact noise performance and durability. Gears with poor surface finish or misaligned bearings can generate excess vibration and audible whine—defeating the purpose of a “silent” gearbox. Additionally, inconsistent quality control in manufacturing leads to unit-to-unit variability, making it difficult to ensure long-term reliability across batches.

Misleading Noise Ratings and Inadequate Testing

Many suppliers advertise “silent” or “low-noise” gearboxes without standardized testing or verifiable data. Claims may be based on ideal lab conditions or outdated measurements that don’t reflect real-world performance. Without access to certified sound pressure level (SPL) data measured under controlled conditions (e.g., ISO 8579), buyers risk integrating gearboxes that introduce unacceptable noise into sensitive applications such as medical devices or audio equipment.

Intellectual Property (IP) Risks from Counterfeit or Cloned Designs

Sourcing from unverified suppliers—especially in regions with lax IP enforcement—exposes companies to significant legal and operational risks. Some manufacturers reverse-engineer premium gearboxes and sell near-identical copies without licensing, potentially infringing on patented gear geometries, housing designs, or assembly methods. Using such components can result in product recalls, lawsuits, or supply chain disruptions if original IP holders take legal action.

Lack of Traceability and Documentation

Transparent sourcing requires comprehensive documentation, including material certifications, test reports, and IP compliance statements. However, many suppliers fail to provide these, making it difficult to verify claims or conduct audits. Without proper traceability, identifying the root cause of field failures or defending against IP allegations becomes nearly impossible.

Overlooking Long-Term Support and Spare Parts Availability

A silent gearbox may meet initial specs, but if the supplier lacks a sustainable support model, downtime and maintenance costs can escalate. Some low-cost manufacturers disappear or discontinue models quickly, leaving buyers without access to replacement parts or technical assistance—especially critical in industrial or medical applications where uptime is essential.

Insufficient Due Diligence on Supplier Credibility

Relying solely on price or marketing materials without vetting the supplier’s engineering capability, production processes, or IP compliance history is a major pitfall. Conducting on-site audits, requesting references, and validating certifications (e.g., ISO 9001, IP rights declarations) are crucial steps often skipped in the pursuit of cost savings, leading to compromised performance and legal exposure.

Logistics & Compliance Guide for Silent Gearbox

This guide outlines key logistics and compliance considerations for the handling, transportation, import/export, and regulatory adherence of Silent Gearbox products. Adherence to these guidelines ensures operational efficiency, legal compliance, and product integrity across the supply chain.

Product Handling & Packaging

Silent Gearbox units must be handled with care to maintain precision engineering and noise-dampening features. Use anti-static and shock-absorbent packaging during storage and transit. Ensure all gearboxes are securely mounted within packaging to prevent internal movement. Clearly label packages with “Fragile,” “This Side Up,” and product-specific identifiers. Avoid exposure to moisture, extreme temperatures, and contaminants during handling.

Transportation Requirements

Transport Silent Gearbox products via climate-controlled and vibration-minimized shipping methods, especially for long distances. Use palletized shipments with corner boards and stretch wrap for stability. For international transit, ensure compliance with IATA (air) or IMDG (sea) regulations if applicable, although gearboxes typically do not contain hazardous materials. Coordinate with carriers experienced in handling industrial machinery to minimize transit risks.

Import/Export Documentation

Maintain accurate and complete documentation for all cross-border shipments. Required documents include commercial invoices, packing lists, bill of lading/air waybill, and certificates of origin. Classify Silent Gearbox units under the correct Harmonized System (HS) code—typically within Chapter 84 (Nuclear reactors, boilers, machinery). Confirm tariff classifications with local customs authorities to avoid delays or penalties.

Regulatory Compliance

Ensure all Silent Gearbox models comply with relevant regional and international standards. Key certifications include CE (European Union), UKCA (United Kingdom), and EAC (Eurasian Economic Union) for mechanical safety and EMC directives. Verify compliance with ISO 14122 (safety of machinery – permanent means of access) and ISO 8579 (gear rating and noise testing). Maintain up-to-date technical files and Declarations of Conformity for audit readiness.

Environmental & RoHS Compliance

Silent Gearbox products must conform to the Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU, limiting the use of lead, mercury, cadmium, and other harmful substances. Confirm material declarations from suppliers and conduct periodic compliance testing. Properly label products with RoHS compliance marks where required. Adhere to WEEE (Waste Electrical and Electronic Equipment) guidelines for end-of-life disposal and recycling.

Customs Clearance & Duties

Prepare for customs clearance by pre-validating all documentation and tariff codes. Engage licensed customs brokers in destination countries to facilitate smooth processing. Be aware of preferential trade agreements (e.g., USMCA, RCEP) that may reduce or eliminate import duties. Retain records of all shipments for a minimum of five years to support compliance audits.

Quality & Traceability

Implement a traceability system for each Silent Gearbox unit, including serial numbers, manufacturing dates, and batch information. This supports warranty claims, recalls (if necessary), and compliance verification. Conduct regular internal audits of logistics processes to ensure adherence to quality management systems such as ISO 9001.

Emergency Response & Recalls

Establish a protocol for responding to logistics-related incidents, including damaged shipments or non-compliant deliveries. In the event of a product recall, activate communication channels with distributors, customs authorities, and end-users promptly. Maintain an incident log and conduct root-cause analysis to prevent recurrence.

Following this guide ensures that Silent Gearbox products are delivered efficiently, safely, and in full compliance with global regulatory standards. Regular review and updates to this document are recommended to reflect changes in legislation or operational practices.

In conclusion, sourcing a silent gearbox requires a careful evaluation of several key factors including noise level specifications, application requirements, quality and precision of manufacturing, material selection, and supplier reliability. Silent gearboxes are essential in applications where noise reduction is critical, such as medical equipment, precision instrumentation, and residential environments. To ensure optimal performance, it is vital to partner with reputable suppliers who offer proven silent gearbox designs, precision engineering, and robust testing protocols. Additionally, considering factors such as maintenance needs, scalability, and total cost of ownership will contribute to a successful and sustainable sourcing decision. By balancing technical performance with supplier expertise and support, organizations can effectively integrate silent gearboxes into their systems, enhancing operational efficiency and end-user satisfaction.