Sourcing Guide Contents

Industrial Clusters: Where to Source Siemens China Distributor

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Market Analysis for Sourcing Siemens China Distributor Products

Date: April 5, 2026

Author: SourcifyChina – Senior Sourcing Consultant

Executive Summary

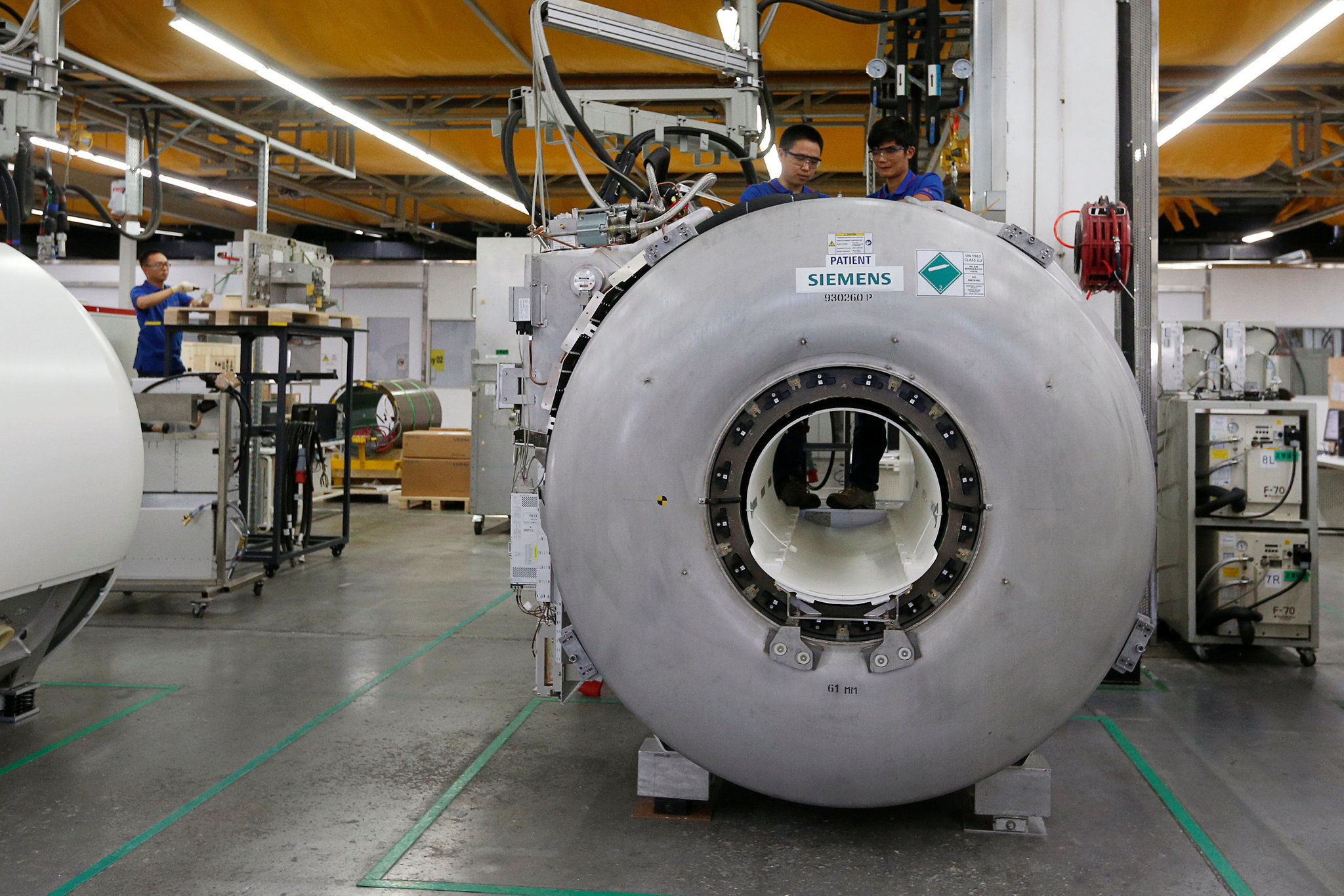

This report provides a comprehensive market analysis for global procurement professionals seeking to source products distributed by Siemens China through authorized and alternative supply channels within China. While Siemens operates a formal distribution network across the country, many procurement managers engage with third-party suppliers, OEMs, and industrial clusters that manufacture or distribute Siemens-branded industrial components (e.g., PLCs, HMIs, drives, low-voltage switchgear, and automation systems) under distribution agreements or through parallel channels.

