Ever wondered how massive machines or construction vehicles make it from factory floors to job sites miles away? Shipping heavy equipment isn’t just about size—it’s about safety, cost, and timing, too. Whether you’re a business owner, contractor, or just curious, understanding the process ensures your investment arrives in top shape.

This article breaks down how heavy equipment is shipped, covering key steps, insider tips, and essential considerations for a smooth, successful delivery.

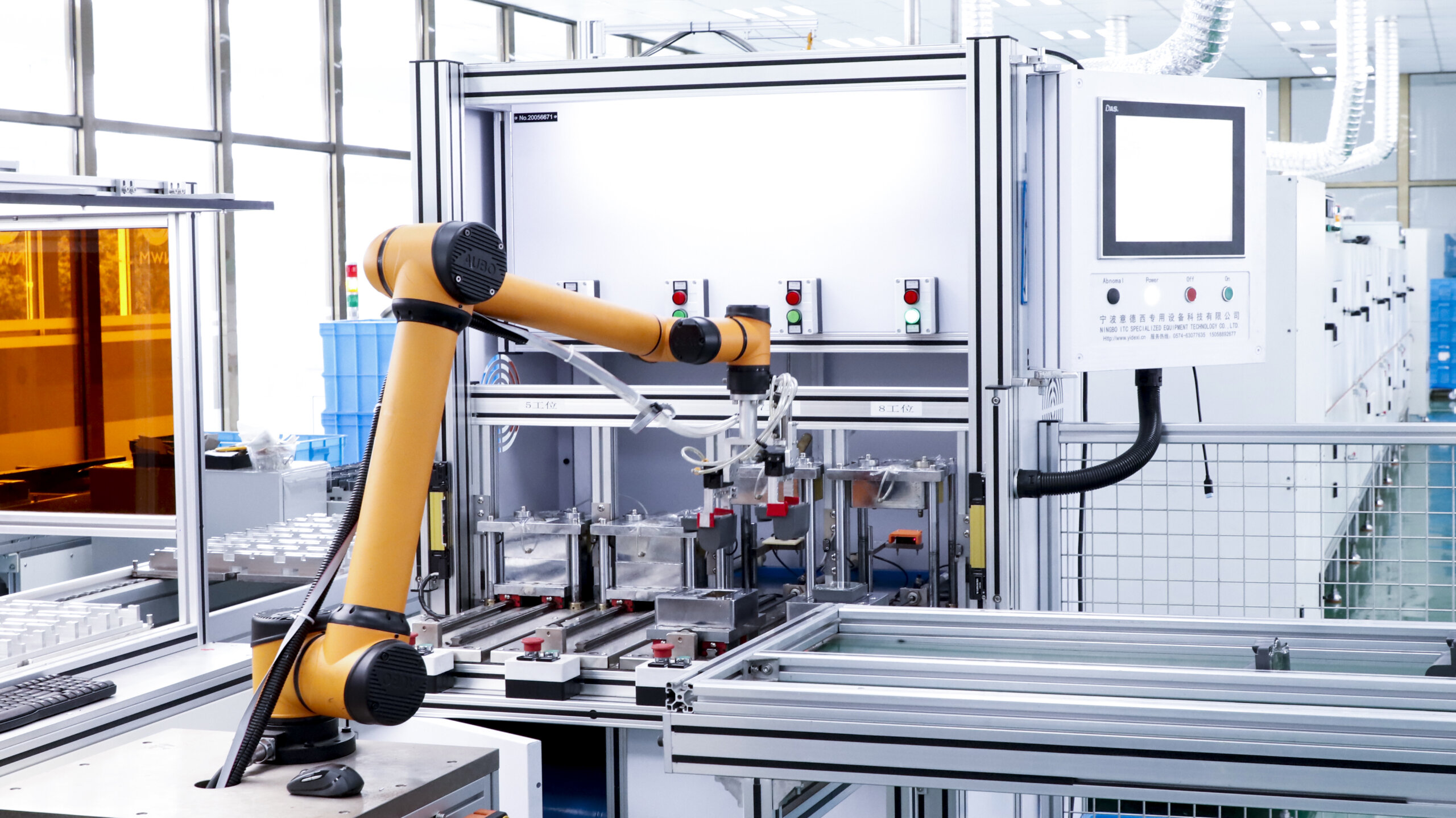

Related Video

How to Ship Heavy Equipment: A Comprehensive Guide

Shipping heavy equipment isn’t as simple as mailing a package. Whether you’re moving a bulldozer, an excavator, industrial machinery, or farm vehicles, these oversized and weighty items demand careful coordination, specialized transport, and compliance with various regulations. From selecting the right transport method to preparing equipment for the journey, understanding each stage helps ensure your machinery arrives safely and on time.

