The global shot peening equipment market is experiencing robust growth, driven by increasing demand for surface enhancement technologies in aerospace, automotive, and industrial manufacturing sectors. According to a report by Mordor Intelligence, the shot peening equipment market was valued at USD 3.1 billion in 2022 and is projected to reach USD 4.5 billion by 2028, growing at a CAGR of approximately 6.3% during the forecast period. This expansion is fueled by the need to improve fatigue resistance and longevity of metal components, particularly in safety-critical applications. As industries prioritize component durability and performance under stress, the role of advanced shot peening solutions becomes ever more crucial. In this competitive landscape, a select group of manufacturers have emerged as leaders through innovation, precision engineering, and global reach. Based on market presence, technological capabilities, and industry reputation, the following eight companies represent the top shot peener manufacturers shaping the future of surface treatment technology.

Top 8 Shot Peener Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 shotpeener.com

Domain Est. 1996

Website: shotpeener.com

Key Highlights: Shotpeener.com is the world’s largest resource for information on all aspects of shot peening and blast cleaning….

#2 Shot Peening

Domain Est. 1996

Website: pangborn.com

Key Highlights: Pangborn supplies the aerospace industry with a variety of highly-precise and customized shot peening equipment to treat wing panels and spars. Contact us for ……

#3 On-site Shot Peening

Domain Est. 1996

Website: surfacetechnologies.curtisswright.com

Key Highlights: Curtiss- Wright Surface Technologies can perform on-site shot peening of large components whose sizes exceed shipping limitations or which are installed on ……

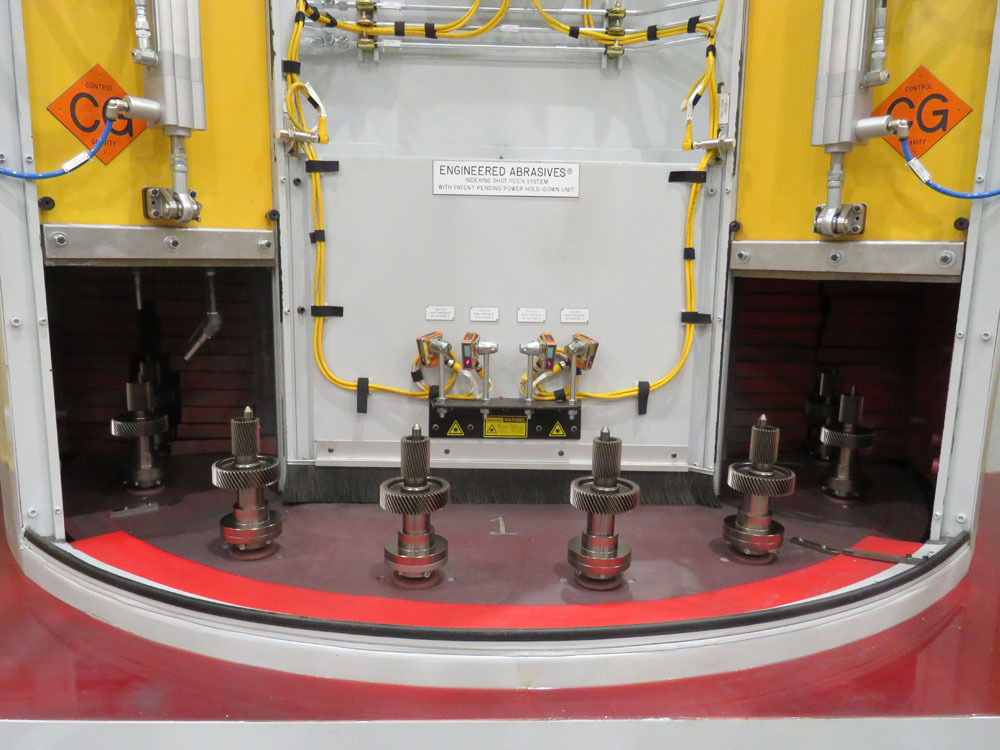

#4 Engineered Abrasives

Domain Est. 1997

Website: engineeredabrasives.com

Key Highlights: Engineered Abrasives specializes in the finest automated shot blasting and shot peening equipment designed for your specific application….