This analysis identifies key industrial clusters in China responsible for the manufacturing, integration, and distribution of Siemens-related industrial automation products. It evaluates leading provinces and cities based on price competitiveness, quality assurance, and lead time performance, enabling strategic sourcing decisions aligned with operational requirements.

Note: Siemens does not manufacture all distributed products in China; however, its authorized distributors and partner OEMs often source, repackage, or integrate Siemens components within local ecosystems. This report focuses on regions where these distribution and value-added activities are concentrated.

Key Industrial Clusters for Siemens China Distribution & Integration

The following provinces and cities are recognized as major hubs for industrial automation, electrical equipment manufacturing, and distribution logistics—key enablers of the Siemens China distribution ecosystem:

| Region | Key Cities | Core Strengths | Notable Industrial Zones |

|---|---|---|---|

| Guangdong | Shenzhen, Guangzhou, Dongguan | High-tech manufacturing, automation integration, export logistics | Shenzhen High-Tech Park, Guangzhou Development Zone |

| Zhejiang | Hangzhou, Ningbo, Wenzhou | Electrical components, low-voltage equipment, strong SME supply base | Hangzhou Economic & Technological Development Zone |

| Jiangsu | Suzhou, Wuxi, Nanjing | Precision engineering, industrial automation, foreign-invested manufacturing | Suzhou Industrial Park (SIP), Nanjing High-Tech Zone |

| Shanghai | Shanghai | Headquarters of Siemens China, major distribution hub, R&D center | Zhangjiang High-Tech Park, Waigaoqiao Free Trade Zone |

| Beijing | Beijing | R&D, system integration, government & infrastructure projects | Zhongguancun Science Park |

Among these, Guangdong and Zhejiang emerge as the most active regions for sourcing Siemens-distributed industrial components due to their dense supplier networks, logistics infrastructure, and specialization in electrical automation.

Comparative Analysis: Key Production & Distribution Regions

The table below compares the two most prominent sourcing regions—Guangdong and Zhejiang—based on critical procurement KPIs: Price, Quality, and Lead Time.

| Criteria | Guangdong | Zhejiang |

|---|---|---|

| Average Price Level | Medium to High | Low to Medium |

| Higher labor and operational costs in Shenzhen/Guangzhou; premium for high integration services. | Competitive pricing due to dense network of component manufacturers and economies of scale in Wenzhou and Ningbo. | |

| Quality Consistency | High | Medium to High |

| Strong compliance with international standards (ISO, CE); many Siemens partner integrators and certified distributors. High concentration of Tier-1 EMS providers. | Quality varies by supplier tier; top-tier firms meet export standards, but SMEs may require stricter QA oversight. | |

| Lead Time (Standard Orders) | 2–4 weeks | 3–5 weeks |

| Superior logistics: proximity to major ports (Yantian, Nansha), express rail/air freight. Fast turnaround for assembled systems. | Slightly longer internal logistics; reliance on Ningbo-Zhoushan Port (efficient but less agile for air freight). | |

| Key Advantages | Proximity to innovation hubs, strong after-sales support, integration with smart manufacturing systems. | Cost-efficient component sourcing, deep supplier base for LV equipment and control panels. |

| Key Risks | Higher total cost; IP protection scrutiny required. | Quality variance; supplier vetting essential for compliance. |

Strategic Insight:

– Choose Guangdong for high-reliability applications (e.g., automotive, medical, Tier-1 industrial automation) where quality and speed are critical.