Let’s break down everything you need to know about shipping heavy equipment effectively.

Understanding Heavy Equipment Shipping

Shipping heavy equipment generally refers to the process of moving large, often oversized, machinery from one location to another, typically by road, rail, sea, or sometimes air. This category includes construction machinery, agricultural vehicles, manufacturing machines, and industrial components.

Specialized carriers, trailers, and logistical planning are required to handle the sheer size and weight. Regulations and costs can vary widely based on dimensions, destinations, and the type of equipment involved.

Key Steps to Ship Heavy Equipment

Shipping heavy equipment can seem overwhelming, but following a clear process makes it manageable. Here’s how it’s typically done:

1. Identify Your Equipment’s Details

Gather all the essential information about the item you need to ship:

- Make, model, and year

- Dimensions (length, width, height)

- Weight (operating and shipping weight)

- Operational condition (working, non-working, partially dismantled)

- Any attachments (buckets, blades, hydraulics)

Knowing these specifics lets you (or your shipping partner) choose the most suitable transport method and trailer.

2. Choose the Appropriate Shipping Method

There are several ways heavy equipment is transported. The best choice depends on the equipment’s size, weight, distance, and destination.

a. Road Transport (Most Common)

- Flatbed Trailers: For smaller or standard-sized machinery.

- Step Deck Trailers: When extra height clearance is needed.

- Lowboy Trailers: For oversized, taller equipment — the deck sits low for additional height room.

- Removable Gooseneck (RGN) Trailers: For extremely heavy or tall equipment needing easy loading and unloading.

b. Rail Freight

- Ideal for very large or multiple machines, especially for cross-country or long-distance transport.

c. Ocean Freight

- For international shipments, roll-on/roll-off (RoRo) ships or flat racks for containers are common.

- Machinery is either driven onto the vessel or loaded via cranes.

d. Air Freight

- Rare and expensive, suitable only for smaller or urgently needed equipment.

3. Secure Permits and Check Regulations

Heavier and oversized loads often require special permits and must adhere to state, federal, or international regulations. Permits can be needed for:

- Capturing oversize (width, height, length) or overweight status.

- Escort vehicles for wide or tall loads.

- Timing restrictions (some roads prohibit heavy loads during certain hours).

Consult with your transport provider for guidance; many handle the permitting process for you.

4. Prepare the Machinery for Shipping

Proper preparation is crucial to protect your equipment and comply with regulations.

- Clean the Equipment: Remove dirt, debris, and contaminants—some border crossings require evidence of a clean machine.

- Remove Loose Parts: Detach or safely secure any components that might move or fall off during transport.

- Check Fluid Levels: Some carriers require fluids like fuel, oil, or coolant to be drained or reduced for safety.

- Inspect and Document: Take photos and note any pre-existing damage or mechanical issues.

- Lock Moving Parts: Secure booms, arms, or rotating parts.

5. Work With a Reputable Heavy Equipment Transporter

Not all carriers have the experience or equipment to move heavy machinery safely. When selecting a transporter, consider:

- Experience with similar equipment and routes.

- Insurance coverage for high-value cargo.

- Good reviews and references.

Some popular industry names offer extensive heavy equipment logistics, machinery crating, and door-to-door delivery options.

6. Load and Secure the Equipment

Loading requires specialized skills and often heavy-duty ramps, cranes, or winches.

- Professionals use chains, straps, and blocking materials to anchor equipment firmly.

- Proper placement ensures balance and prevents shifting during transit.

7. Track and Receive

Most experienced shippers provide tracking updates. Upon arrival:

- Inspect your equipment immediately.