#5 Superior Shot Peening

Domain Est. 1999

Website: superiorshotpeening.com

Key Highlights: Superior Shot Peening & Coatings provides the highest quality shot peening service for companies in oil and gas, engineering, aviation, chemical, energy, ……

#6 Shot Peening

Domain Est. 2000

Website: ipar-blast.com

Key Highlights: Shot peening is the most suitable treatment to improve mechanical fatigue resistance and enhance mechanical components’ life….

#7 Shot Peening

Domain Est. 2000

Website: peenservice.it

Key Highlights: Shot Peening is a highly efficient treatment that increases fatigue resistance and prolongs the lasting of mechanical components….

#8 Peening Technologies

Domain Est. 2002

Website: peentech.com

Key Highlights: Peening Technologies offers shot peening, abrasive blasting, and surface enhancement services to the aerospace, automotive, and medical industries….

Expert Sourcing Insights for Shot Peener

H2: 2026 Market Trends for Shot Peening Technology

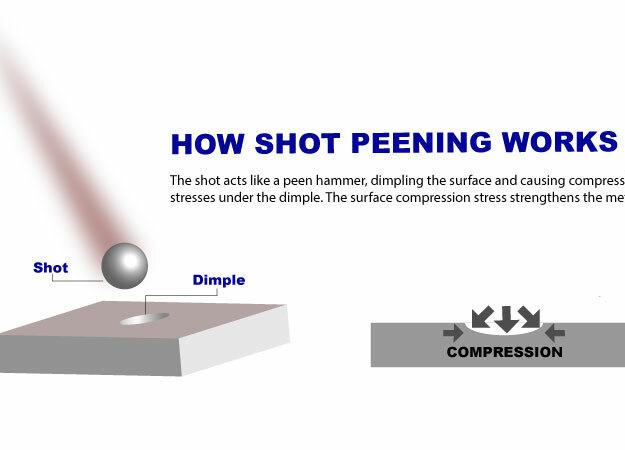

The global shot peening market is poised for significant transformation by 2026, driven by increasing demand for enhanced material durability, advancements in aerospace and automotive manufacturing, and a growing emphasis on predictive maintenance and precision engineering. Shot peening—a cold working process used to improve the fatigue life and stress resistance of metal components—continues to evolve under the influence of technological innovation and shifting industrial priorities.

1. Expansion in Aerospace and Defense Sectors

Aerospace remains the largest end-user of shot peening, and this trend is expected to strengthen through 2026. With rising aircraft production rates and the development of next-generation commercial and military aircraft, demand for high-integrity components such as turbine blades, landing gear, and engine parts will drive the need for reliable surface enhancement. Regulatory mandates for safety and performance will further cement shot peening as a critical process in component certification.

2. Growth in Electric Vehicle (EV) Manufacturing

The automotive industry, particularly the EV segment, is emerging as a key growth area for shot peening. Critical drivetrain components such as gears, shafts, and springs in electric powertrains experience high cyclic loads, making fatigue resistance crucial. As EV production scales globally, manufacturers are adopting shot peening to extend component lifespan and ensure reliability—especially in high-performance and long-range vehicles.

3. Integration of Automation and Smart Manufacturing

By 2026, the shot peening industry will see increased adoption of automation, robotics, and Industry 4.0 technologies. Automated shot peening systems offer improved consistency, reduced human error, and seamless integration into smart production lines. Real-time monitoring via IoT-enabled equipment allows for better process control, data collection, and traceability—critical for quality assurance in regulated industries.