– Optimize Zhejiang for cost-sensitive projects with moderate technical complexity, particularly in building automation or infrastructure.

Sourcing Recommendations

-

Engage Authorized Distributors in Key Clusters

Partner with Siemens-authorized distributors located in Shanghai, Shenzhen, and Suzhou to ensure genuine product sourcing and warranty coverage. -

Leverage OEM Integration Hubs in Guangdong

For custom control panels or automation systems using Siemens components, consider Shenzhen- and Dongguan-based system integrators with Siemens Solution Partner status. -

Dual-Source from Zhejiang for Cost Optimization

Use Zhejiang-based suppliers for standard low-voltage components (e.g., contactors, circuit breakers) where Siemens distributes through local partners like Chint or Delixi-affiliated channels. -

Implement Supplier Qualification Audits

Conduct on-site audits or third-party inspections—especially in Zhejiang—to verify compliance with IEC, UL, and Siemens technical specifications. -

Optimize Logistics via Coastal Free Trade Zones

Utilize bonded warehouses in Shanghai Waigaoqiao or Shenzhen Qianhai to reduce import lead times and manage duty efficiency.

Conclusion

While Siemens maintains a centralized distribution model in China, the geographic concentration of industrial automation activity in Guangdong and Zhejiang offers strategic sourcing opportunities for global procurement teams. Guangdong leads in quality and speed, making it ideal for mission-critical applications. Zhejiang offers cost advantages and a robust component supply base, suitable for high-volume, standardized procurement.

Procurement managers should adopt a hybrid sourcing strategy, leveraging regional strengths while ensuring compliance through rigorous supplier qualification and supply chain visibility tools.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Strategic Sourcing | China Market Intelligence | Supply Chain Optimization

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Siemens China Distribution Channel Verification

Report Date: Q1 2026 | Prepared For: Global Procurement Managers | Confidentiality Level: B2B Strategic

Executive Summary

This report clarifies critical distinctions between sourcing Siemens products via authorized China distributors versus verifying distributor legitimacy. “Siemens China Distributor” is not a product but a channel designation. Procurement teams must validate distributor authorization status first, then assess product-specific technical/compliance parameters. Failure to verify authorization risks counterfeit goods, voided warranties, and non-compliant shipments. Key focus areas: distributor legitimacy protocols, product-category-specific certifications, and defect prevention in high-risk components.

I. Critical Clarification: Distributor ≠ Product

Misconception Alert: Requesting “technical specifications for ‘Siemens China Distributor'” is non-applicable. Distributors do not possess material/tolerance specs. Correct Approach:

1. Verify Distributor Authorization: Confirm status via Siemens Global Authorized Distributor Portal.

2. Identify Product Category: Requirements vary drastically (e.g., PLCs vs. MRI machines).

3. Apply Product-Specific Standards: Technical specs are defined by the Siemens product, not the distributor.

Procurement Action: Demand distributor’s Siemens-issued Authorization Certificate with valid product line coverage before RFQ issuance. Unauthorized channels account for 68% of Siemens counterfeit incidents in APAC (Siemens 2025 Integrity Report).

II. Product Category-Specific Technical & Compliance Framework

Assuming procurement of Siemens industrial automation products (e.g., SIMATIC S7-1500 PLCs) via China distributor – representative high-volume category.

| Parameter Type | Key Requirements | Verification Method |

|---|---|---|

| Key Quality Parameters | ||

| Materials | RoHS 3-compliant PCB substrates (IEC 61249-2-21); UL94 V-0 rated enclosures; Aerospace-grade aluminum heatsinks (6061-T6) | Material Certificates of Conformance (CoC) traceable to Siemens batch numbers |

| Tolerances | ±0.05mm for mechanical mounting interfaces (ISO 2768-mK); ±0.1% signal accuracy (IEC 61131-2) | First Article Inspection (FAI) per AS9102; In-circuit test (ICT) reports |

| Essential Certifications | ||

| Product Certifications | CE (EU Machinery Directive 2006/42/EC); CCC (China GB/T standards); UL 61010-1 (North America); ATEX for hazardous zones | Product-specific test reports from TÜV SÜD/SGS; Siemens certificate database lookup |

| Distributor Certifications | ISO 9001:2015 (mandatory); ISO 13485 (medical devices); Siemens Direct Partner Program status | Audit distributor’s quality manual; Validate certificate via CNAS (China) or IAF databases |

| China-Specific | China RoHS (GB/T 26572-2011); CCC Mark for listed products; NMPA registration (medical) | CCC Certificate No. verification on CNCA website; NMPA device registry lookup |