- Compare its condition with your pre-shipment documentation.

- Report any damage to the carrier and your insurance provider.

Key Considerations and Common Challenges

Shipping heavy equipment comes with unique complexities. Awareness of potential obstacles means you’re better prepared to handle them.

1. Size and Weight Restrictions

- Roads, bridges, and ports often have limits on vehicle size and load weight.

- Some routes may require detours due to low clearances or weight-restricted bridges.

2. Cost Factors

- Main cost drivers include distance, equipment weight/dimensions, permits, fuel, and service type (standard, expedited).

- Additional fees may apply for difficult access, remote delivery sites, or extra time required for loading/unloading.

3. Insurance

- Standard carrier insurance may not fully cover expensive machinery.

- Consider supplemental insurance for peace of mind.

4. Timing and Scheduling

- Delays can occur due to weather, route changes, or permit processing.

- Careful planning reduces these risks and helps avoid costly downtime.

Practical Tips and Best Practices

To make your equipment shipment go smoothly, keep these best practices in mind:

- Book Early: Especially for oversized or international moves, early planning allows time for permits and carrier availability.

- Compare Quotes: Get estimates from several experienced transporters and clarify what’s included.

- Ask About Experience: Make sure your carrier has a solid track record with equipment like yours.

- Read Reviews: Customer feedback offers insight into reliability and service quality.

- Label Clearly: If you’re shipping multiple attachments or components, mark them or pack them separately.

- Stay Informed: Request regular updates and designate one person as the main point of contact.

Cost-Saving Tips for Shipping Heavy Equipment

Heavy equipment shipping is a significant investment, but there are ways to optimize costs:

- Consolidate Shipments: If possible, combine multiple machines in one trip or use shared freight.

- Choose Off-Peak Times: Rates can fluctuate seasonally—as well as by day of the week—based on demand.

- Opt for Standard Delivery: Expedited shipping comes at a premium—plan ahead to avoid rush fees.

- Prep Equipment Efficiently: Well-prepared equipment is quicker (and cheaper) to load.

- Negotiate: Especially for large or repeat shipments, ask about volume discounts.

Discuss all fees in advance, including any surcharges for permits, fuel, border clearance, or specialized handling.

Common Benefits of Professional Heavy Equipment Shipping

Why rely on the experts?

- Safety: Professionals reduce the risk of accidents, damage, or injury during transport.

- Compliance: They manage complex permits, regulations, and paperwork.

- Efficiency: Specialized carriers have the right equipment and experience for smooth loading and securement.

- Insurance Protection: Professional operators provide coverage for high-value machinery.

In Summary

Shipping heavy equipment involves more than moving a big machine from point A to B. It’s a carefully choreographed process that balances logistics, safety, cost, and regulatory compliance. By understanding the steps, working with reputable transporters, and preparing in advance, you can ship your machinery safely, timely, and cost-effectively.

Frequently Asked Questions (FAQs)

1. How much does it cost to ship heavy equipment?

The cost can range widely, typically from several hundred to several thousand dollars, depending on factors like distance, equipment size, weight, permits, and delivery method. For a precise quote, provide detailed information about your equipment and shipping needs to prospective transporters.

2. Do I need insurance for shipping heavy equipment?

Yes. While carriers offer basic liability coverage, high-value equipment often needs additional insurance to provide full protection in case of damage during loading, transit, or unloading.

3. How long does it take to ship heavy equipment?

Transit time depends on the distance, route, permits required, and whether the shipment is domestic or international. Local moves may take a day or two, while cross-country or overseas shipments can take a week or more.

4. Do I have to prepare my equipment for shipping?

Absolutely. You are responsible for cleaning, securing, and sometimes partially dismantling machinery before transport. Removing loose parts and draining fluids helps prevent damage and speeds up the loading process.

5. Can I ship non-working or partially dismantled machinery?

Yes. Transporters regularly move non-operational or dismantled equipment, but special loading tools (like winches or cranes) may be required. Always disclose the condition when requesting quotes to avoid surprises or delays.

By understanding both the process and potential pitfalls, you’re well-equipped to ship your heavy equipment safely and efficiently. With good planning and the right partners, your machinery will be ready for its next job site without hassle.