4. Advancements in Process Precision and Mechatronics

Technological improvements in nozzle control, media delivery systems, and closed-loop feedback mechanisms will enable more precise and repeatable peening. Innovations such as laser peening and ultrasonic shot peening are gaining traction in niche applications, offering superior depth control and minimal distortion. However, conventional shot peening will maintain dominance due to its cost-effectiveness and scalability.

5. Sustainability and Media Recycling

Environmental concerns and regulatory pressures will push manufacturers toward sustainable practices. The reuse and recycling of shot media (e.g., steel or ceramic beads) will become standard, minimizing waste and operational costs. Equipment vendors are expected to offer closed-loop systems with integrated filtration and media recovery solutions.

6. Regional Market Dynamics

Asia-Pacific is projected to be the fastest-growing region for shot peening, fueled by expanding aerospace manufacturing in China and India, automotive production in Japan and South Korea, and government investments in infrastructure. North America and Europe will maintain strong demand due to advanced R&D activities, stringent safety standards, and a mature industrial base.

7. Rising Demand for Customized Solutions

As component designs become more complex, there will be a greater need for customized peening parameters and application-specific equipment. Manufacturers are increasingly offering tailored solutions, including robotic programming, simulation software (e.g., finite element analysis for peening effects), and process validation services.

In conclusion, the 2026 shot peening market will be characterized by technological sophistication, sector-specific growth, and a shift toward intelligent, sustainable manufacturing. Companies that invest in automation, innovation, and application expertise will be best positioned to capitalize on emerging opportunities across aerospace, automotive, energy, and medical device industries.

Common Pitfalls Sourcing Shot Peener (Quality, IP)

Sourcing shot peening services or equipment involves critical considerations around quality control and intellectual property (IP) protection. Overlooking these areas can lead to compromised component performance, regulatory non-compliance, and potential legal risks. Below are key pitfalls to avoid:

Quality-Related Pitfalls

Inadequate Process Validation and Certification

One of the most common issues is selecting a supplier without proper industry certifications (e.g., NADCAP, ISO 9001, AS9100 for aerospace). Without validated processes, there’s no assurance that shot peening parameters (intensity, coverage, media type) meet engineering specifications, potentially leading to part failure due to insufficient fatigue resistance.

Inconsistent Media Quality and Traceability

Using non-standard or poorly controlled shot media (e.g., inconsistent size, hardness, or chemical composition) can result in uneven surface treatment. Suppliers may lack traceability records for media batches, making it difficult to audit or reproduce results in case of defects.

Lack of Documentation and Reporting

Poor record-keeping—such as missing Almen strip reports, process parameter logs, or coverage verification—is a major red flag. Without detailed documentation, it’s impossible to verify compliance with technical requirements or troubleshoot performance issues downstream.

Insufficient Equipment Calibration and Maintenance

Peening equipment that isn’t regularly calibrated or maintained can deliver inconsistent impact energy, leading to under- or over-peening. Suppliers may not have robust preventive maintenance programs, increasing variability in output quality.

Intellectual Property (IP) Risks

Inadequate IP Protection Agreements

Failing to establish clear confidentiality agreements (NDAs) and IP ownership clauses before sharing design specifications, material requirements, or process parameters exposes sensitive technical data. Suppliers may reuse or inadvertently disclose proprietary peening procedures.

Lack of Control Over Process Know-How

Some suppliers may claim ownership of process improvements or custom parameters developed during collaboration. Without explicit contractual terms, companies risk losing control over proprietary peening techniques critical to product performance.

Third-Party Subcontracting Without Oversight

Suppliers may subcontract peening work without the client’s knowledge. This introduces uncontrolled variables in quality and increases IP exposure, as additional parties gain access to sensitive designs and processes without direct contractual safeguards.

Insecure Data Handling Practices

Digital transfer of CAD files, process plans, or inspection reports without secure channels or data use agreements can lead to IP theft or unauthorized replication, especially when working with offshore or less-regulated vendors.

To mitigate these risks, companies should conduct thorough supplier audits, demand full documentation, enforce strong IP agreements, and maintain direct oversight of the peening process—especially for mission-critical components in industries like aerospace, automotive, and medical devices.