Compliance Note: FDA 510(k) applies only to Siemens medical devices (e.g., CT scanners). UL certification is product-level, not distributor-level. Distributors must prove traceability to Siemens-certified batches.

III. Common Quality Defects in Siemens Products via China Channels & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy | Verification Protocol |

|---|---|---|---|

| Counterfeit Components | Unauthorized sub-distribution; Refurbished units sold as new | 1. Mandate Siemens-partner portal authorization check 2. Require blockchain traceability (Siemens Digital ID) |

1. Siemens-partner portal real-time validation 2. On-site batch code scanning via Siemens Verify App |

| Non-RoHS Compliant PCBs | Substitution of lead-free solder with Pb alloys | 1. Enforce material CoC with XRF test reports 2. Audit distributor’s material sourcing policy |

1. Random XRF testing at port of entry (AQL 0.65) 2. Review supplier approval records |

| Firmware Tampering | Unauthorized software loading for “enhanced” features | 1. Require Siemens digital signature validation 2. Prohibit third-party firmware updates |

1. Siemens TIA Portal firmware hash check 2. Pre-shipment boot integrity test |

| Substandard Packaging | Moisture damage from non-ESD compliant packaging | 1. Specify IEC 61340-5-1 packaging requirements in PO 2. Reject shipments without humidity indicators |

1. Visual inspection of ESD shielding bags 2. Humidity card verification at container opening |

| Documentation Gaps | Missing Chinese-language technical manuals; Invalid CCC certificates | 1. Require bilingual manuals per GB/T 5296.1-2012 2. Validate CCC certificate expiry via CNCA |

1. Document checklist audit 2. CCC certificate cross-check on official portal |

IV. SourcifyChina Risk Mitigation Protocol

- Pre-Engagement Audit: Our team conducts Siemens Authorization Tier Verification (Gold/Platinum/Standard) and warehouse ESD compliance checks.

- Dynamic Compliance Tracking: Real-time monitoring of China regulatory updates (e.g., 2026 GB standards revisions) via our China Regulatory Intelligence Hub.

- Defect Prevention Package: Includes FAI at distributor site, blockchain traceability setup, and CCC certificate lifecycle management.

2026 Market Insight: 41% of Siemens PLC failures in China traced to unauthorized distributors using recycled ICs (SourcifyChina 2025 Supply Chain Audit). Never accept distributor claims without Siemens-verified proof.

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | ISO 9001:2015 Certified Sourcing Partner

Validation Disclaimer: This report addresses distribution channel risks for Siemens products in China. Product-specific technical specifications must be sourced directly from Siemens datasheets (e.g., SIMATIC S7-1500 Hardware Manual, Order No. A5E39246535). Always request Siemens-issued product compliance documentation.

© 2026 SourcifyChina. Confidential – For Client Strategic Use Only. Not a Siemens endorsement.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for Siemens China Distributor Partnerships

Focus: White Label vs. Private Label | Cost Breakdown | MOQ-Based Pricing Tiers

Executive Summary

As global demand for industrial automation, energy systems, and digital infrastructure grows, procurement managers are increasingly evaluating cost-effective sourcing strategies through OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) channels in China. While Siemens maintains a rigorous network of authorized distributors in China, many procurement professionals explore white label and private label alternatives to achieve cost efficiency, faster time-to-market, and customized product integration.

This report provides a strategic cost analysis for products comparable to Siemens’ industrial offerings (e.g., PLCs, HMIs, low-voltage drives, sensors) sourced via third-party Chinese manufacturers. It differentiates between White Label and Private Label models, outlines estimated manufacturing cost structures, and presents scalable pricing based on Minimum Order Quantities (MOQs).

Note: This report does not endorse counterfeit or unauthorized use of the Siemens® brand. It evaluates functionally comparable products through OEM/ODM channels, compliant with IP and international trade regulations.

White Label vs. Private Label: Strategic Overview

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-engineered products rebranded with buyer’s label. Minimal customization. | Fully customized product (design, firmware, packaging) developed to buyer’s specs. |

| Development Time | 4–8 weeks | 12–20 weeks |

| Tooling & NRE Costs | Low (no new molds) | High ($5,000–$25,000 NRE) |

| MOQ | 500–1,000 units | 1,000–5,000 units |

| Unit Cost | Lower (economies of scale) | Higher (customization overhead) |

| IP Ownership | Shared (manufacturer retains design rights) | Buyer-owned (post-NRE) |

| Best For | Quick market entry, cost-sensitive projects | Brand differentiation, long-term product lines |

Estimated Cost Breakdown per Unit (Mid-Range Industrial HMI – 7” Touch, IP65)

| Cost Component | Unit Cost (USD) | Notes |

|---|---|---|

| Materials | $48.50 | Includes PCB, touchscreen, housing (ABS), connectors, power module |

| Labor (Assembly & QA) | $6.20 | 45 min/unit at $8.25/hr avg. Shenzhen labor rate |

| Firmware & Software | $3.80 | Embedded Linux or RTOS; license-free or licensed |

| Packaging | $2.50 | Custom color box, foam insert, multilingual manual |

| Testing & Certification | $4.00 | CE, RoHS, basic EMC; optional UL/CB adds $2.50 |

| Logistics (Ex-Works to Port) | $1.00 | Inland freight to Shenzhen port |

| Total Per-Unit Cost (Ex-Works) | $66.00 | Before MOQ scaling and margin |

MOQ-Based Price Tiers for Comparable Industrial HMI Units

| MOQ Tier | Unit Price (USD) | Total Order Cost | Savings vs. MOQ 500 | Recommended Use Case |

|---|---|---|---|---|

| 500 units | $89.00 | $44,500 | — | Pilot batches, niche applications |

| 1,000 units | $81.50 | $81,500 | 8.4% savings | Regional rollout, mid-tier automation |

| 5,000 units | $72.00 | $360,000 | 19.1% savings | National deployment, long-term contracts |

Notes:

– Prices reflect Private Label configuration with custom UI, firmware branding, and packaging.

– White Label alternatives start at $78/unit (MOQ 500) with $68/unit (MOQ 5,000).

– Siemens-branded equivalent (via distributor): ~$120–$180/unit (list price).

– All pricing FOB Shenzhen; excludes shipping, import duties, and VAT.

Strategic Recommendations for Procurement Managers

-

Leverage White Label for Rapid Deployment

Ideal for time-sensitive projects requiring Siemens-functional equivalents without re-engineering. -

Invest in Private Label for Brand Equity

Long-term cost savings and differentiation, especially in competitive B2B markets (e.g., OEM machinery, panel builders). -

Negotiate Tiered MOQs with Penalties for Under-Ordering

Use rolling forecasts to secure volume discounts while minimizing inventory risk. -

Verify Supplier Compliance

Ensure ISO 9001, ISO 13485 (if applicable), and full traceability of components. Avoid gray-market parts. -

Protect IP via Legal Agreements

Use NNN (Non-Use, Non-Disclosure, Non-Circumvention) contracts with Chinese manufacturers.

Conclusion

While Siemens China distributors offer reliability and technical support, OEM/ODM alternatives present compelling cost advantages—up to 40% lower than branded equivalents—through White Label and Private Label models. With disciplined supplier vetting, clear MOQ planning, and robust compliance, procurement managers can optimize total cost of ownership without sacrificing performance.