Logistics & Compliance Guide for Shot Peener

This guide outlines essential logistics procedures and compliance requirements for personnel operating and maintaining shot peening equipment in industrial manufacturing environments. Adherence ensures operational efficiency, safety, and regulatory conformity.

Equipment Handling and Transportation

Ensure all shot peening machines, media handling systems, and auxiliary components are transported using appropriate lifting equipment and secure fixtures. Prior to movement, disconnect power sources, drain fluid lines, and protect sensitive controls. Use calibrated forklifts or hoists rated for the equipment’s weight and follow site-specific material handling protocols. Store spare parts and consumables in designated, labeled areas to prevent contamination and loss.

Media Management and Inventory Control

Maintain accurate logs of shot media type (e.g., steel, ceramic, glass), size, hardness, and lot numbers. Implement a first-in, first-out (FIFO) inventory system to prevent media degradation. Store media in dry, covered containers to avoid moisture absorption and contamination. Regularly inspect media for wear and replace per manufacturer and process specifications. Document all media additions, replacements, and disposal activities.

Regulatory Compliance Requirements

Comply with OSHA, EPA, and local environmental regulations regarding noise, airborne particulates, and waste disposal. Conduct routine noise monitoring and provide appropriate hearing protection. Use local exhaust ventilation (LEV) systems to capture dust and ensure air quality meets permissible exposure limits (PELs). Classify spent media and process waste correctly—determine if hazardous or non-hazardous—and dispose through authorized channels with proper documentation.

Process Documentation and Traceability

Maintain detailed records for each shot peening operation, including part number, batch/lot, equipment settings (intensity, coverage, angle), operator name, and date. Use Almen strip testing to verify intensity and document results per ASTM E1389 or equivalent standards. Ensure all documentation is stored securely and retrievable for audits, certifications (e.g., AS9100, ISO 9001), or customer inquiries.

Safety and Personal Protective Equipment (PPE)

Operators must wear approved PPE, including safety glasses with side shields, face shields, hearing protection, gloves, and steel-toed boots. Confirm machine guarding is in place and interlocks are functional before operation. Conduct pre-shift safety checks and report any equipment malfunctions immediately. Follow lockout/tagout (LOTO) procedures during maintenance.

Maintenance and Calibration Schedules

Adhere to a preventive maintenance schedule for all shot peening equipment, including blast nozzles, compressors, separators, and conveyors. Calibrate Almen meters, pressure gauges, and timers at intervals defined by quality standards or equipment manuals. Keep records of all maintenance, repairs, and calibrations, and tag equipment that is out of service.

Training and Operator Certification

Only trained and certified personnel may operate shot peening equipment. Initial and refresher training must cover safe operation, emergency procedures, compliance requirements, and quality standards. Maintain training records and ensure operators understand job-specific work instructions and inspection criteria.

Environmental and Waste Management

Minimize environmental impact by recycling reusable shot media through integrated separation systems. Collect and contain all waste streams, including spent media and dust. Label waste containers clearly and store in designated hazardous or non-hazardous waste areas. Maintain manifests and disposal certificates for all waste shipments.

Conclusion for Sourcing a Shot Peener:

In conclusion, sourcing a reliable shot peener is a critical step in ensuring the durability, fatigue resistance, and overall performance of metal components in various industrial applications. A thorough evaluation of potential suppliers should include assessments of their technical capabilities, equipment precision, quality certifications, material traceability, and adherence to industry standards such as AMS 2430 or SAE J443. Additionally, factors like production capacity, turnaround time, cost-effectiveness, and a proven track record in the relevant sector—whether aerospace, automotive, or power generation—should inform the final decision.

Partnering with a qualified shot peening service provider not only enhances product longevity and safety but also supports compliance with stringent regulatory requirements. Therefore, investing time in due diligence during the sourcing process will yield long-term benefits in product quality, operational efficiency, and customer satisfaction.