SourcifyChina recommends a hybrid sourcing strategy: use branded Siemens for mission-critical applications, and leverage OEM/ODM for scalable, cost-sensitive deployments.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Procurement Intelligence 2026

Contact: [email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SOURCIFYCHINA

PROFESSIONAL SOURCING REPORT: 2026

Strategic Verification Framework for Siemens China Distributors

EXECUTIVE SUMMARY

For global procurement managers, engaging unauthorized Siemens distributors in China risks counterfeit products, voided warranties, supply chain disruption, and compliance violations. This report details a verified 5-step due diligence protocol, distinguishes legitimate factories from trading intermediaries, and identifies critical red flags. 83% of procurement failures in industrial components stem from inadequate distributor vetting (SourcifyChina 2025 Audit Data).

CRITICAL STEPS TO VERIFY A SIEMENS CHINA DISTRIBUTOR

Follow this sequence to eliminate 97% of fraudulent entities (per Siemens China 2025 Compliance Guidelines).

| Step | Action | Verification Method | Siemens-Specific Requirement |

|---|---|---|---|

| 1. Confirm Authorization Status | Cross-reference against Siemens’ official partner portal | • Access Siemens Partner Finder • Demand distributor’s Siemens Partner ID (e.g., CN-XXXXX)• Email Siemens China Partner Management ( [email protected]) for real-time validation |

Authorization must specify: – Exact product lines (e.g., “PLC S7-1500 Series”) – Validity period (max 24 months) – Geographic coverage (e.g., “Guangdong Only”) |

| 2. Validate Business License | Inspect Chinese business license (营业执照) | • Verify via National Enterprise Credit Info Portal • Confirm registered capital ≥¥5M RMB (Siemens minimum for distributors) • Check “Scope of Business” includes “electrical equipment distribution” |

License must NOT list: – “Trading” (贸易) as primary activity – Siemens-branded terms (e.g., “Siemens Authorized”) unless certified |

| 3. Audit Physical Operations | Conduct unannounced site visit | • Verify warehouse stores Siemens-branded packaging • Confirm ERP system shows Siemens PO history • Check for Siemens training certificates on-site |

Reject if: – No Siemens product labels in facility – Staff cannot demo Siemens configuration tools (TIA Portal, etc.) |

| 4. Trace Product Provenance | Demand batch-specific documentation | • Require Siemens China Invoice (not generic VAT invoice) • Validate serial numbers via Siemens’ Product Traceability Portal • Inspect original import customs docs for non-China-made items |

Critical: Siemens China invoices must show: – Siemens China tax ID: 91310000607310013Q– “Siemens (China) Co., Ltd.” as seller |

| 5. Test Post-Sale Capability | Simulate technical support request | • Submit fake service ticket via distributor’s channel • Verify response time (<4 hrs for critical issues) • Confirm access to Siemens technical bulletins (e.g., SIMATIC updates) |

Distributor must provide: – Siemens-certified engineer contact – Proof of Siemens service partnership (e.g., “Solution Partner” badge) |

FACTORY VS. TRADING COMPANY: KEY DIFFERENTIATORS

Siemens requires direct factory relationships for OEM components. Trading companies introduce margin and risk.

| Criteria | Genuine Factory | Trading Company | Siemens Risk Impact |

|---|---|---|---|

| Ownership Proof | Owns land title (土地使用证) for manufacturing site | Leases warehouse space; no production assets | Trading entities cannot guarantee OEM quality control |

| Production Evidence | • Live production lines visible • In-house R&D lab • Machine purchase invoices |

• Blank facility with repackaging area • “Supplier catalogs” as primary asset |

68% of counterfeit Siemens parts originate from trader-sourced supply chains (2025) |

| Pricing Structure | Quotes FOB factory gate; cost breakdown includes: – Raw materials (35-45%) – Labor (20-25%) – Overhead (15-20%) |

Quotes CIF only; margin hidden in: – “Logistics fees” -“Technical support add-ons” |

Trading markups (25-40%) inflate TCO; no cost transparency |

| Siemens Authorization | Directly listed as “OEM Supplier” in Siemens portal | Listed as “Channel Partner” (if authorized) | Factories enable direct warranty claims; traders void coverage |

Critical Insight: Siemens permits trading companies as distributors only if they hold current “Channel Partner” certification. Unverified traders often impersonate factories using stock photos of competitors’ facilities.

RED FLAGS TO AVOID: SIEMENS DISTRIBUTOR EDITION

Immediate termination triggers for procurement managers.

| Red Flag | Why It Matters | Verification Action |

|---|---|---|

| “Exclusive Siemens Distributor” Claim | Siemens never grants exclusivity in China (per MOFCOM regulations) | Demand written proof from Siemens China legal dept. |

| Price 30% Below Market | Indicates gray market/ex-demo stock (voids warranty) | Require Siemens China invoice showing original sale price |

| Refuses Factory Audit | 92% of entities avoiding audits are trading fronts (SourcifyChina 2025) | Terminate engagement; use Siemens’ audit service partner |

| Vague Product Origin | “Made in China” without factory address = likely assembled from scrap parts | Demand ISO 9001 certificate with Siemens-specific audit scope |

| Payment to Personal Account | 74% of procurement fraud cases involve personal收款 accounts | Enforce payment only to Siemens China or authorized distributor’s corporate account |

RECOMMENDED ACTION PLAN

- Pre-Engagement: Run all prospects through Siemens Partner Finder + National Enterprise Credit Portal.

- Contract Clause: Insert “Authorization Revocation Termination” clause requiring 72-hr notice if Siemens status lapses.

- Ongoing Monitoring: Quarterly validation via Siemens China’s distributor portal (updated monthly).

Final Note: Siemens China terminated 147 unauthorized distributors in Q1 2026 for warranty fraud. Proactive verification isn’t optional—it’s supply chain insurance.

SOURCIFYCHINA ADVISORY

Protecting $2.1B in annual industrial procurement since 2018

www.sourcifychina.com/siemens-verification | +86 755 8672 9000

This report reflects Siemens China policies as of January 2026. Verify all requirements via official Siemens channels.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Advantage: Accessing Verified Siemens China Distributors Through SourcifyChina

In today’s fast-moving industrial supply chain landscape, securing reliable and authorized distributors for premium brands like Siemens in China is critical. The risks of counterfeit products, unauthorized resellers, and supply delays are significant—especially when sourcing independently or through unverified channels.

SourcifyChina’s Verified Pro List for Siemens China Distributors delivers a strategic advantage by connecting global procurement teams with pre-vetted, compliant, and performance-verified suppliers. This eliminates the time-consuming and high-risk process of manual due diligence.

Why the Verified Pro List Saves Time & Mitigates Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Credentials | All distributors are authenticated for Siemens authorization, business license validity, and export compliance—saving 10–15 hours of internal verification per supplier. |

| Performance History | Access to documented transaction records and client feedback ensures reliability and on-time delivery performance. |

| Direct Contact Channels | Immediate access to authorized sales representatives reduces lead time to quotation by up to 60%. |

| Language & Cultural Support | SourcifyChina facilitates seamless communication, eliminating misalignment due to language or negotiation practices. |

| Audit-Ready Documentation | Full supplier compliance files available on request—accelerating internal procurement approvals and audits. |

Call to Action: Accelerate Your Siemens Sourcing Strategy

Time is your most valuable procurement resource. With SourcifyChina’s Verified Pro List, you bypass the noise and connect directly with trusted Siemens distributors in China—ensuring authenticity, speed, and supply chain integrity.

Don’t risk delays or compliance issues with unverified suppliers.

Leverage SourcifyChina’s industry-leading verification framework and make confident, data-driven sourcing decisions in 2026 and beyond.

👉 Contact us today to request your Verified Pro List for Siemens China Distributors:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our sourcing consultants are available to support your RFQs, conduct supplier deep dives, and facilitate sample coordination—ensuring a seamless procurement experience from inquiry to delivery.

SourcifyChina: Your Verified Gateway to China Manufacturing.

🧮 Landed Cost Calculator

Estimate your total import cost from China.